Printing process for modified titanium dioxide and preparation method of modified titanium dioxide printing material

A technology of titanium dioxide and printing technology, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of high probability of electron-hole recombination, accelerated electron and hole recombination, and insufficient catalytic performance. Sexuality and other issues, to achieve uniform distribution, improve production efficiency, good response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

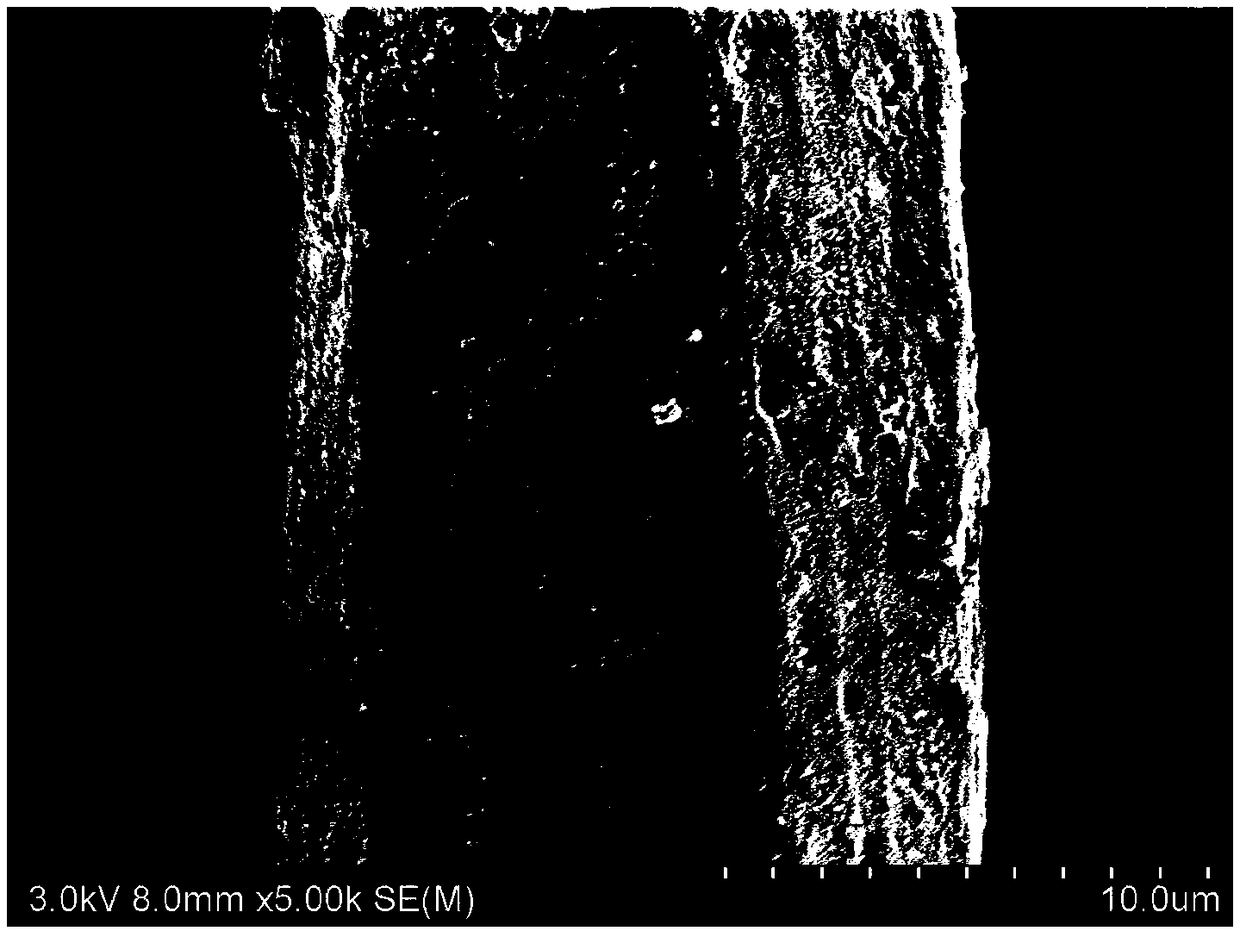

[0038]Introducing amino ions and simple gold into titanium dioxide to obtain a printing material containing at least modified titanium dioxide; using printing equipment to print the printing material containing modified titanium dioxide on the base cloth, the base cloth is at least including rice-shaped structured special-shaped fibers Fabric, wherein the metal in the metal element is preferably Au.

