Preparation method of reinforced composite wear-resistant lining board of precast framework

A technology of composite wear-resistant lining plates and reinforcements, applied in heat exchange equipment, rotors, cylinders, etc., can solve the problems of easy generation of pores, slag inclusion, easy peeling and cracking of wear-resistant layers, and easy falling off of hard phases. Good resistance to high temperature deformation, convenient and reliable production process, and the effect of ensuring the reliability of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of high chromium alloy skeleton reinforcement and high manganese steel composite wear-resistant lining

[0035] see Figure 1~3 , the preparation method of the present embodiment is carried out according to the following steps:

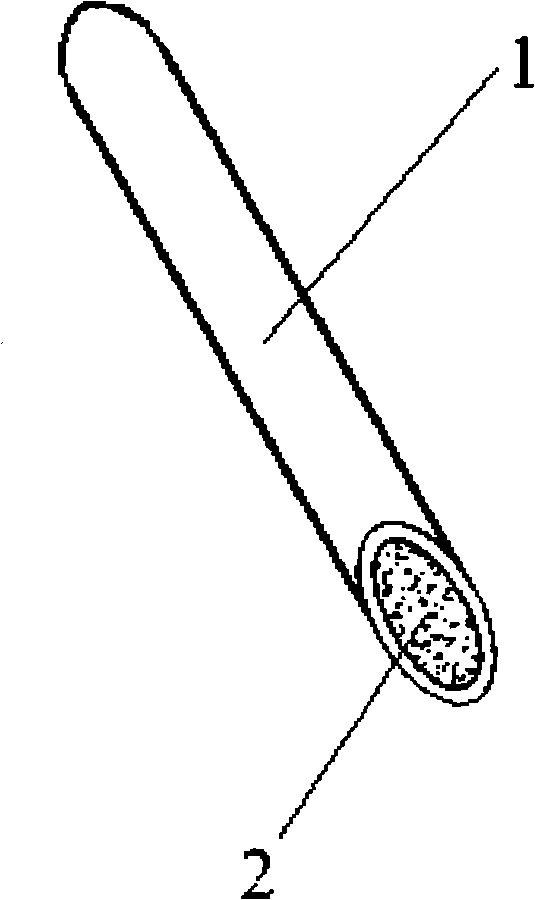

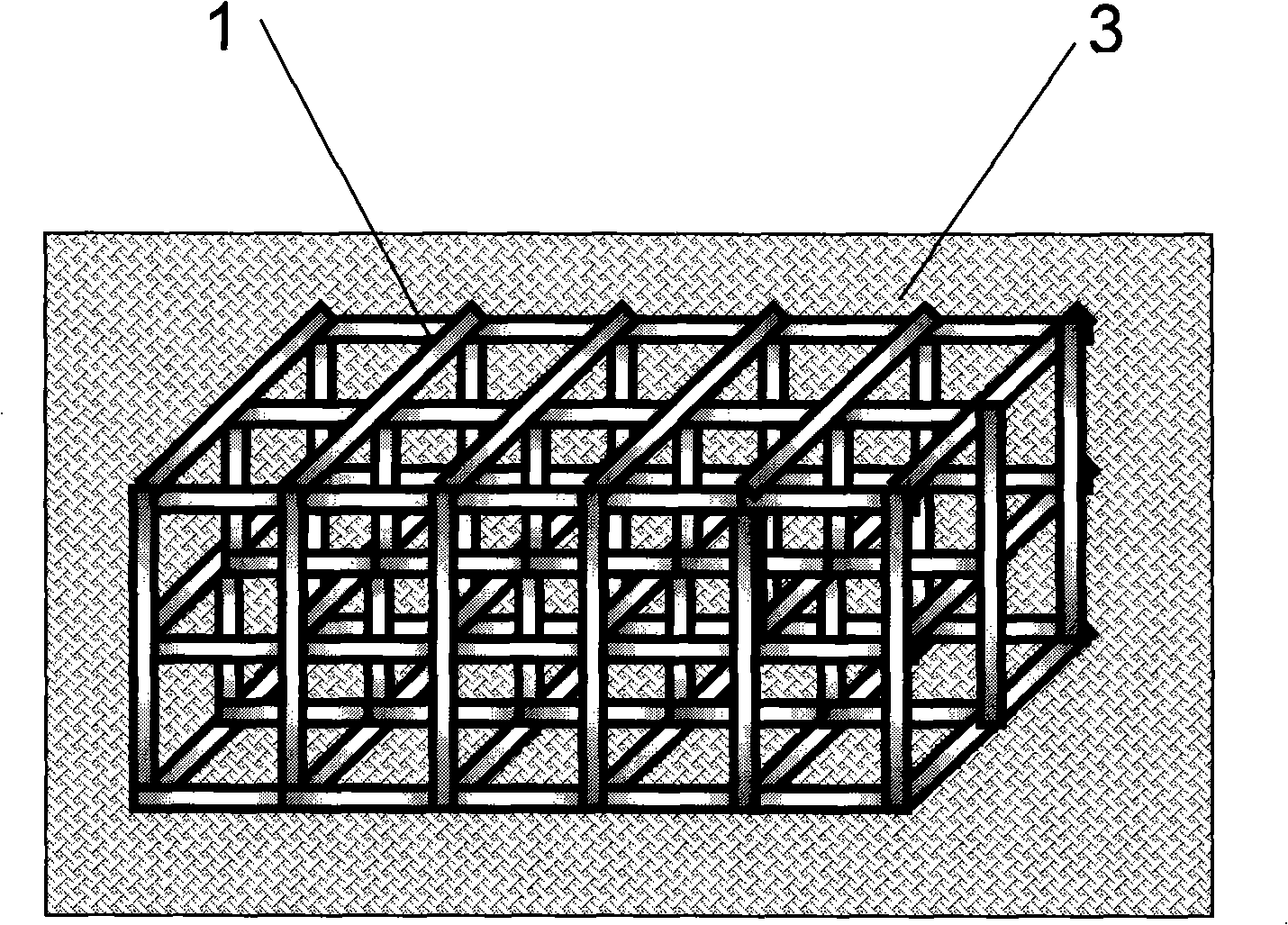

[0036] A. Select the pipe wire 1 with a diameter of φ2.8mm, the outer steel skin is low-carbon steel, and the prepared high-carbon ferrochrome powder 2 is installed inside, the particle size is 0.15-0.2mm, and the filling rate is 50%. According to the structure of the lining plate, the pipe wire 1 Cutting, bending, weaving, superposition to make skeleton prefabricated body;

[0037] B. Choose sodium silicate sand as the refractory material 3, fill it into the voids of the skeleton prefabricated body, cover and compact it into a block, and form a block with a certain strength after drying;

