Discontinuous flexible material fetching device and gluing and compounding equipment

A flexible material and reclaiming device technology, applied in lamination devices, lamination auxiliary operations, lamination and other directions, can solve the problems of poor material bubble quality, poor product consistency, low production efficiency, etc., to increase the composite force, prevent The effect of air bubbles and cushioning compound force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

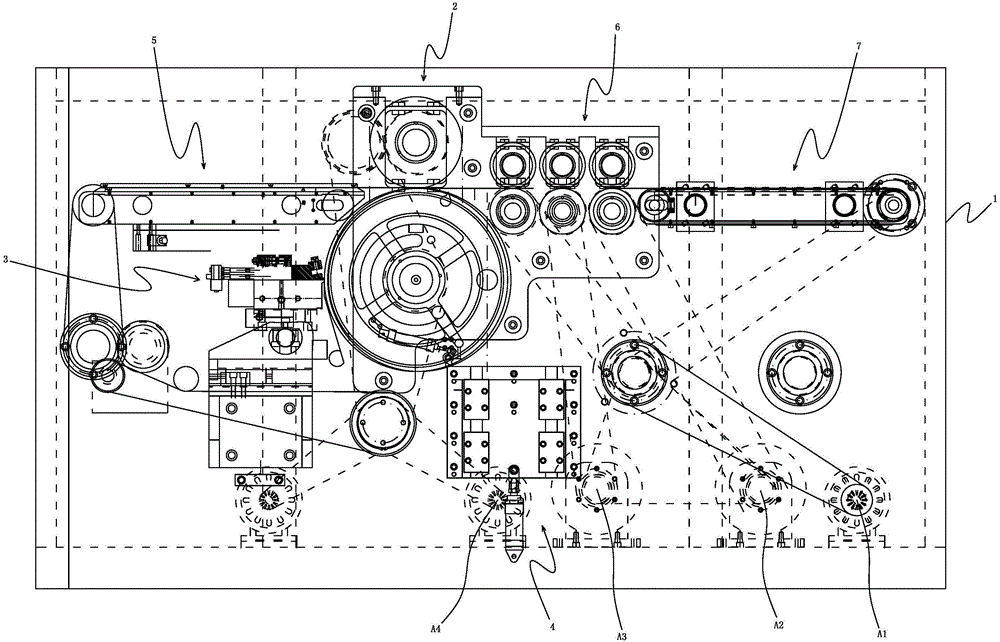

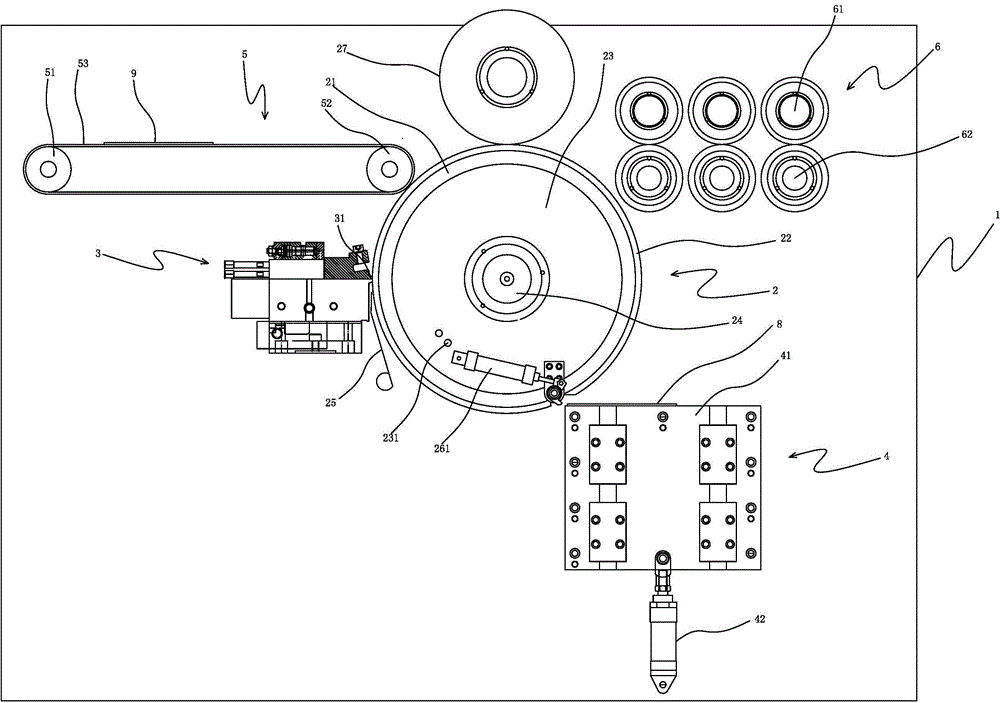

[0031] refer to Figure 1 to Figure 9 As shown, a gluing and compounding equipment for discontinuous flexible materials is used for compounding plate-like materials 9 and flexible materials 8, including a frame 1, a feeding device 4, a reclaiming device, a gluing device 3, an upper Pressure roller 27, conveying mechanism 5 and auxiliary composite mechanism 6.

