Patents

Literature

38results about How to "Act as glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special organic fertilizer for watermelons and preparation method of special organic fertilizer

The invention discloses a special organic fertilizer for watermelons and a preparation method of the special organic fertilizer, and belongs to the technical field of fertilizers. The special organic fertilizer is prepared from the following raw materials in parts by weight: 30-40 parts of chicken manure, 20-35 parts of decomposed plant straw, 10-15 parts of wheat bran, 10-15 parts of peanut oil residue, 5-10 parts of oil sludge, 5-10 parts of humic acid, 2-5 parts of urea, 10-20 parts of trace elements, 5-10 parts of a complex microbial agent and 5-10 parts a functional microbial agent. The special organic fertilizer can provide abundant nutritive elements for the watermelons according to the growth characteristics of watermelons in various periods, and the special organic fertilizer can increase the yield, improve the quality and character and promote the good growth of watermelons. By using the special organic fertilizer, the use amount of unreasonable fertilizers can be reduced.

Owner:DANGSHAN CHUNYUAN FERTILIZER CO LTD

Special biological organic fertilizer for cucumbers and preparation method of the special biological organic fertilizer

InactiveCN106747933ASmooth releaseAbundant supplyBiocideBio-organic fraction processingPlant diseaseNutrient

The invention discloses special biological organic fertilizer for cucumbers and a preparation method of the special biological organic fertilizer, which belong to the technical field of organic fertilizers. The fertilizer is prepared from cattle and sheep excrement, corn straws, peanut seedlings, hazelnut meal, humic acid, brown sugar, EM fungicide, rhizoma coptidis, honeysuckle flower, Houttuynia cordata, radix isatidis, urea, trace elements, attapulgite, sepiolite powder, soil conditioner and a composite microorganism agent according to a given weight proportion. The fertilizer has rich nutrients, satisfies the nutrient demand for the growth of the cucumbers at different periods, can effectively improve the physical and chemical properties of the soil, can improve the water and fertility retention capacity of the soil, can prevent various physical and chemical diseases of plants, and can effectively improve and the yield and quality of the cucumbers.

Owner:LINYI ACADEMY OF AGRI SCI

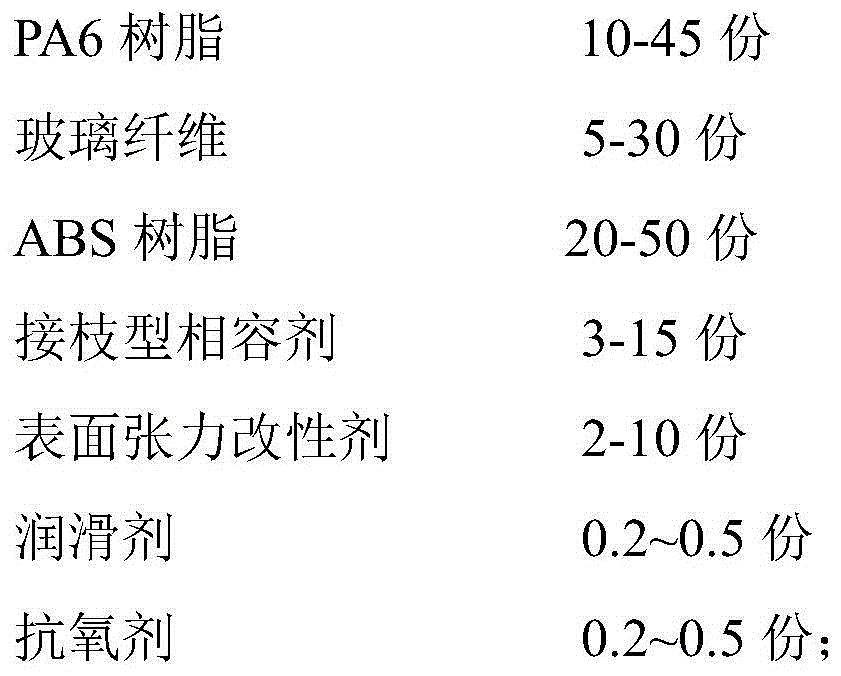

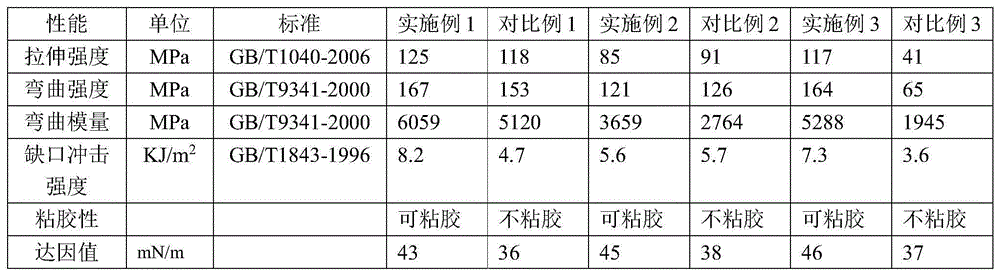

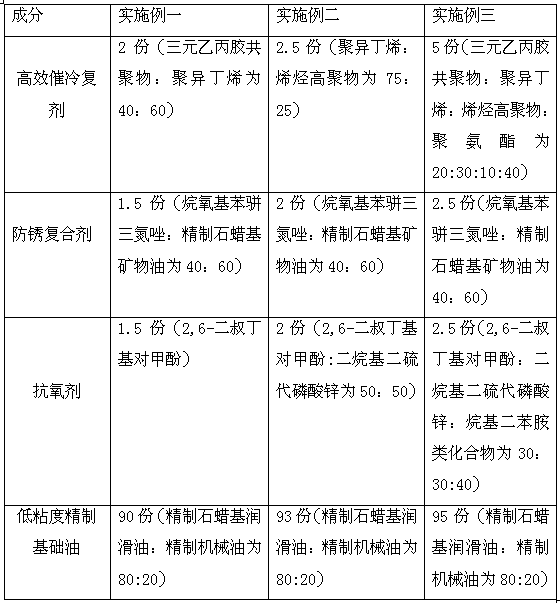

Adhesive high-surface-tension glass-fiber-reinforced PA6/ABS (polyamide 6/acrylonitrile-butadiene-styrene) composite material and preparation method thereof

The invention relates to an adhesive high-surface-tension glass-fiber-reinforced PA6 / ABS (polyamide 6 / acrylonitrile-butadiene-styrene) composite material which comprises the following components in parts by weight: 10-45 parts of PA6 resin, 5-30 parts of glass fiber, 20-50 parts of ABS resin, 3-15 parts of graft compatilizer, 2-10 parts of surface tension modifier, 0.2-0.5 part of lubricant and 0.2-0.5 part of antioxidant. The preparation method comprises the following steps: weighing all the components according to parts by weight except the glass fiber, mixing in a high-efficiency mixing machine, putting into a main feed port of a double screw extruder, adding the glass fiber into the double screw extruder via a glass fiber port, extruding, passing through a cooling water tank, and granulating with a granulator. Compared with the prior art, the adhesive high-surface-tension glass-fiber-reinforced PA6 / ABS composite material has the characteristics of high surface tension, favorable adhesiveness, stable dimension, excellent chemical resistance and the like, and is suitable for the fields of adhesive automobiles, sports equipment, electronic and electric appliances and the like with certain mechanical properties and excellent impact properties.

Owner:FINE BLEND COMPATILIZER JIANGSU CO LTD

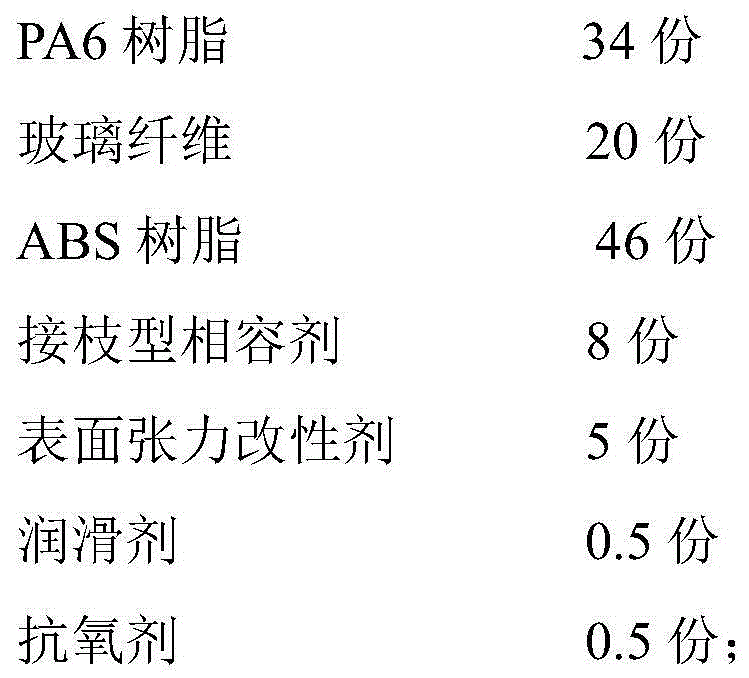

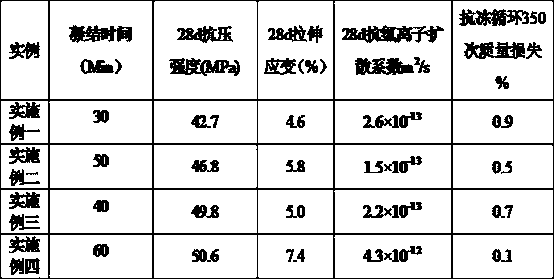

Ultrahigh-ductility cement-based material for repairing and reinforcing

The invention relates to the technical field of building materials, and discloses an ultrahigh-ductility cement-based material for repairing and reinforcing. The material is composed of the followingcomponents in parts by mass: 300-600 parts of cementing material; 700-1400 parts of aggregate; 100-300 parts of water; 2 -10 parts of nano particles; 1-10 parts of microcapsules; 1-20 parts of PVA and / or PE fiber; 10-30 parts of titanium dioxide slag; 30-60 parts of auxiliary agent solutions; 10-50 parts of emulsion; and 10- 50 parts of light-burned ferronickel slag, wherein the capsule core material of the microcapsule is a mixture of starch glue, silica sol, a silane coupling agent and water, and the mass ratio is (10-40): (10-40): (5-15): (10-50). The ultrahigh-ductility cement-based material for repairing and reinforcing is controllable in setting time, high in ductility and high in durability and the problems that the common repairing and reinforcing cement-based material is poor in ductility and uncontrollable in setting time are solved.

