Preparation method of framework reinforcement compound hammerhead

A composite hammer and reinforcement technology, applied in grain processing and other directions, can solve the problems of easy softening and deformation of alloy powder core bars, destroying the order of arrangement, difficult control of alloy elements, etc., achieving good high temperature deformation resistance and convenient production method. Reliable and ensure the effect of filling reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

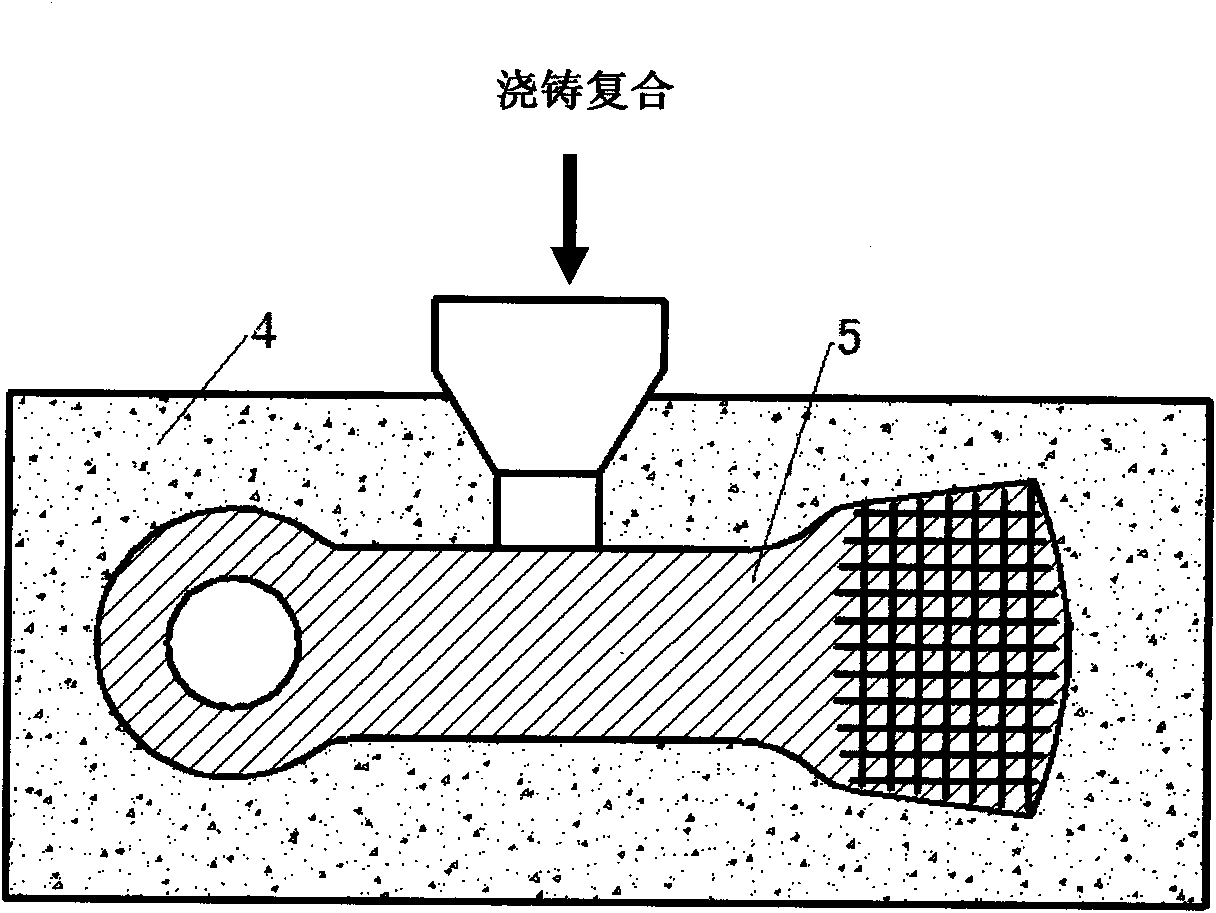

[0033] According to the preparation method of the framework reinforcement composite hammer head of the present invention, the prepared composite hammer head is composed of a skeleton reinforcement body containing a hard phase and a matrix metal, which specifically includes the following steps:

