Fully automatic valve welding and bag making machine

A fully automatic, bag-making machine technology, applied in the field of bag-making equipment, can solve the problems of deviation, no effective positioning, and the quality of the composite buckle and bag film cannot be effectively guaranteed, so as to prevent deviation, Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below:

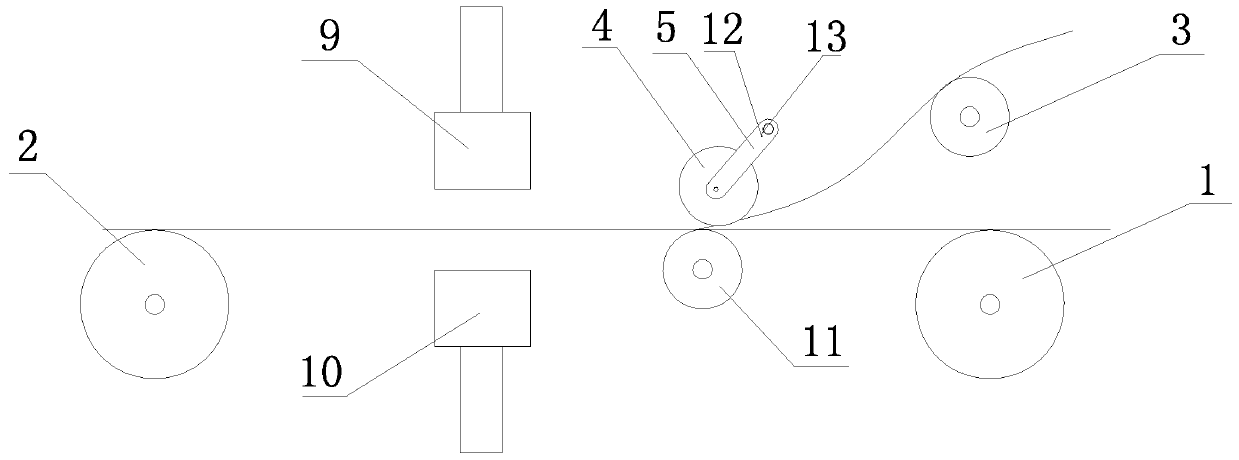

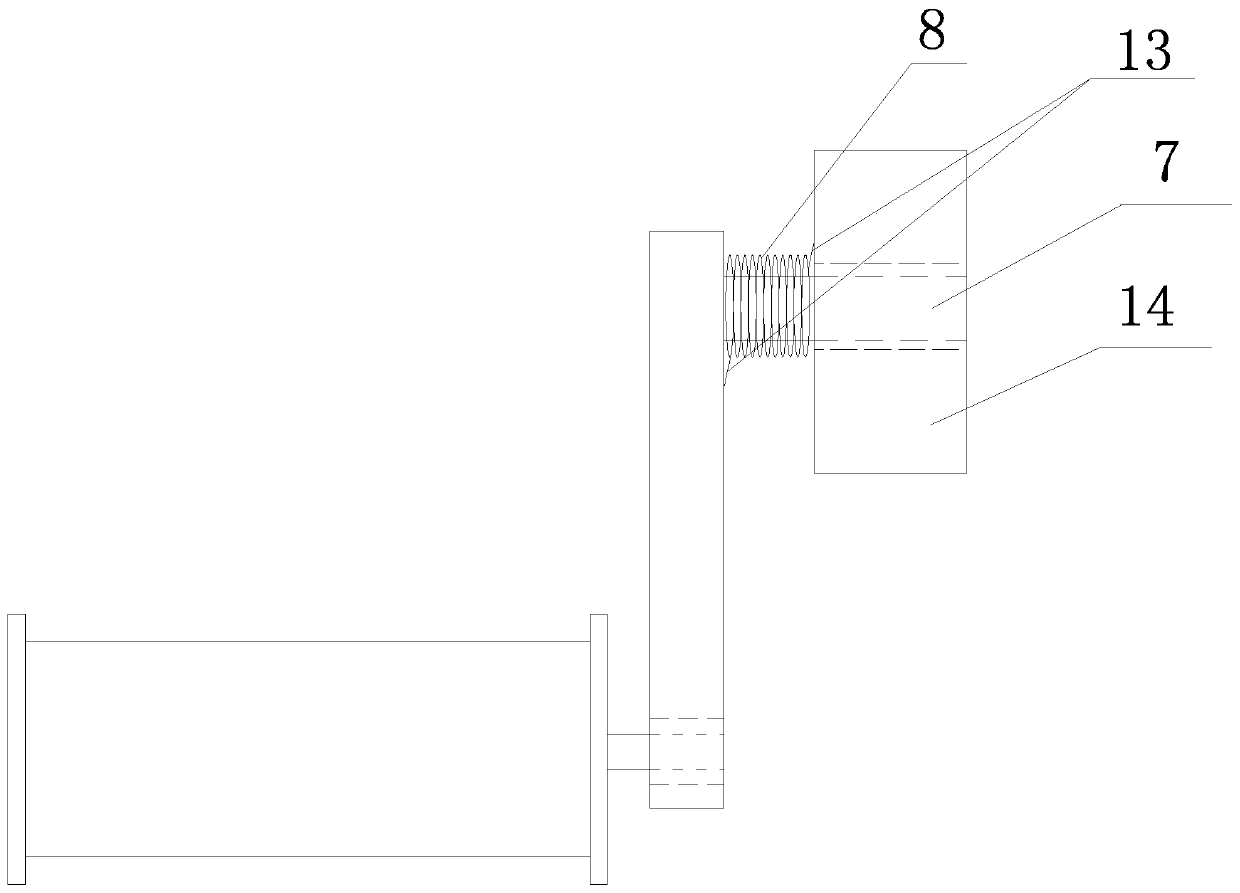

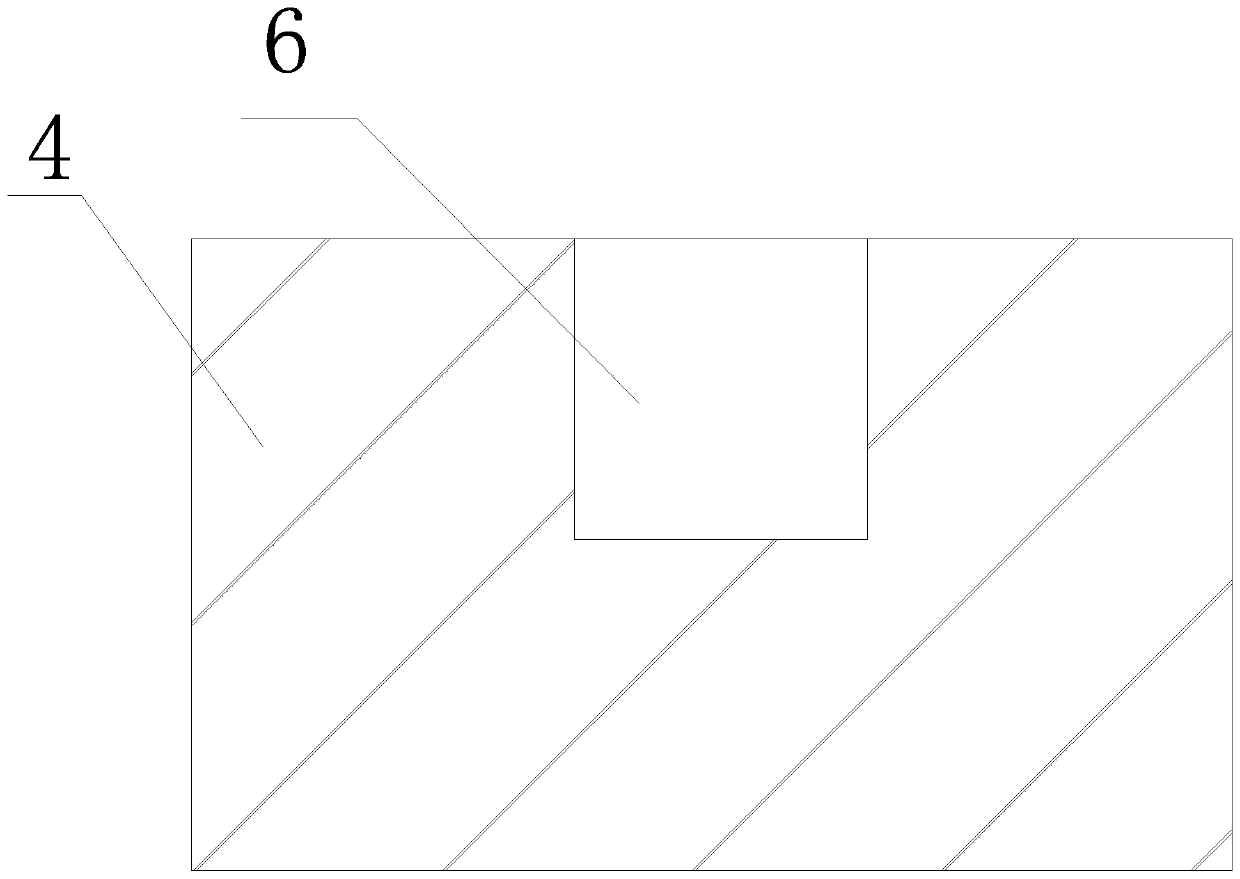

[0019] A fully automatic welding valve bag making machine, including a frame 14 and a feeding device, a traction device, a hole-cutting and welding valve device, a buckle compound device, and a horizontal sealing device that are sequentially arranged on the frame 14 along the film material conveying direction and a cutting device, the front and rear sides of the bar compounding device are respectively provided with a first guide roller 1 and a second guide roller 2 for conducting film material, and the first guide roller 1 and the second guide roller 2 are in the On the same horizontal plane and arranged in parallel, a strip positioning mechanism and a third guide roller 3 arranged on the front side of the strip positioning device are arranged between the strip compound device and the first guide roller 1, and the strip positioning The mechanism includes an upper pressing roller 4 and a swing lever 5, the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com