Owner:南京绿色增材智造研究院有限公司

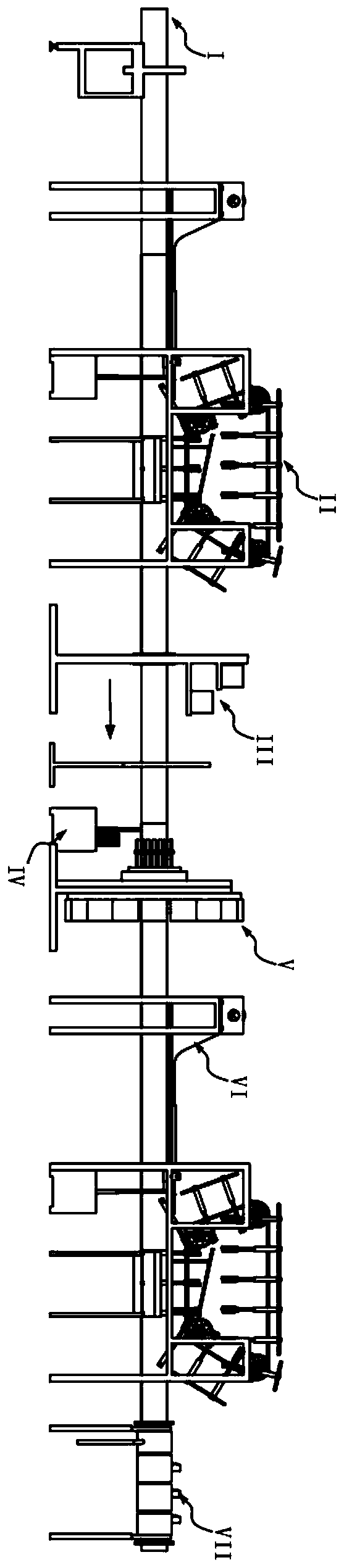

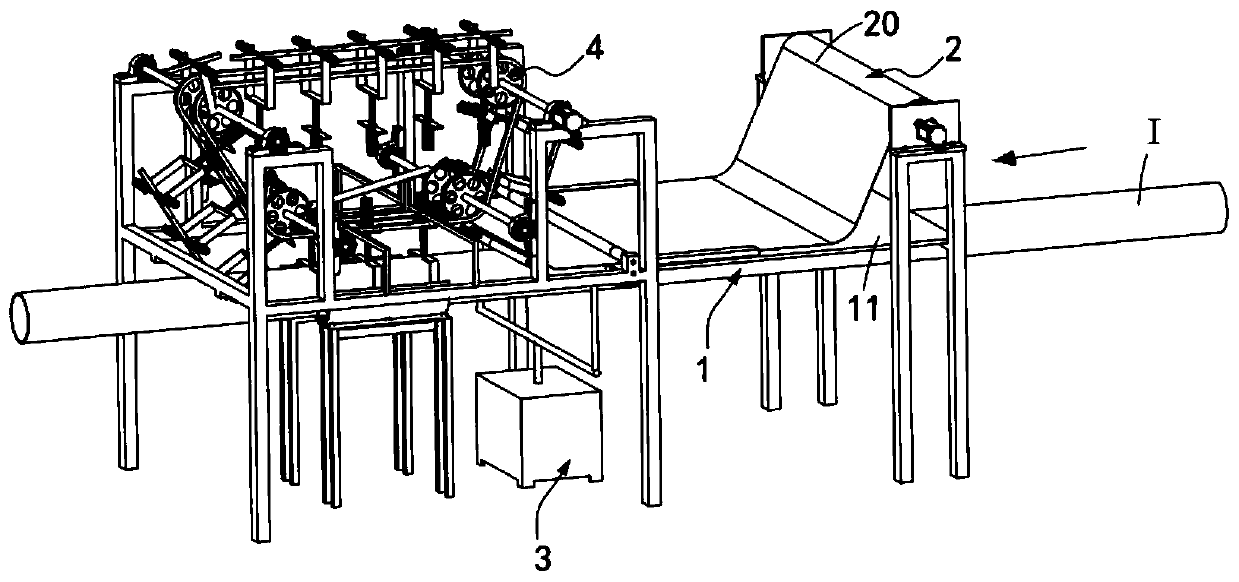

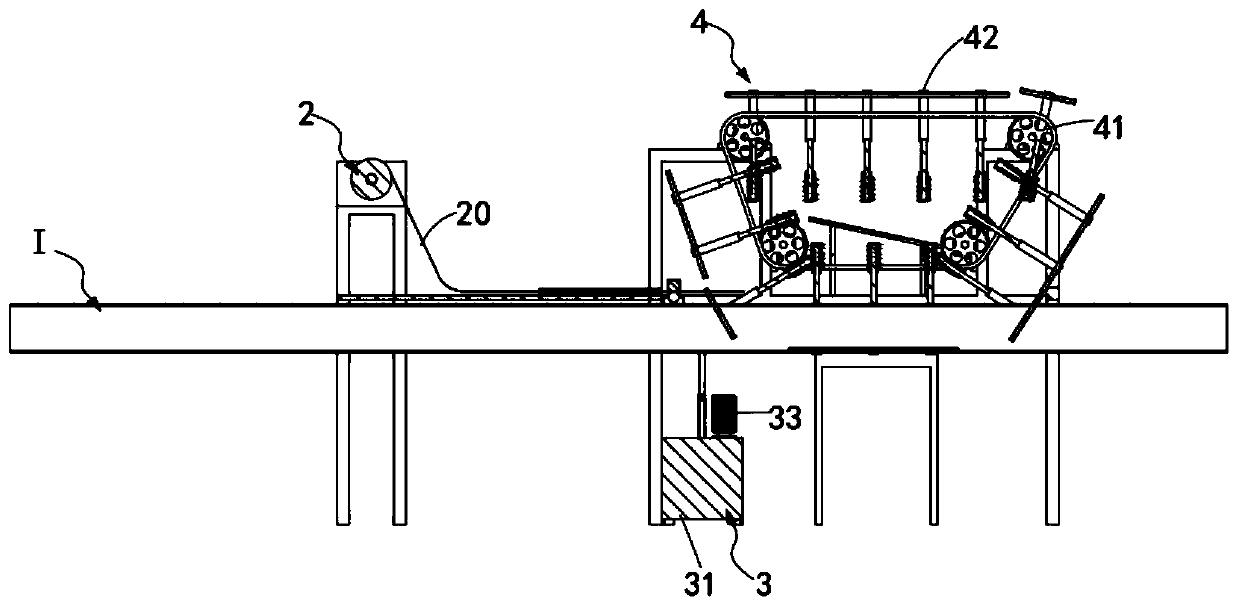

Production process and production line of high-strength fiber knitting and extruding pipeline

ActiveCN110421874AIncreasing the thicknessSolve the technical problem of too low thicknessGeneral water supply conservationTubular articlesGlass fiberProduction line

The invention provides a production process and a production line of a high-strength fiber knitting and extruding pipeline. According to the production process and the production line, the glue coating mechanism is adopted to glue a glass fiber cloth woven by glass fiber, then the glass fiber cloth is directly wrapped through a coating mechanism, and a woven fiber layer formed through weaving theglass fiber is replaced, so that the thickness increase of a fiber hooking connection caused by hooking and weaving is avoided, and thickness of the inner layer and the outer layer of a glass fiber tube is reduced, and strength of the winding layer is improved. According to the production process, after the glass fiber cloth woven through the glass fiber is glued, the glass fiber cloth is directlywrapped to replace the woven fiber layer formed through the glass fiber hooking, so that thickness increase of the fiber hooking connection caused by hooking and weaving is avoided, the thickness ofthe inner layer and the outer layer of the glass fiber tube is reduced, the strength of the winding layer is improved, and the technical problem that the thickness of the winding layer caused by innerand outer layer glass fiber weaving is too low is solved.

Owner:华盟(浙江)机械装备科技有限公司

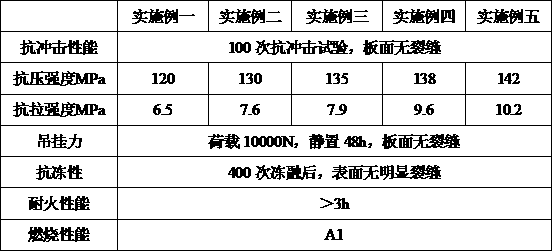

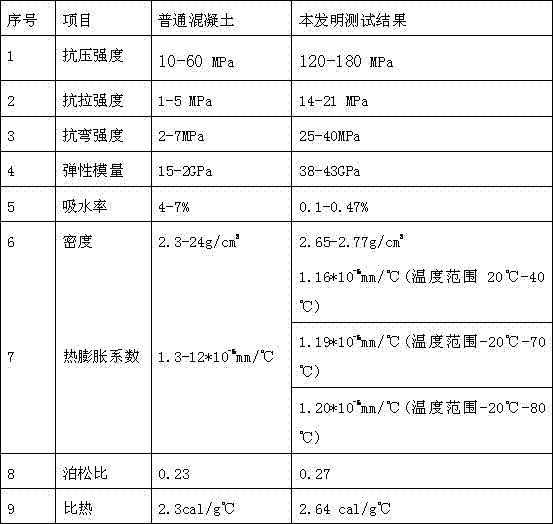

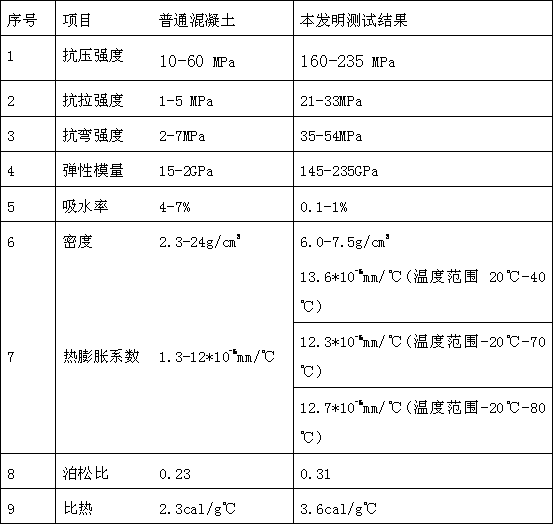

High-strength concrete plate and preparation method thereof

The invention relates to the technical field of building materials, and discloses a high-strength concrete plate and a preparation method thereof. The high-strength concrete plate is composed of the following components by mass parts: 300-500 parts of cementing materials, 700-1500 parts of aggregates, 5-15 parts of water reducing agents, 30-50 parts of emulsions, 30-75 parts of water and 5-10 parts of fibers. The preparation method comprises the following steps: 1) uniformly stirring the emulsion, the water reducing agent and the water in proportion; 2) uniformly stirring the cementing material, the aggregate and the fibers in proportion and uniformly adding the mixed liquid obtained in the step 1) into the mixture in a spraying form in the stirring process; 3) pouring the obtained mixed material into a mold, compacting under the condition of 0.1-20 MPa, maintaining the pressure for 30 s and demolding to obtain a porous concrete plank; and 4) carrying out moisture maintenance on the demolded concrete plank. The prepared concrete pltae is high in strength and small in cement consumption and can be used as a fabricated building plate.

