Isolating film, top-emitting photoelectric device and manufacturing method and application thereof

A technology for optoelectronic devices and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, electrical components, etc., can solve problems such as stability and lifespan to be improved, poor light extraction rate and light purity, etc., to improve light extraction efficiency. and luminous purity, good mechanical properties and chemical stability, luminous efficiency and improved light purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

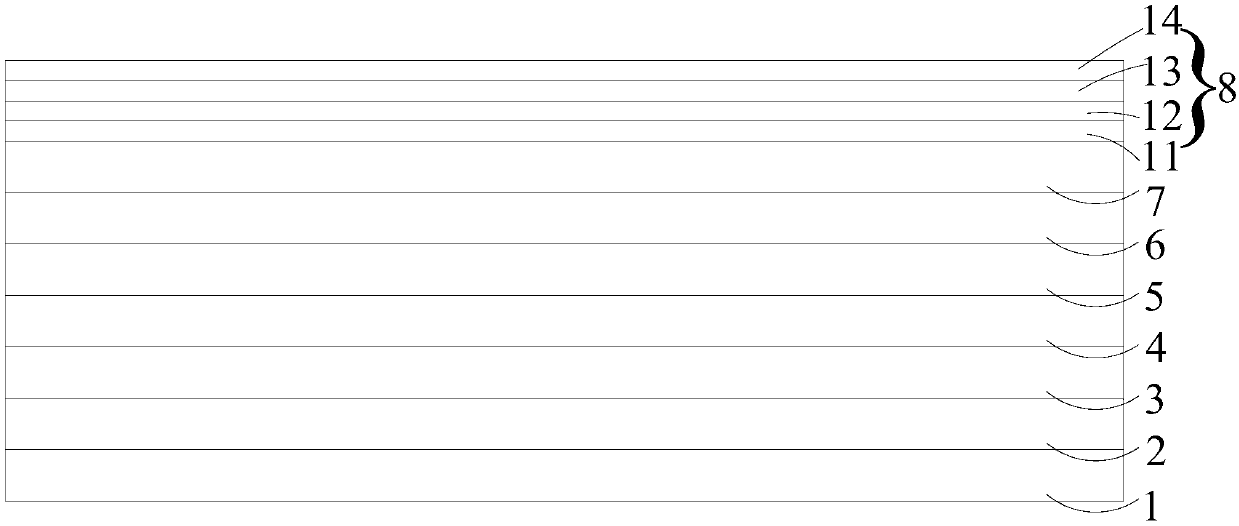

[0069] A top-emitting photoelectric device, comprising a substrate, and an Al / ITO electrode, a hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer, a top electrode, and an encapsulation layer stacked outward from a surface of the substrate ;

[0070] Wherein, the thickness of Al / ITO electrode is 50nm;

[0071] The hole injection layer is made of PEDOT:PSS with a thickness of 50nm;

[0072] The material of the hole transport layer is poly-TPD, and its thickness is 30nm;

[0073] The material of the quantum dot light-emitting layer is CdSe / ZnS, and its thickness is 20nm;

[0074] The material of the electron transport layer is ZnO, and its thickness is 30nm;

[0075] The material of the top electrode is a magnesium-silver alloy with a thickness of 30nm;

[0076] The thickness of the encapsulation layer is 125nm;

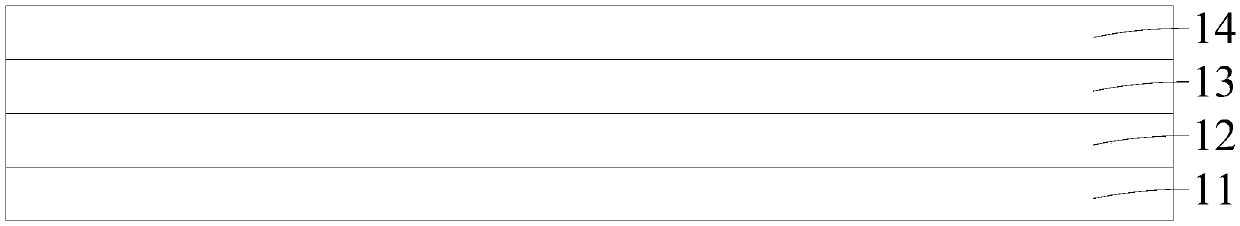

[0077]The encapsulation layer is a layer of composite film layer, and the composite film layer is sequen...

Embodiment 2

[0084] A top-emitting photoelectric device, comprising a substrate, and an Al / ITO electrode, a hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer, a top electrode, and an encapsulation layer stacked outward from a surface of the substrate ;

[0085] Wherein, the thickness of Al / ITO electrode is 50nm;

[0086] The hole injection layer is made of PEDOT:PSS with a thickness of 50nm;

[0087] The material of the hole transport layer is poly-TPD, and its thickness is 30nm;

[0088] The material of the quantum dot light-emitting layer is CdZnS / ZnSe, and its thickness is 20nm;

[0089] The material of the electron transport layer is ZnO, and its thickness is 30nm;

[0090] The material of the top electrode is magnesium-silver alloy, and its thickness is 50nm;

[0091] The thickness of the encapsulation layer is 270nm;

[0092] The encapsulation layer is a layer of composite film layer, and the composite film layer is seq...

Embodiment 3

[0099] A top-emitting photoelectric device, comprising a substrate, and an Al / ITO electrode, a hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer, a top electrode, and an encapsulation layer stacked outward from a surface of the substrate ;

[0100] Wherein, the thickness of Al / ITO electrode is 50nm;

[0101] The hole injection layer is made of PEDOT:PSS with a thickness of 50nm;

[0102] The material of the hole transport layer is poly-TPD, and its thickness is 30nm;

[0103] The material of the quantum dot light-emitting layer is CdS / ZnSe, and its thickness is 20nm;

[0104] The material of the electron transport layer is ZnO, and its thickness is 30nm;

[0105] The material of the top electrode is a magnesium-silver alloy with a thickness of 30nm;

[0106] The thickness of the encapsulation layer is 200nm;

[0107] The encapsulation layer is a layer of composite film layer, and the composite film layer is seque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com