Embodiment 2

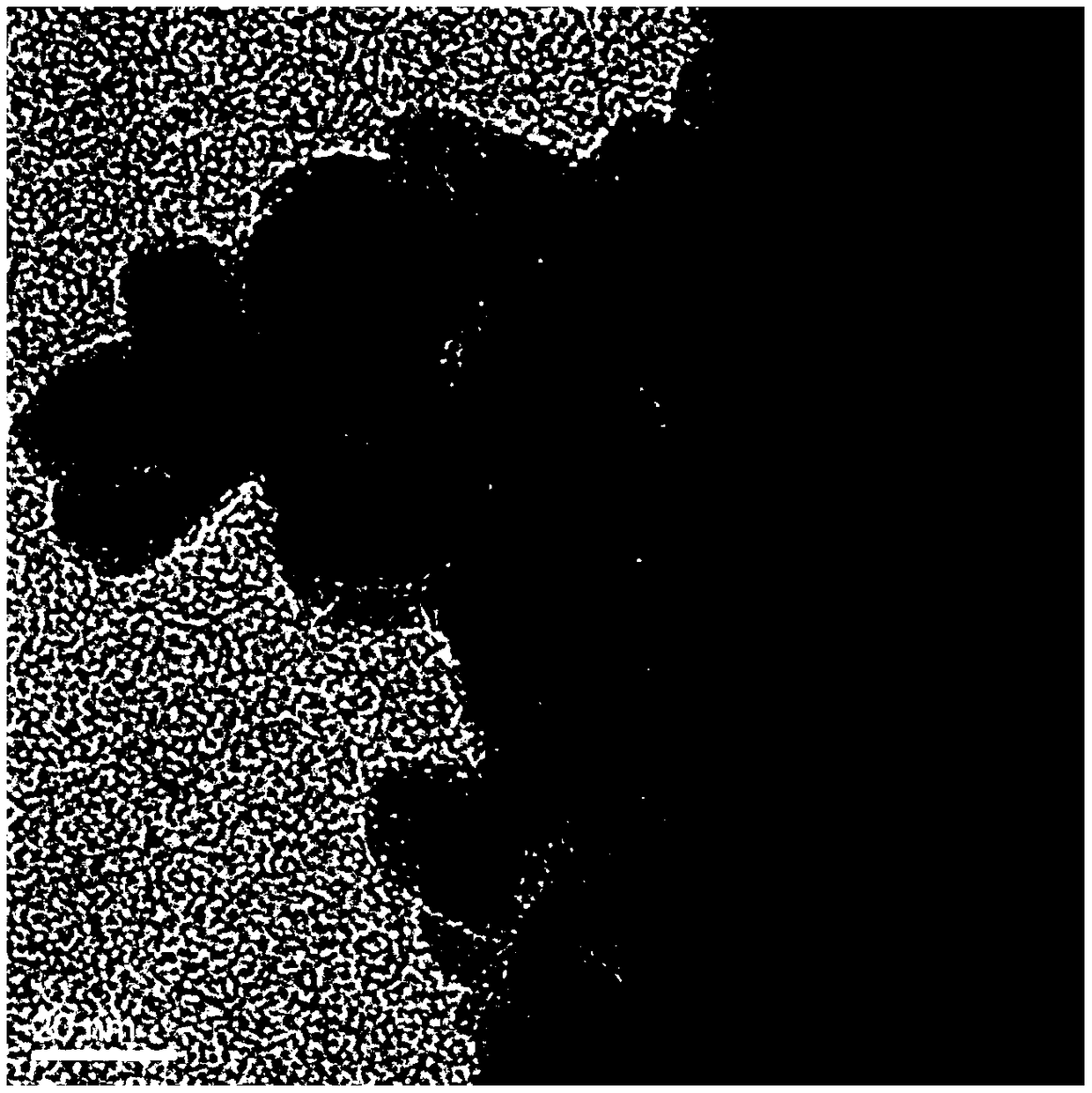

[0040] Add 80ml of tetrabutyl titanate ethanol solution with a concentration of 125g / L dropwise into the mixed solution consisting of 10ml formic acid and 10ml deionized water, and keep stirring until the solution turns light blue. Stand and age until the sol becomes gel. 0.5ml concentration is that the chloroauric acid ethanol solution of 0.1mol / L is added in the aqueous solution of the amino-terminated hyperbranched polymer that 10ml concentration is 30g / L, heat and boil until the solution is pale pink. Mix 50ml of ethanol solution of amino-terminated hyperbranched polymer with a concentration of 60g / L into the solution, continue to stir until it is evenly mixed, then add 10g of titanium dioxide gel, use a cell pulverizer to mix evenly, and put it into polytetrafluoroethylene for reaction In the kettle, heat at 200°C for 8 hours. After cooling, the solution was washed three times with ethanol, centrifuged, washed three times with deionized water, centrifuged, and dried to o...

Embodiment 3

[0042] Add 80ml of tetrabutyl titanate ethanol solution with a concentration of 125g / L dropwise into the mixed solution consisting of 10ml formic acid and 10ml deionized water, and keep stirring until the solution turns light blue. Stand and age until the sol becomes gel. 0.30ml concentration of 0.1mol / L silver nitrate aqueous solution was added to 10ml concentration of 50g / L amino-terminated hyperbranched polymer aqueous solution, heated and boiled until the solution was bright yellow. Mix 30ml of ethanol solution of amino-terminated hyperbranched polymer with a concentration of 15g / L into the solution, continue to stir until it is evenly mixed, then add 10g of titanium dioxide gel, use a cell pulverizer to mix evenly, and then put it into polytetrafluoroethylene for reaction In the kettle, heat at 200°C for 10 hours. After cooling, the solution was washed three times with ethanol, centrifuged, washed three times with deionized water, centrifuged, and dried to obtain N-Au co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com