Roller adjustment device, adjustment method and application thereof, and bending machine

An adjustment device and roller technology, which is applied in the field of bending machines, can solve the problems of lower bending accuracy and lower service life of oil cylinders, and achieve the effects of improving yield, extending service life and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

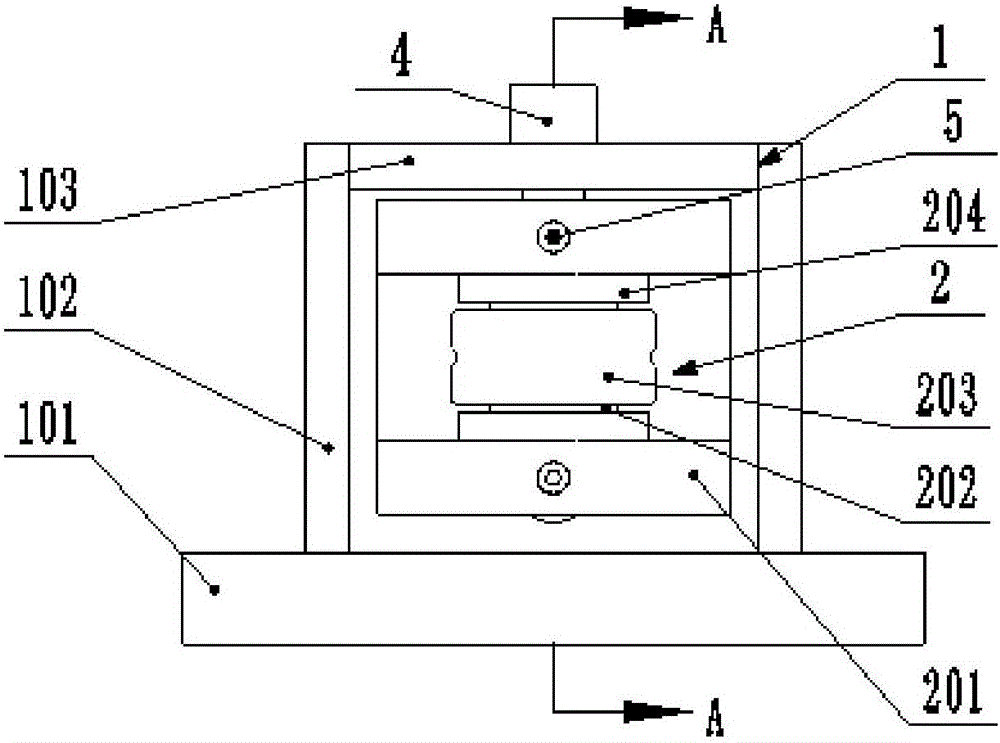

[0049] Such as Figure 6 and Figure 7 As shown, a bending machine of this embodiment has a bending force greater than 300t, and it includes a frame, a slider 7 and an oil cylinder 8 . Wherein, there are two oil cylinders 8, which are symmetrically installed on the left and right sides of the frame, and the two oil cylinders 8 are respectively connected to the left and right ends of the slider 7 to drive the slider 7 to move up and down. A roller adjustment device is installed on each of the oil cylinders 8 , and the roller adjustment device is in contact with the front surface of the slide block 7 .

