Ultrathin plastic film, preparation method of ultrathin plastic film and express bag

A plastic film, ultra-thin technology, applied in the field of plastic products, can solve the problems of mechanical properties decline, etc., and achieve the effect of good mechanical properties, low manufacturing cost, and thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

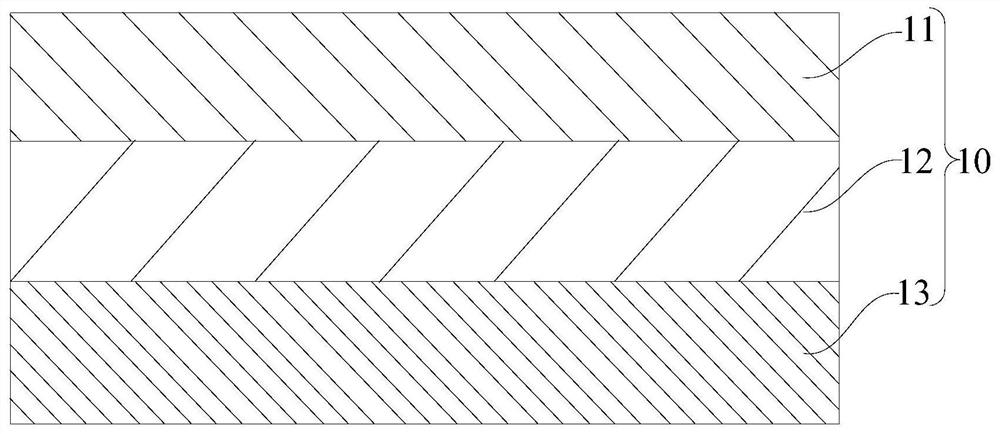

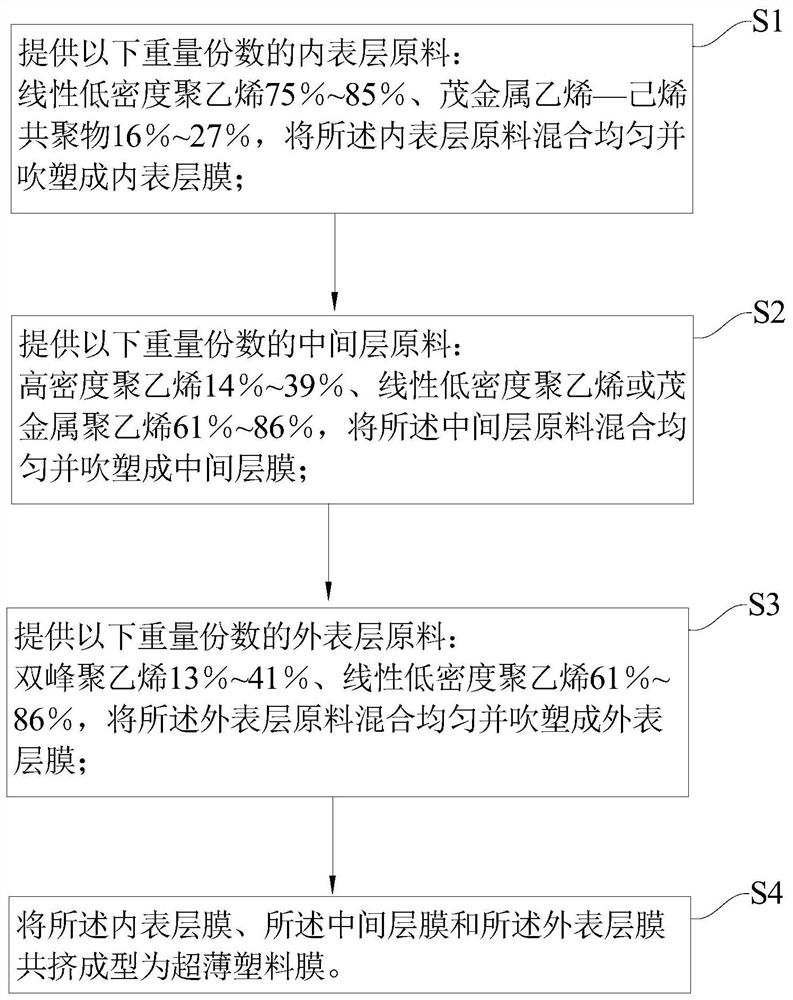

[0071] Such as figure 2 As shown, the embodiment of the present invention also provides a method for preparing an ultra-thin plastic film 10, comprising the following steps:

[0072] S1: Provide the following raw materials for the inner surface layer 11 in parts by weight:

[0073] Linear low-density polyethylene 75% to 85%

[0074] Metallocene ethylene-hexene copolymer 12%~27%

[0075] Mixing the raw materials of the inner surface layer 11 evenly and blow molding the inner surface layer 11 film;

[0076] S2: Provide the following raw materials for the middle layer 12 in parts by weight:

[0077] High-density polyethylene 14% to 33%

[0078] Linear low-density polyethylene or metallocene polyethylene 56% to 87%

[0079] Mix the raw materials of the middle layer 12 evenly and blow them into the middle layer 12 film;

[0080] S3: Provide the following raw materials for the outer layer 13 in parts by weight:

[0081] Bimodal polyethylene 15%~37%

[0082] Linear Low Densi...

Embodiment 1

[0091] Weigh raw materials according to the following proportions:

[0092] The raw materials of the inner skin layer 11 include the following substances in weight percentage:

[0093] 80% linear low density polyethylene, 17% metallocene ethylene-hexene copolymer and 3% black masterbatch.

[0094] The raw material of middle layer 12 comprises the following material of percentage by weight:

[0095] High-density polyethylene 17%, linear low-density polyethylene or metallocene polyethylene 68%, and white masterbatch 15%.

[0096] The raw materials of the outer layer 13 include the following substances in percentage by weight:

[0097] Bimodal polyethylene 17%, linear low density polyethylene 68% and white masterbatch 15%.

[0098] Among them, the weight-average molecular weight of linear low-density polyethylene is 120,000 g / mol to 135,000 g / mol;

[0099] The weight average molecular weight of metallocene polyethylene is 240,000 g / mol to 260,000 g / mol;

[0100] The weight a...

Embodiment 2

[0104] Weigh raw materials according to the following proportions:

[0105] The raw materials of the inner skin layer 11 include the following substances in weight percentage:

[0106] 80% linear low density polyethylene, 17% metallocene ethylene-hexene copolymer and 3% black masterbatch.

[0107] The raw material of middle layer 12 comprises the following material of percentage by weight:

[0108] High-density polyethylene 17%, linear low-density polyethylene or metallocene polyethylene 68%, and white masterbatch 15%.

[0109] The raw materials of the outer layer 13 include the following substances in percentage by weight:

[0110] Bimodal polyethylene 17%, linear low density polyethylene 68% and white masterbatch 15%.

[0111] Among them, the weight-average molecular weight of linear low-density polyethylene is 110,000 g / mol to 125,000 g / mol;

[0112] The weight average molecular weight of metallocene polyethylene is 230,000 g / mol to 240,000 g / mol;

[0113] The weight a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com