Novel tape-cast composite non-woven fabric color membrane

A technology of casting composite and non-woven fabrics, which is applied in the field of packaging materials and can solve the problems of high cost and high price of non-woven fabric color films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

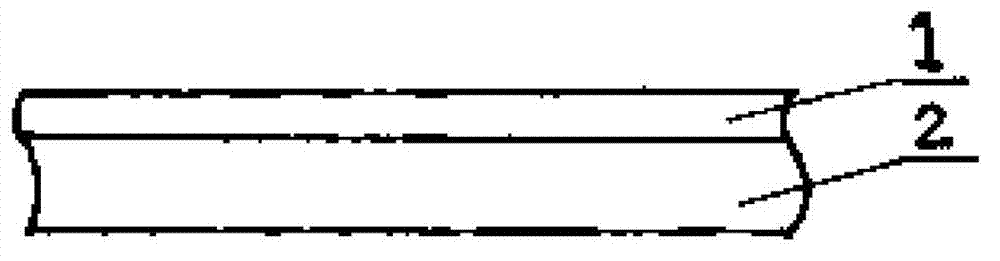

Image

Examples

Embodiment 1

[0014] The coating layer is made by mixing 85wt% adhesive and 15wt% low-density polyethylene resin particles. The non-woven fabric and the color film are composited by casting at 240°C, and the thickness of the color film is 8 microns.

Embodiment 2

[0016] 80wt% adhesive and 20wt% low-density polyethylene resin particles are mixed as the coating layer, and the non-woven fabric and the color film are cast and compounded at 260°C, and the thickness of the color film is 15 microns.

Embodiment 3

[0018] The coating layer is made by mixing 70wt% adhesive and 30wt% low-density polyethylene resin particles. The non-woven fabric and the color film are composited by casting at 280°C, and the thickness of the color film is 10 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com