Patents

Literature

40results about How to "Guaranteed composite quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

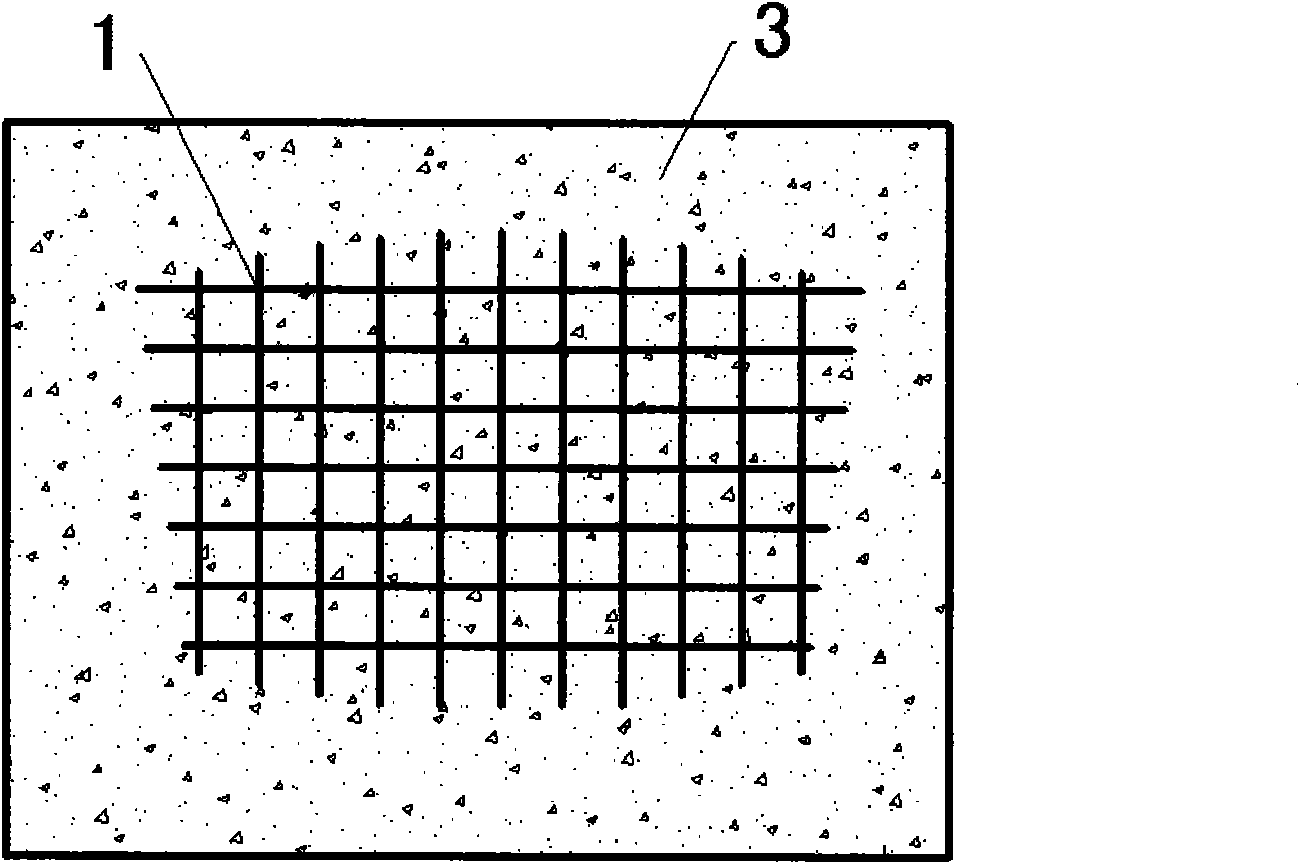

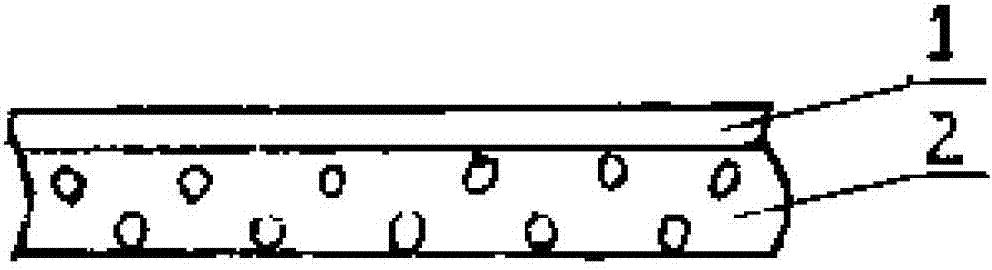

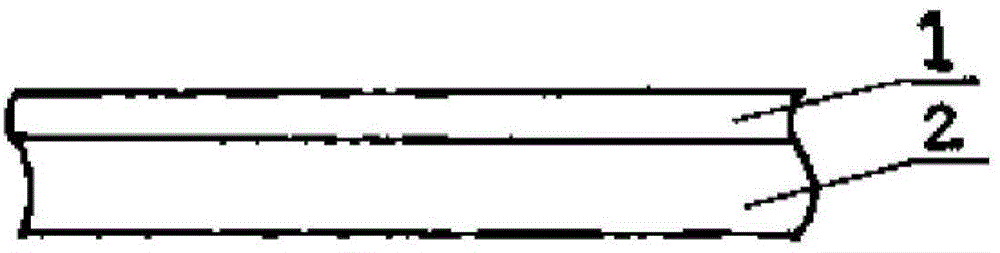

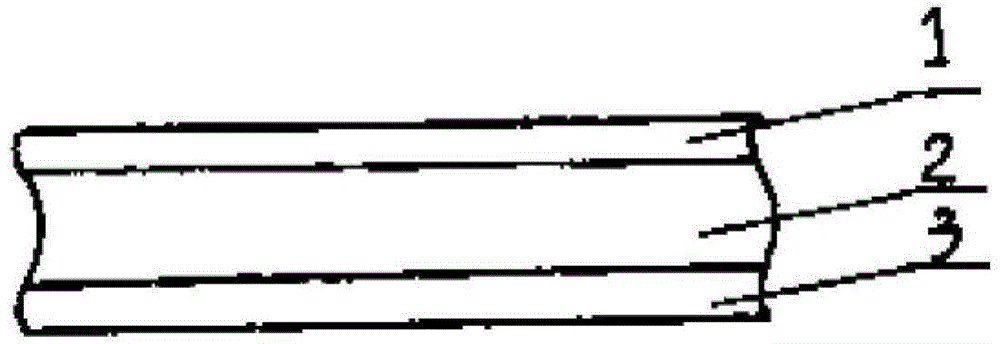

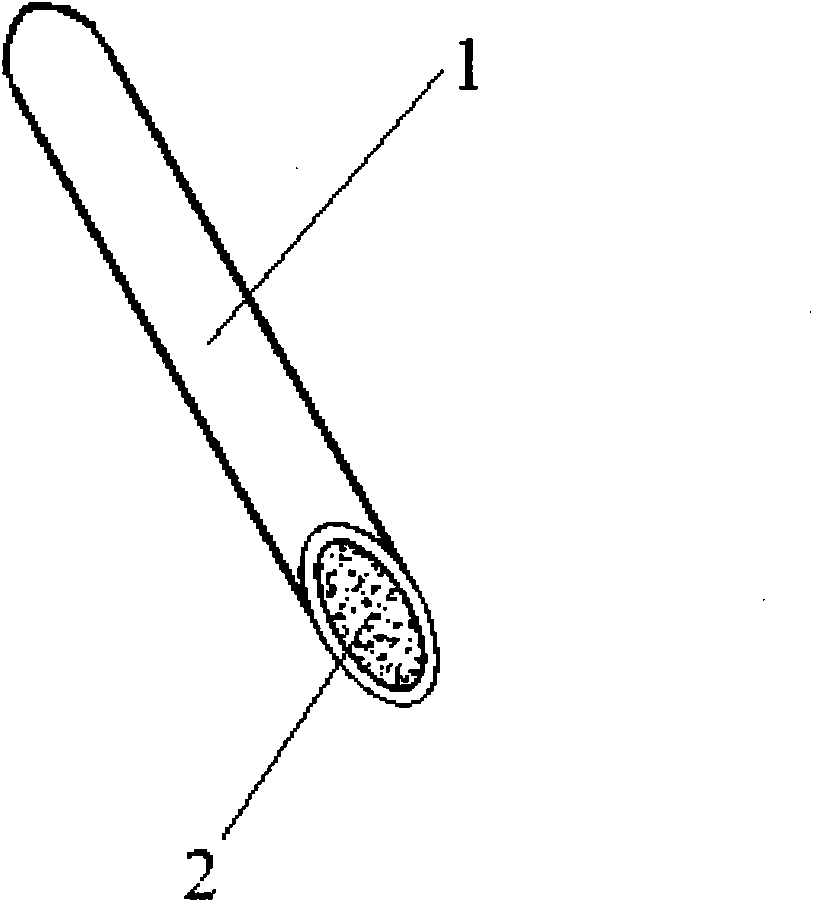

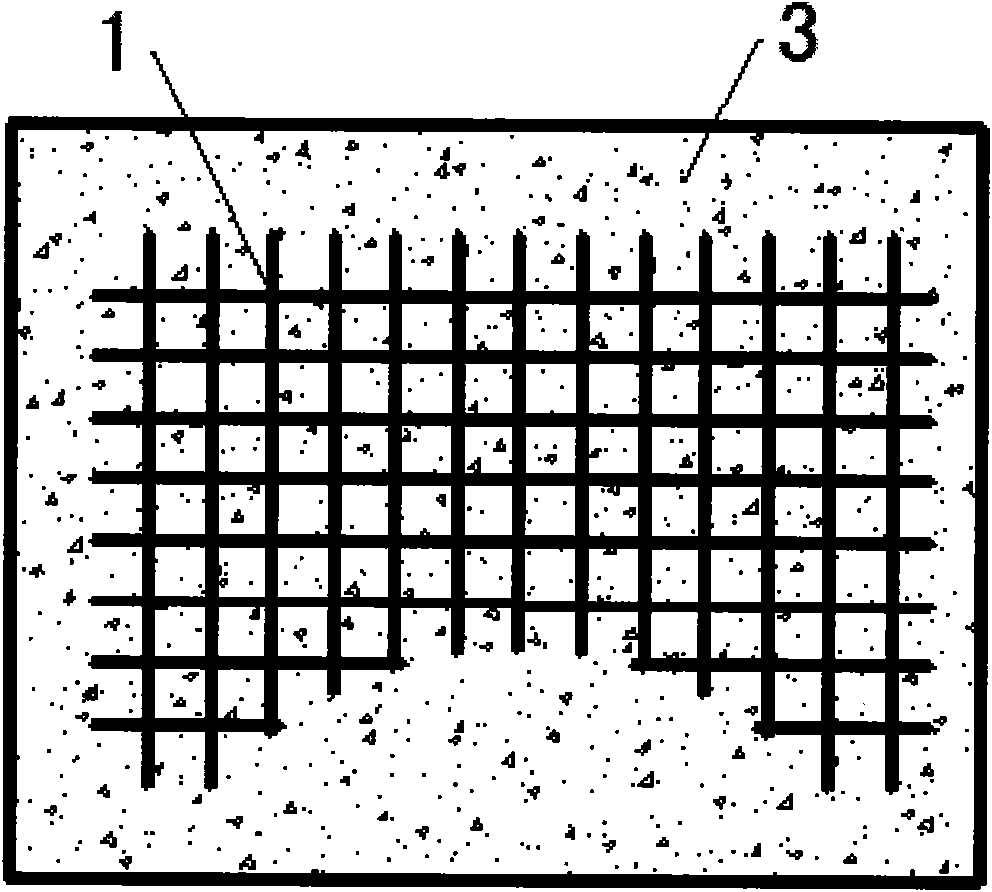

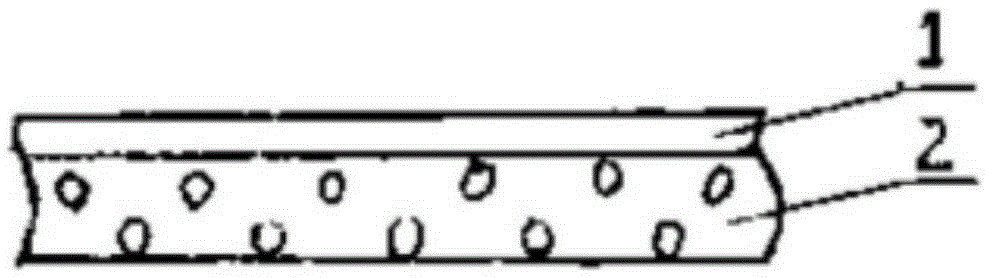

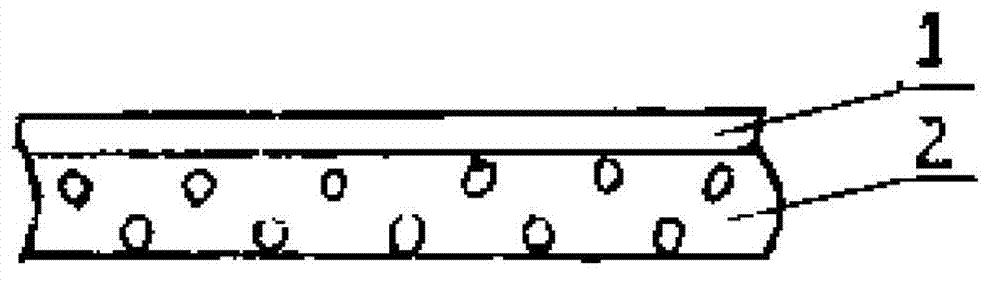

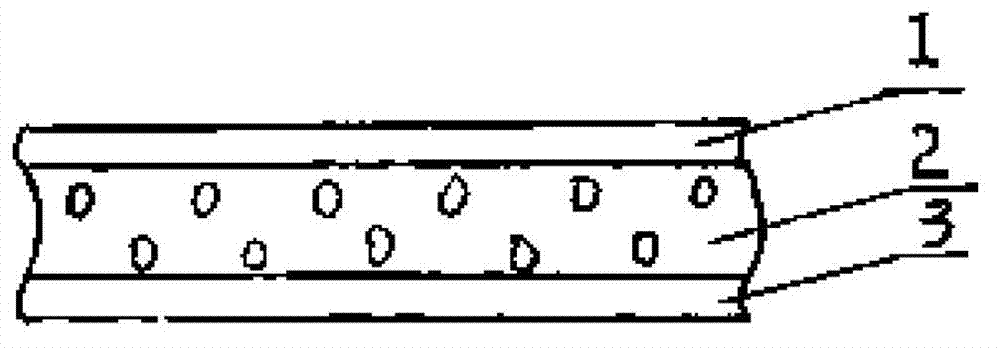

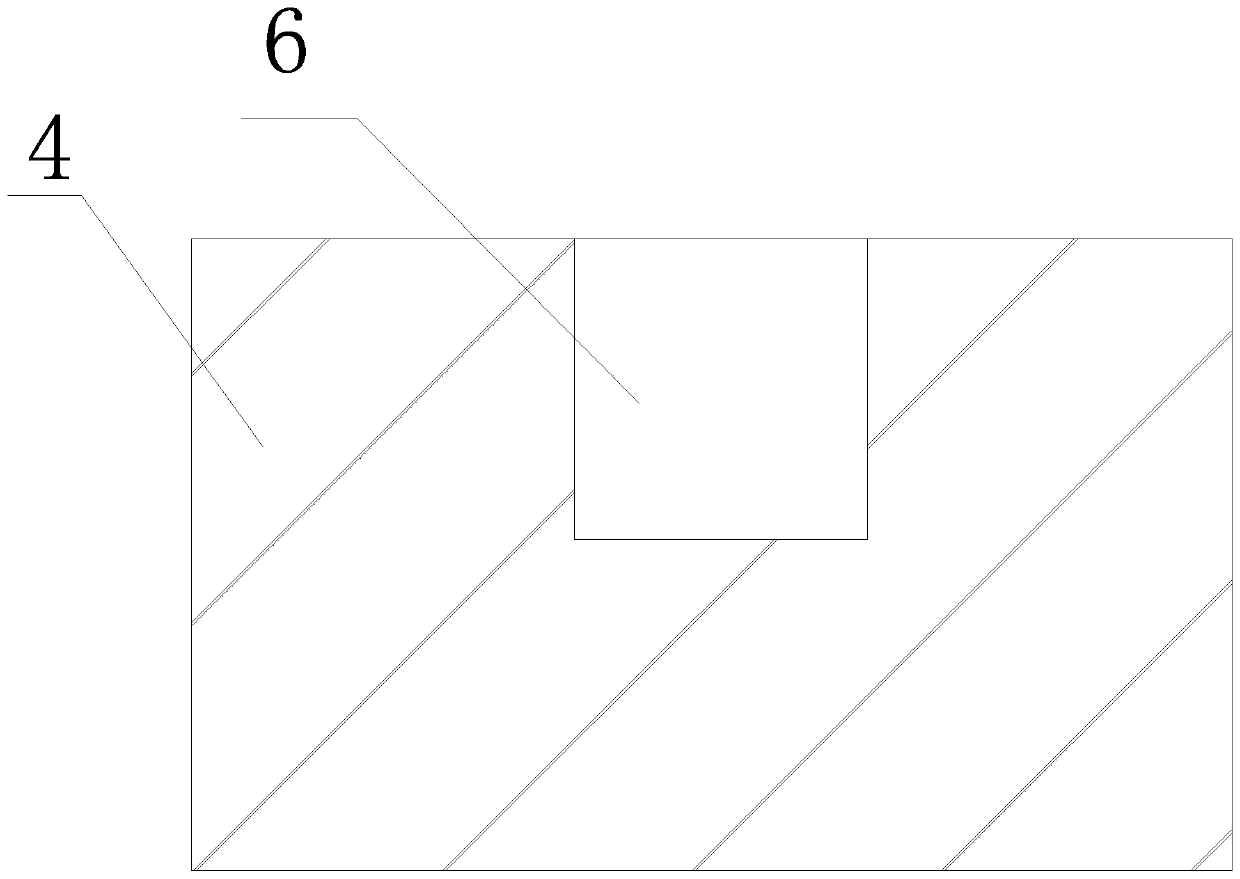

Preparation method of reinforced composite wear-resistant lining board of precast framework