Owner:南京绿色增材智造研究院有限公司

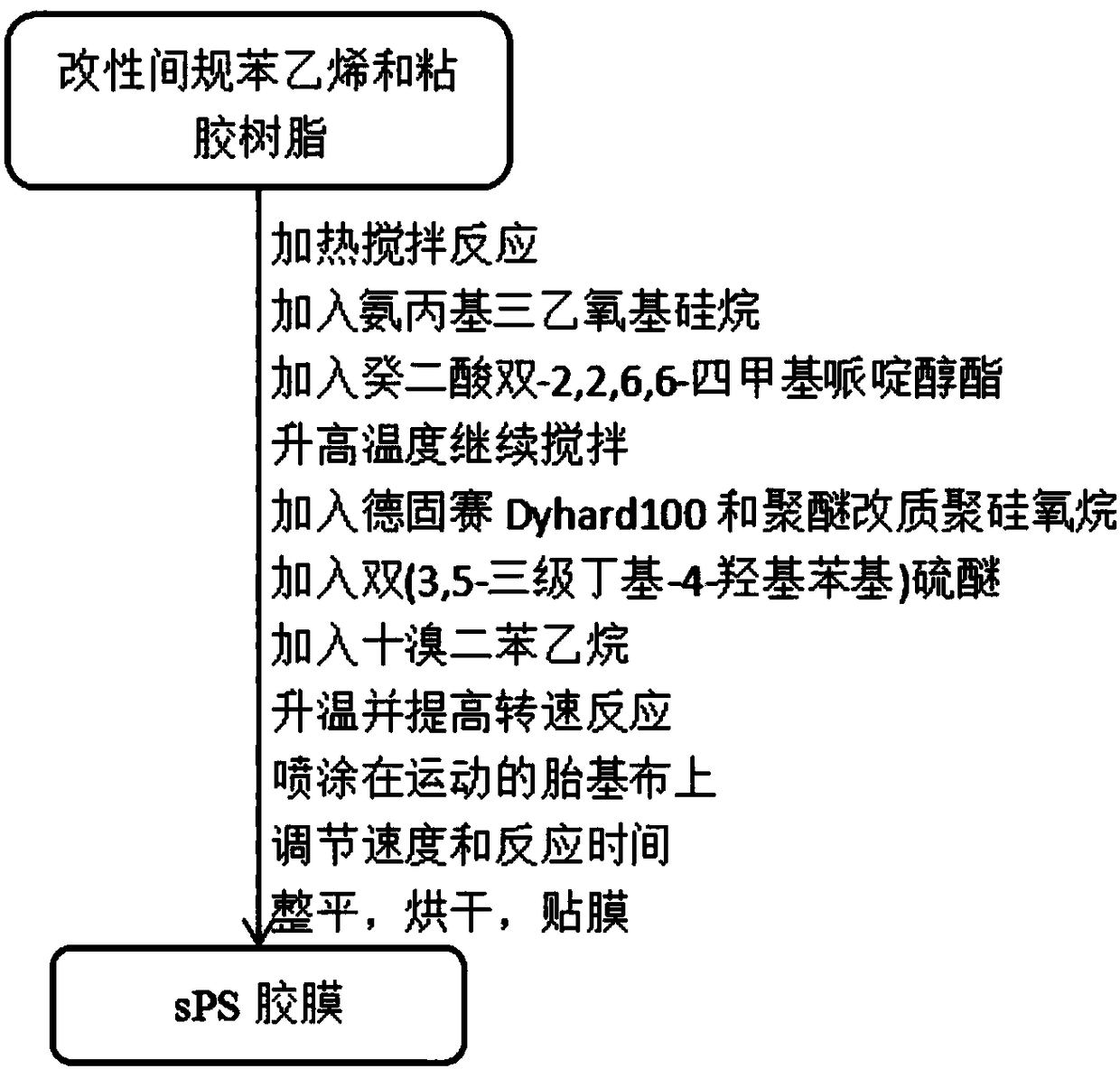

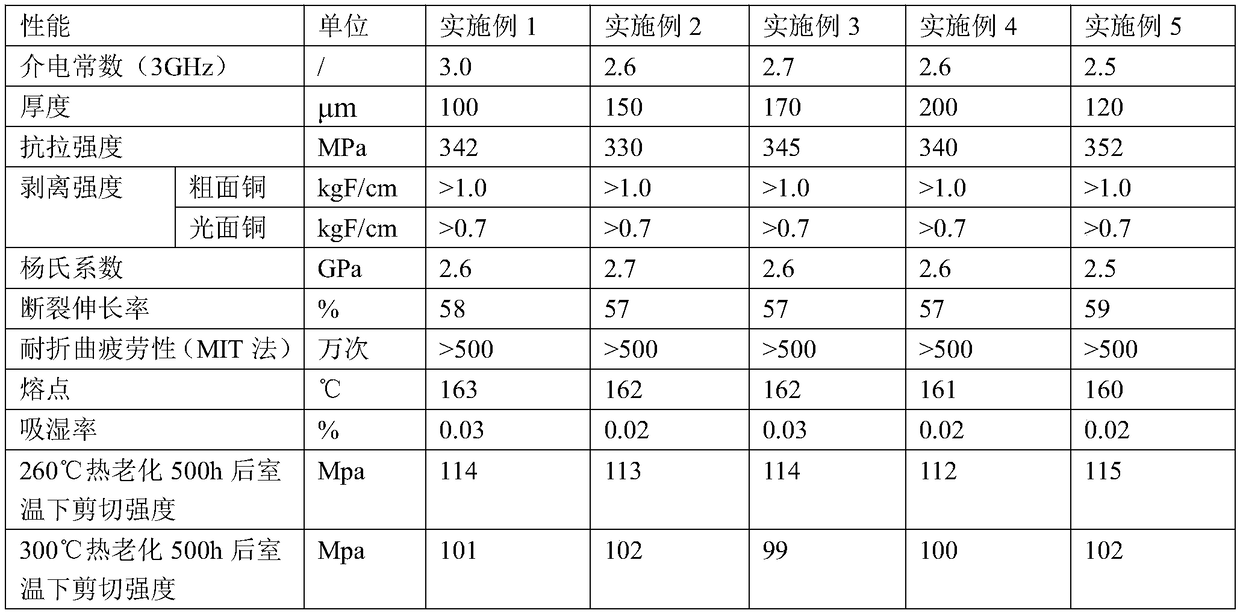

sPS (syndiotactic polystyrene) film for FPC (Flexible Printed Circuit) industry and preparation method thereof

InactiveCN109504318AImprove mechanical propertiesStrong mechanical propertiesNon-macromolecular adhesive additivesFilm/foil adhesivesTriethoxysilanePolystyrene

The invention provides a sPS (syndiotactic polystyrene) film and a preparation method thereof. The film is prepared from the following raw materials in parts by weight: 100 to 120 parts of modified sPS, 60 to 80 parts of adhesive resin, 10 to 15 parts of Degussa Dyhard 100, 5 to 10 parts of polyether modified polysiloxane, 5 to 10 parts of bis(3,5-tert-butyl-4-hydroxyphenyl) thioether, 1 to 4 parts of decabromodiphenyl ethane, 1 to 3 parts of bis(2,2,6,6-tetramethyl-4-piperidyl)sebacate and 1 to 3 parts of aminopropyltriethoxysilane. The modified syndiotactic polystyrene is added into the film; through the modification by oxidized graphene and aluminium oxide, the prepared modified syndiotactic polystyrene has good mechanical performance and high polarity; the conductivity and the flame-resistant performance are obviously improved; the wide application prospects are realized.

Owner:苏州市新广益电子股份有限公司

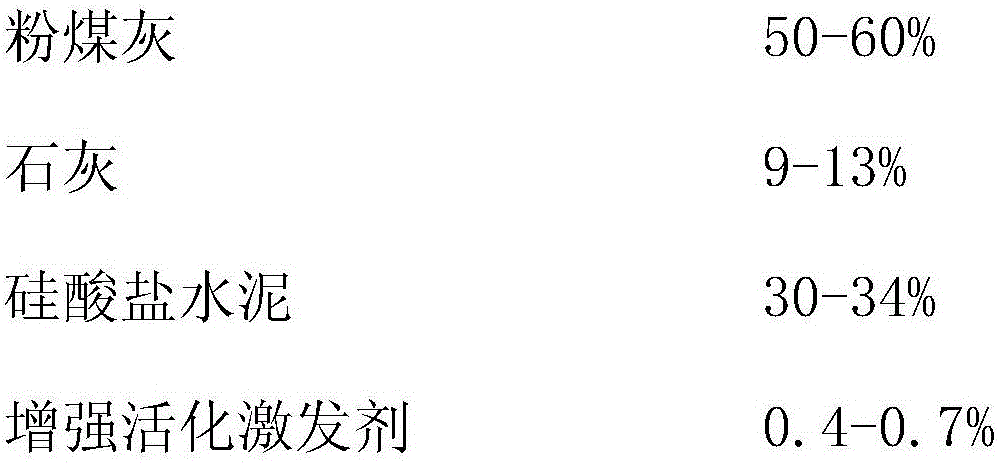

Fly ash-based dredger fill solidification reinforcing agent

The invention relates to a dredger fill solidification reinforcing agent which comprises the following components, by mass percent, 50-60% of fly ash, 9-13% of lime, 30-34% of portland cement and 0.4-0.7% of enhanced activation exciting agent; the portland cement is ordinary portland cement; the enhanced activation exciting agent comprises, by mass percent, 50-70% of lignin, 10-15% of natural high-molecular polymers, 15-35% of amide organic matters and 1-5% of sodium salt; and when in use, the dredger fill solidification reinforcing agent is added according to 7-16% of the wet mass of a dredger fill body to be reinforced and stabilized, and is mixed with the dredger fill body. With the adoption of the novel, efficient, environment-friendly and economical dredger fill solidification reinforcing agent, the pollution to the environment from the fly ash is alleviated, the recycling of waste is realized, and the problem that the bearing capacity of a dredger fill foundation in a project is not sufficient is solved.

Owner:刘文白

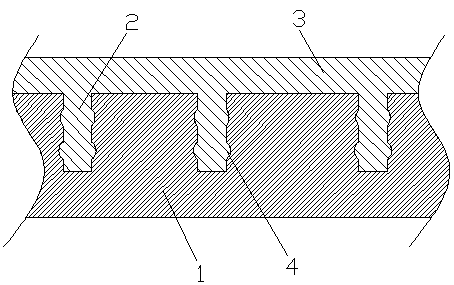

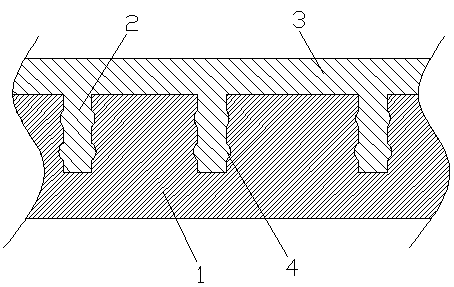

Abrasion-resisting lining plate for producing aluminum oxide in ore grinding operation

ActiveCN107930781AExtended service lifeEasy to replaceGrain treatmentsRubber materialAluminium oxide

An abrasion-resisting lining plate for producing aluminum oxide in ore grinding operation comprises a steel lining plate and an abrasion-resisting rubber lining plate arranged on the inner wall face of the steel lining plate. A plurality of counter bores are distributed in the inner wall face of the steel lining plate so that when abrasion-resisting rubber materials is pressed into the abrasion-resisting rubber lining plate on the inner wall face of the abrasion-resisting rubber lining plate, part of abrasion-resisting rubber materials enter the counter bores to form connection bolt columns toachieve connection between the steel lining plate and the abrasion-resisting rubber lining plate. According to the abrasion-resisting lining plate, due to the fact that the abrasion-resisting rubberlining plate is arranged on the surface of the steel lining plate, the abrasion-resisting rubber lining plate plays a role in protecting the steel lining plate when a grinding body and ores directly impact the abrasion-resisting rubber lining plate, the abrasion-resisting rubber lining plate is easy to change after being damaged, and the service life of the steel lining plate is greatly prolonged.

