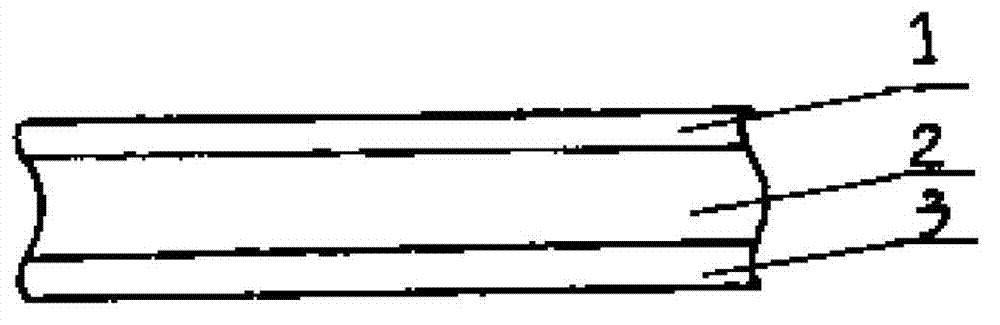

Composite embossed non-woven fabric

A non-woven, low-pressure film technology, applied in the field of non-woven composite materials and composite embossed non-woven fabrics, can solve the problems of high cost of composite embossed non-woven fabrics and high prices of adhesives, reduce production costs, and improve adhesion. The effect of knot strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] First, the upper low-pressure film and the middle layer of pearl cotton are directly hot-pressed by the ginning machine at a hot-pressing temperature of 110°C and a roller speed of 800RPM. The coating layer is formed by mixing 80wt% adhesive and 20wt% low-density polyethylene resin particles. The lower layer of non-woven fabric and low-pressure film formed by hot pressing and pearl cotton are cast and composited at 240°C, and the thickness of the aluminum film is 8 microns.

Embodiment 2

[0018] First, the upper low-pressure film and the middle layer of pearl cotton are directly hot-pressed by a ginning machine at a hot-pressing temperature of 110°C and a roller speed of 1200RPM, and are mixed with 60wt% adhesive and 40wt% low-density polyethylene resin particles as the coating layer. The lower non-woven fabric and the low-pressure film formed by hot pressing and pearl cotton are cast and compounded at 280°C, and the thickness of the aluminum film is 25 microns.

Embodiment 3

[0020] First, the upper low-pressure film and the middle layer of pearl cotton are directly hot-pressed by the ginning machine at a hot-pressing temperature of 110°C and a roller speed of 1000RPM. The coating layer is formed by mixing 70wt% adhesive and 30wt% low-density polyethylene resin particles. The lower layer of non-woven fabric and hot-pressed low-pressure film and pearl cotton are cast and composited at 260 ° C, and the thickness of the aluminum film is 15 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com