Novel compound aluminum foil air bubble film

A composite aluminum foil and air bubble film technology, which is applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of high price of adhesives and high cost of composite aluminum foil bubble film packaging materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

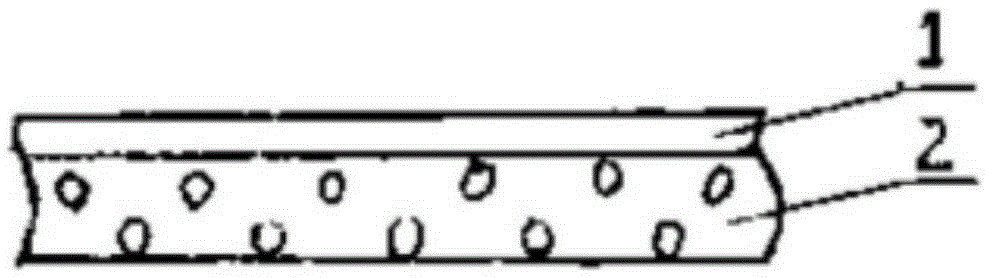

[0010] Refer to attached figure 1 , a new type of composite aluminum foil air bubble film packaging material, which is composed of an upper layer of aluminum foil (1) and a lower layer of air bubble film (2) through coating material casting, and the coating material is a combination of adhesive and low density polyethylene resin particles mixture; the lower layer of the air bubble film (2) is flow-cast and compounded with one layer of aluminum foil (3) through the coating material; the amount of low-density polyethylene resin particles in the coating material is 60wt%; the The thickness of the aluminum foil is 50 microns; the diameter of the bubble body of the bubble film is 2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com