Owner:平顶山京钰实业有限公司

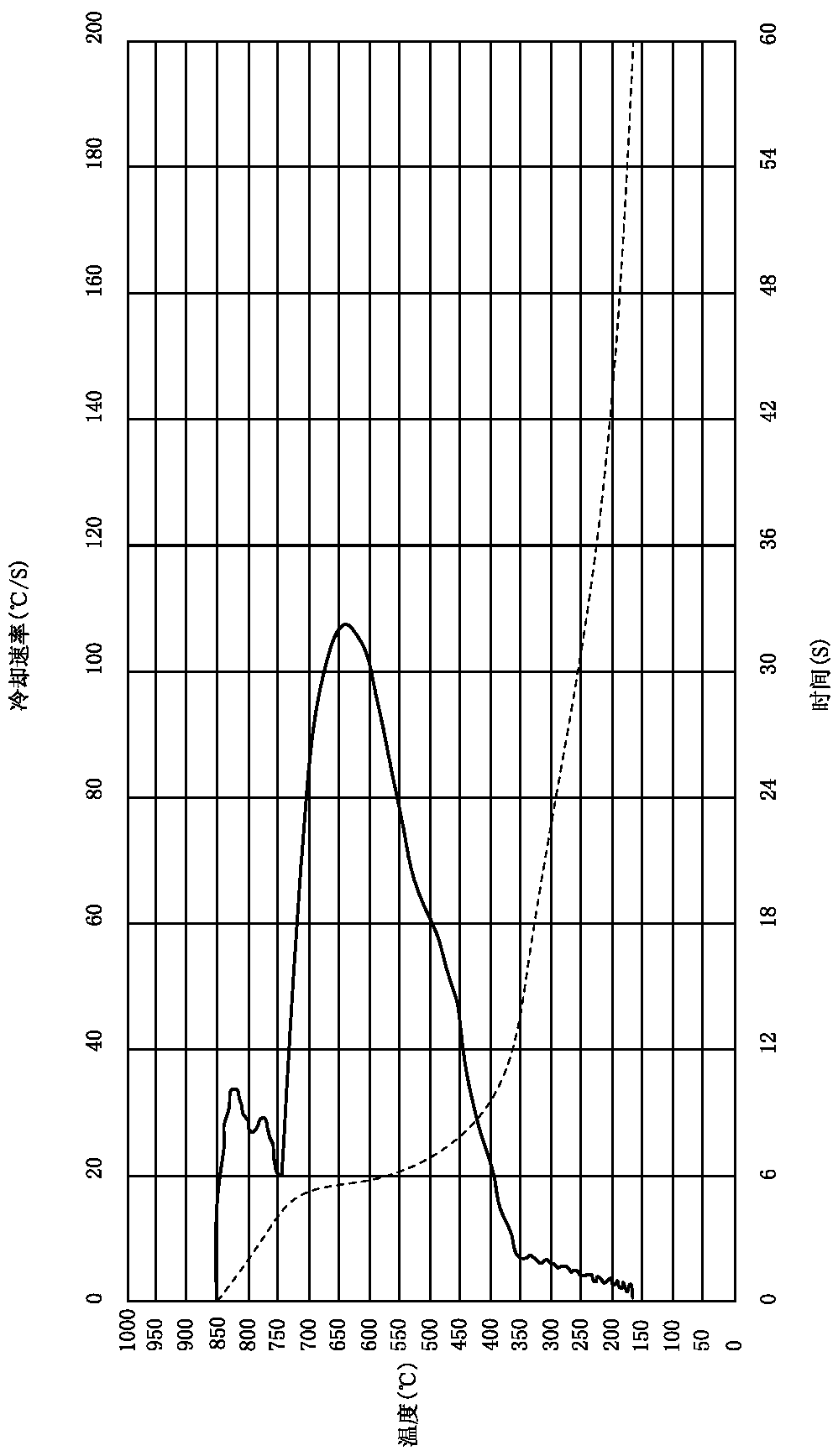

Automobile leaf spring free quenching technology

InactiveCN108676978AImprove quenching qualityEfficient productionFurnace typesQuenching agentsQuenchingOverburden pressure

The invention discloses an automobile leaf spring free quenching technology, and belongs to the technical field of leaf spring machining heat treatment technologies. The automobile leaf spring free quenching technology is characterized by comprising the following steps that firstly, reeds are heated to 860 DEG C-920 DEG C in a stepping type quenching heating furnace, and heat preservation is conducted for 20-25 min; secondly, the reeds are sorted and discharged out of a furnace according to the lengths, wherein the lengths are smaller than or equal to 700 mm, are 700-900 mm, are 900-1,300 mm and are larger than or equal to 1,300 mm correspondingly; thirdly, after the reeds are moved to a forming platform through a robot, chain type overburden pressure forming is adopted; and fourthly, rapid quenching oil is set in a quenching oil groove, the forming platform is used for directly conveying the reeds into the quenching oil groove in a free state, the reeds are quenched within 30 s from furnace discharging to oil entry. According to the automobile leaf spring free quenching technology, the reed quenching quality can be improved while efficient production is achieved.

Owner:SHANDONG LEOPARD AUTOMOTIVE HLDG

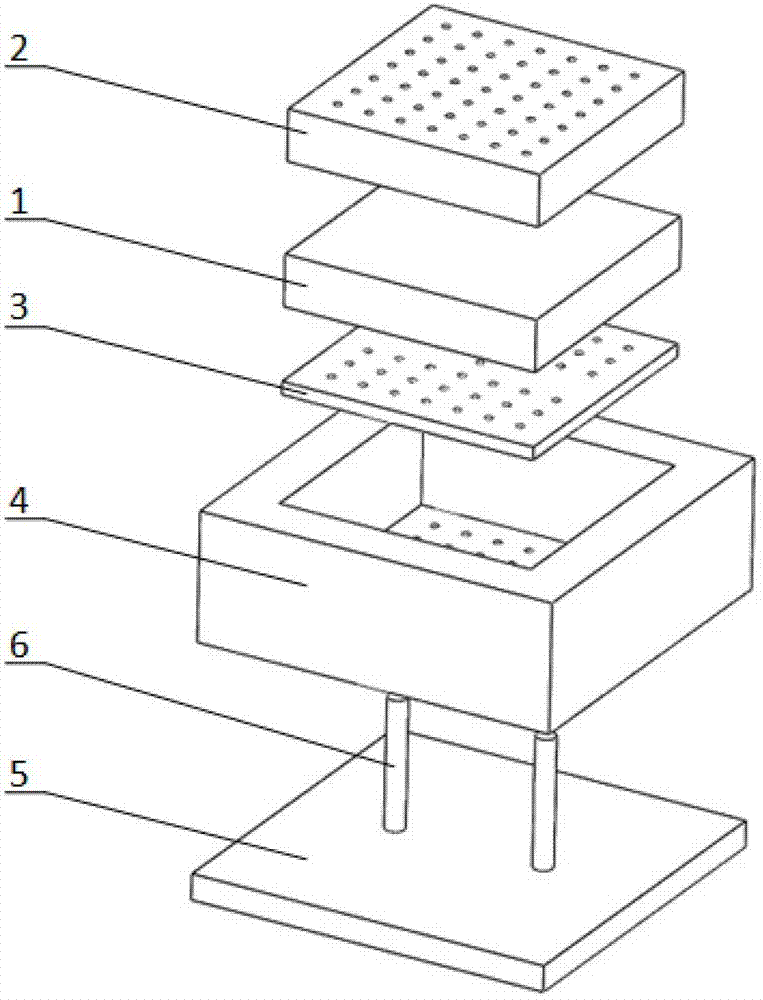

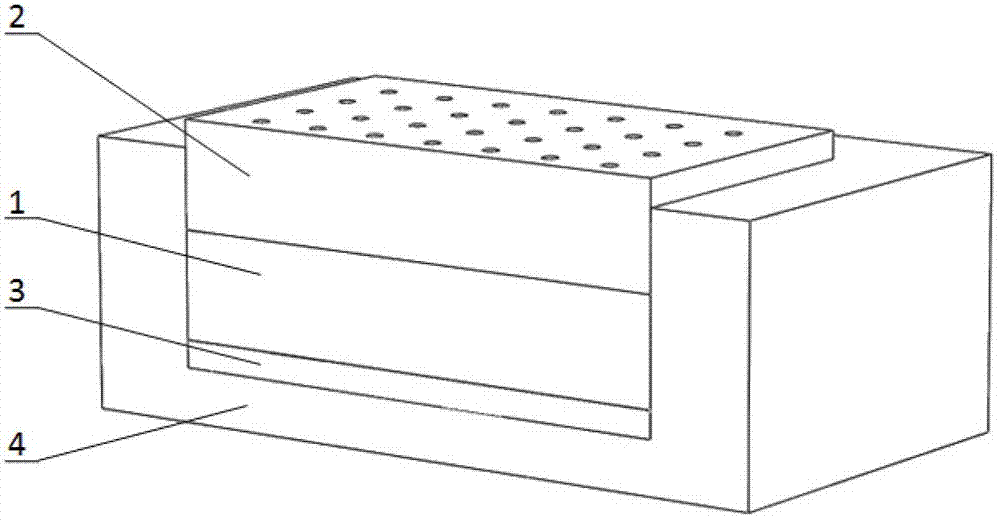

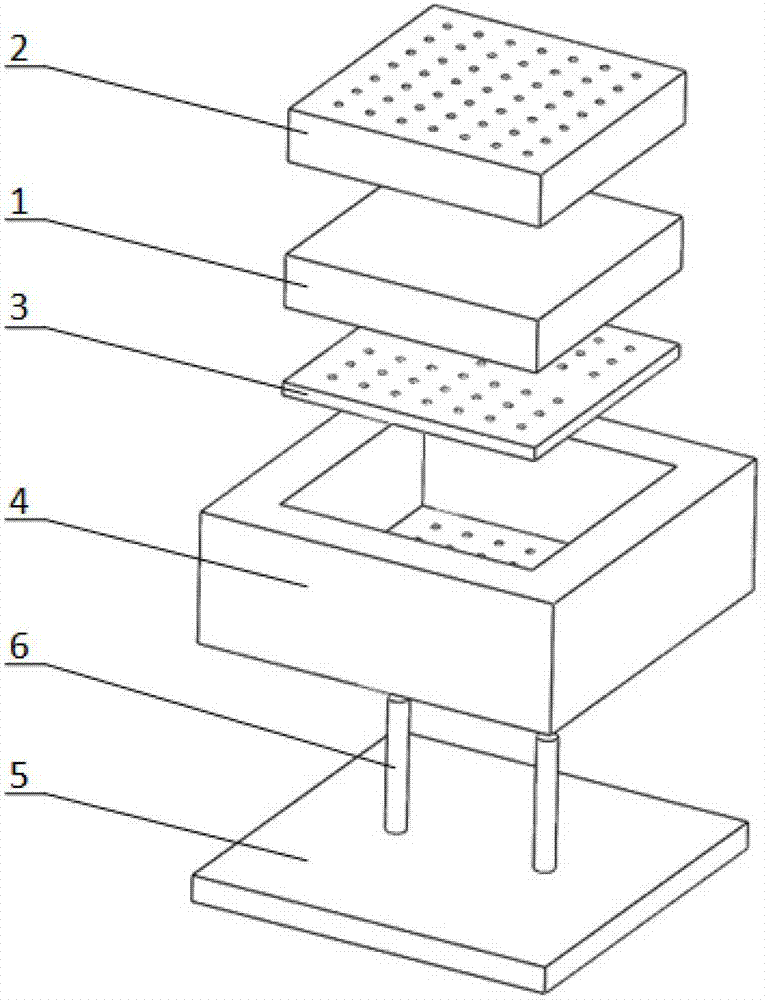

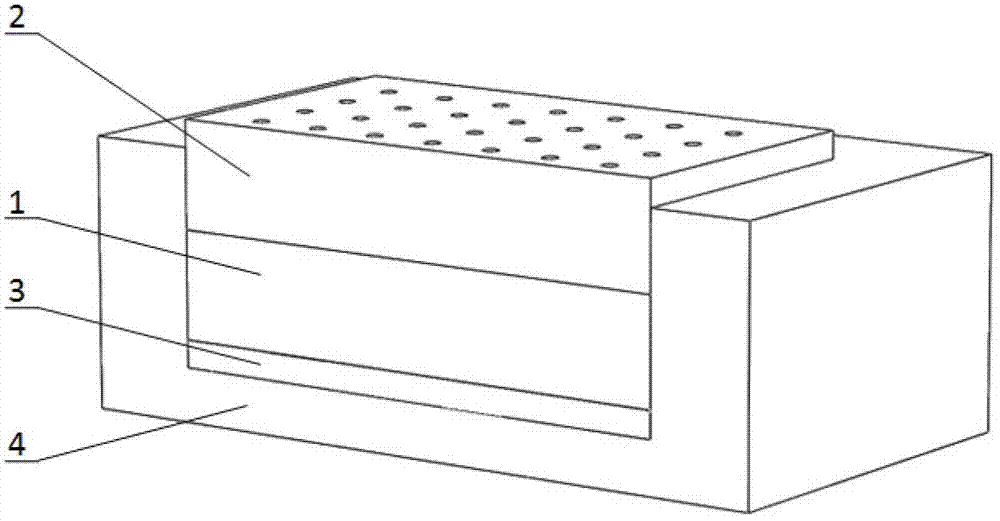

Seaweed biomass plate, processing method and special mold thereof

The invention relates to a seaweed biomass plate, and provides a natural, degradable and high-strength seaweed biomass plate which is to solve the problems that the biomass plate in the prior art has low strength, and the added additives are difficult to degrade and unsafe. The seaweed biomass plate is produced by the following steps: taking seaweed as a raw material, crushing, hot-pressing and molding and drying the raw material to produce the seaweed biomass plate, wherein the main ingredients comprise seaweed plant cellulose, hemicellulose and pectin substances. The invention also provides a processing method of the seaweed biomass plate, which comprises procedures of crushing, hot-pressing molding and drying, and a special mold comprising a pressing plate with a water filtering hole and a groove body. The seaweed biomass plate provided by the invention has the characteristics of high strength, compact structure and degradation; and the plate is natural, nontoxic and safe.