[0034] (1) Select the tube wire with hard material inside, cut, bend, weave, superimpose the tube wire, and make the skeleton prefabricated body according to the structure of the hammer head wear part;

[0035] (2) Use refractory materials to fill the voids in the skeleton prefabricated body, and cover and compact it into a block, dry it, and form a block with a certain strength;

[0036] (3) Put the block into a vacuum metallurgical sintering furnace for smelting and sintering. At high temperature, the outer steel skin of the tube wire and the hard material inside are melted and dissolved to form a sufficient metallurgical structure. Under the positioning of the refractory material, L...

Embodiment 1

[0048] Example 1: Preparation of high chromium alloy skeleton reinforcement and high manganese steel composite hammer head

[0049] see Figure 1~3 , the preparation method of the present embodiment is carried out according to the following steps:

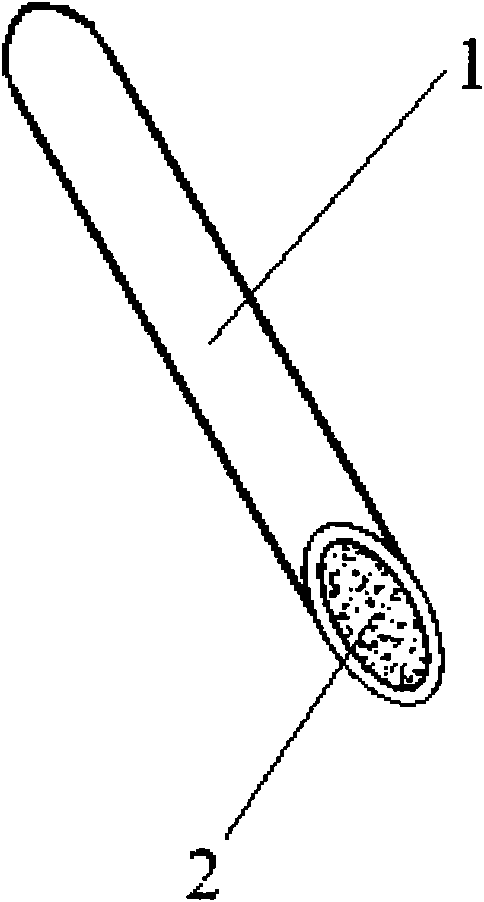

[0050] A. Select the pipe wire 1 with a diameter of φ3.2mm, the outer steel skin is low-carbon steel, and the prepared high-carbon ferrochrome powder 2 is installed inside, the particle size is 0.15-0.2mm, and the filling rate is 45%. According to the structure of the hammer head wear part, the Tube wire 1 is cut, bent, braided, and stacked to form a skeleton prefabricated body;