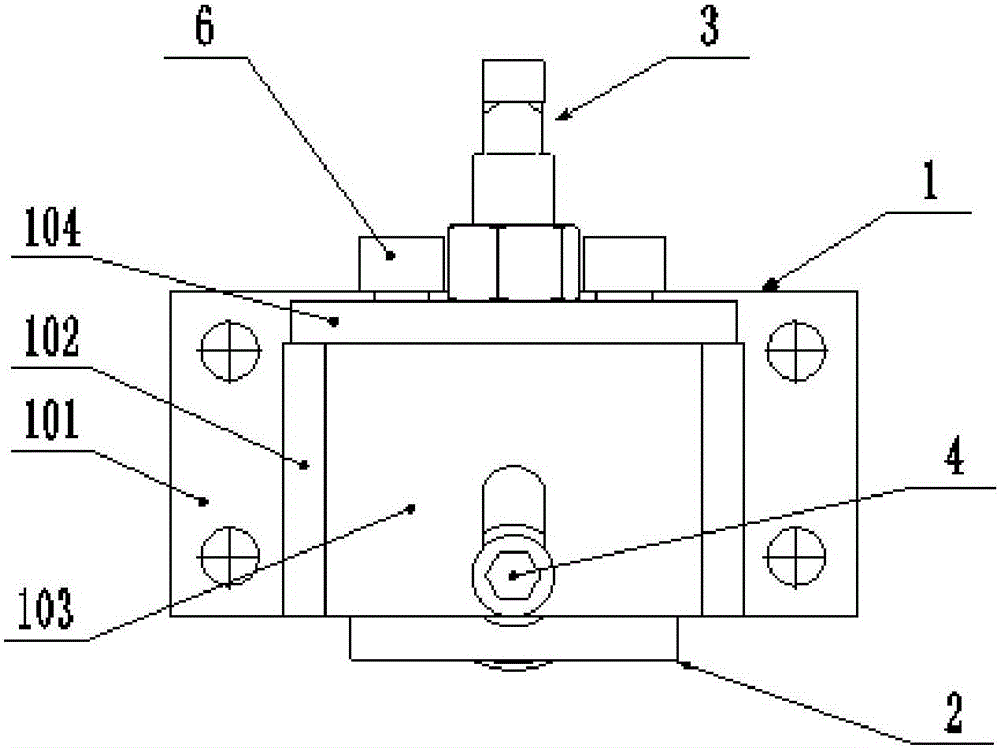

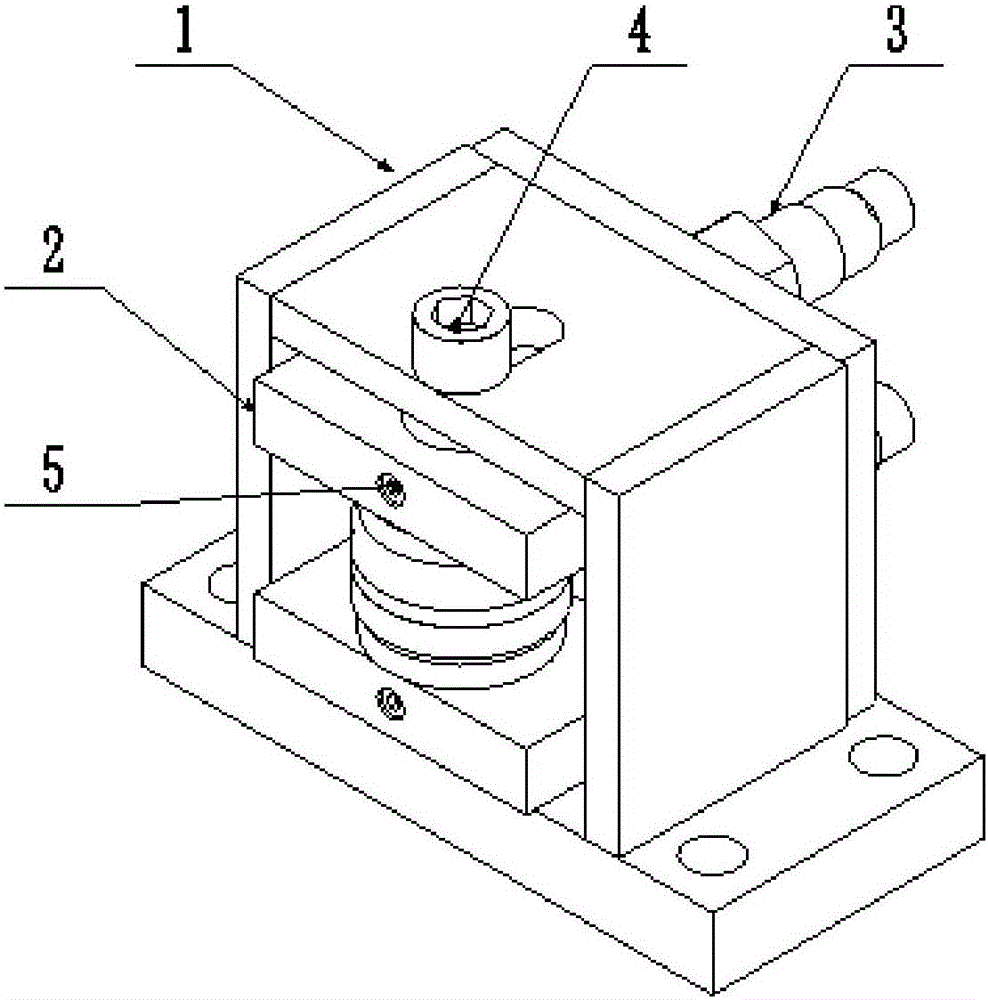

[0050] Specifically in this embodiment, such as Figure 1-5 As shown in , the roller adjustment device includes a mounting base 1 , a roller assembly 2 , an adjustment assembly 3 , an axial screw 4 , a radial screw 5 and a locking screw 6 . The mounting seat 1 is a cavity structure with an open front end and closed other surfaces, and is welded by a bottom plate 101, two side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com