Owner:JIANGNAN UNIV

Washing-resistant rubber lining for cyclone and preparation method thereof

InactiveCN108148230AEasy to replaceExtended service lifeReversed direction vortexPolymer scienceNano al2o3

The invention discloses a washing-resistant rubber lining for a cyclone and a preparation method thereof. The rubber lining is prepared by taking the nitrile rubber and butadiene rubber as matrix, taking polyurethane cellosilk, carbon fiber and polyamide fiber as the skeleton fiber, taking the sepiolite powder, carbon black and nano-aluminum oxide powder as filler, taking a aluminic ester couplingagent, liquid coumarone resin and modifying additive as the additive, and mixing the raw materials with anti-wearing auxiliary, a sulfurizing agent BPO and DM, wherein the anti-wearing auxiliary is prepared by mixing nitrile rubber powder, dioctyl phthalate, aluminium oxide, succinic acid and KH580; the modifying additive is prepared by mixing KH570, nanometer aluminum hydroxide, acetone and barium hydroxide. By arranging the rubber lining on the inner wall of the cyclone, thus the ore pulp directly impacts on the rubber lining, and the aim of protecting the inner wall of the cyclone is achieved; the rubber lining is easy to change after being damaged, and the service life of the cyclone is greatly prolonged.

Owner:北京中选耐磨设备有限公司平顶山分公司

New technology for preparing high-performance waterproof fiberboard with semipermeable membrane technology enhancing enzymolysis degree

InactiveCN104149152AEasy to solveGuaranteed to be environmentally friendlyFlat articlesDomestic articlesROSIN POWDERFiber

The invention relates to a technology. According to the technology, multiple biological enzyme programs are used for processing crop waste straw, a semipermeable membrane technology is used for solving the problem that hydrolysates inhibit the enzymolysis degree, and a high-performance waterproof fiberboard is produced. The technology is characterized in that the crop waste straw is loosened through a loosening machine, the laccase and hemicellulase programs are added for hydrolysis, the hydrolysis process is conducted in a system with a semipermeable membrane capable of filtering out medium and small size molecules, after hydrolysis is completely conducted, processed straw fibers and the medium and small size molecules filtered out by the semipermeable membrane are mixed again, moisture is evaporated, drying is conducted until the water content reaches 1-5 percent, about 3 percent of rosin powder is added to be evenly stirred and put into a die to be laid and packaged, and the rosin powder is pressed under the designated temperature, pressure intensity and time. Raw materials are sufficient, the price is low, materials are cheap, a chemical adhesive waterproof agent does not need to be added on the manufactured fiberboard, cost of the board is reduced, the manufacturing technology is environmentally friendly and free of pollution, and the obtained fiberboard is good in mechanical property, good in waterproof performance, high in finished product qualification rate and not prone to deformation.

Owner:HUBEI UNIV +1

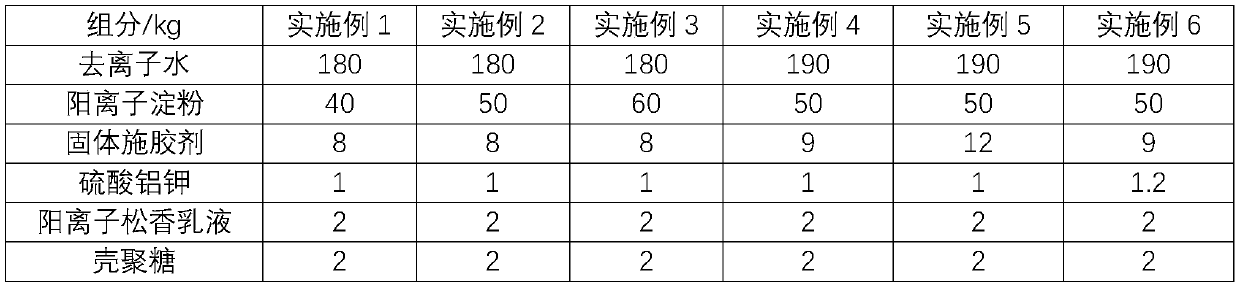

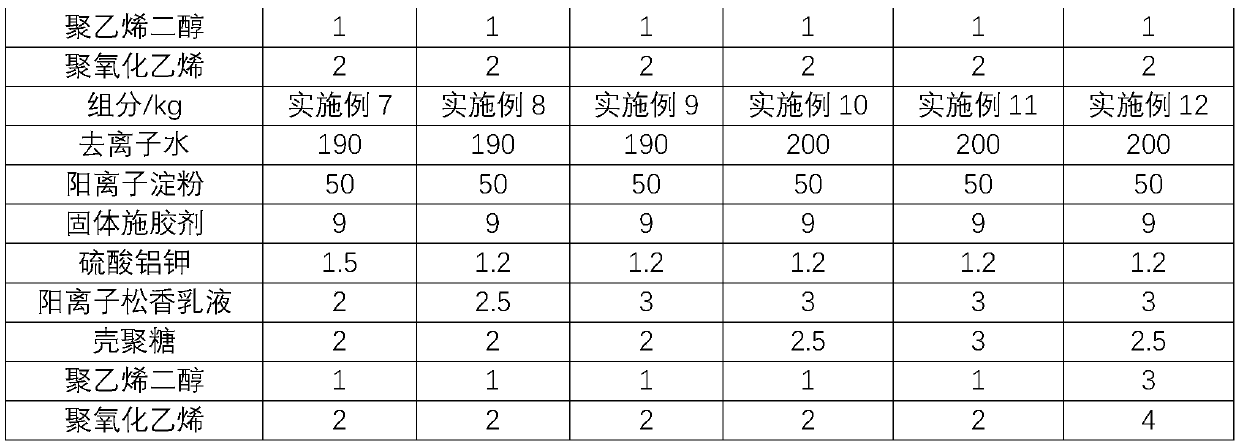

Production method of high-strength corrugated base paper

InactiveCN111021130AHigh recovery rateAvoid situations such as layeringWater-repelling agents additionPaper-making machinesFiberPaper production

The invention relates to a production method of high-strength corrugated base paper in the field of corrugated paper production. The production method comprises the steps: step 1, pulping waste paper;step 2, screening the paper pulp in the step 1, and carrying out grading treatment on accepted pulp obtained through screening; step 3, performing slag removal, fine screening and concentration treatment on long fibers to obtain long fiber pulp, and storing the long fiber pulp; carrying out second-stage slag removal, third-stage slag removal and sand setting treatment on slag pulp obtained by long fiber first-stage slag removal, carrying out long fiber first-stage slag removal treatment on accepted pulp subjected to second-stage slag removal, and carrying out second-stage slag removal treatment on accepted pulp subjected to third-stage slag removal; and carrying out long fiber second-stage fine screening on the slag pulp after the first-stage fine screening of the long fibers, concentrating by an inclined net, and continuously carrying out primary screening treatment on pulp obtained after grinding; step 4, carrying out short fiber first-stage slag removal on short fibers and then concentrating to obtain short fiber slurry, storing the short fiber slurry, and carrying out second-stage slag removal treatment on the short fiber first-stage slag removal slag pulp; and step 5, papermaking. Slag pulp generated in the process in the step 3 and the step 4 is treated again, and the recovery rate of fibers in the waste paper treatment process is increased.

Owner:陕西东方环保产业集团东鹏再生资源利用有限公司

Cast iron processing cutting fluid

InactiveCN105670739AImprove cooling and lubrication effectSolve the problem of cavitationAdditivesArray data structureBetaine

The invention discloses a cast iron processing cutting fluid which is composed of the following components in parts by mass: 15-20 parts of ethanediol monostearate, 5-8 parts of triethanolamine, 3-5 parts of ginger juice, 8-12 parts of ethanediol, 6-10 parts of octadecyldihydroxyethyl betaine, 3-5 parts of polysorbate, 6-10 parts of alkylphenol polyoxyethylene, 3-5 parts of antiwear additive, 5-8 parts of rust inhibitor, 1-2 parts of defoaming agent and 0.2-0.5 part of colorant. The cast iron processing cutting fluid is compounded by selecting favorable materials and adopting a scientific processing method under the conditions of high temperature and high pressure. The cast iron processing cutting fluid has the advantages of favorable fusion effect, no stratification, high antimicrobial capacity, favorable antirust effect and fewer precipitates in the use process, thereby ensuring the product to be clean and acceptable. The nitrites and phosphorus and sulfur compounds are eliminated in the product formula, and the ginger juice is added, so that the cast iron processing cutting fluid is green and environment-friendly, reduces the damage and harm of the chemicals to the environment and human body, is nontoxic, can obviously enhance the smoothness of the processed surface, can provide favorable antirust protection for parts, and is suitable for machining of ferrous metals, aluminum and aluminum alloys.

Owner:周紫阳

Processing center lubricating fluid with stable concentration

The invention discloses processing center lubricating fluid with stable concentration. The processing center lubricating fluid with stable concentration is composed of the following components in parts by mass: 65-75 parts of isopropyl alcohol, 6-10 parts of propylene glycol methyl ether, 5-8 parts of propylene glycol, 3-5 parts of sodium lauryl glucose carboxylate, 2-4 parts of lauryl glucose, 90-120 parts of tea water, 1-2 parts of a corrosion inhibitor, 0.3-0.5 part of a defoamer, 0.02-0.05 part of a coloring agent, 0.03-0.05 part of a mould inhibitor and 0.2-0.6 part of a buffer agent. The processing center lubricating fluid with stable concentration has the advantages that excellent materials are selected, a scientific processing method is adopted, nitrite and phosphorus and sulphur compounds are eliminated in a product formula, the tea water is added, environmental protection is realized, destroy and damage of chemicals to the environment and human bodies are reduced, the blending effect is good, the evaporation is uniform and the concentration is stable at high temperature, the corrosion resistance is strong, the corrosion, cavitation and scaling of the inner surface can be prevented, a protective layer is formed, the lubricating, rustproof and cooling effects are good, economy and practicability are realized, no toxicity is produced, fragrance is distributed, and machine tools, workpieces and clamps can be protected and harm to an operator is reduced while good performance is kept.