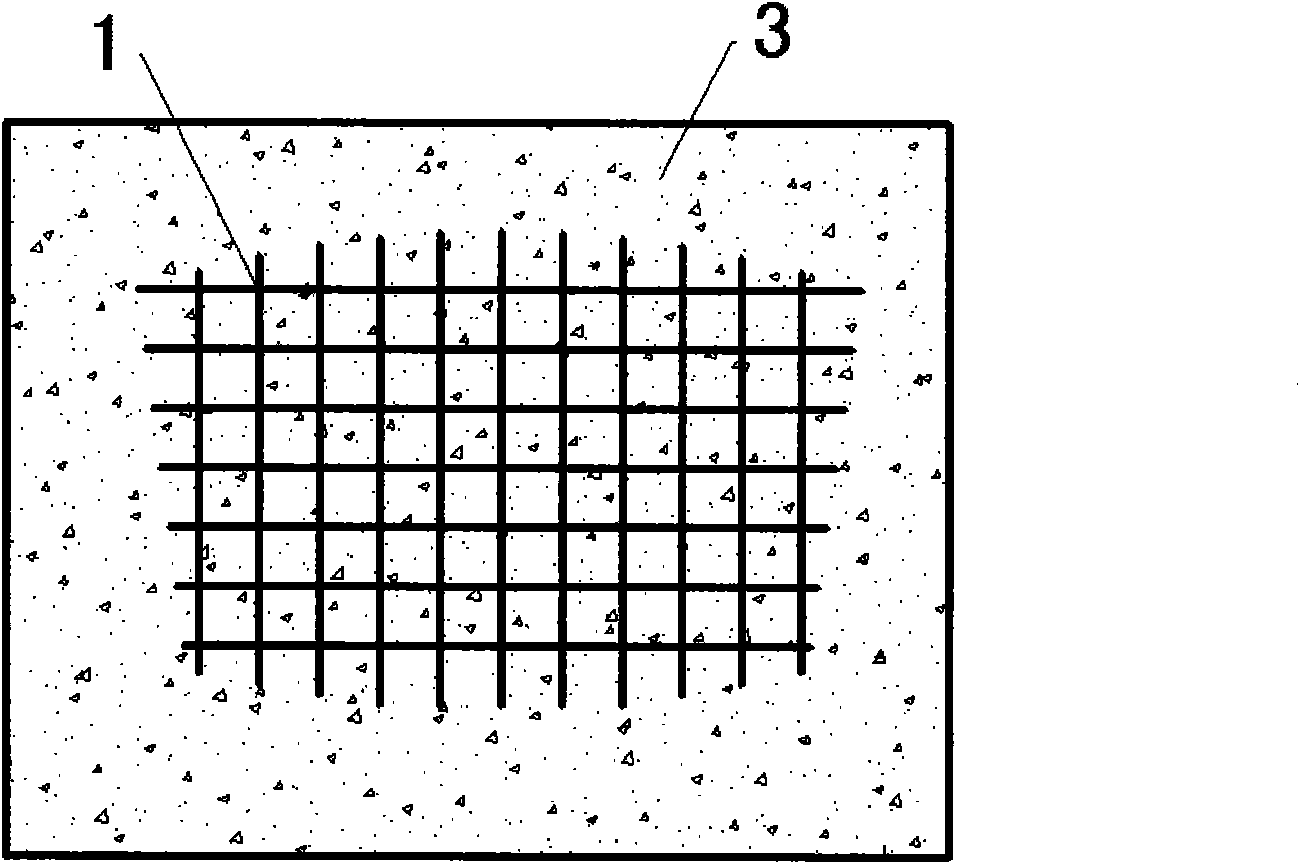

[0051] B. Choose sodium silicate sand as the refractory material 3, fill it into the voids of the skeleton prefabricated body, cover and compact it into a block, and form a block with a certain strength after drying;

[0052] C. Put the block into a vacuum metallurgical sintering furnace for high-temperature smelting and sintering. The outer steel skin ...

Embodiment 2

[0058] Embodiment 2: make the composite hammer head of tungsten carbide cemented carbide and 35 steel

[0059] see Figure 1~3 , the preparation method of the present embodiment is carried out according to the following steps:

[0060] A. Select the tube wire 1 with a diameter of φ5.0mm, the outer steel skin is low-carbon steel, and the prepared tungsten carbide particles 2 are installed inside, the particle size is 0.5-1 mm, and the filling rate is 35%. According to the structure of the hammer head wear part, the tube wire 1 Cutting, bending, weaving, superposition to make skeleton prefabricated body;

[0061] B. Select resin sand as the refractory material 3, fill it into the void of the skeleton prefabricated body, cover and compact it into a block, and form a block with a certain strength after drying;

[0062] C. Put the block into a vacuum metallurgical sintering furnace for high-temperature smelting and sintering. The outer steel skin of the tube wire 1 and the tungst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com