Winding pipe coating film exhausting device

An exhaust device and coating film technology, applied in the field of plastic pipe processing equipment, can solve the problem of being stored in a relatively humid or high humidity environment or being exposed to rain during transportation, reducing the distance between the coating film and the surface of the PP pipe. The firmness of inter-bonding, affecting the appearance of pipes and other issues, to achieve long service life, good processing quality, and improve the appearance of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

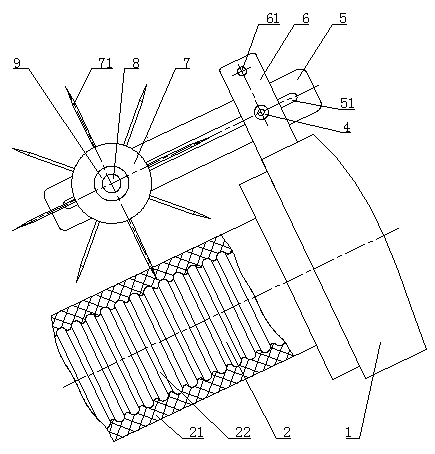

[0007] see figure 1 , the present invention comprises machine head 1, also comprises connecting plate 5, support plate 6, pin wheel 7, rotating shaft 8 and bearing 9, described support plate 6 is connected with machine head 1, and described connecting plate 5 is connected with support plate by screw 4 6 connection, bearing 9 is housed in the inner hole of described pin wheel 7, and rotating shaft 8 is housed in the inner hole of described bearing 9, and described pin wheel 7 is connected with connecting plate 5 through rotating shaft 8, and the inner hole of described pin wheel 7 Eight steel needles 71 uniformly distributed in the circumferential direction are arranged on the outer circular surface. The connecting plate 5 is provided with a long waist-shaped hole 51 . The support plate 6 is provided with two screw holes 61 . A transition fit is adopted between the inner hole of the pin wheel 7 and the outer circular surface of the bearing 9 . A transition fit is adopted bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com