Owner:周紫阳

Preparation method of aerospace special high-performance composite material presoak

The invention discloses a preparation method of an aerospace special high-performance composite material presoak, and relates to the technical field of composite materials. The aerospace special high-performance composite material presoak is prepared from modified acrylamide-acrylic resin, the resin can be dissolved in water to prepare an emulsion, and the adhesive property is good; carbon fibersare used as a main material, self-made resin, nanofiller, a coupling agent and a curing agent are added to obtain the presoak containing the carbon fibers, the presoak is used for impregnating basaltfibers, and a carbon fiber layer can be formed on the outer layers of the basalt fibers after high-temperature roasting, so that the use amount of the carbon fibers in the material is reduced, and thestrength of the material is guaranteed.

Owner:ANHUI FOSTER FISHING GEAR

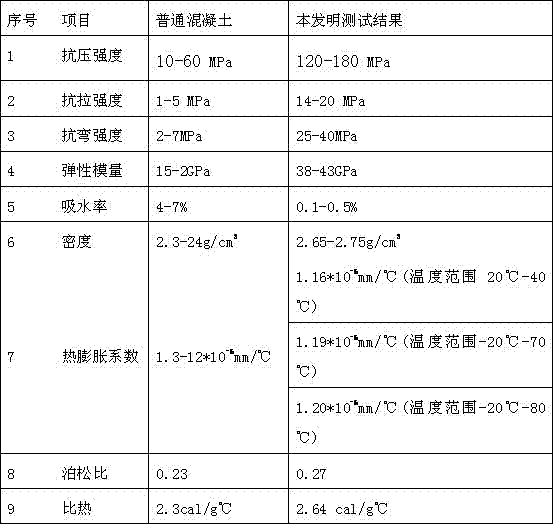

Machine tool bed cast from waste ceramic

The invention discloses a machine tool bed cast from waste ceramics. The machine tool bed has the advantages of being high in stability, low in thermal expansion coefficient, good in pressure and tension resistance, and the like, and in addition, as waste ceramics are adopted as a raw material, the problem that waste ceramics are randomly disbanded, hard to recycle, and the like, is solved, and the purpose of turning wastes into wealth is achieved. The machine tool bed cast from waste ceramics is mainly prepared from the following raw materials in parts by weight: 70-75 parts of waste ceramicpieces or waste ceramic granules, 8-15 parts of waste ceramic powder, 7-10 parts of an epoxy resin, 1.75-2.5 parts of a curing agent, 1 part of a carbon fiber, 1 part of a basalt fiber, 0-1 part of bismuth, Bi, 0-1 part of antimony, 8-10 parts of silicon powder and 0-10 parts of alumina powder.

Owner:福建振丰矿物新材料有限公司

Feed capable of improving immunity of piglets and preparation method thereof

InactiveCN109007375AImprove immunitySoft tasteFood processingAnimal feeding stuffAnimal scienceAdditive ingredient

The invention discloses feed capable of improving the immunity of piglets and a preparation method thereof, which andbelongs to the field of feed processing. Energy feed and protein feed are used as main base materials of the feed; and by adding various auxiliary materials, on the premise of not damaging the nutritional ingredients of the feed, the performance of improving the immunity of the feedfor improving the immunity can be improved, the use of antibiotics can also be avoided, and the healthy processing of the meat can be facilitated; and the prepared feed is loose and soft in taste, the energy feed and the protein feed can provide a necessary nutritional base for the growth of organisms, and the cooperation of the additives and the main materials facilitates the growth of the piglets and improves the body immunity of the piglets, and the disease rate can be reduced.