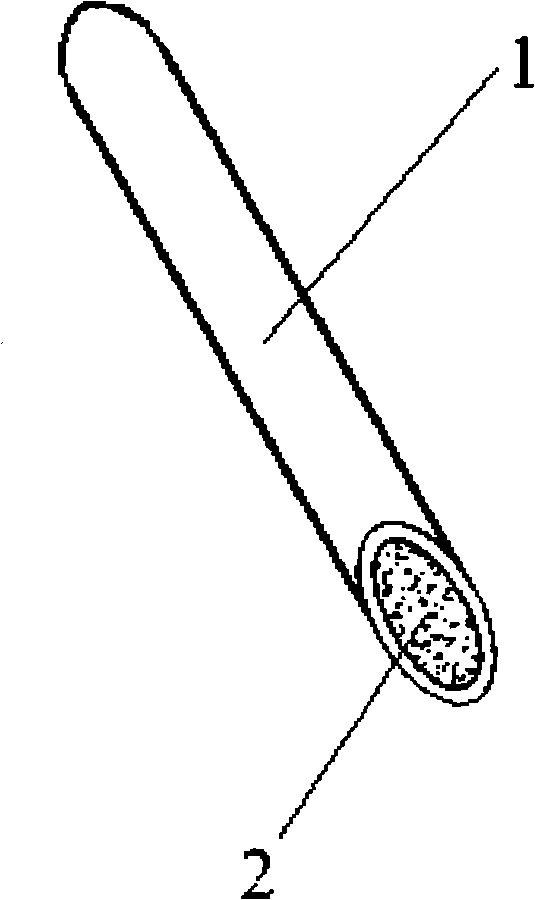

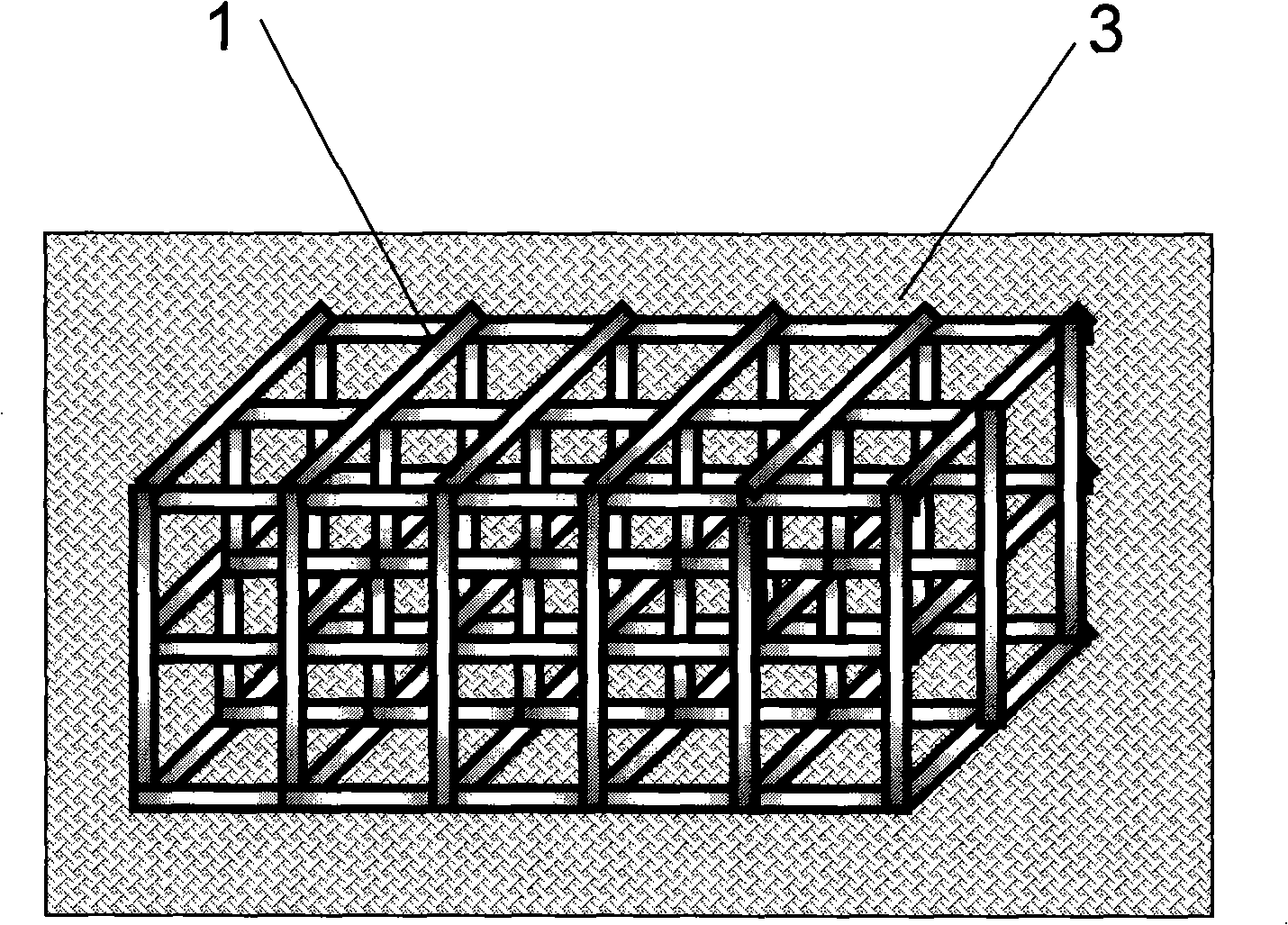

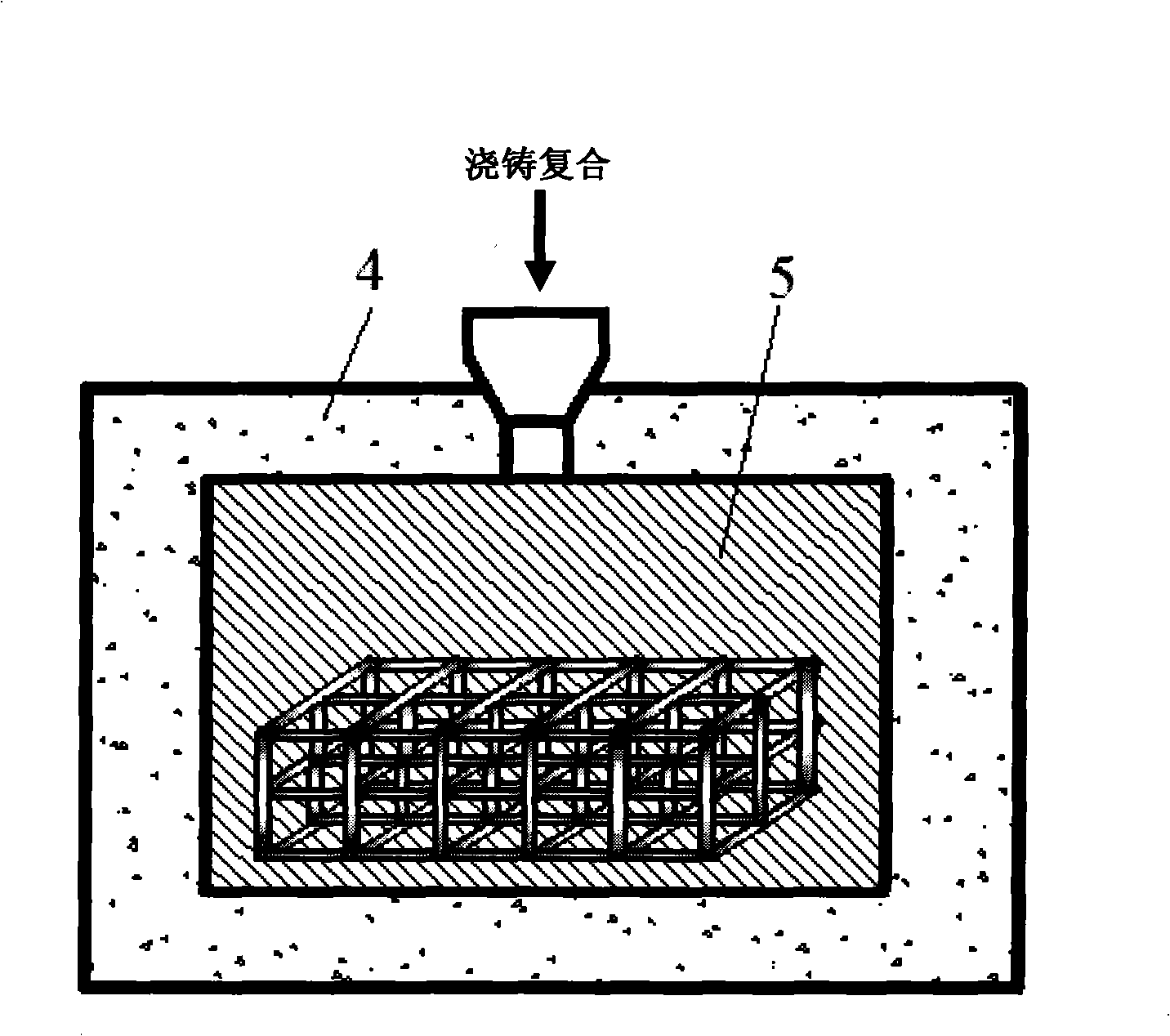

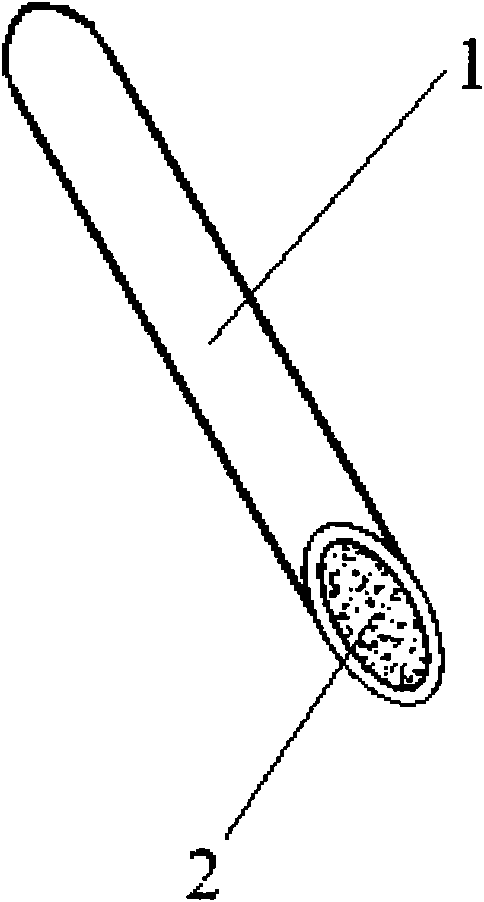

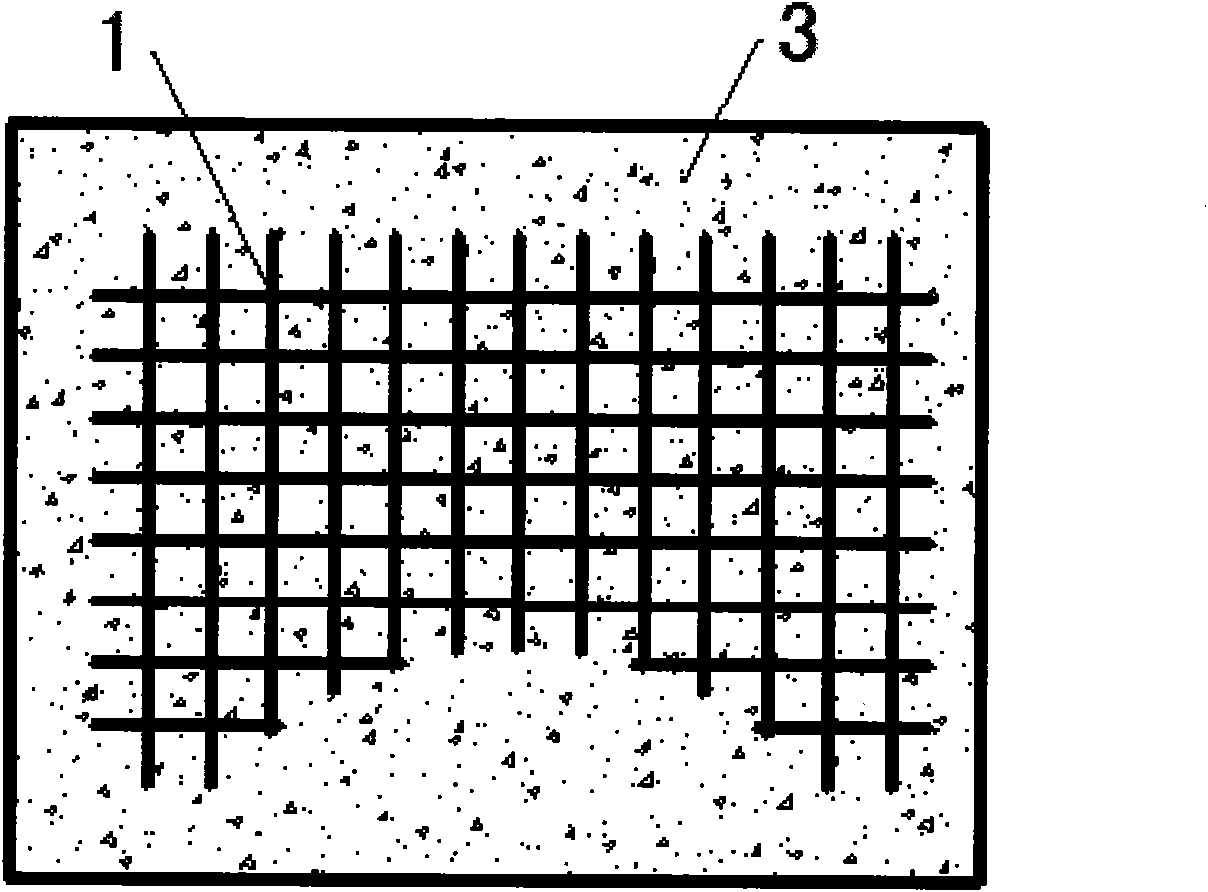

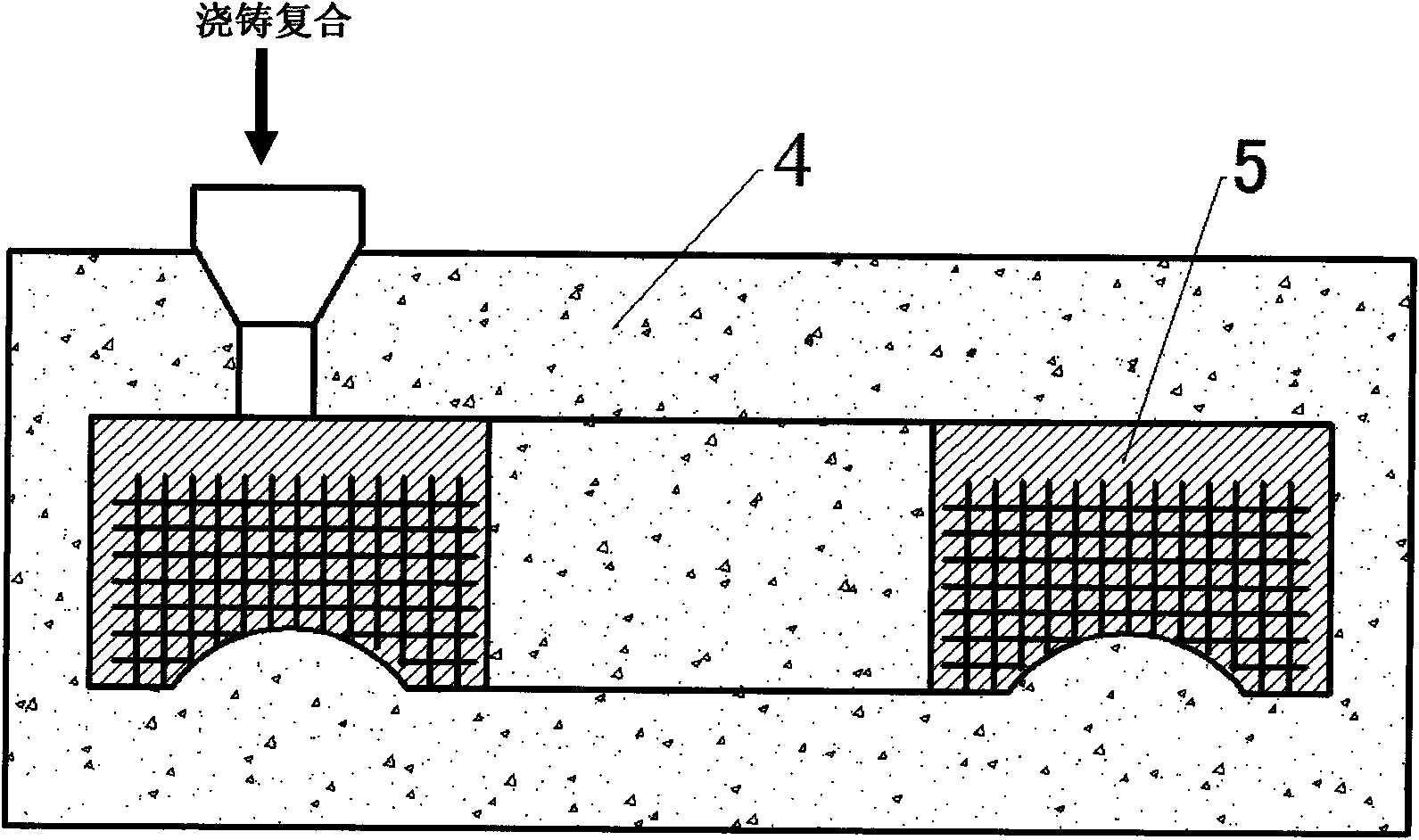

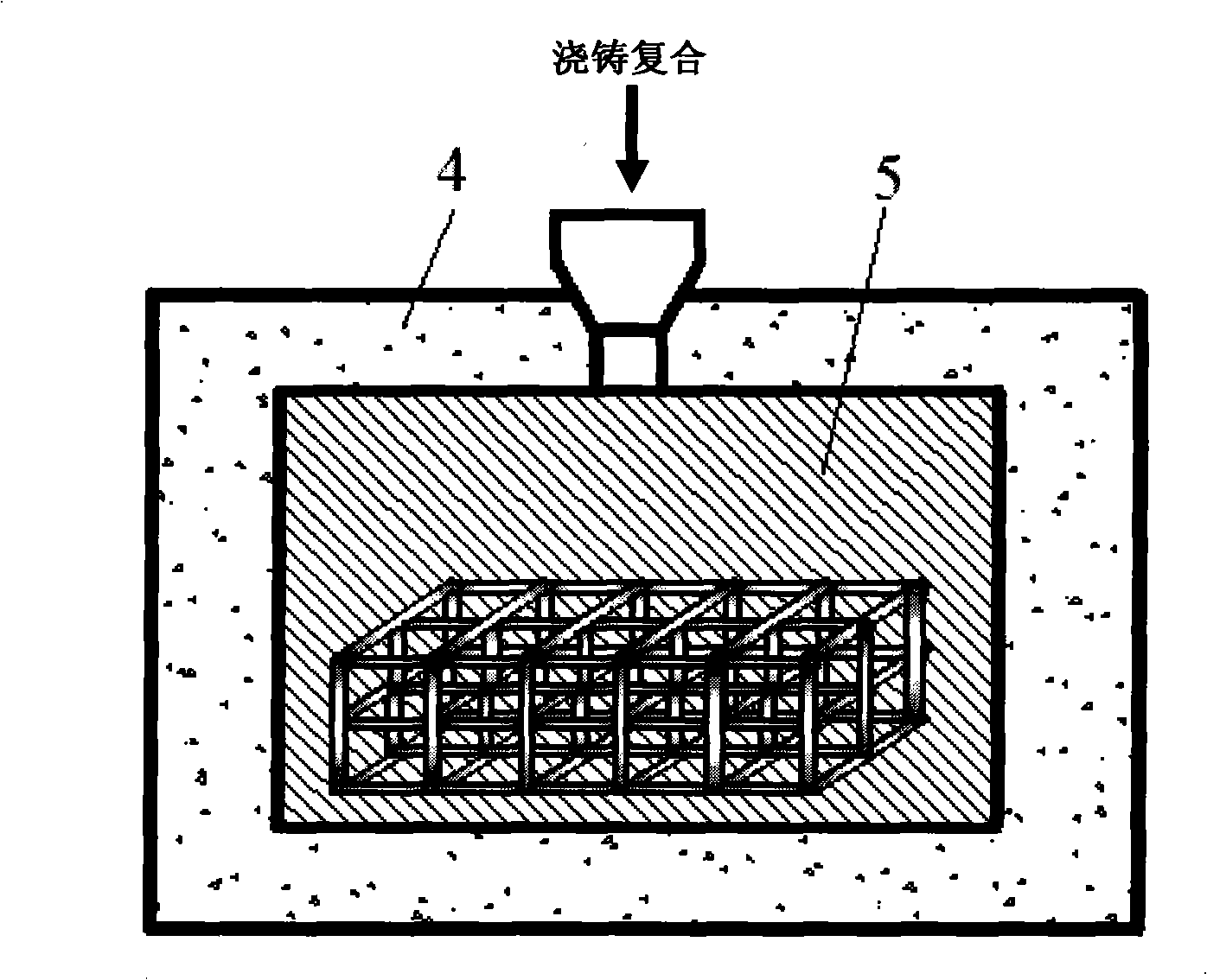

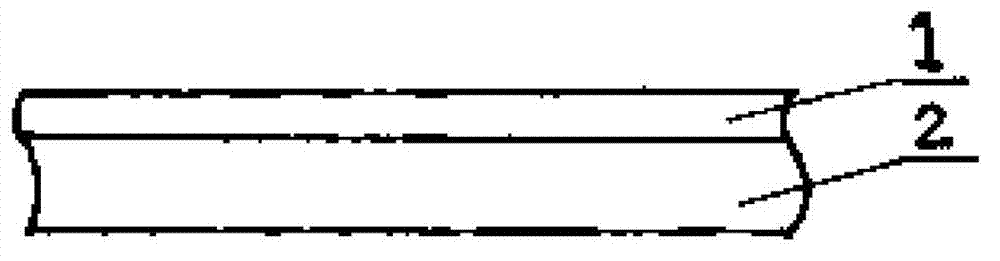

The invention discloses a preparation method of a reinforced composite wear-resistant lining board of a precast framework. The prepared reinforced composite wear-resistant lining board is formed by compounding a framework reinforced body containing hard phases and base body metal. The preparation method comprises the following steps: adopting a framework precast body made of tube wires filled with hard materials, performing the vacuum high-temperature sintering, forming the framework reinforced body containing hard phases, and leading the framework reinforced body to perform the metal casting composite molding with the base body metal, so as to form the lining board formed by compounding the framework reinforced body containing hard phases and the base body metal. The framework reinforced body is performed by the vacuum high-temperature sintering to form a complete metallurgical texture structure, which has order arrangement, uniform distribution, stable performance and strong integrity, can always keep complete framework structure after compounding with the base body metal, thereby developing the high wear-resistance of the hard phases in the framework reinforced body, and keeping better flexibility of the base body metal. The reinforced composite wear-resistant lining board can be compounded locally or gradiently, or integrally, and can be widely applied to wear-resistant fields of mine, electricity, metallurgy, coal, building materials, and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