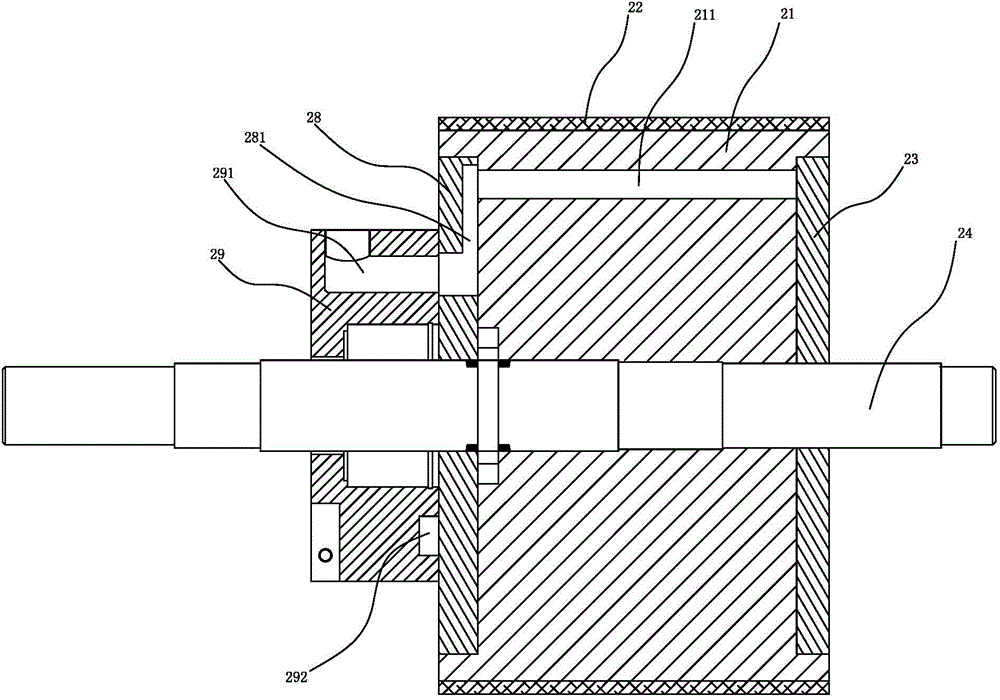

[0032] The frame 1 is a wallboard type frame, and the feeding device 4 is used to provide flexible materials 8 to the take-up roller 2 of the take-off device, including a lifting table 41 that can directly move up and down at the feeding position and the standby position and a connecting drive upgrade platform 41 The cylinder 42 that moves up and down, the top surface of the lifting table 41 is used to place the flexible material 8, when the take-up roller 2 of the reclaiming device rotates to the feeding position, the lifting table 41 rises to make the edge of the flexible material 8 and the groove of the adsorption gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com