Owner:ANHUI QIANGJIAZHUANG ECOLOGICAL AGRI

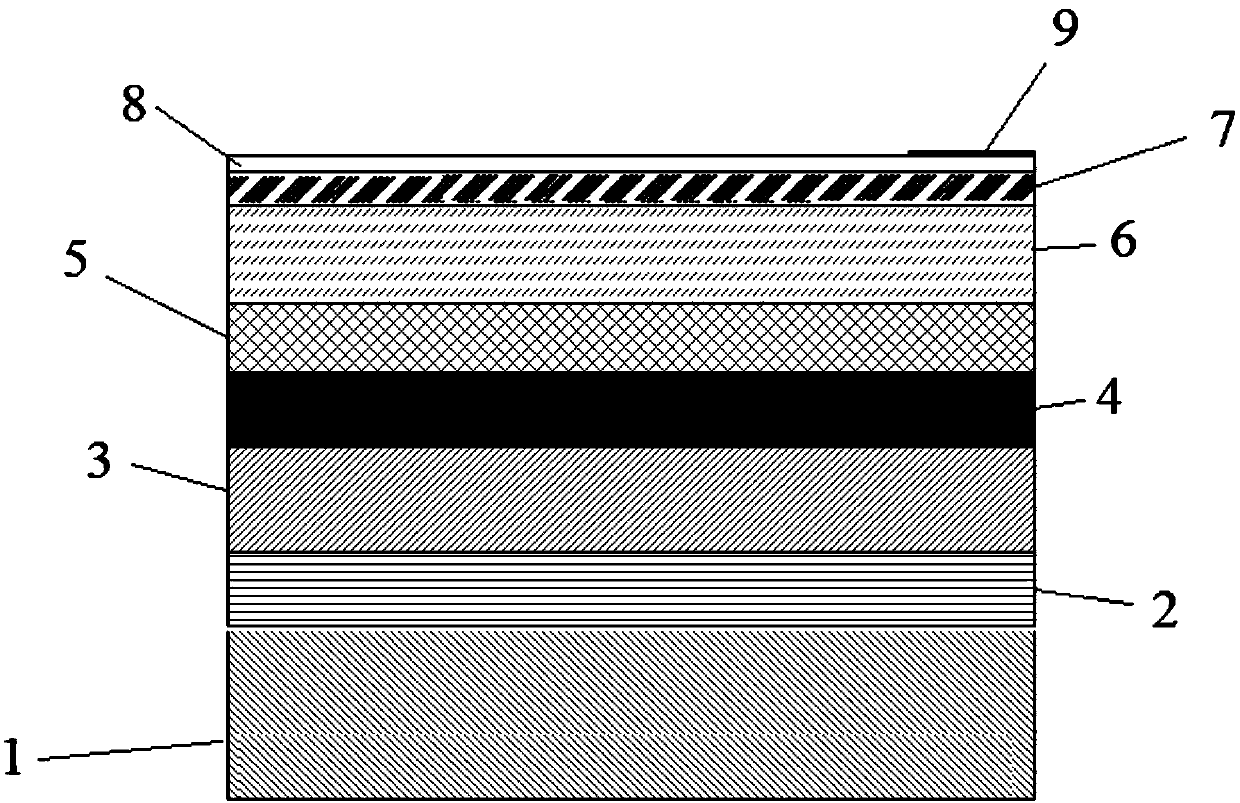

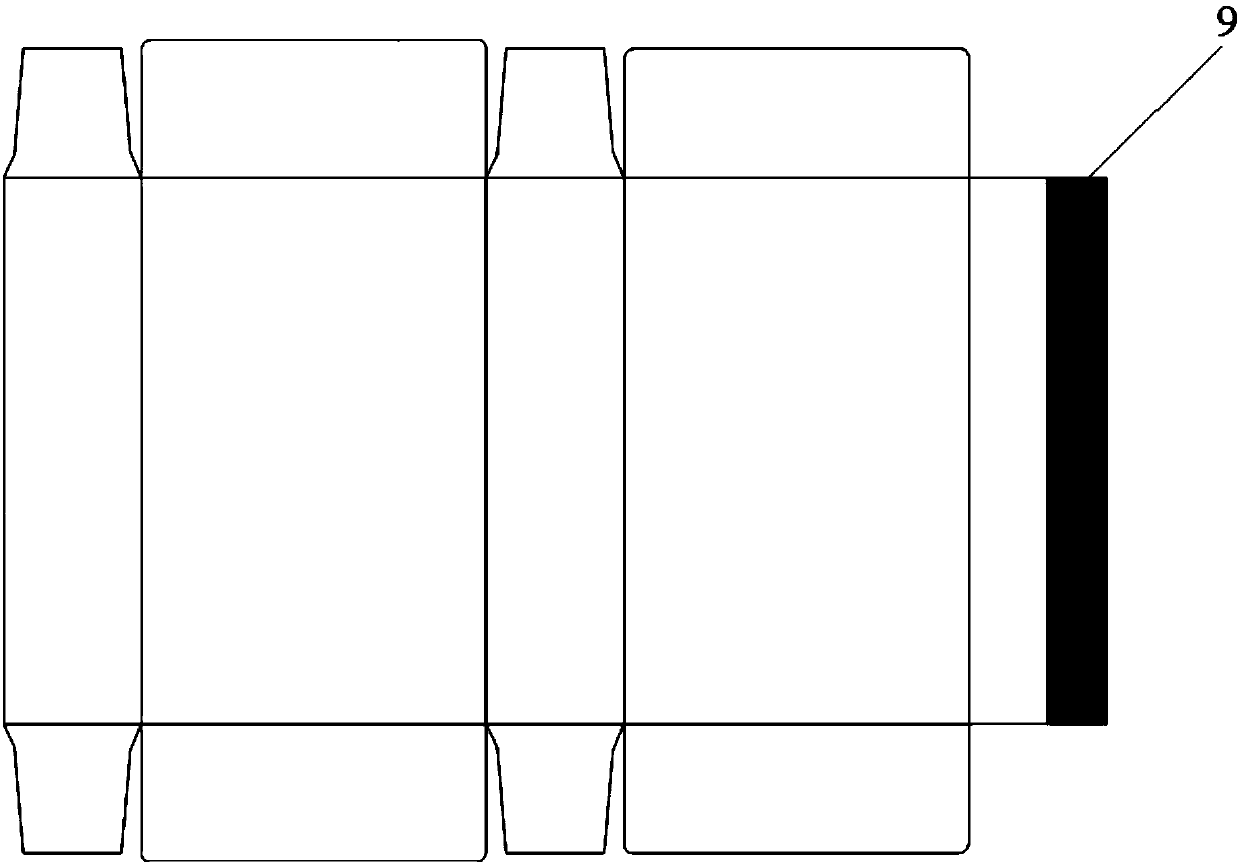

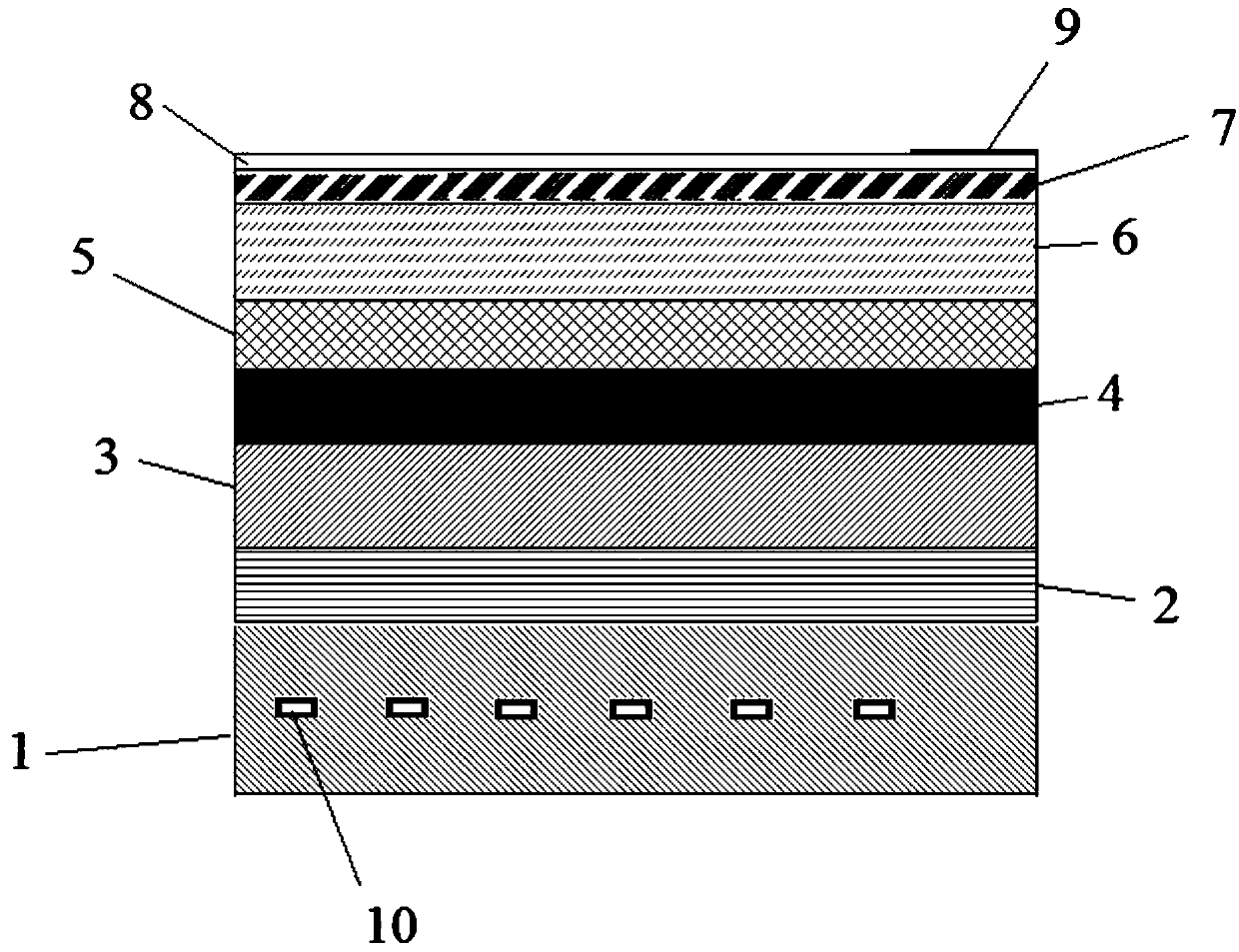

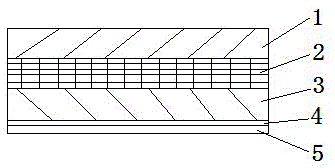

High-firmness and high-blocking anti-fake packaging box

The invention relates to a high-firmness and high-blocking anti-fake packaging box. The high-firmness and high-blocking anti-fake packaging box is formed through box sticking of a packaging paperboard. The high-firmness and high-blocking anti-fake packaging box is characterized in that the packaging paperboard comprises a paperboard body (1), a first glue sticking layer (2), an aluminum film plating layer (3), a second glue sticking layer (4), a holographic laser anti-fake layer (5), a BOPP film layer (6), a crylic acid glue layer (7) and a PET thin film layer (8) which are sequentially composited from bottom to top, and a first plasma bonding face (9) is formed at a sealed position of the packaging paperboard through machining. Compared with the prior art, the packaging paperboard has theadvantages that the sticking firmness is high, the mechanical strength is high, blocking is high, and the anti-fake effect is outstanding.

Owner:上海新洲包装印刷有限公司

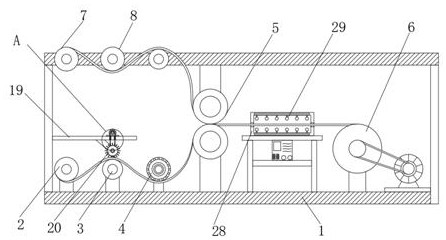

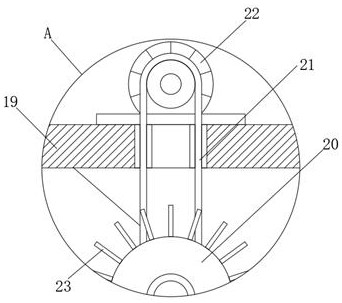

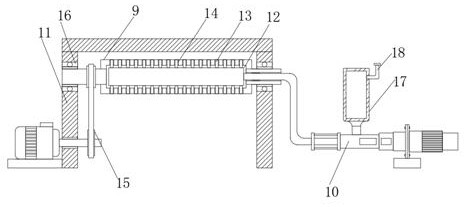

Composite production apparatus and method for aluminum foil glass fabric

ActiveCN113510993AConvenient composite pressingAct as glueLamination ancillary operationsLaminationAdhesive glueAluminum foil

The invention relates to the technical field of aluminum foil glass fabrics, and particularly discloses a composite production apparatus and method for an aluminum foil glass fabric. The apparatus comprises a fixing frame, a glue releasing roller assembly, a composite roller and a material collecting roller, wherein the fixing frame is composed of a base and a top plate fixedly connected to the base, an aluminum foil discharging roller and a supporting cylinder are arranged on the left side of the top face of the base, the composite roller is located in the middle of the top face of the base on the fixing frame, and the material collecting roller is located on the right side of the top face of the base. According to the composite production apparatus, the glue discharging roller assembly is arranged on the fixing frame and matched with the composite roller and the material collecting roller, so the effect of smearing glue on the surface of aluminum foil can be achieved; meanwhile, the effect of supplementing glue to the surface of a glue discharging roller at any time can be achieved through the arrangement of a glue dispensing pump; then through cooperation of the arrangement of the composite roller, the aluminum foil and the glass fabric can be conveniently compounded and pressed; and finally, the compounded aluminum foil glass fabric can be wound through the arrangement of the material receiving roller.

Owner:南京苏夏设计集团股份有限公司

Ultra-high ductility cement-based materials for repair and reinforcement

The invention relates to the technical field of building materials, and discloses an ultra-high ductility cement-based material for repair and reinforcement, which consists of the following components by mass: 300-600 parts of cementitious material; 700-1400 parts of aggregate; 100-300 parts of water 2~10 parts of nanoparticles; 1~10 parts of microcapsules; 1~20 parts of PVA and / or PE fiber; 10~30 parts of titanium white slag; 30~60 parts of auxiliary agent solution; 10-50 parts of lightly burned ferronickel slag; wherein, the core material of the microcapsules is a mixture of starch gel, silica sol, silane coupling agent and water, and the mass ratio is 10-40:10-40:5-15 : 10~50. The repairing and strengthening ultra-high ductility cement-based material of the invention has controllable setting time, high ductility and strong durability, and solves the problems of poor ductility and uncontrollable setting time of common repairing and strengthening cement-based materials.

Owner:南京绿色增材智造研究院有限公司

A glass fiber net reinforced bamboo fiber molded slide plate and its preparation method

ActiveCN109795182BHigh bonding strengthGood resistance to impact fractureGlass/slag layered productsEpoxyGlass fiber

Owner:INT CENT FOR BAMBOO & RATTAN

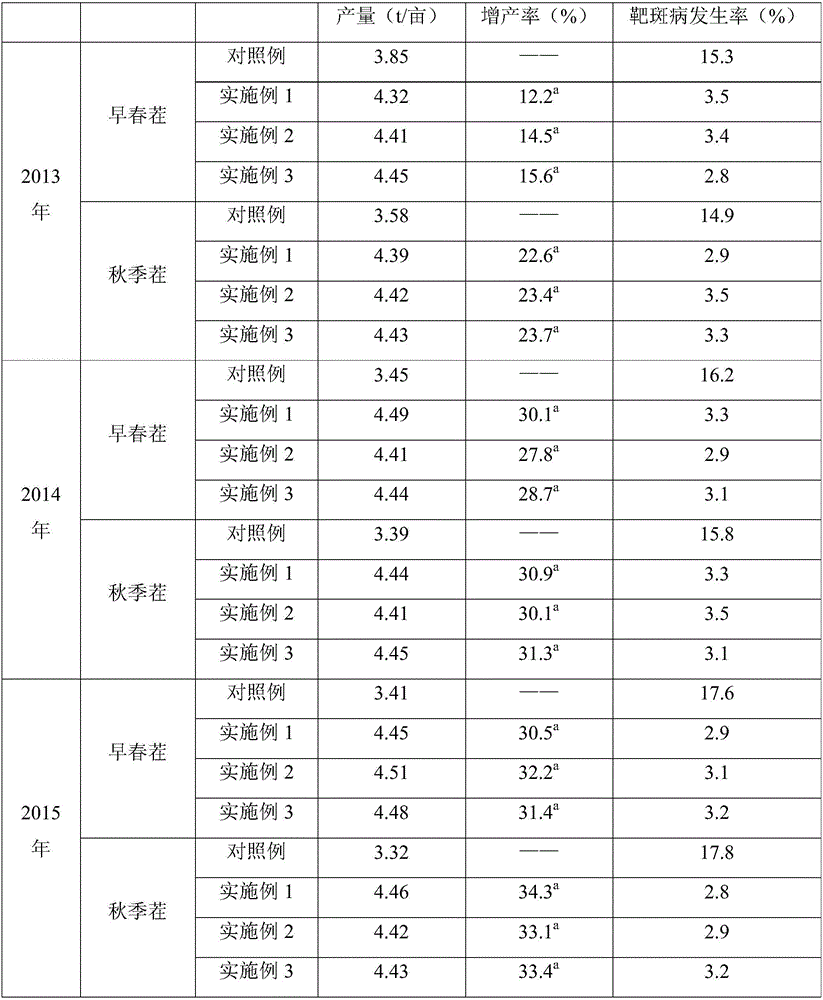

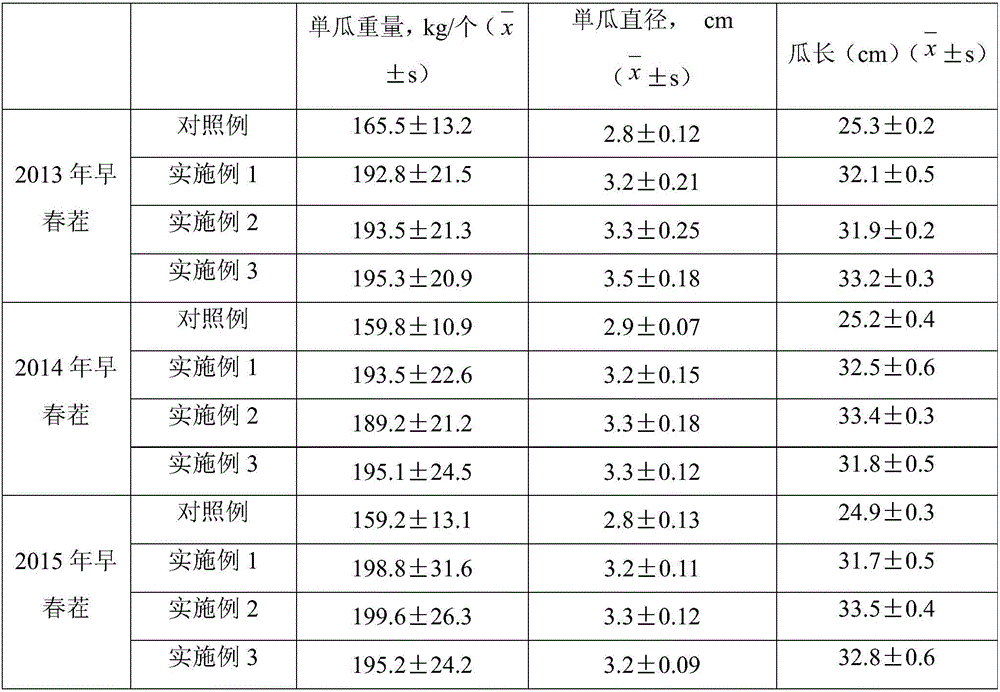

A kind of special organic fertilizer for watermelon and preparation method thereof

The invention discloses a special organic fertilizer for watermelons and a preparation method of the special organic fertilizer, and belongs to the technical field of fertilizers. The special organic fertilizer is prepared from the following raw materials in parts by weight: 30-40 parts of chicken manure, 20-35 parts of decomposed plant straw, 10-15 parts of wheat bran, 10-15 parts of peanut oil residue, 5-10 parts of oil sludge, 5-10 parts of humic acid, 2-5 parts of urea, 10-20 parts of trace elements, 5-10 parts of a complex microbial agent and 5-10 parts a functional microbial agent. The special organic fertilizer can provide abundant nutritive elements for the watermelons according to the growth characteristics of watermelons in various periods, and the special organic fertilizer can increase the yield, improve the quality and character and promote the good growth of watermelons. By using the special organic fertilizer, the use amount of unreasonable fertilizers can be reduced.