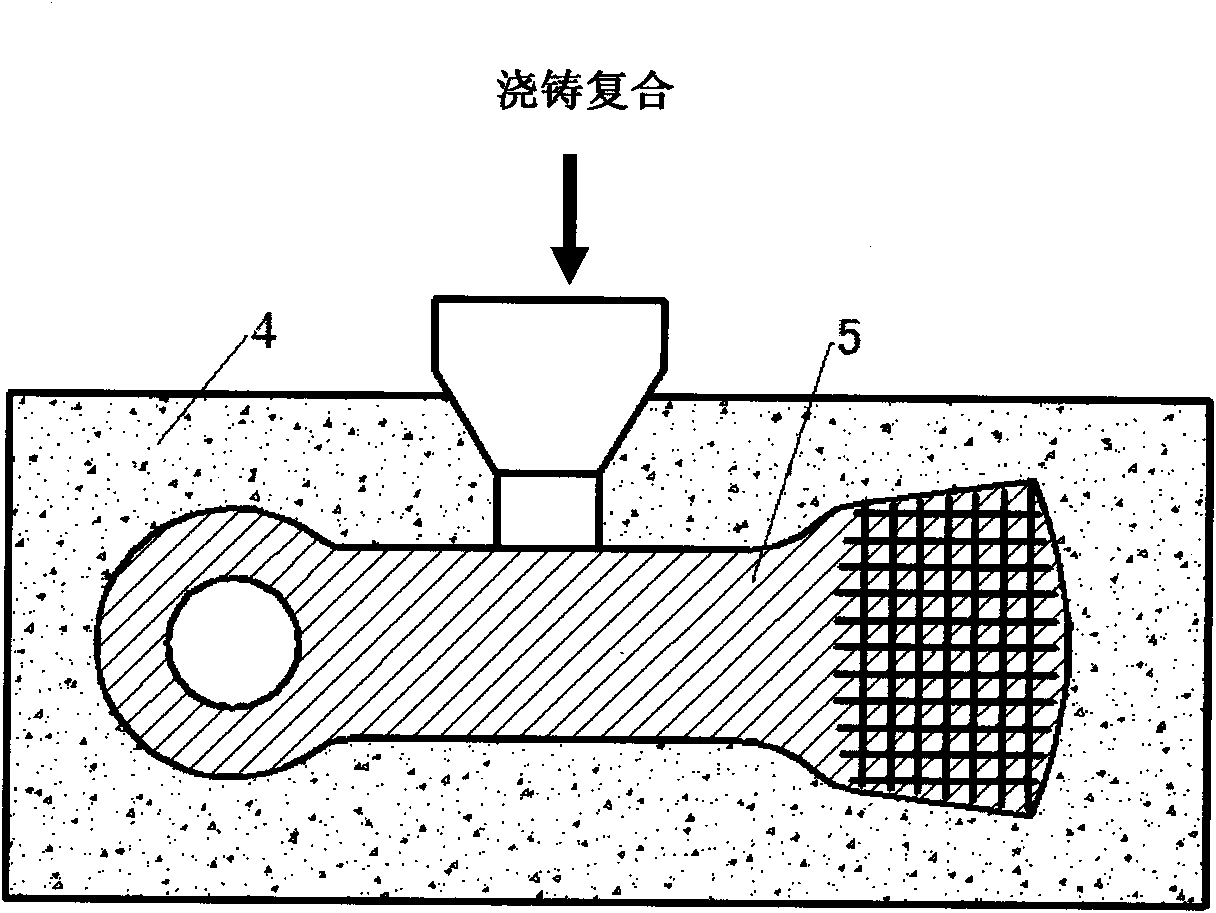

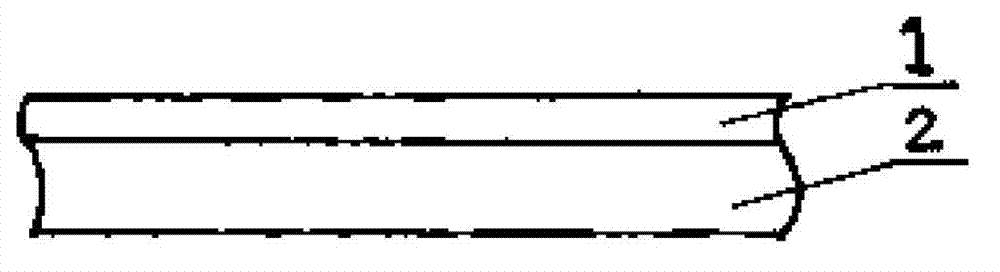

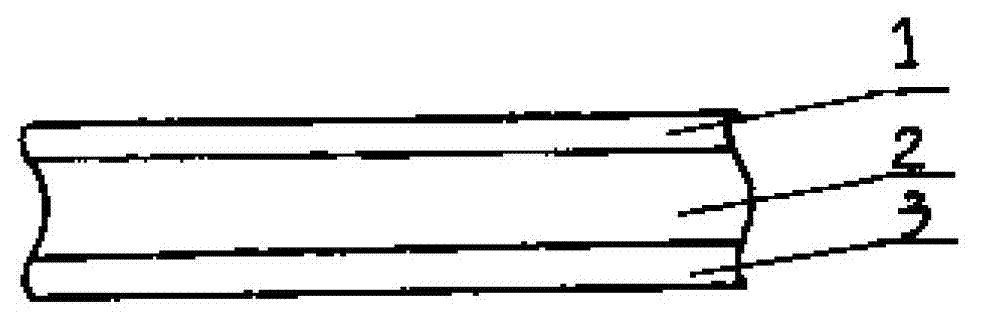

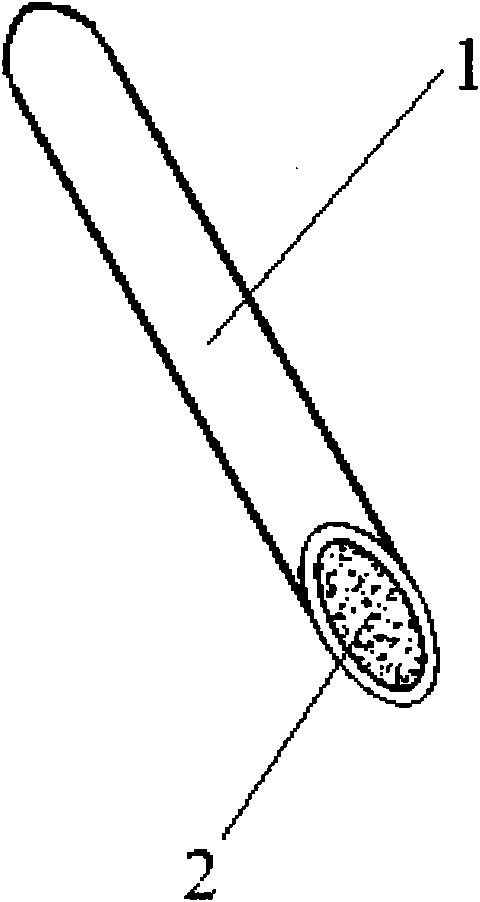

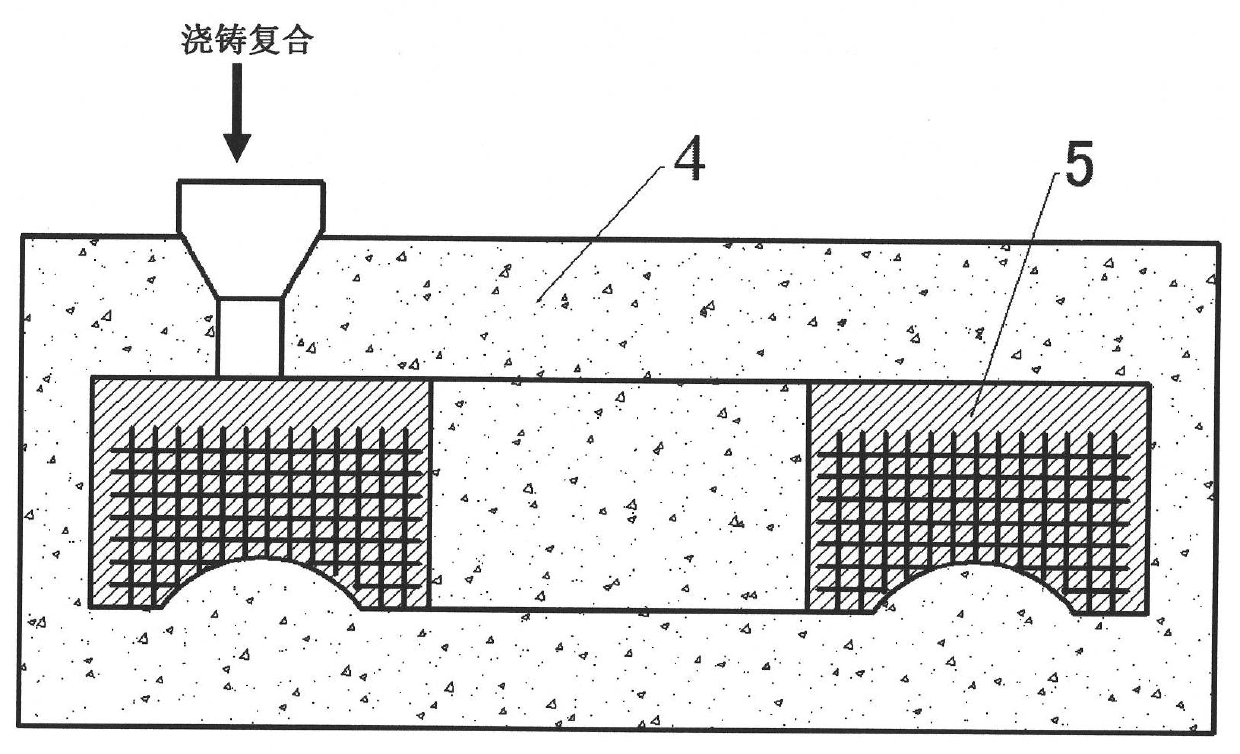

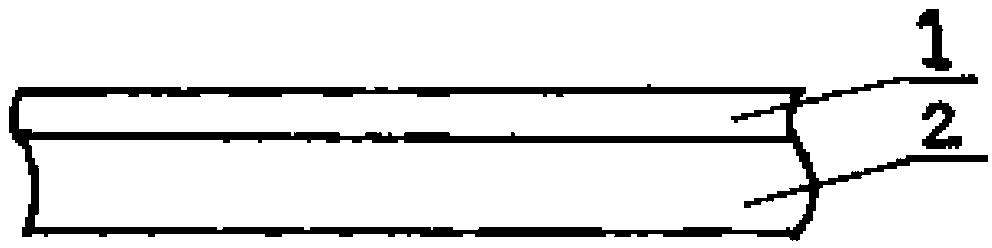

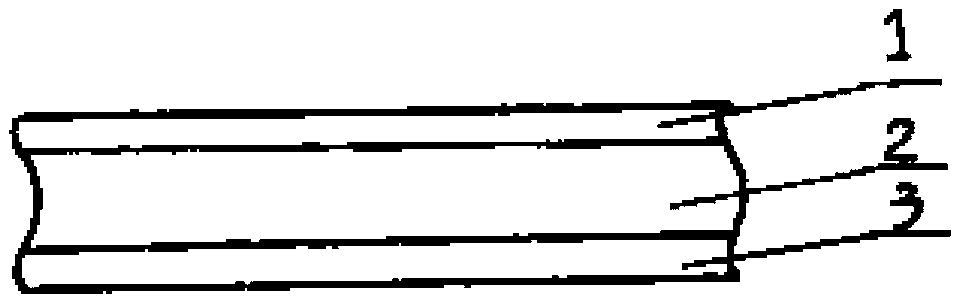

Preparation method of framework reinforcement compound hammerhead

InactiveCN101658917AImprove wear resistanceImprove toughnessGrain treatmentsCompound aWear resistance

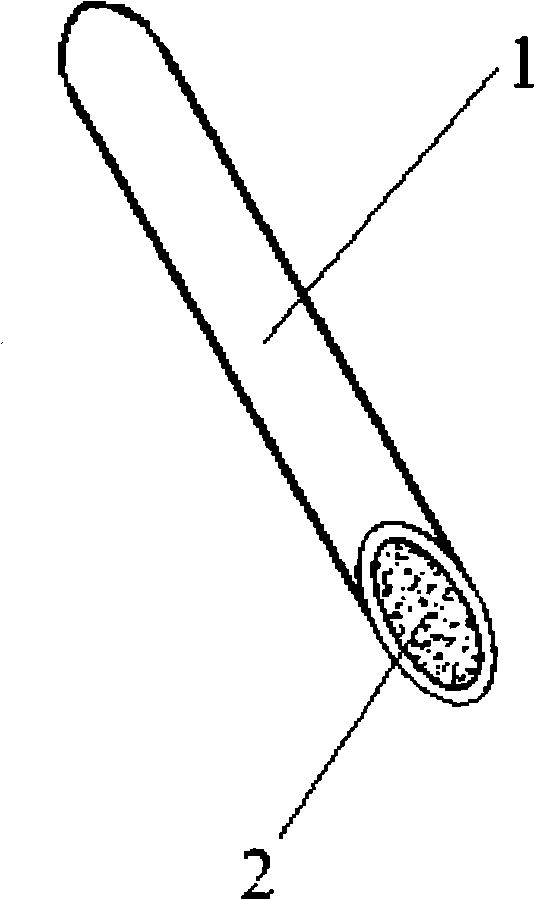

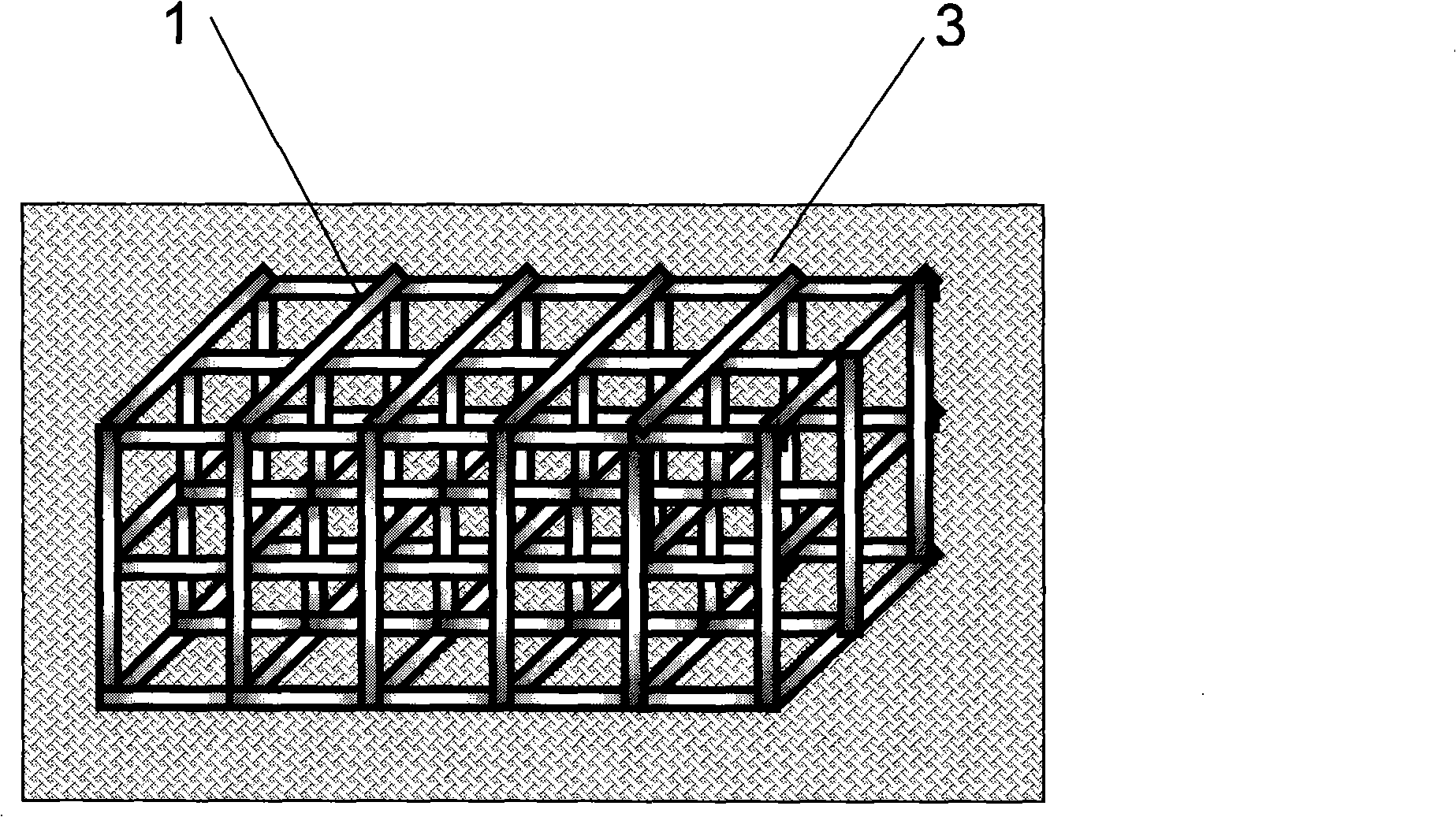

The invention discloses a preparation method of a framework reinforcement compound hammerhead. The made compound hammerhead is formed by compounding a framework reinforcement containing hard phase anda base metal. The method comprises the following processes: making a framework prefabricated part by utilizing a pipe thread filled with hard materials; carrying out vacuum high temperature metallurgy sintering on the framework perform so as to make the framework reinforcement containing the hard phase; and compounding the framework reinforcement with the base metal for molding to form the hammerhead formed by compounding the framework reinforcement containing the hard phase and the base metal. The framework reinforcement forms a sufficient metallurgical structure through vacuum high temperature metallurgy sintering, has orderly arrangement, uniform distribution, stable performance and strong integrity, and can keep complete framework structure when being compounded with the base metal. The invention not only exerts the highly wearable property of the hard phase in the framework reinforcement, but also keeps good toughness of the base metal, and can carry out local compound, graded compound or overall compound, thereby achieving the best use effect and obviously enhancing the comprehensive property.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