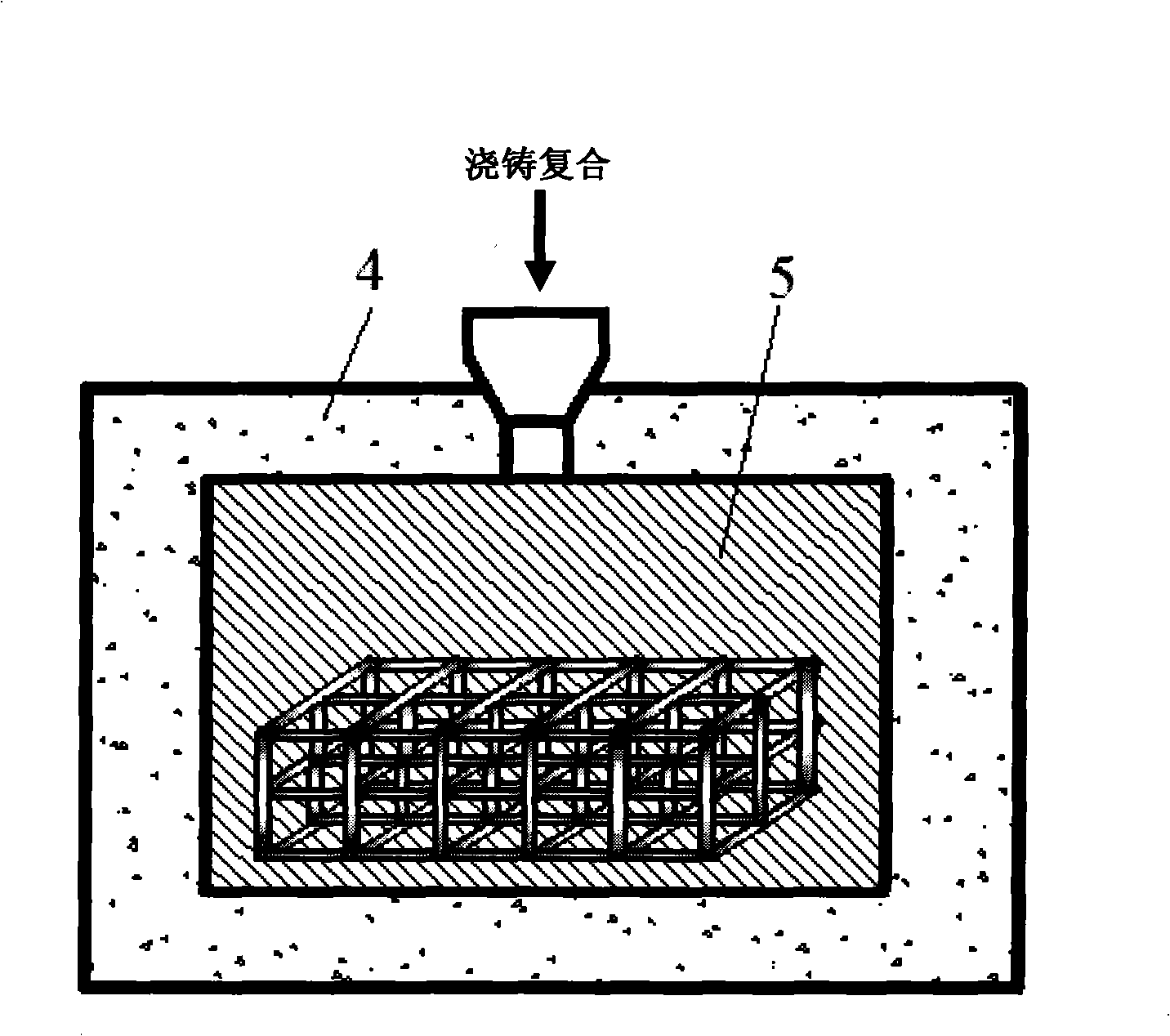

[0038] C. Put the block into a vacuum metallurgical sintering furnace for high-temperature smelting and sintering. The outer steel ...

Embodiment 2

[0044] Embodiment 2: Making a composite wear-resistant lining plate of tungsten carbide cemented carbide and 35 steel

[0045] see Figure 1~3 , the preparation method of the present embodiment is carried out according to the following steps:

[0046] A. Select the pipe wire 1 with a diameter of φ4.0mm, the outer steel skin is low-carbon steel, and the prepared tungsten carbide particles 2 are installed inside, the particle size is 0.5-1 mm, and the filling rate is 30%. According to the structure of the lining plate, the pipe wire 1 is cut , bending, weaving, and superposition to make a skeleton prefabricated body;

[0047] B. Select resin sand as the refractory material 3, fill it into the void of the skeleton prefabricated body, cover and compact it into a block, and form a block with a certain strength after drying;

[0048] C. Put the block into a vacuum metallurgical sintering furnace for high-temperature smelting and sintering. The outer steel skin of the tube wire 1 a...

Embodiment 3

[0054] Embodiment 3: Making a composite wear-resistant lining plate of silicon carbide ceramics and ductile iron.

[0055] see Figure 1~3 , the preparation method of the present embodiment is carried out according to the following steps:

[0056] A. Select the pipe wire 1 with a diameter of φ5.0mm, the outer steel skin is low-carbon steel, and the prepared silicon carbide ceramic particles 2 are installed inside, the particle size is 1-2mm, and the filling rate is 20%. According to the structure of the lining plate, cut the pipe wire 1 Cutting, bending, weaving, superposition to make skeleton prefabricated body;

[0057] B. Choose water glass sand and graphite powder to mix as refractory material 3, the mass ratio of water glass sand and graphite powder is 2:1, fill it into the gap of the skeleton prefabricated body, and cover and compact it into a block shape, After drying, it forms a block with a certain strength;

[0058] C. Put the block into a vacuum metallurgical sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com