Owner:DANGSHAN CHUNYUAN FERTILIZER CO LTD

Cement fiber melamine laminated board and manufacturing method thereof

ActiveCN102619313BNot easy to scratchLow costCovering/liningsSynthetic resin layered productsFiberMelamine

The invention discloses a cement fiber melamine laminated board, which comprises a cement fiber base board (1) and is characterized in that a melamine impregnated paper laminated layer (2) is adhered on the cement fiber base board (1). The invention further discloses a manufacturing method of the cement fiber melamine laminated board, which mainly adopts a hot-pressing process. Hot-pressing pressure is 1000 to 1200 tons, hot-pressing time is 45 to 50 seconds, and hot-pressing temperature is 170 DEG C to 190 DEG C. The cement fiber melamine laminated board has the advantages of being low in cost, good in fireproof and dampproof effects and convenient to install, and the surface of the board is not easy to scratch and crack, cannot bleed water when weather is wet, and is not easy in adhesive failure.

Owner:宁波尚展新材料有限公司

Machine tool bed cast by utilizing steel-making tailings

The invention provides a machine tool bed which is cast by utilizing steel-making tailings. The machine tool bed is mainly prepared from the following raw materials in parts by weight: 65-75 parts ofsteel-making tailings, 5-10 parts of iron sand powder, 5-10 parts of silica powder, 5-10 parts of quartz sand, 5-10 parts of quartz powder, 7-10 parts of epoxy resin, 1.75-2.5 parts of a curing agent,1 part of carbon fiber, 1 part of basalt fiber, 0-1 part of bismuth and 0-1 part of antimony. The machine tool bed cast by utilizing the steel-making waste slag, provided by the invention, can comprehensively and obviously improve the mechanical performance of a machine tool, improve the stability of the machine tool, reduce the coefficient of thermal expansion, improve the machining process precision and product yield of the machine tool, and indirectly reduce the machining cost. The utilization of the steel-making waste slag for casting the machine tool bed realizes recycling of resources,realizes the change of waste into treasure, and reduces environmental pollution, which is a major innovation of machine tool bed casting materials, and has a great significance.

Owner:福建振丰矿物新材料有限公司

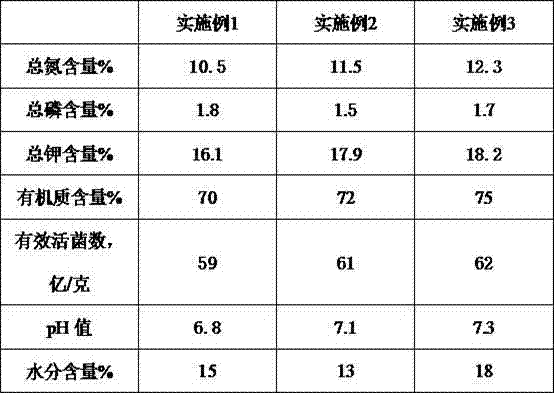

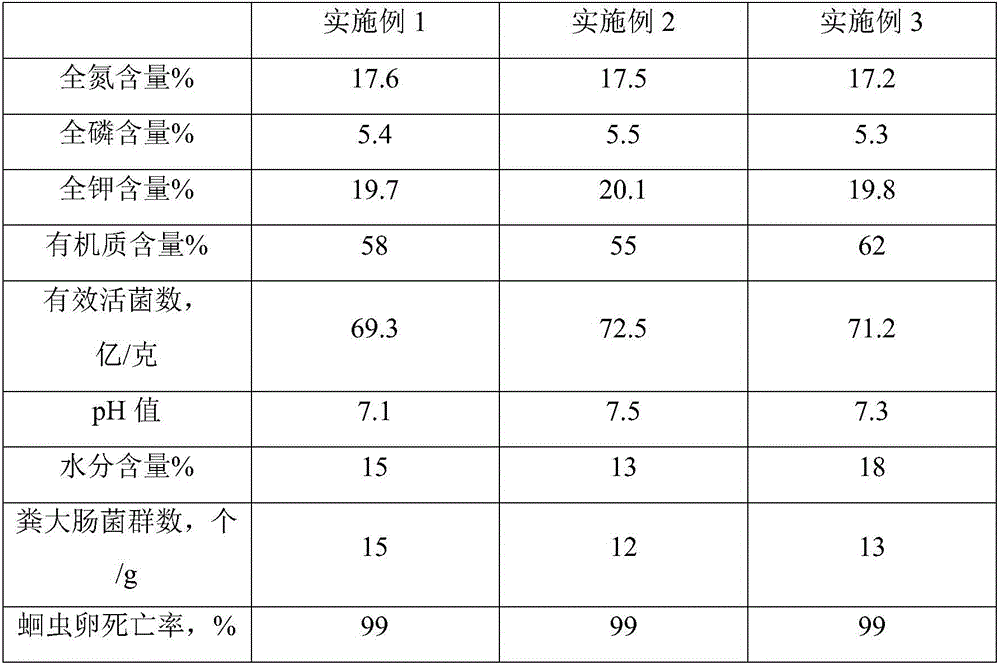

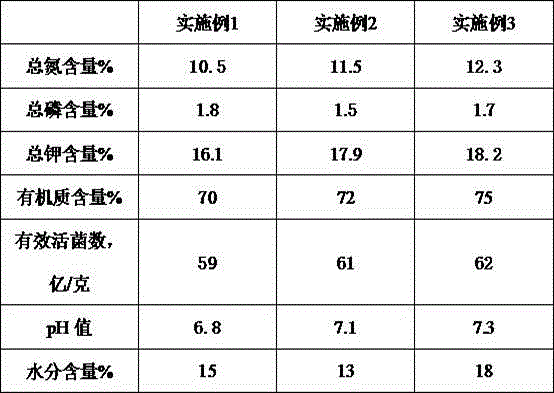

Biological organic fertilizer and preparation method thereof

The invention relates to a biological organic fertilizer and a preparation method thereof. The organic fertilizer is prepared from the following raw materials in parts by weight: (1) 50-80 parts of dewatered sludge, (2) 10-50 parts of protein waste slag, (3) 0-10 parts of urea, (4) 0-10 parts of activated carbon and (5) 0.2-1 part of functional strain microbial inoculum. The preparation method comprises the following steps: (1) preparing a functional strain; (2) fermenting the raw materials; and (3) performing post treatment. According to the invention, the problem of secondary environmental pollution caused by sludge generated in the mycelium CSTR (continuous stirred tank reactor) anaerobic fermentation, organic acid waste water EGSB (expanded granular sludge bed) anaerobic fermentation and aerobic treatment process and protein waste slag generated by organic acid factory microbial fermentation is solved; the waste is changed into valuable substances, thereby meeting the related requirements of circular economy; and the indices of the prepared biological organic fertilizer, such as the organic content, the active viable count and the like, meet the requirements of related industrial standards. Besides, the preparation method provided by the invention is simple and has the advantages of no discharge of three wastes, low investment, quick action and low cost.

Owner:QINGDAO RUIMIN RESOURCE COMPREHENSIVE UTILIZATIONCO

A wear-resistant liner used in grinding operations to produce alumina

An abrasion-resisting lining plate for producing aluminum oxide in ore grinding operation comprises a steel lining plate and an abrasion-resisting rubber lining plate arranged on the inner wall face of the steel lining plate. A plurality of counter bores are distributed in the inner wall face of the steel lining plate so that when abrasion-resisting rubber materials is pressed into the abrasion-resisting rubber lining plate on the inner wall face of the abrasion-resisting rubber lining plate, part of abrasion-resisting rubber materials enter the counter bores to form connection bolt columns toachieve connection between the steel lining plate and the abrasion-resisting rubber lining plate. According to the abrasion-resisting lining plate, due to the fact that the abrasion-resisting rubberlining plate is arranged on the surface of the steel lining plate, the abrasion-resisting rubber lining plate plays a role in protecting the steel lining plate when a grinding body and ores directly impact the abrasion-resisting rubber lining plate, the abrasion-resisting rubber lining plate is easy to change after being damaged, and the service life of the steel lining plate is greatly prolonged.

Owner:平顶山京钰实业有限公司

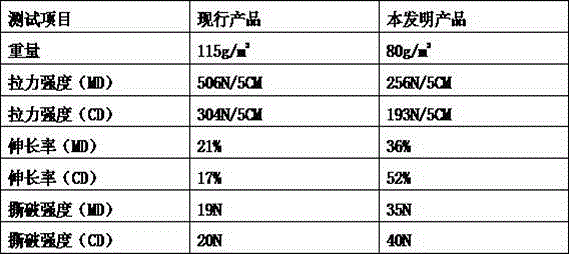

High-strength and low-stretch non-woven fabric for car seats and its manufacturing method

ActiveCN104149423BHigh tear strengthImprove skid resistanceSynthetic resin layered productsLaminationCar seatNonwoven fabric

The invention provides a high-strength and low-stretch non-woven fabric for car seats, comprising two layers of PET staple fiber needle-punched non-woven fabric layers, and the PET staple fiber needle-punched non-woven fabric layers are PET staple fiber needle-punched non-woven fabric layers respectively Woven fabric layer one and PET staple fiber needle-punched nonwoven fabric layer two, PET staple fiber spunbond nonwoven fabric layer between the PET staple fiber needle-punched nonwoven fabric layer one and PET staple fiber needle-punched nonwoven fabric layer two The cloth layer, the PET staple fiber needle-punched non-woven fabric layer one and the PET staple fiber needle-punched non-woven fabric layer two are short fiber layers formed by mixing L-PET and PET. The invention also provides its preparation method. The invention uses three layers of non-woven fabrics with different structures and different processes to combine long and short fibers, the fiber direction is disordered, there is no distinction between warp and weft, the difference in longitudinal and transverse tensile force and elongation of the product is small, and the tear strength is greatly improved.

Owner:昆山同昌汽车新材料有限公司

Seaweed biomass plate, its processing method and special mold

The invention relates to a seaweed biomass plate, and provides a natural, degradable and high-strength seaweed biomass plate which is to solve the problems that the biomass plate in the prior art has low strength, and the added additives are difficult to degrade and unsafe. The seaweed biomass plate is produced by the following steps: taking seaweed as a raw material, crushing, hot-pressing and molding and drying the raw material to produce the seaweed biomass plate, wherein the main ingredients comprise seaweed plant cellulose, hemicellulose and pectin substances. The invention also provides a processing method of the seaweed biomass plate, which comprises procedures of crushing, hot-pressing molding and drying, and a special mold comprising a pressing plate with a water filtering hole and a groove body. The seaweed biomass plate provided by the invention has the characteristics of high strength, compact structure and degradation; and the plate is natural, nontoxic and safe.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com