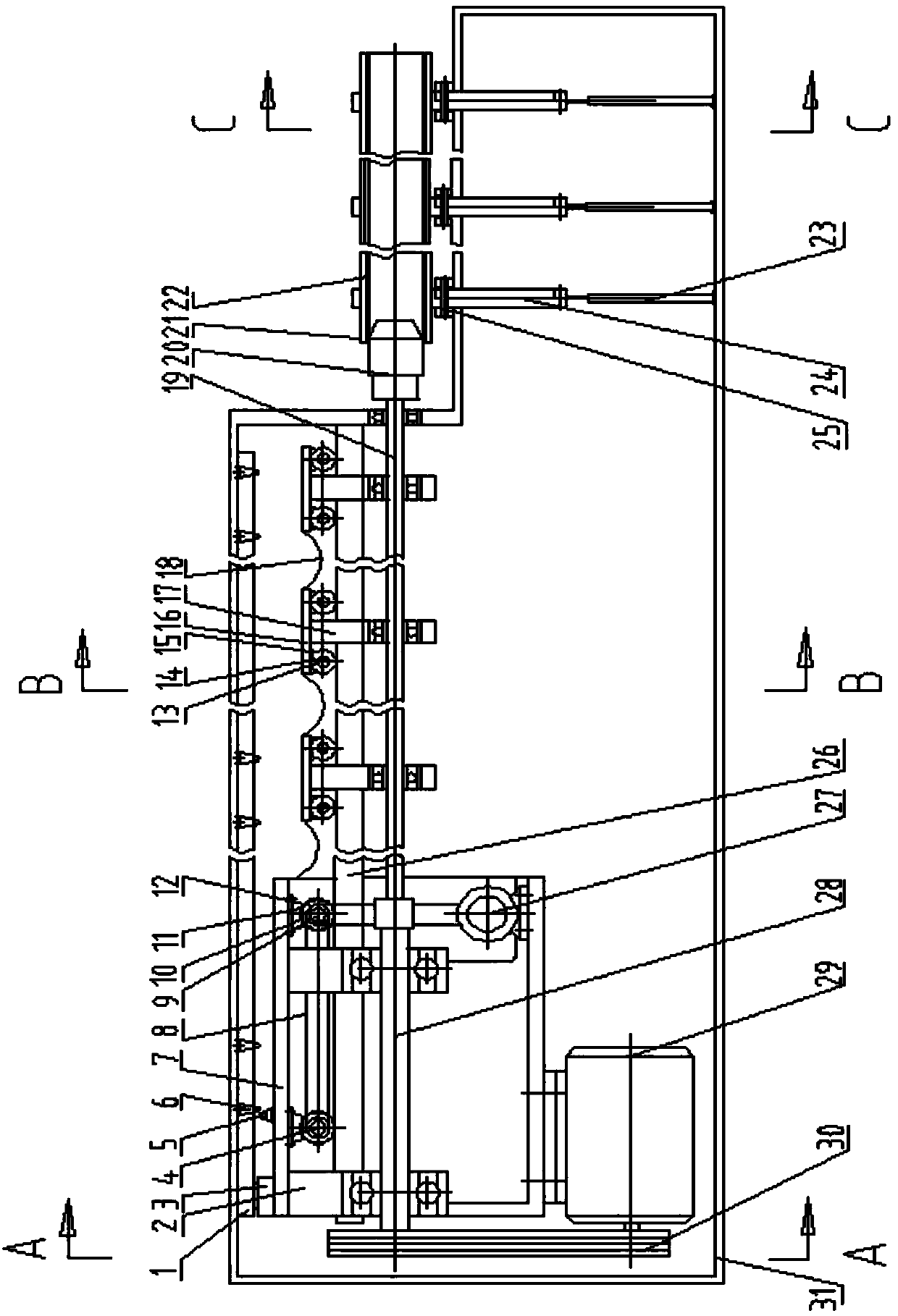

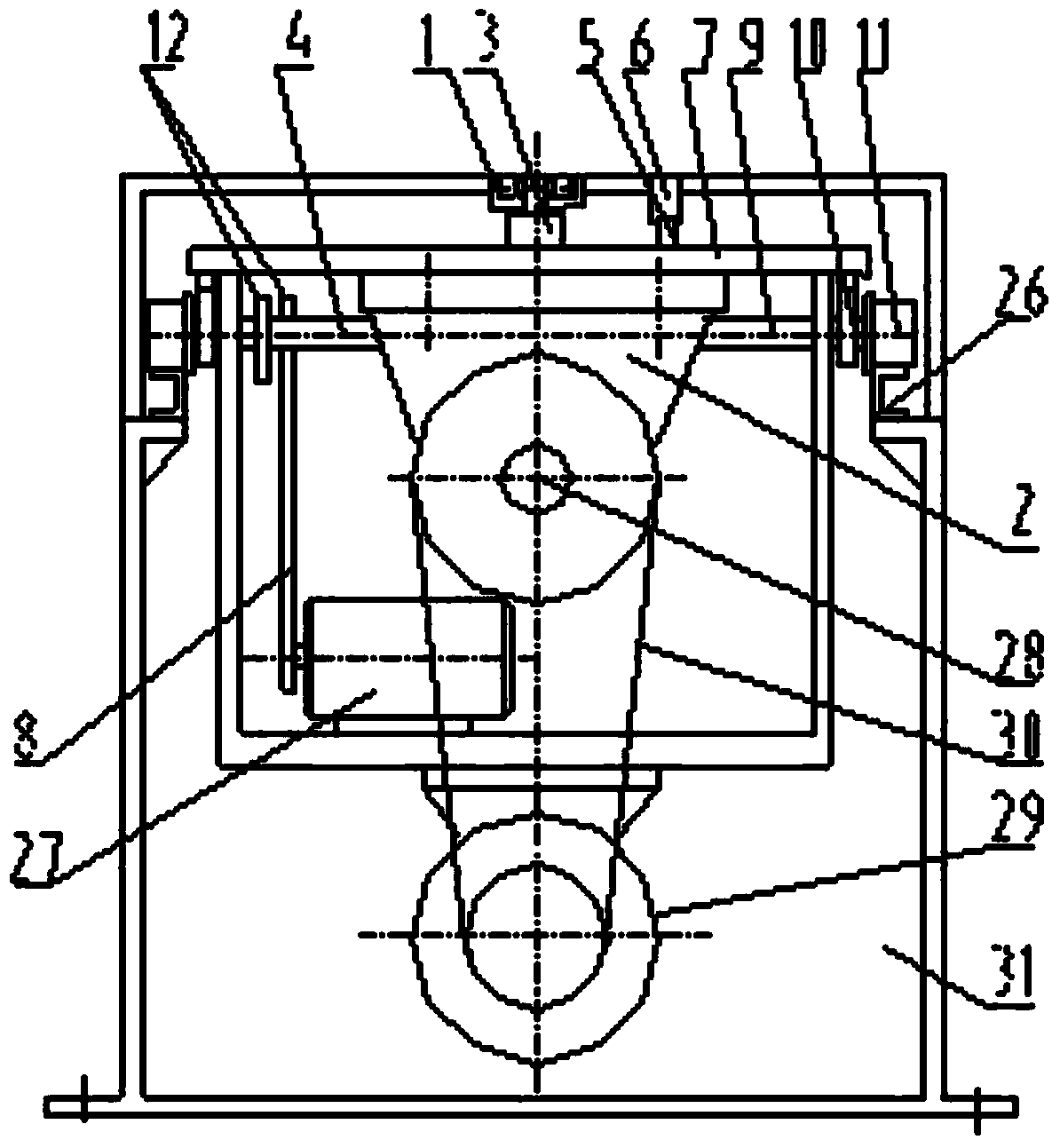

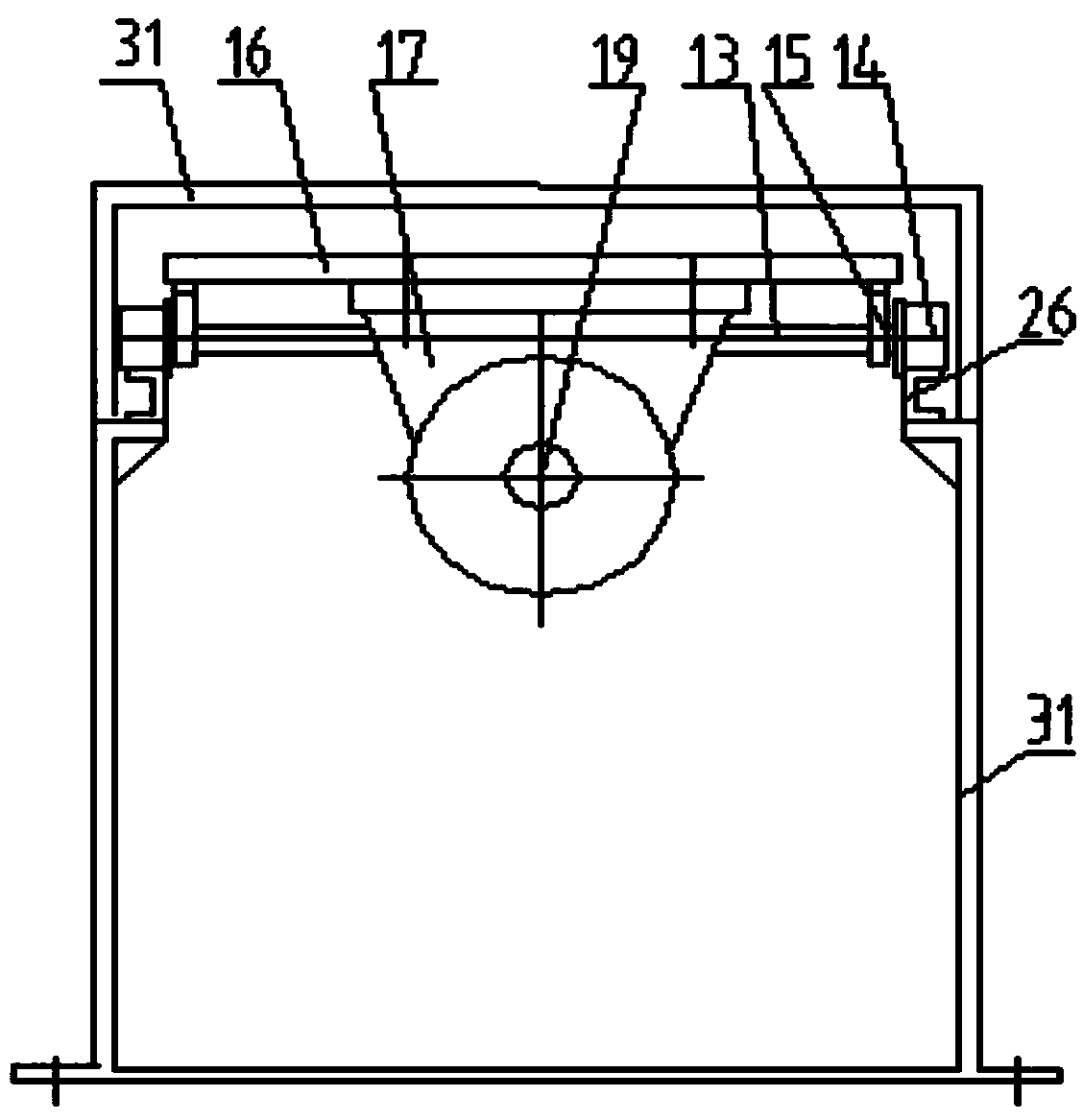

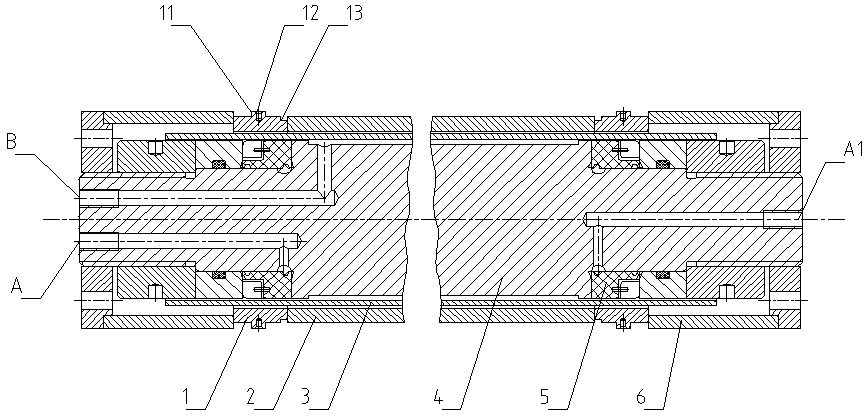

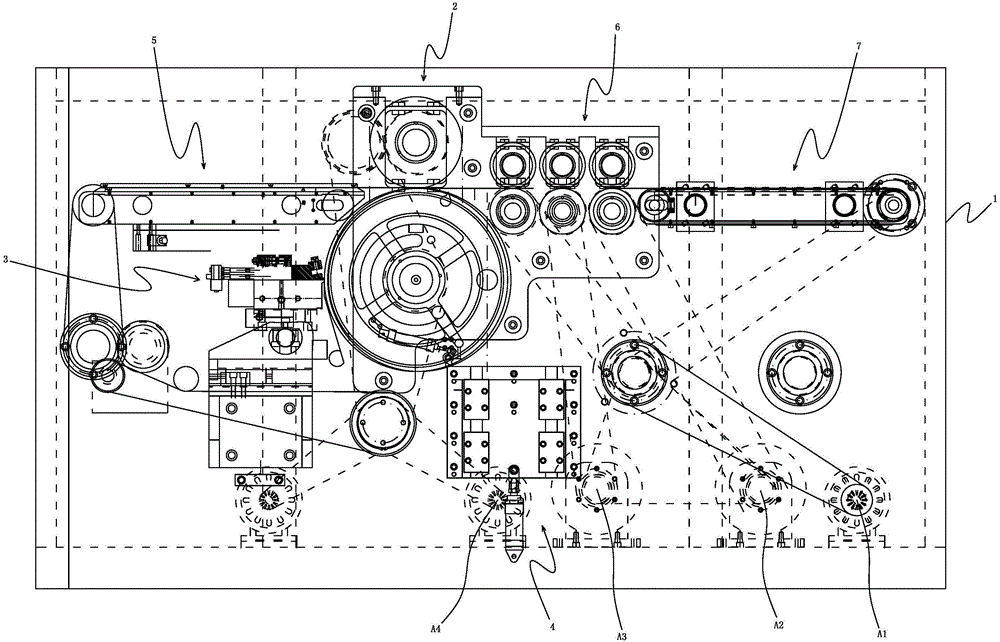

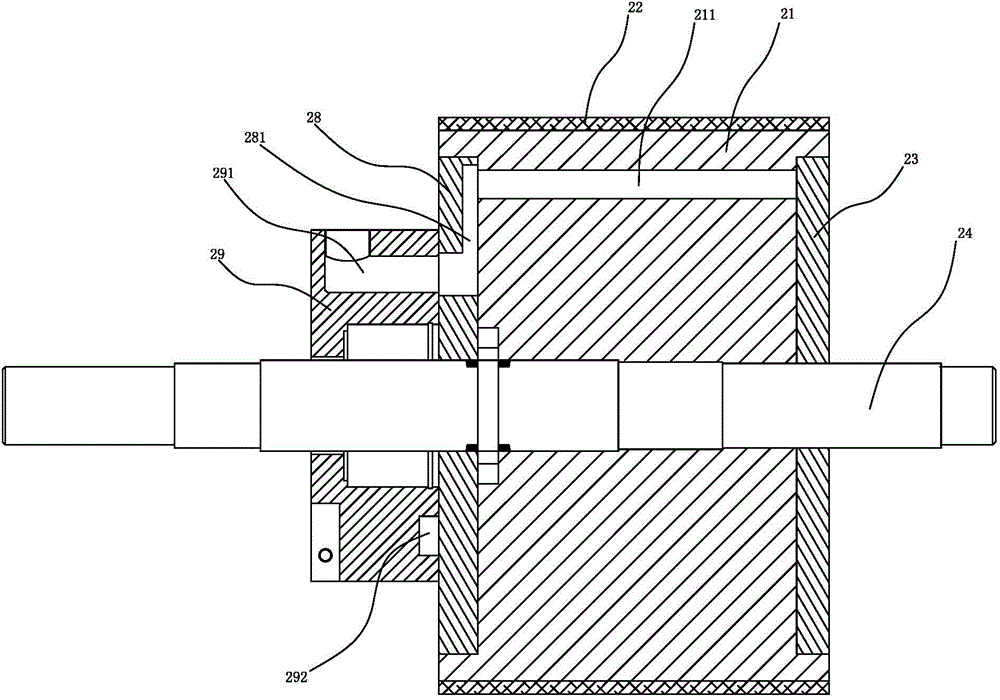

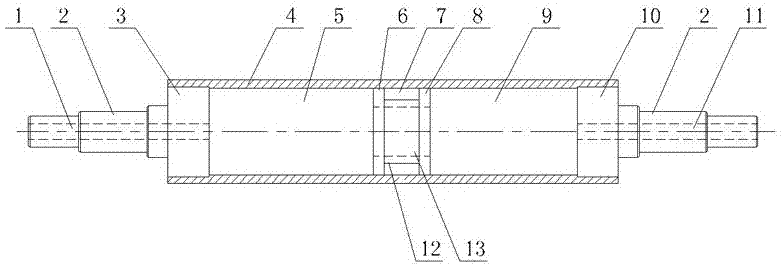

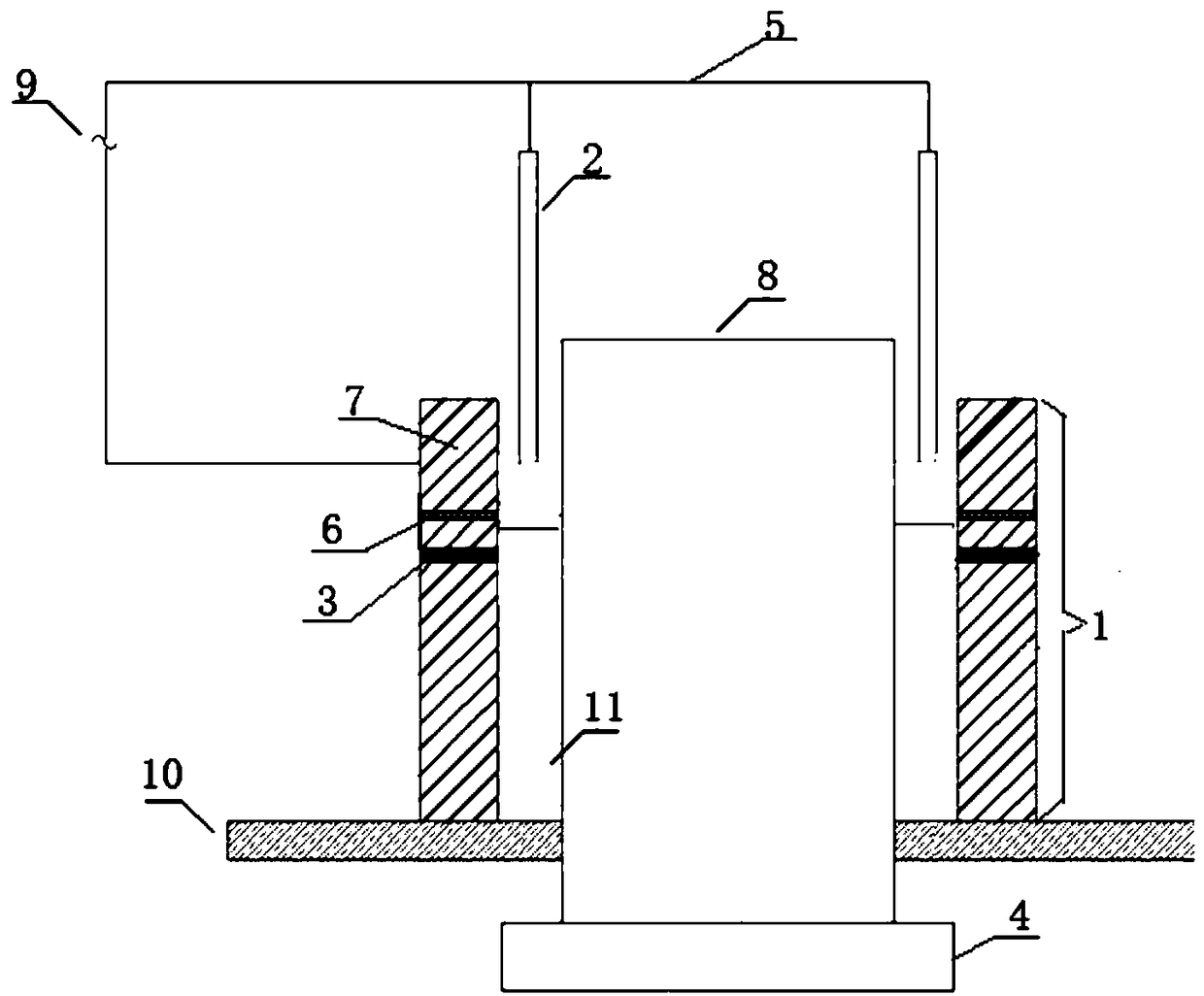

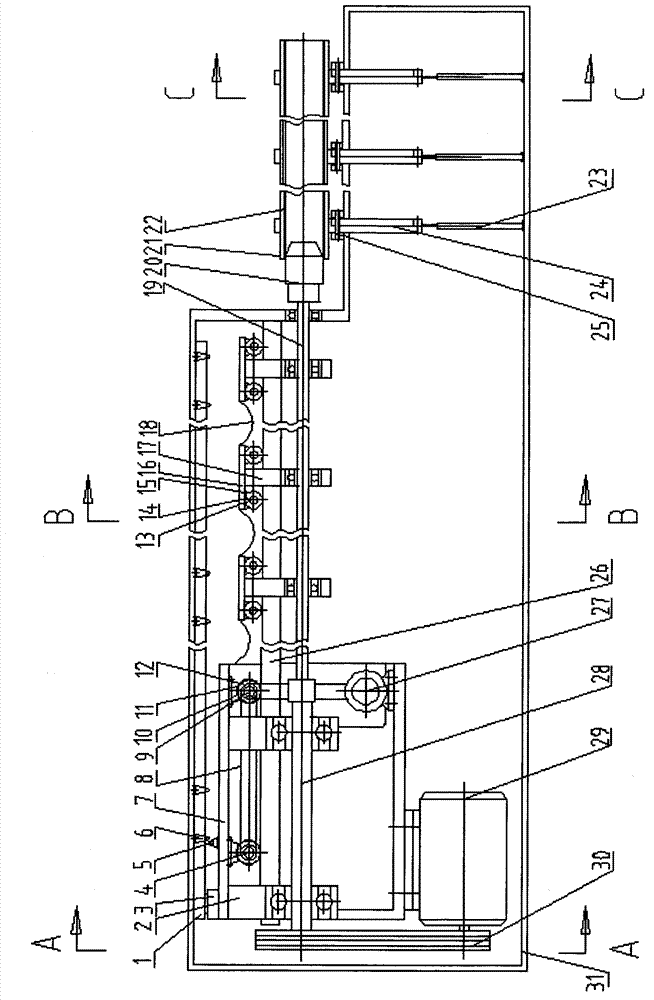

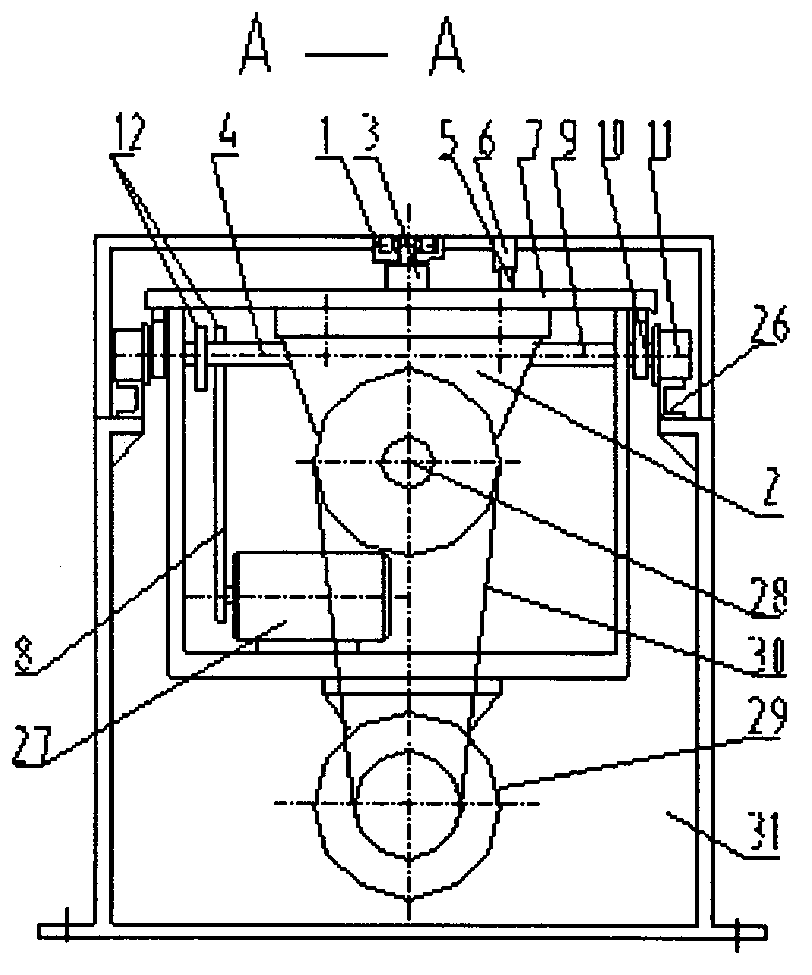

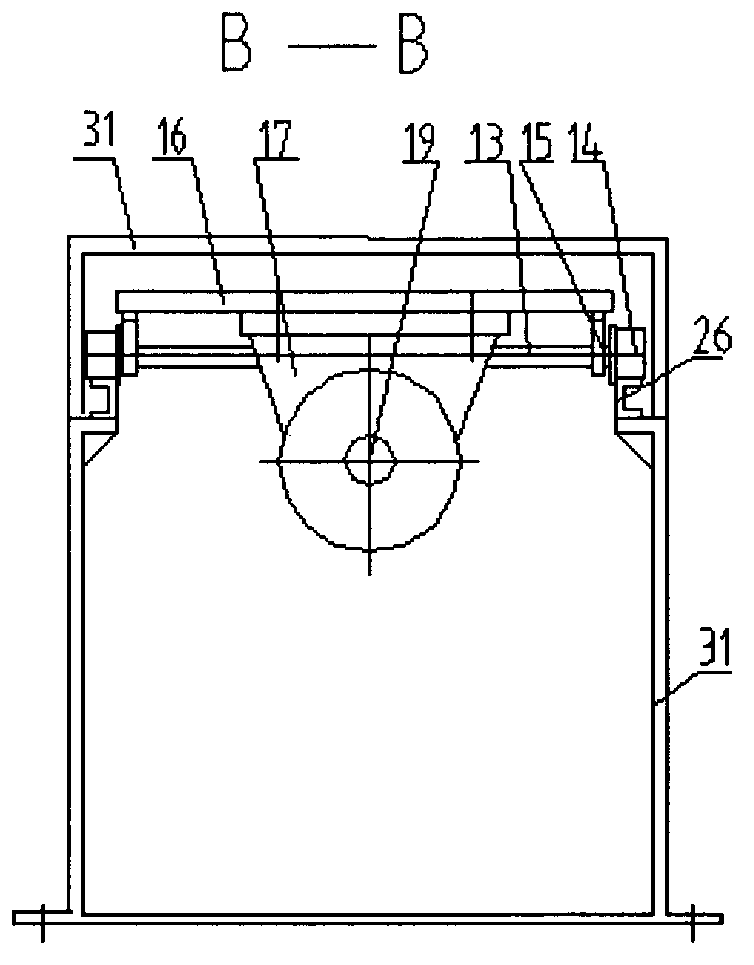

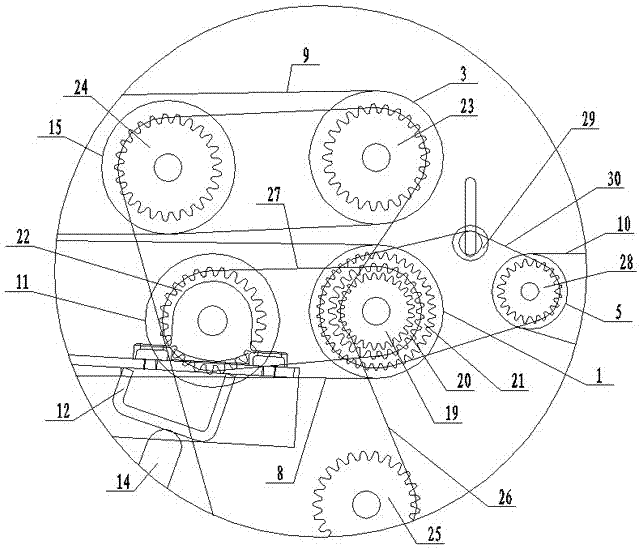

Internal forward spinning nested process composite machine tool with dual metal tubes

The invention discloses an internal forward spinning nested process composite machine tool with dual metal tubes. The internal forward spinning nested process composite machine tool comprises a tank body (7) and a machine body (31), wherein a spindle motor (29), a travel motor (27), a spindle bearing block (2), a travel wheel bearing block (10), a sliding contact (3) and a travel contact (5) are arranged on the tank body (7); a spindle (28) is arranged on the spindle bearing block (2); a front travel wheel axle (9) and a rear travel wheel axle (4) are arranged on the travel wheel bearing block (10); a travel track (26), a sliding contact linear rail (1), a travel switch (6), a pivot seat (25) and an air cylinder (23) are arranged on the machine body (31); a clamp (24) is arranged on the pivot seat (25) and is connected with the air cylinder (23); the sliding contact (3) is arranged in the sliding contact linear rail (1). The composite machine tool is reasonable in structural design and is convenient to operate; particularly, the stability of feed travel can be maintained; a clamping force has no influence on elastic deformation of an outer pipe and plastic deformation of an inner pipe; the inner pipe and the outer pipe are combined, so that high quality can be obtained; the problems that a spinning shaft is unstable in feed, the clamping force influences the elastic deformation of the outer pipe and the plastic deformation of the inner pipe and the like during the processing in the prior art can be solved.

Owner:JIANGSU QING YANG PIPE

Composite EPE-air bubble film packaging material

InactiveCN102848621AGuaranteed composite qualityReduce manufacturing costLayered productsLow-density polyethyleneAdhesive

The invention discloses a composite EPE-air bubble film packaging material. The material is prepared by compounding EPE and an air bubble film through tape casting of a coating layer which is obtained by mixing an adhesive and a low density polyethylene resin particle, wherein an upper layer is the EPE, a lower layer is the air bubble film, the usage amount of the low density polyethylene resin particle accounts for 30 to 40% of the weight of a coating material, and the diameter of an air bubble body of the air bubble film is 3 to 30 mm. Since the low density polyethylene resin particle is cheaper than the adhesive, the composite EPE-air bubble film packaging material provided by the invention has reduced production cost while the compounding quality of the EPE and the air bubble film is ensured.

Owner:SUZHOU JIUDING

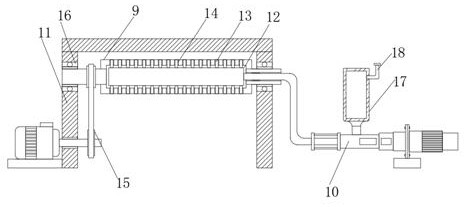

Aluminum-steel composite plate and compositing process thereof

InactiveCN109248916AGuaranteed composite qualityGuaranteed Compounding EfficiencyMetal rolling arrangementsSheet steelComposite plate

The invention discloses an aluminum-steel composite plate. An aluminum alloy plate is combined to the upper surface of a steel plate base; another aluminum alloy plate is combined to the lower surfaceof the steel plate base. The invention also discloses a compositing process of the aluminum-steel composite plate. The compositing process includes the steps of heating a low-carbon steel plate and an aluminum alloy plate at 300-450 DEG C for 3-6 min, stacking the heated low-carbon steel plate and aluminum alloy plate according to an actually required shape, placing the stack on a horizontal bench top, placing a press roller on the upper surface of the stack, heating the aluminum-steel composite plate blank again at 200-300 DEG C, and performing trimming reshaping and surface treatment on thealuminum-steel composite plate blank. The plate layers herein can be softened and melted into a composite whole; the finished product is better than existing single-layer plates or composite plates made of other materials, in product strength, toughness and service life.

Owner:OKUMTEC TECH WENZHOU CO LTD

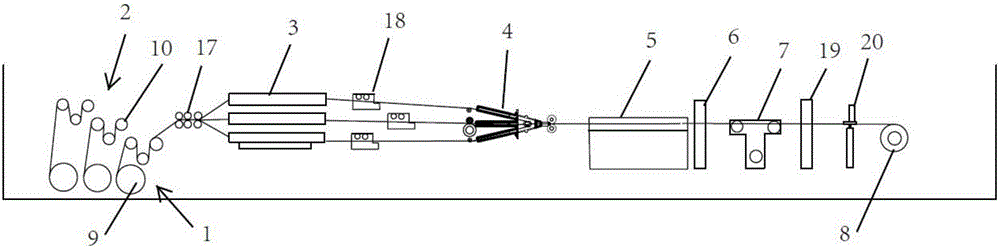

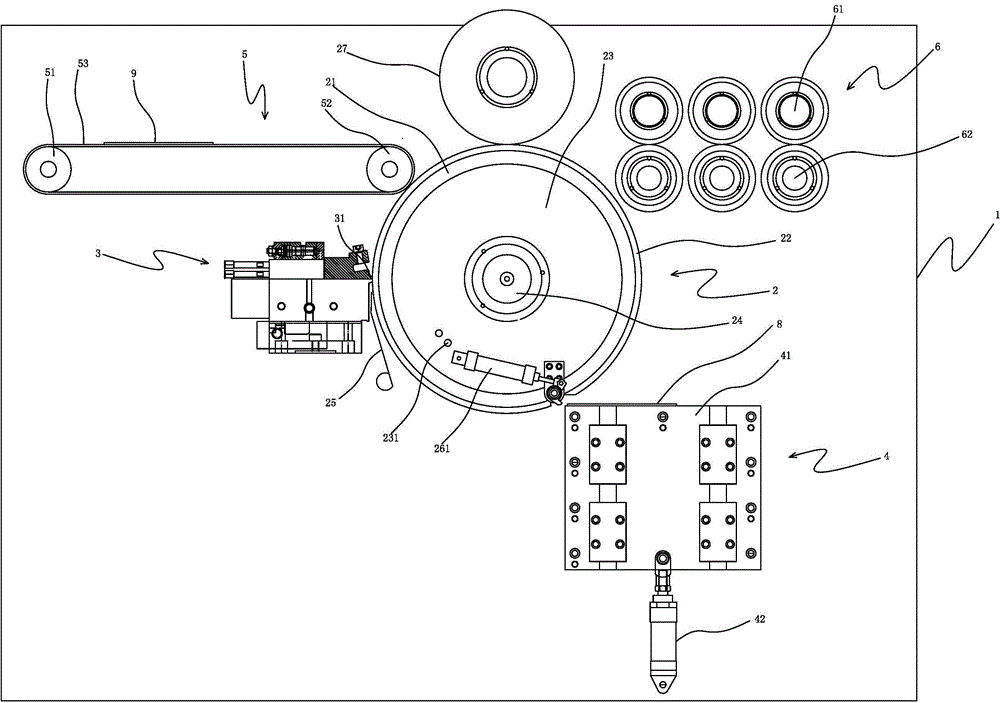

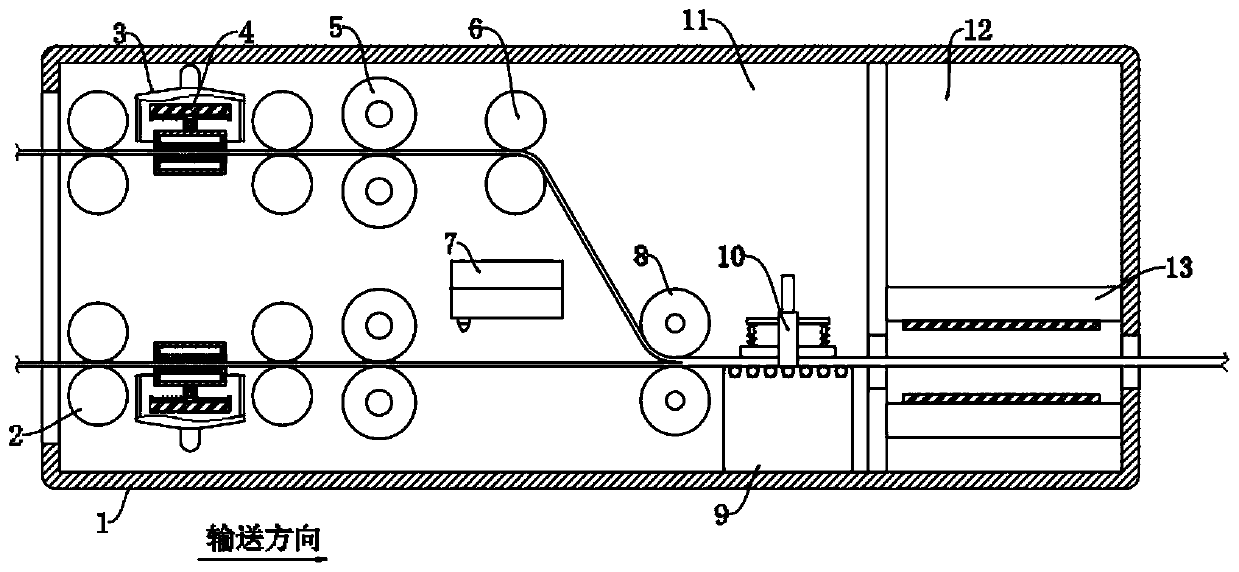

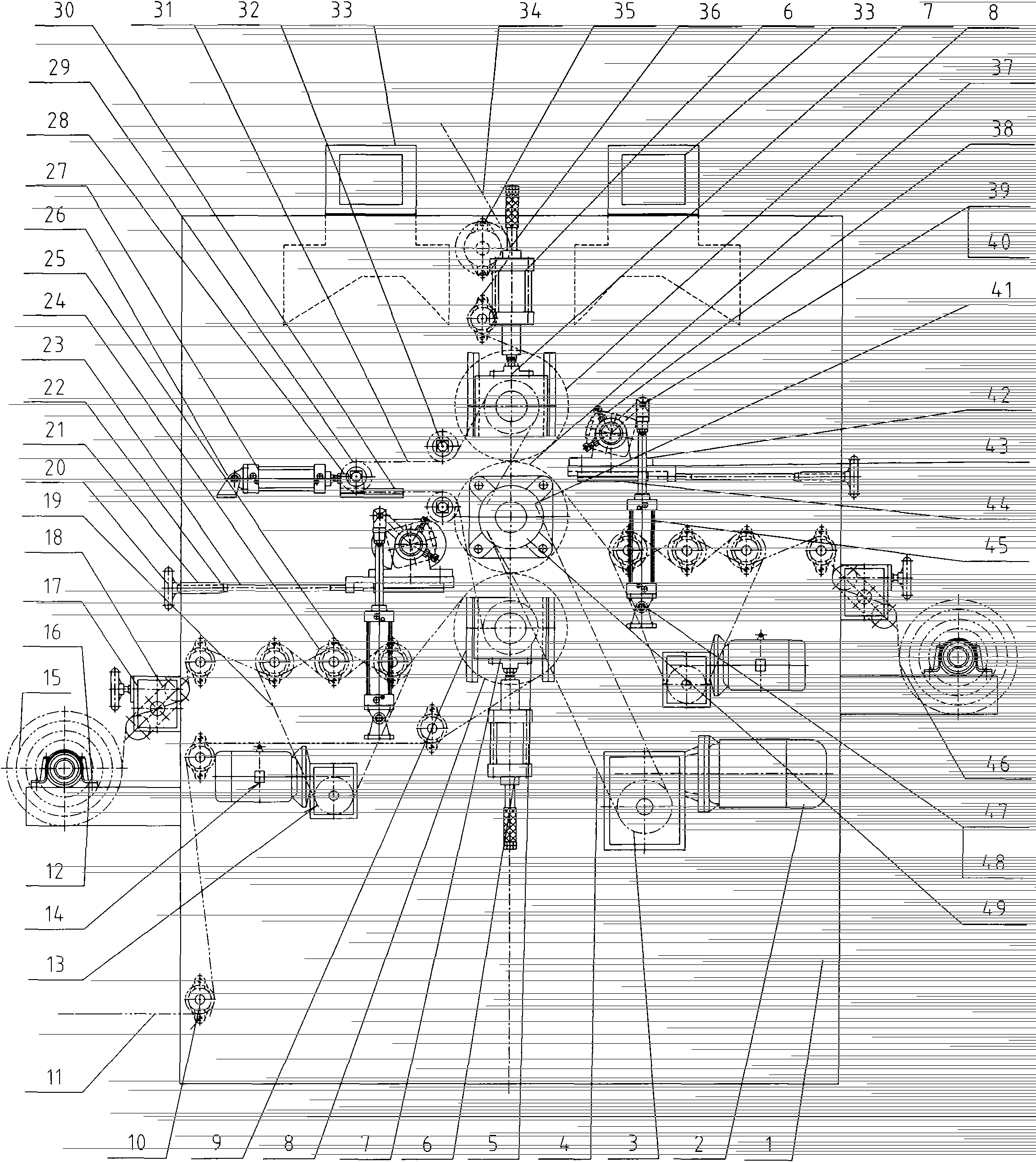

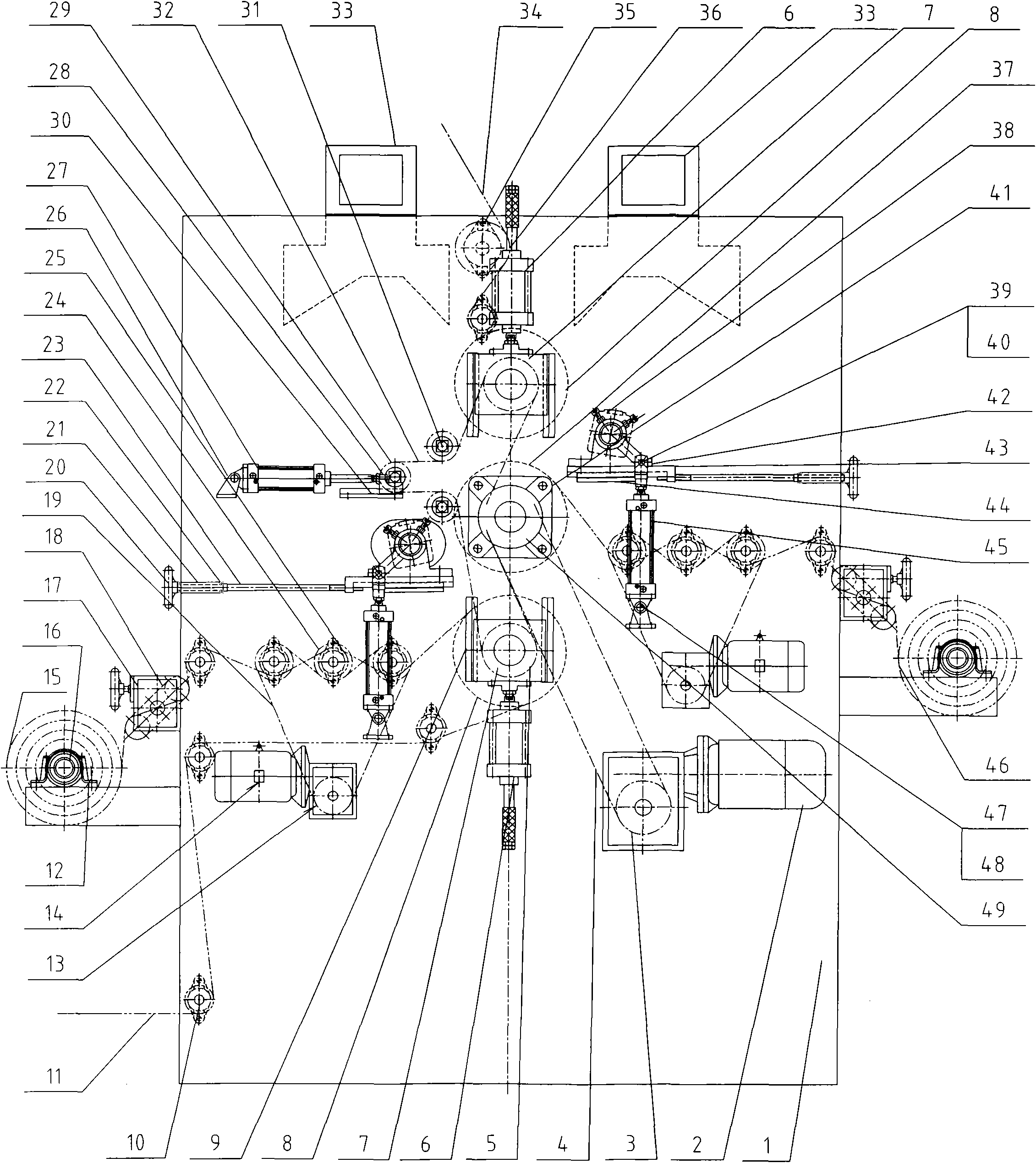

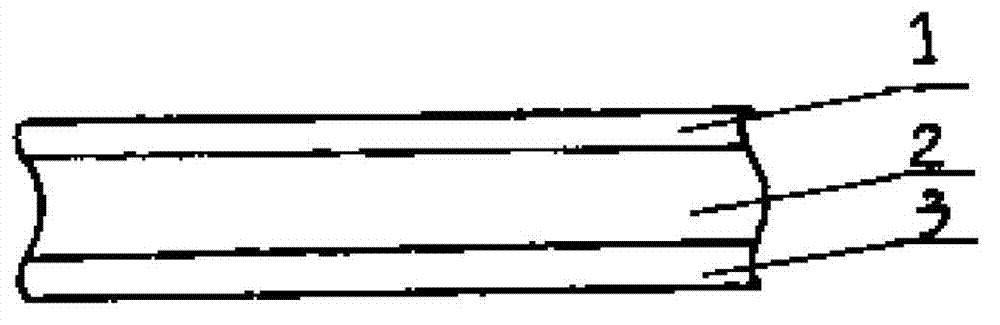

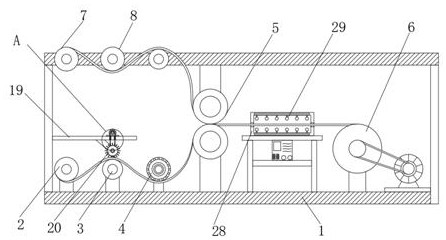

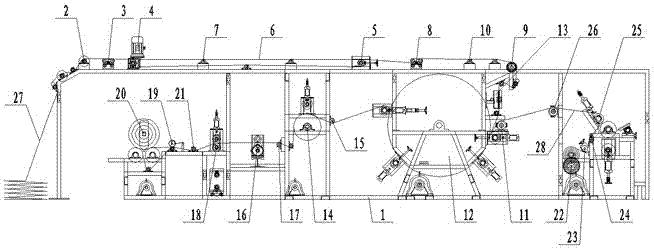

Rolling mill for three-layer compounded micro-profiled electric contact strip

ActiveCN106077081AImprove cleanlinessGuaranteed composite qualityGuiding/positioning/aligning arrangementsMeasuring devicesEngineeringBonding strength

The invention discloses a rolling mill for a three-layer compounded micro-profiled electric contact strip. The rolling mill comprises a paying-off part, a paying-off tension part, cleaning troughs, a compounding part, a cooling trough, a universal rolling part, a taking-up tension part and a taking-up part, wherein the paying-off part, the paying-off tension part, the cleaning troughs, the compounding part, the cooling trough, the universal rolling part, the taking-up tension part and the taking-up part are sequentially arranged. The paying-off part comprises a plurality of paying-off frames, the paying-off tension part comprises a plurality of tension control mechanisms, and the compounding part comprises a compounding body and a bidirectional rolling mechanism, wherein a plurality of wire inlet rails are arranged on the side, located at the cleaning troughs, of the compounding body, a wire guiding nozzle is arranged on the other side of the compounding body, and the bidirectional rolling mechanism is arranged on a wire outlet part of the wire guiding nozzle. The universal rolling part comprises a pair of horizontal rollers and a pair of vertical rollers, and the number of the paying-off frames is smaller than that of the tension control mechanisms. The compounded strip rolled by the rolling mill is good in surface quality and high in bonding strength, the strip is compounded laterally in three layers, the process is continuous and compact, and adjustment is easy and convenient.

Owner:SUZHOU CHUANGHAO NEW MATERIAL TECH CO LTD

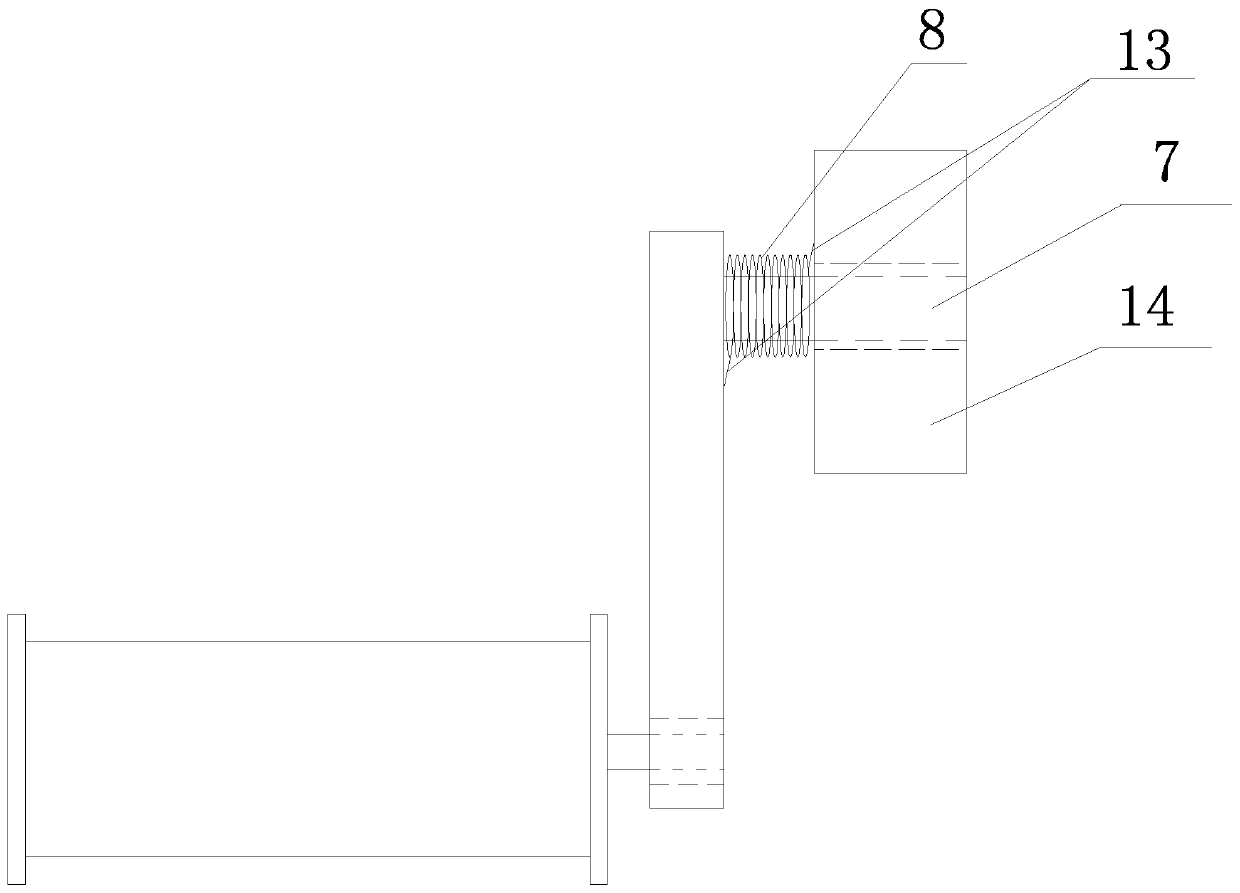

Composite pipe hydraulic expansion method, manufacturing device and obtained composite pipe

ActiveCN103629445AGood removal effectGuaranteed bonding qualityPipe elementsRigid pipesEngineeringScrew thread

The invention provides a composite pipe hydraulic expansion method, which comprises the following steps that (1) a plug provided with a sealing ring in the circumferential direction is inserted into an inner pipe; (2) sealing pressure liquid is introduced to a position between the plug and an inner ring of the sealing ring for sealing the end part of the inner pipe; (3) the expansion is carried out, before the expansion, a sleeve ring with the same inner diameter as an outer pipe of a composite pipe is arranged in a way of tightly pasting the end surface of the outer pipe of the composite pipe requiring the expansion, and in addition, the innermost end of the sealing ring is arranged outside the end surface of the outer pipe of the composite pipe. The sealing position exceeds the end surface of the outer pipe, so the pressure inside an inner pipe cavity can reach the end part of the outer pipe, and the combining quality is ensured. The defect of composite blind region reservation at the end part of the composite pipe manufactured in the prior art is overcome, and the composite pipe can be used without cutting off the blind region, so the cost is reduced in aspects of both materials and the process. The cutting is not needed, so great convenience is brought for the subsequent processing of external screw threads formed at the pip end of the composite pipe before the expansion.

Owner:QINGDAO ZHONGRUITAI MESNAC TECH CO LTD

Composite aluminum foil packing material of pearl wool

ActiveCN102849335AGuaranteed composite qualityReduce manufacturing costFlexible coversWrappersAluminiumLow-density polyethylene

The invention discloses a composite aluminum foil packing material of pearl wool. The composite aluminum foil packing material of pearl wool is prepared by curtain-coating and compounding a coating layer formed by pearl wool and an aluminum foil cast with a thickness of 15-40mum under temperatures 240 DEG C, 260 DEG C and 280 DEG C. An upper layer is the aluminum foil and a lower layer is the pearl wool. A coating material of the coating layer is a mixture of an adhesive and low-density polyethylene resin particles. The coating layer contains 30-45wt% of low-density polyethylene resin particles. The price of the low-density polyethylene resin particle is lower than that of the adhesive, so that the production cost of the composite aluminum foil packing material is reduced while the compound quality of the pearl wool and the aluminum foil is ensured.

Owner:厦门谱睿科技有限公司

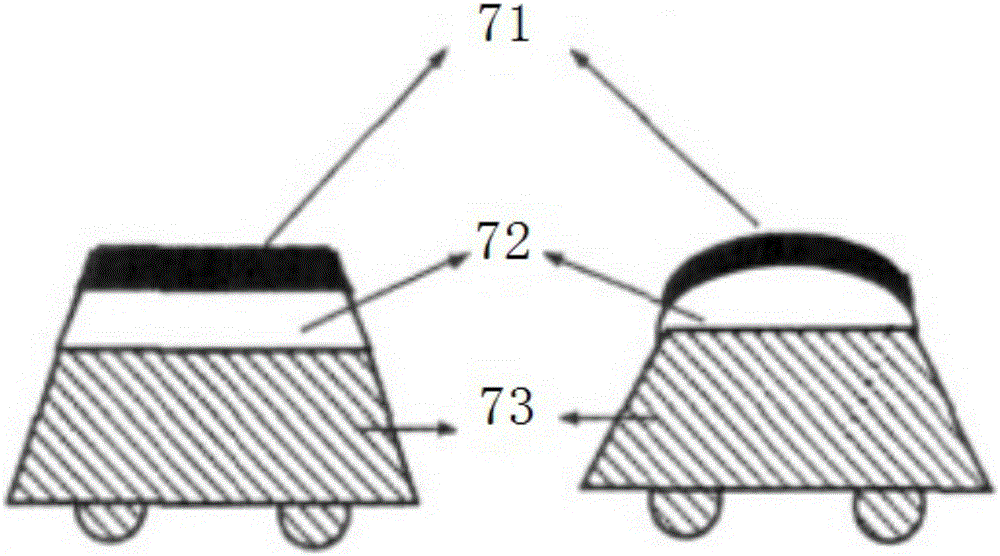

Discontinuous flexible material fetching device and gluing and compounding equipment

InactiveCN104802489AAffect normal rotationAvoid offsetLamination ancillary operationsLaminationCompound aEngineering

The invention relates to a discontinuous flexible material fetching device and gluing and compounding equipment. The gluing and compounding equipment is used for compounding a plate-shaped material and a flexible material, and comprises a machine frame, a material charging device, a material fetching device, a glue coating device, an upper press roller, a conveying mechanism and an auxiliary compounding mechanism. When the gluing and compounding equipment works, the material charging device is used for providing the flexible material for a material fetching roller of the material fetching device; the material fetching roller is used for absorbing the flexible material and rotationally conveying the flexible material; the flexible material is flattened by a flattening plate and is sent to a glue discharging lip edge of the glue coating device and the material fetching roller; the flexible material is uniformly coated with the glue by the glue coating device, and is sent to the upper pressing roller and the material fetching roller; meanwhile, the conveying mechanism is used for conveying the plate-shaped material to the pressing roller and the material fetching roller to be compounded; after compounding, the compounded material is conveyed into the auxiliary compounding mechanism to be further compounded, so as to guarantee the compounding quality.

Owner:福建省精泰设备制造有限公司

Expandable polyethylene (EPE) and aluminium foil compound packing material

InactiveCN104827726AGuaranteed composite qualityReduce manufacturing costFlexible coversWrappersAluminium foilLow-density polyethylene

The invention discloses an expandable polyethylene (EPE) and aluminium foil compound packing material. The packing material is prepared by carrying out casting compounding on EPE and aluminium foil via a coating layer formed by mixing an adhesive and low-density polyethylene (LDPE) resin particles, wherein the upper layer is formed by the aluminium foil and the lower layer is formed by EPE; an aluminium foil layer can be also formed below EPE through casting compounding via a coating material of the coating layer; the usage amount of the LDPE resin particles accounts for 30-45% of the weight of the coating material; the thickness of an aluminium film is 15-40 mu m. The EPE and aluminium foil compound packing material has the effect of reducing the production cost while ensuring the compounding quality of EPE and aluminium foil since the LDPE resin particles have lower price than the adhesive.

Owner:赫曼斯碳纳米管科技江苏有限公司

Preparation method of prefabricated framework reinforcement compound grinding disc

InactiveCN101658916AImprove wear resistanceImprove toughnessCocoaGrain treatmentsWear resistanceToughness

The invention discloses a preparation method of a prefabricated framework reinforcement compound grinding disc. The made compound grinding disc is compounded by a framework reinforcement containing hard phase and a base metal. The method adopts the following processes: making a framework prefabricated part by utilizing a pipe thread filled with hard materials; carrying out vacuum high-temperaturemetallurgy sintering on the framework prefabricated part to form the framework reinforcement containing the hard phase; and compounding the framework reinforcement with the base metal for molding to form the grinding disc compounded by the framework reinforcement containing the hard phase and the base metal. The framework reinforcement forms a sufficient metallurgical structure through vacuum high-temperature metallurgy sintering, has orderly arrangement, uniform distribution, stable performance and strong integrity, can keep a complete framework structure when being compounded with the base metal. The invention not only exerts high-wearing property of the hard phase in the skeleton reinforcement, but also keeps good toughness of the base metal, and can carry out local compound, graded compound or overall compound, thereby achieving the best use effect and obviously enhancing the comprehensive property.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

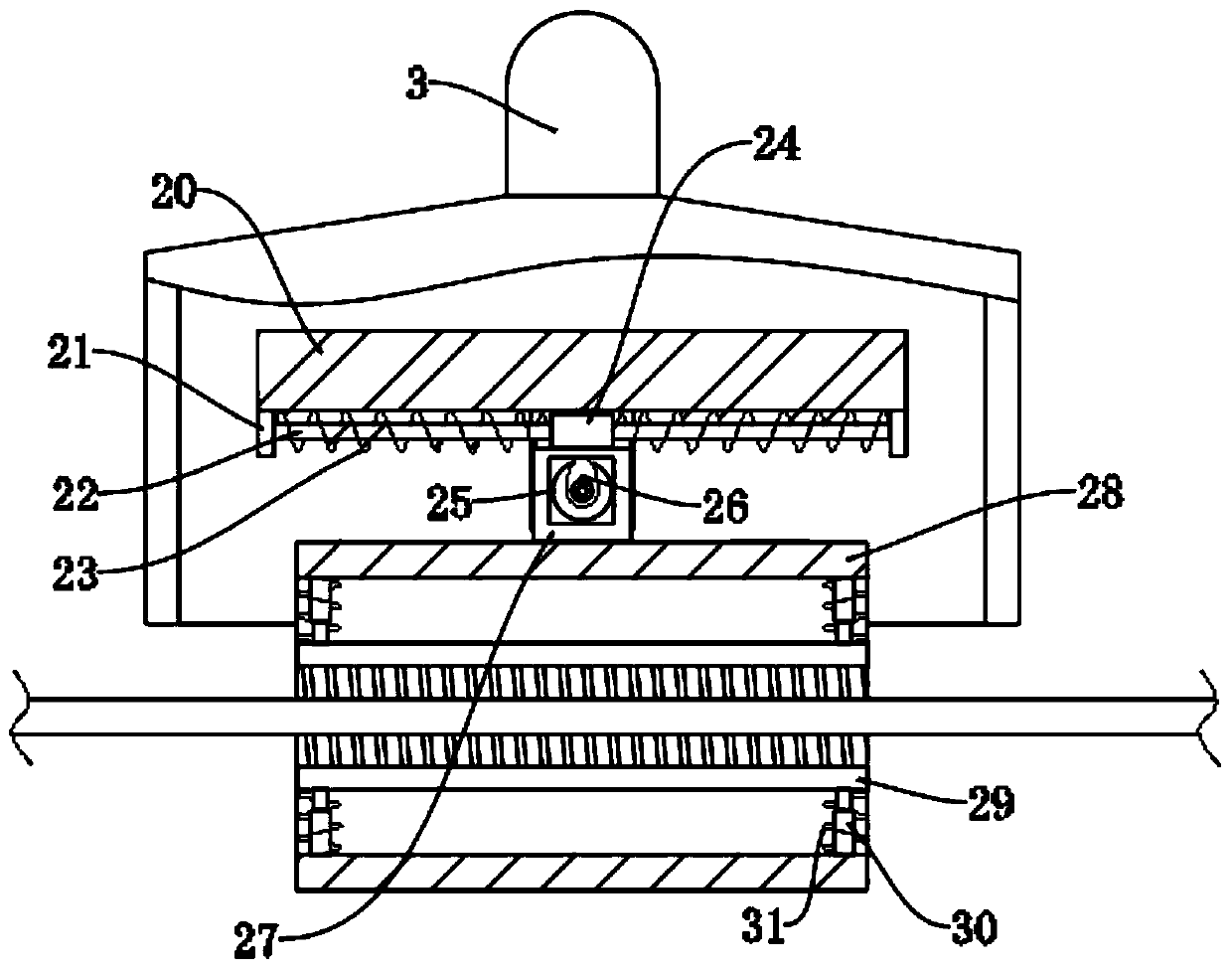

Fabric compounding device with deodorizing and refreshing functions

PendingCN111204112AGuaranteed gluingGuaranteed composite qualityLamination ancillary operationsLaminationAdhesive glueMechanical engineering

The invention discloses a fabric compounding device with deodorizing and refreshing functions. The fabric compounding device comprises a machine shell; a compounding chamber and a deodorizing chamberare sequentially arranged in the machine shell in the material conveying direction; a feeding mechanism, a gluing mechanism, a pair of composite pressing rollers and a re-pressing mechanism are sequentially arranged in the compounding chamber in the material conveying direction; the feeding mechanism comprises an upper feeding line and a lower feeding line which are arranged up and down; the upperfeeding line comprises two pairs of first guide wheels, a pair of heating rollers and a pair of second guide wheels which are arranged in the conveying direction, and a cleaning structure is arrangedbetween the two pairs of first guide wheels; the lower feeding line comprises two pairs of first guide wheels and a pair of heating rollers which are arranged in the conveying direction, and a cleaning structure is arranged between the two pairs of first guide wheels. The fabric can be subjected to dust removal, preheating and softening before compounding, and glue is more uniform and deeply permeates the fabric; meanwhile, the re-pressing mechanism is arranged, the subsequent gluing and compounding quality is guaranteed, and a fragrance fumigator can be used for removing odor and fumigatingthe compounded fabric.

Owner:FUJIAN CHARME TEXTILE

Double-burner flame laminating machine

InactiveCN103419461AAchieve a compositeReasonable structureLaminationLamination apparatusElectric machineryRoller chain

The invention provides a double-burner flame laminating machine. The double-burner flame laminating machine comprises a frame, two burners, a fixed pressure roller and a transmission mechanism. The fixed pressure roller is installed in the middle of the frame. Two movable pressure rollers are arranged respectively on the fixed pressure roller and a lower slide rail. The movable pressure rollers are connected respectively to cylinders. The cylinders drive the two movable pressure rollers so that the movable pressure rollers are respectively pressed to or separated from the fixed pressure roller. The two burners are arranged on the frame at two sides of the fixed pressure roller. The transmission mechanism comprises a motor, a chain wheel group, chains and a tensioning cylinder. A chain wheel on an output shaft of the motor is connected to a fixed pressure roller chain wheel, two movable pressure roller chain wheels, tensioning transition chain wheels and a tensioning sliding chain wheel by the chains. When the movable pressure rollers rise or fall, the tensioning cylinder drives the tensioning sliding chain wheel to move synchronously so that the chains are always in a tensioning state and thus synchronous rotation of the two movable pressure rollers and the fixed pressure roller is guaranteed. The double-burner flame laminating machine has a reasonable structure, is convenient for operation, realizes one-step compounding of a surface material, an inner material and sponge, improves production efficiency and guarantees compounding quality.

Owner:JIANGSU KUNTAI MACHINERY

Preparation method of prefabricated framework reinforcement compound grinding disc

InactiveCN101658916BImprove wear resistanceImprove toughnessCocoaGrain treatmentsWear resistanceToughness

The invention discloses a preparation method of a prefabricated framework reinforcement compound grinding disc. The made compound grinding disc is compounded by a framework reinforcement containing hard phase and a base metal. The method adopts the following processes: making a framework prefabricated part by utilizing a pipe thread filled with hard materials; carrying out vacuum high-temperaturemetallurgy sintering on the framework prefabricated part to form the framework reinforcement containing the hard phase; and compounding the framework reinforcement with the base metal for molding to form the grinding disc compounded by the framework reinforcement containing the hard phase and the base metal. The framework reinforcement forms a sufficient metallurgical structure through vacuum high-temperature metallurgy sintering, has orderly arrangement, uniform distribution, stable performance and strong integrity, can keep a complete framework structure when being compounded with the base metal. The invention not only exerts high-wearing property of the hard phase in the skeleton reinforcement, but also keeps good toughness of the base metal, and can carry out local compound, graded compound or overall compound, thereby achieving the best use effect and obviously enhancing the comprehensive property.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for manufacturing a cashmere coat

ActiveCN110219078AMake sure it is dense and crispAccurate grasp of stretch elasticityWeft knittingLayered productsYarnDaily wear

The invention discloses a method for manufacturing a cashmere coat, and belongs to the technical field of garment manufacturing. The method for manufacturing the cashmere coat includes the sequentialsteps of step (1), cashmere cloth weaving, step (2), fulling processing, step (3), combined processing and step (4), garment manufacturing. In the cashmere cloth weaving step, wool yarns are knitted into cashmere knitted fabrics by a circular knitting machine. In the fulling processing step, the cashmere knitted fabrics are washed by cloth washing liquid and clear water in sequence, and then driedand set for standby use. In the combined processing step, the cashmere knitted fabrics are combined and bonded with bonding fabrics by a four-roller cloth combination machine. In the garment manufacturing step, the combined fabrics are tailored according to a garment model and then sewn into the cashmere coat as required by a normal sewing machine. The method has the advantages that the manufacturing process of the cashmere coat is precise, the product quality is high, the fabrics are dense and stiff, sueded surfaces are well-shaped and uniform, the hand feel is soft, and the finished cashmere coat has high shape retention properties to meet the needs of daily wear.

Owner:JIAXING TUHUANG CASHMERE CO LTD

Composite steel roller

InactiveCN107498976AMeet special composite work requirementsGuaranteed composite qualityLaminationLamination apparatusStructural engineeringIndustrial engineering

The invention discloses a composite steel roller, comprising a roller body; the roller body is a hollow tube; a left end cover and a right end cover are respectively and fixedly arranged at the two ends of the roller body; the outer end faces of the left end cover and the right end cover are respectively and fixedly connected with a left roller shaft and a right roller shaft; the composite steel roller is characterized in that a left spacer plate and a right spacer plate are arranged in the middle position of an inner hole of the roller body, and a middle closed cavity is defined by the left spacer plate and the right spacer plate; a left closed cavity is defined by the left spacer plate and the left end cover, and a right closed cavity is defined by the right spacer plate and the right end cover; the left closed cavity and the right closed cavity are communicated with each other by means of a pipe hole; a pipe sleeve provided with the pipe hole passes through the middle of the middle closed cavity, and the two ends of the pipe sleeve are respectively fixed on the left spacer plate and the right spacer plate; a separation distance is reserved between the excircle of the pipe sleeve and the inner hole of the roller body; a left roller shaft is provided with a left axial hole so as to enable the left closed cavity to be communicated with cooling inflow water, and a right roller shaft is provided with a right axial hole so as to enable the right closed cavity to be communicated with cooling discharge water. Only the two ends of the roller body of the composite steel roller can be cooled, so that the requirements of a special composite work are more widely met.

Owner:瑞安市博威机械配件有限公司

Composite embossed non-woven fabric

InactiveCN102848660AGuaranteed composite qualityHigh bonding strengthSynthetic resin layered productsLow-density polyethyleneNonwoven fabric

The invention discloses a composite embossed non-woven fabric which is prepared by subjecting EPE and a low-pressure membrane to direct hot pressing on an embossing calendar under the conditions of a hot pressing temperature of 110 to 120 DEG C and a rotating speed of a pressure roller of 800 to 1200 RPM and then compounding the pressed low-pressure membrane and EPE with a non-woven fabric through tape casting of a coating layer formed by a mixture of an adhesive and a low density polyethylene resin particle, wherein an upper layer is the low-pressure membrane, a middle layer is the EPE, a lower layer is the non-woven fabric, the usage amount of the low density polyethylene resin particle accounts for 20 to 40% of the weight of a coating material, and the thickness of the low-pressure membrane is 8 to 25 mu m. Since the low density polyethylene resin particle is cheaper than the adhesive, the composite embossed non-woven fabric provided by the invention has reduced production cost while the compounding quality of the non-woven fabric, the EPE and the low-pressure membrane is ensured, and improves bonding strength of the low-pressure membrane and the EPE through controlling the hot pressing temperature and the rotating speed of the pressure roller, allowing bonding between the low-pressure membrane and the EPE to be firmer.

Owner:SUZHOU JIUDING

Novel compound aluminum foil air bubble film

InactiveCN105269886AGuaranteed composite qualityReduce manufacturing costSynthetic resin layered productsMetal layered productsLow-density polyethyleneAdhesive

The invention discloses a novel compound aluminum foil air bubble film which is formed by compounding an air bubble film and an aluminum foil through a coating layer formed by mixing an adhesive and low-density polyethylene resin particles in a tape casting manner, wherein the upper layer is the aluminum foil, and the lower layer is the air bubble film; another layer of aluminum foil can be further compounded below the air bubble film through a coating layer in a tape casting manner; the use amount of the low-density polyethylene resin particles is 60 percent of the weight of a coating material; each aluminum foil is 50 microns in thickness; and the diameter of each air bubble body of the air bubble film is 2mm. As the price of the low-density polyethylene resin particles is lower than that of the adhesive, a novel compound aluminum foil air bubble film packaging material provided by the invention guarantees the compounding quality of the air bubble film and the aluminum foil, and the production cost is reduced.

Owner:CHONGQING SHENGYU NEW MATERIAL CO LTD

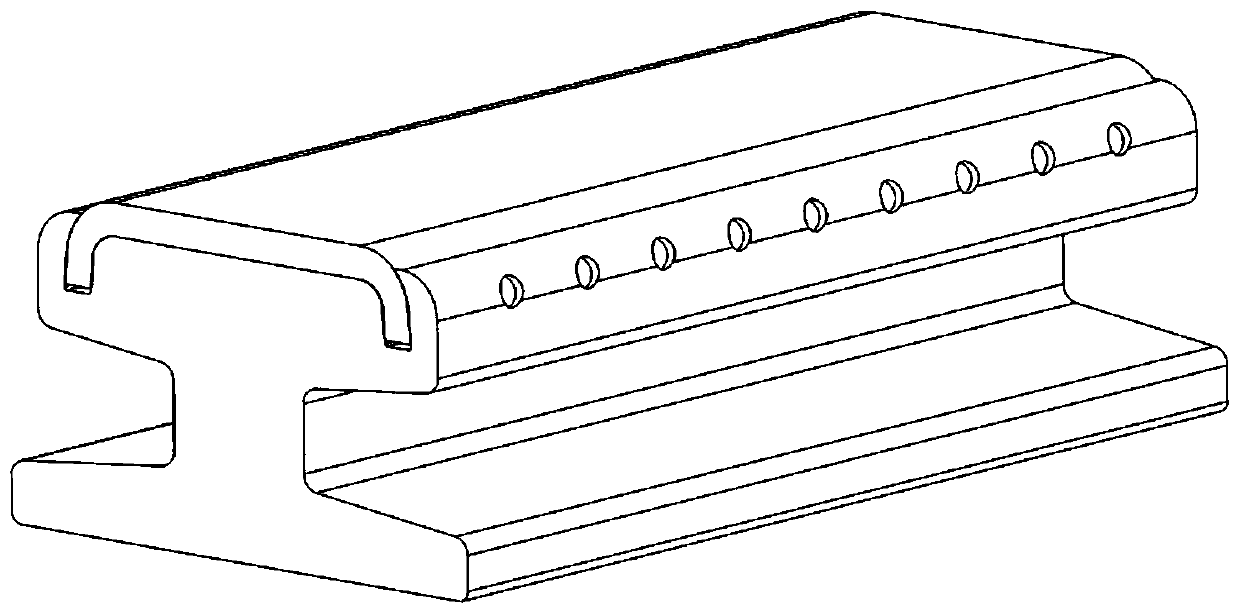

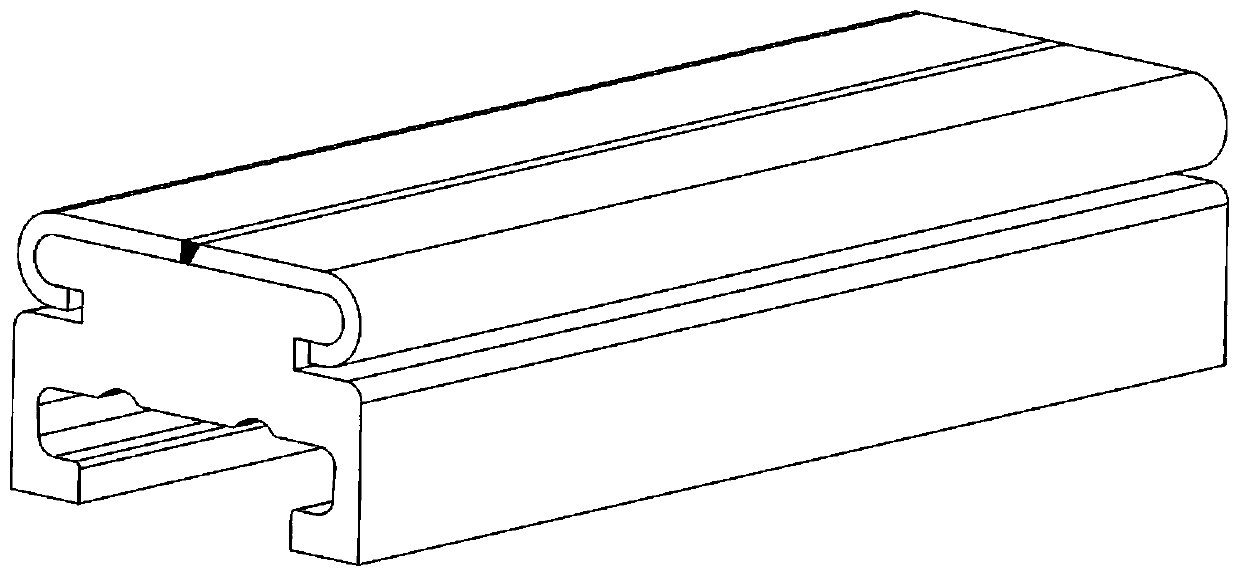

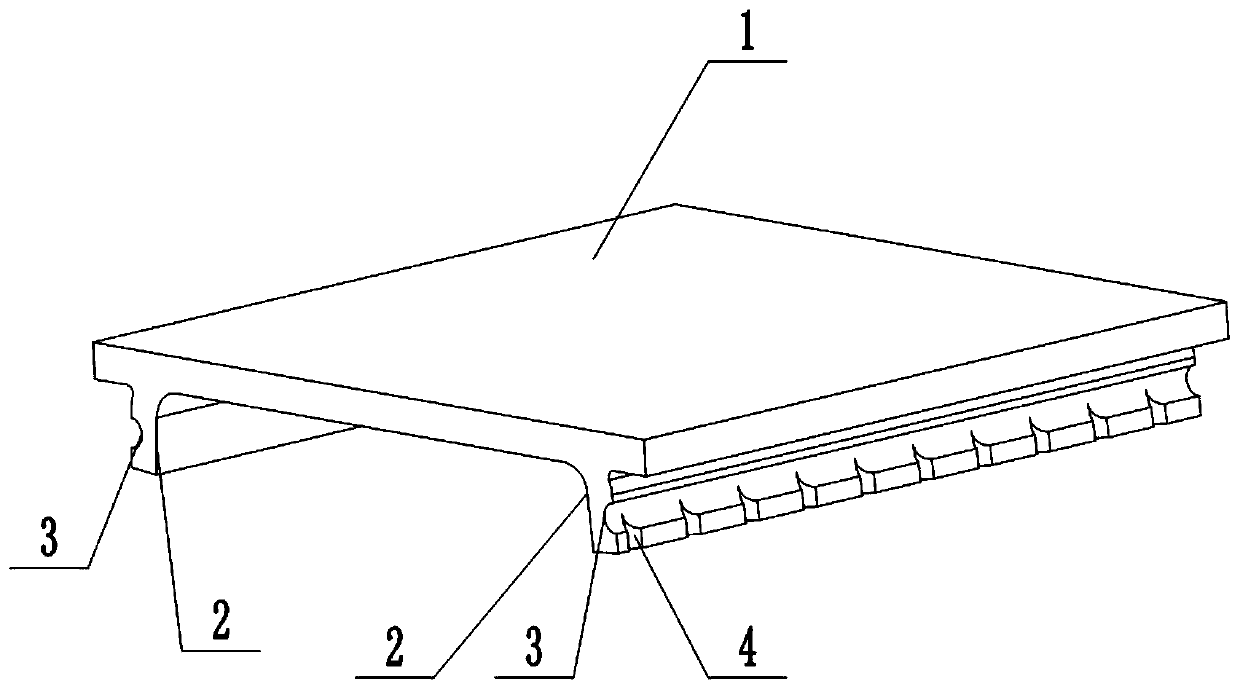

Special-shaped steel belt and steel aluminum composite conductor rail

PendingCN110745034AMeet the standard requirements for tensile strengthMeet the standard requirements for pull-out resistancePower railsSS - Stainless steelAluminum composites

The invention discloses a special-shaped steel belt and a steel aluminum composite conductor rail. A steel belt cross section is of a pi-shaped structure, and the special-shaped steel belt comprises asteel belt body and two supporting legs; and the two supporting legs are symmetrically located below the steel belt body, and arc grooves are formed in the outer sides of the two supporting legs in the length direction of the steel belt. The special-shaped steel belt is used for the steel aluminum composite conductor rail, the width of a stainless steel belt is the same as the width of an aluminum rail, so that the effective contact surface width of the stainless steel belt and a collector shoe is increased, the effective current collection surface proportion is increased, reliable current collection of the collector shoe is guaranteed, and meanwhile, the standard requirements of the stainless steel belt and aluminum rail tensile resistance in the circuit direction and the standard requirements of the stainless steel belt and aluminum rail pulling resistance in the vertical circuit direction of the composite conductor rail are met.

Owner:CHINA RAILWAY HIGH SPEED ELECTRIFICATION EQUIP CORP LTD

Preparation method of reinforced composite wear-resistant lining board of precast framework

The invention discloses a preparation method of a reinforced composite wear-resistant lining board of a precast framework. The prepared reinforced composite wear-resistant lining board is formed by compounding a framework reinforced body containing hard phases and base body metal. The preparation method comprises the following steps: adopting a framework precast body made of tube wires filled with hard materials, performing the vacuum high-temperature sintering, forming the framework reinforced body containing hard phases, and leading the framework reinforced body to perform the metal castingcomposite molding with the base body metal, so as to form the lining board formed by compounding the framework reinforced body containing hard phases and the base body metal. The framework reinforcedbody is performed by the vacuum high-temperature sintering to form a complete metallurgical texture structure, which has order arrangement, uniform distribution, stable performance and strong integrity, can always keep complete framework structure after compounding with the base body metal, thereby developing the high wear-resistance of the hard phases in the framework reinforced body, and keeping better flexibility of the base body metal. The reinforced composite wear-resistant lining board can be compounded locally or gradiently, or integrally, and can be widely applied to wear-resistant fields of mine, electricity, metallurgy, coal, building materials, and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Novel tape-cast composite non-woven fabric color membrane

InactiveCN102848625AGuaranteed composite qualityReduce manufacturing costLayered productsChemistryWoven fabric

The invention discloses a novel tape-cast composite non-woven fabric colorful membrane which is prepared by compounding a non-woven fabric with a color membrane through tape casting of a coating layer formed by a mixture of an adhesive and a low density polyethylene resin particle, wherein an upper layer is the color membrane, a lower layer is the non-woven fabric, the usage amount of the low density polyethylene resin particle accounts for 15 to 30% of the weight of a coating material, and the thickness of the color membrane is 8 to 15 mu m. Since the low density polyethylene resin particle is cheaper than the adhesive, the non-woven fabric color membrane provided by the invention has reduced production cost while the compounding quality of the non-woven fabric and the color membrane is ensured.

Owner:SUZHOU JIUDING

Novel composite aluminum membrane-air bubble film

InactiveCN102848619AGuaranteed composite qualityReduce manufacturing costLaminationLamination apparatusLow-density polyethyleneAdhesive

The invention discloses a novel composite aluminum membrane-air bubble film packaging material. The material is prepared by compounding an air bubble film and an aluminum membrane through tape casting of a coating layer which is obtained by mixing an adhesive and a low density polyethylene resin particle, wherein an upper layer is the aluminum membrane, a lower layer is the air bubble film, another layer of the aluminum membrane can be compounded below the air bubble film through tape casting of a coating material of the coating layer, the usage amount of the low density polyethylene resin particle accounts for 25 to 35% of the weight of the coating material, the thickness of the aluminum membrane is 8 to 25 mu m, and the diameter of an air bubble body of the air bubble film is 3 to 30 mm. Since the low density polyethylene resin particle is cheaper than the adhesive, the novel composite aluminum membrane-air bubble film packaging material provided by the invention has reduced production cost while the compounding quality of the air bubble film and the aluminum membrane is ensured.

Owner:SUZHOU JIUDING

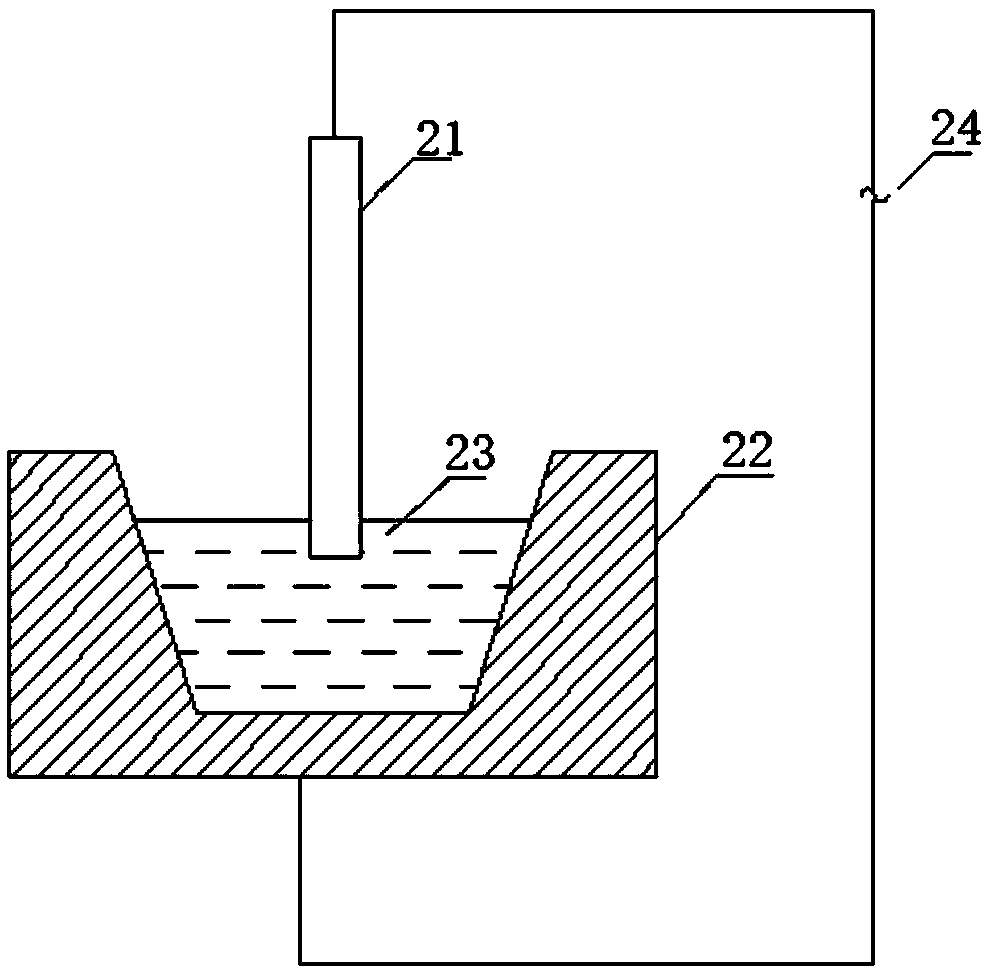

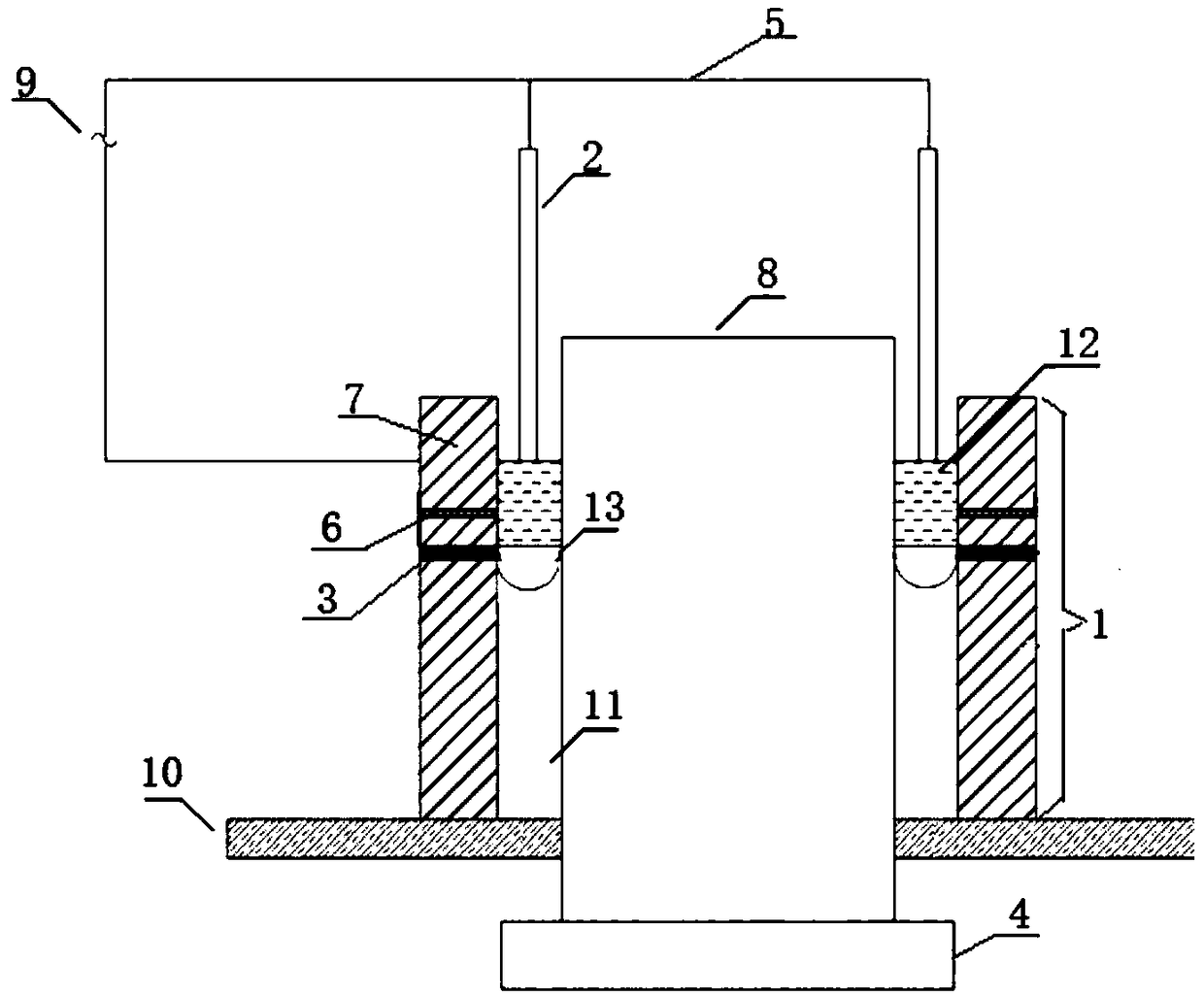

A kind of equipment and method for preparing composite steel ingot

The invention relates to equipment for preparing composite steel ingots, which includes: a conductive crystallizer with an upper opening and a lower opening with a cylindrical structure having a first diameter, a consumable electrode assembly including a plurality of consumable electrodes, and a plurality of consumable electrodes. The upper opening of the extremely self-conducting crystallizer extends into the cylindrical structure and is spaced a first distance from the inner circumferential surface of the cylindrical structure; and a first power source electrically connected to the conductive crystallizer and the consumable electrode assembly; wherein the first distance is less than half the first diameter. The invention also provides a method for preparing a composite steel ingot. The consumable electrode is inserted into the molten slag, and the power supply circuit of the conductive crystallizer is connected to realize the compounding of the core rod and the outer layer of molten steel; the consumable electrode is realized through a liquid level detector. The melting speed and the ingot extraction speed are well matched to ensure the stability of the steel ingot compounding process. The device and method of the present invention can realize the preparation of large steel ingots, ensure the stable and orderly operation of the multi-layer composite process, improve the problems of segregation, porosity and shrinkage of large-sized steel ingots, while improving production efficiency and ensuring composite quality.

Owner:NORTHEASTERN UNIV LIAONING

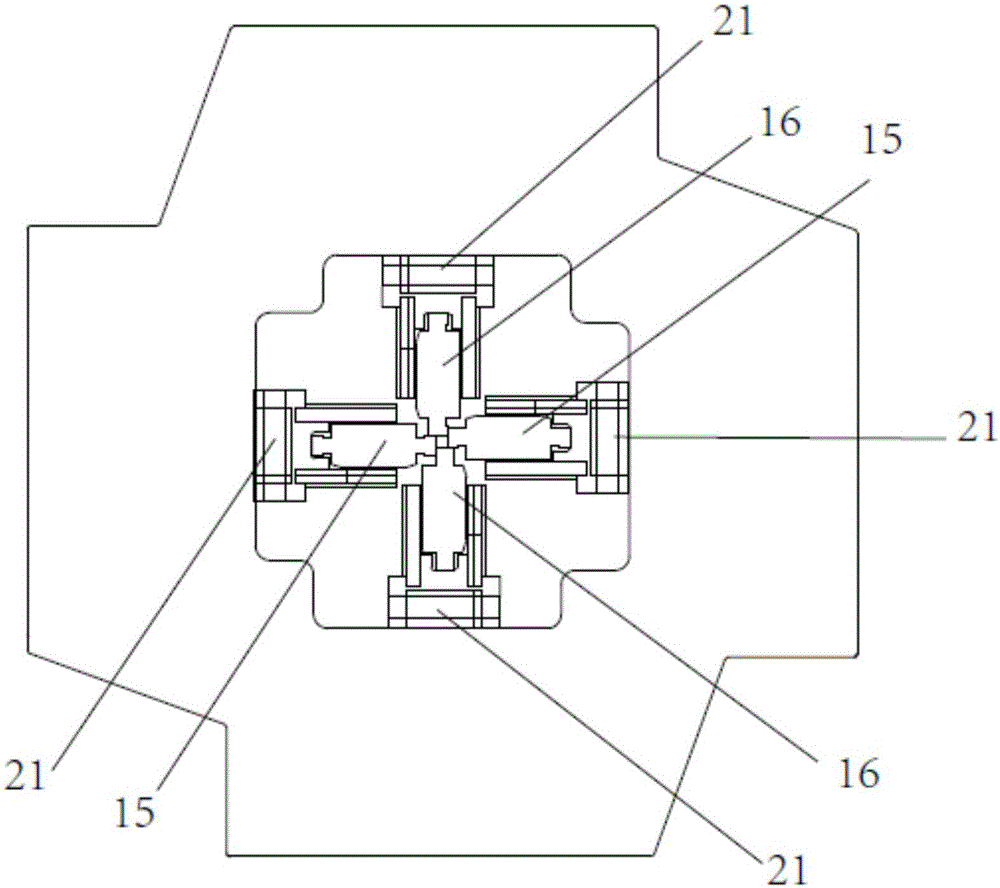

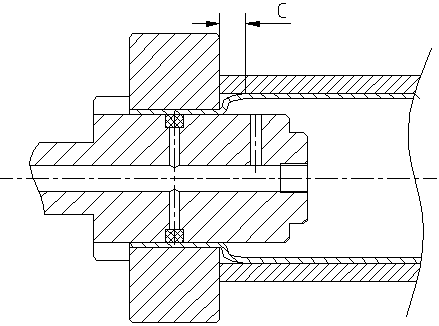

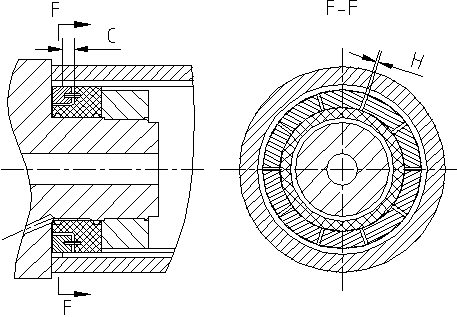

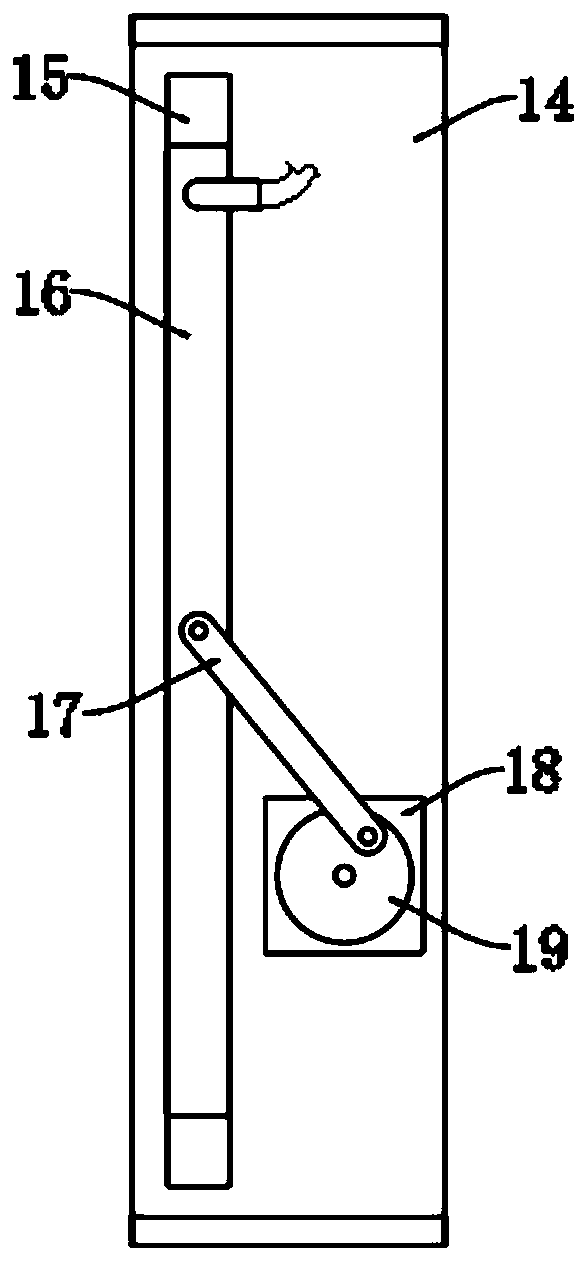

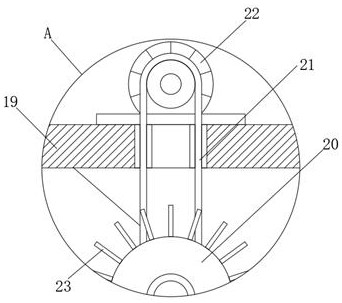

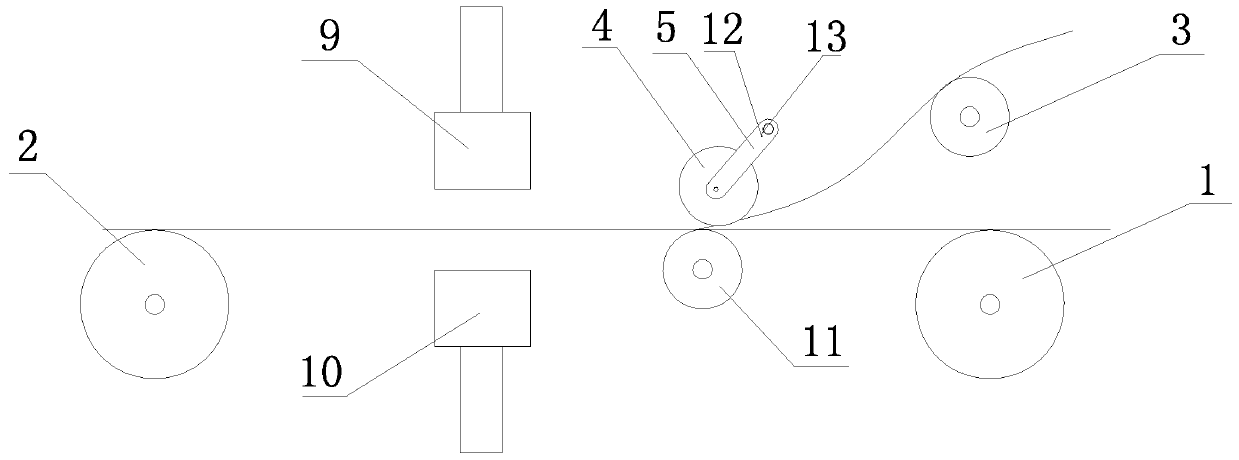

Spinning and clamping device of spinning composite machine

ActiveCN103317037BDoes not affect elastic deformationDoes not affect plastic deformationMetal-working feeding devicesPositioning devicesEngineeringCantilever

Owner:JIANGSU QING YANG PIPE +2

Composite production apparatus and method for aluminum foil glass fabric

ActiveCN113510993AConvenient composite pressingAct as glueLamination ancillary operationsLaminationAdhesive glueAluminum foil

The invention relates to the technical field of aluminum foil glass fabrics, and particularly discloses a composite production apparatus and method for an aluminum foil glass fabric. The apparatus comprises a fixing frame, a glue releasing roller assembly, a composite roller and a material collecting roller, wherein the fixing frame is composed of a base and a top plate fixedly connected to the base, an aluminum foil discharging roller and a supporting cylinder are arranged on the left side of the top face of the base, the composite roller is located in the middle of the top face of the base on the fixing frame, and the material collecting roller is located on the right side of the top face of the base. According to the composite production apparatus, the glue discharging roller assembly is arranged on the fixing frame and matched with the composite roller and the material collecting roller, so the effect of smearing glue on the surface of aluminum foil can be achieved; meanwhile, the effect of supplementing glue to the surface of a glue discharging roller at any time can be achieved through the arrangement of a glue dispensing pump; then through cooperation of the arrangement of the composite roller, the aluminum foil and the glass fabric can be conveniently compounded and pressed; and finally, the compounded aluminum foil glass fabric can be wound through the arrangement of the material receiving roller.

Owner:南京苏夏设计集团股份有限公司

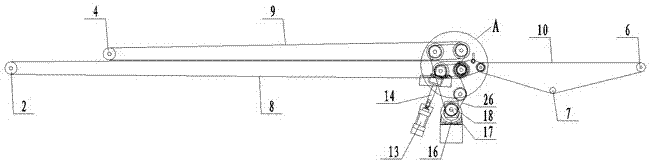

Panel compositing machine synchronous conveying mechanism

The invention discloses a panel compositing machine synchronous conveying mechanism. The panel compositing machine synchronous conveying mechanism comprises a lower feeding driving roller, a lower feeding driven roller arranged on one side of the lower feeding driving roller, an upper feeding driving roller arranged at the upper end of the lower feeding driving roller, an upper feeding driven roller arranged at the upper end of the lower feeding driven roller, a discharging driving roller arranged on the other side of the lower feeding driving roller, a discharging driven roller arranged on the other side of the lower feeding driving roller, and a discharging supporting roller arranged between the discharging driving roller and the discharging driven roller. The lower feeding driving roller and the lower feeding driven roller are connected through a lower conveying belt. The upper feeding driving roller and the upper feeding driven roller are connected through an upper conveying belt. The discharging driving roller, the discharging driven roller and the discharging supporting roller are connected through a discharging conveying belt. A downward pressing roller is arranged between the lower feeding driving roller and the lower feeding driven roller and connected with a piston rod of a jacking air cylinder through a connecting frame.

Owner:JIANGSU KUNTAI MACHINERY

Waterproof garment fabric laminating machine

InactiveCN106863983ANovel structureImprove composite effectLaminationLamination apparatusHeat conductingEngineering

The invention discloses a waterproof garment fabric laminating machine. The waterproof garment fabric laminating machine comprises a frame, a cloth distribution device arranged at the forefront end of the frame, a front pneumatic edge-aligning device arranged on the frame located at the rear end of the cloth distribution device, a front conveyor belt device arranged on the frame located at the rear end of the front pneumatic edge-aligning device, and a rear conveyor belt device arranged on the frame located at the rear end of the front conveyor belt device, wherein the front conveyor belt device and the rear conveyor belt device are in connection through a conveyor belt; the frame between the front conveyor belt device and the rear conveyor belt device is provided with a plurality of heat-conducting oil support preheating wheels matching with the conveyor belt; a rear pneumatic edge-aligning device is arranged on the frame located at the rear end of the rear conveyor belt device; a first driving synchronous scutching device is arranged on the frame located at the rear end of the rear pneumatic edge-aligning device; and the frame between the rear pneumatic edge-aligning device and the first driving synchronous scutching device is provided with a plurality of cloth guiding wheels.

Owner:JIANGSU HONGHUA SPECIAL EQUIP CO LTD

A kind of preparation method of carbon nanotube non-woven fabric

ActiveCN102704351BEnsure Structural IntegrityImprove wettabilityInorganic fibres/flakesSolvent moleculeResin matrix

The invention belongs to a preparation method of a carbon nano tube reinforcement material and relates to a carbon nano tube non-woven fabric without a surfactant and solvent residue and the preparation method of the carbon nano tube non-woven fabric. The preparation method comprises the steps: mixing a carbon nano tube and the surfactant in solvent according to a certain ratio to prepare a carbon nano tube dispersing agent; preparing the carbon nano tube non-woven fabric by adopting a vacuum or pressure-assisted solution deposition method; carrying out high-temperature anoxic treatment on the obtained carbon nano tube non-woven fabric; and removing the surfactant and the solvent left in a preparation process to obtain the carbon nano tube non-woven fabric without the surfactant and the solvent residue. According to the preparation method disclosed by the invention, the residual surfactant and solvent molecules in the preparation process of the carbon nano tube non-woven fabric are completely removed when the structure of the carbon nano tube is not damaged and the structural integrity of the carbon nano tube non-woven fabric is kept through high-temperature anoxic treatment, so that the infiltrating effect of a resin matrix on the carbon nano tube non-woven fabric and the interface binding ability of the carbon nano tube and the resin matrix are improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Fully automatic valve welding and bag making machine

The invention provides a fully automatic valve welding and bag making machine. The lengths of hot-press parts of an upper heating die 9 and a lower heating die 10 of the bag making machine are 1680 mm, a 800 mm long buggy bag can be machined at one time, multi-time delivering is not needed, and 22 finished products are produced every minute; a buckle locating mechanism is arranged on the bag making machine, a position of a buckle is located during conduction from buckle to a membrane material to prevent deviation of the buckle, the composite quality of the buckle and bag membrane is ensured, and then the quality of a product is promised; and the fully automatic valve welding and bag making machine includes a rack, a feeding device, a drafting device, a hole cutting and valve welding device, a buckle composite device, a horizontal sealing device and a cutting device, wherein the front side and the rear side of the buckle composite device are provided with a first material guiding rollerand a second material guiding roller, the buckle locating device and a third material guiding roller are arranged between the buckle composite device and the first material guiding roller, the bucklelocating device includes an upper pressing roller and a swing rod, a ring-type groove matched with the width of the buckle is arranged on the periphery of the upper pressing roller, and a torsion spring sleeves a rotating shaft.

Owner:嘉兴星创科技有限公司

Composite aluminum foil packing material of pearl wool

ActiveCN102849335BGuaranteed composite qualityReduce manufacturing costFlexible coversWrappersLow-density polyethyleneCompound a

The invention discloses a composite aluminum foil packing material of pearl wool. The composite aluminum foil packing material of pearl wool is prepared by curtain-coating and compounding a coating layer formed by pearl wool and an aluminum foil cast with a thickness of 15-40mum under temperatures 240 DEG C, 260 DEG C and 280 DEG C. An upper layer is the aluminum foil and a lower layer is the pearl wool. A coating material of the coating layer is a mixture of an adhesive and low-density polyethylene resin particles. The coating layer contains 30-45wt% of low-density polyethylene resin particles. The price of the low-density polyethylene resin particle is lower than that of the adhesive, so that the production cost of the composite aluminum foil packing material is reduced while the compound quality of the pearl wool and the aluminum foil is ensured.

Owner:厦门谱睿科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com