Production method of high-strength corrugated base paper

A technology of corrugated base paper and production method, which is applied in the direction of papermaking, papermaking machines, textiles and papermaking, etc. It can solve the problems of ineffective utilization and waste of resources, and achieve the effects of less foam, saving resources and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for producing high-strength corrugated base paper, comprising the steps of:

[0051] Step 1: waste paper pulping treatment, the obtained pulp is stored for later use; the specific processing steps are to process 1100kg of domestic waste paper through a bulk bag machine to remove impurities; Slurry, the coarse pulp, slag, and plastic are discharged, and the slurry is transported to the drum slurry storage tank through the discharge pump; the slurry in the drum slurry storage tank is transported to the high-consistency slag remover for treatment, and the high-concentration slag remover is removed. The pulp is collected to the pulp storage tank for subsequent use, and the mass concentration of the pulp in the pulp storage tank is 4.1%;

[0052] Step 2: The pulp in step 1 is subjected to a screening process, and the good stock obtained from the primary screening process is classified to obtain long fibers and short fibers; the specific step of the primary screening...

Embodiment 2

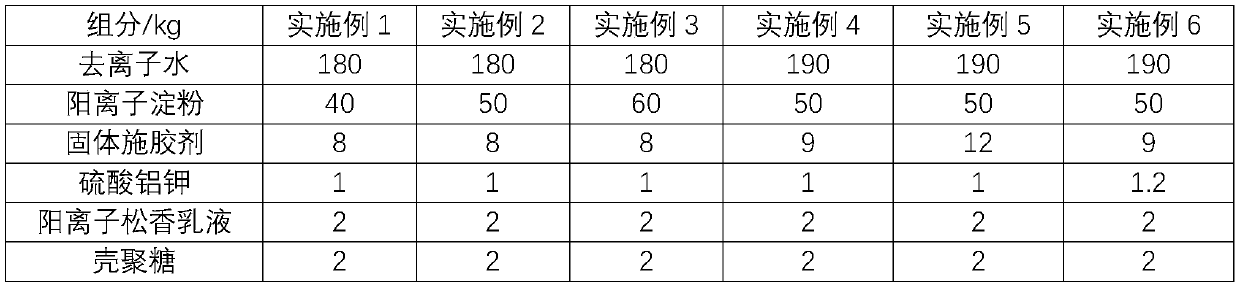

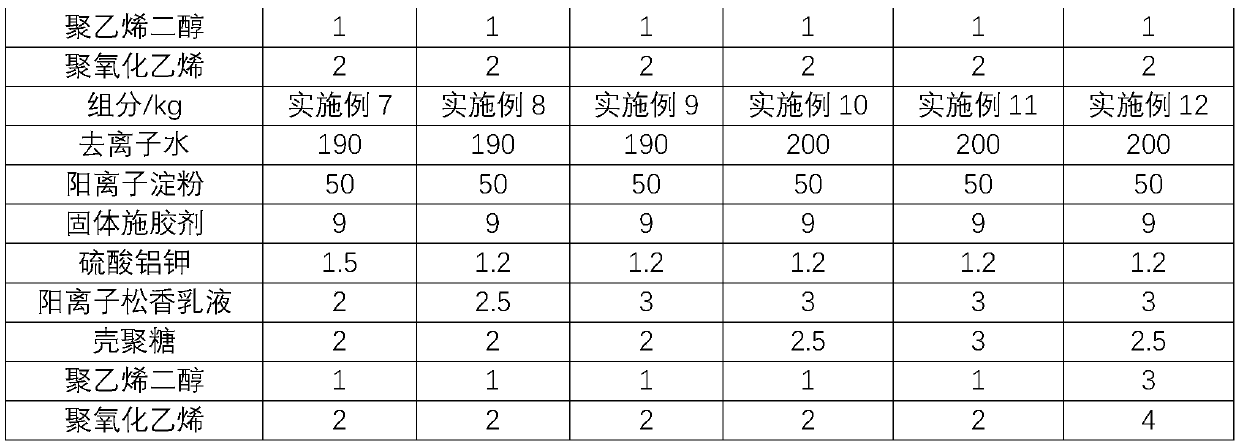

[0066] The difference between Example 2 and Example 1 lies in the content of the sizing agent.

Embodiment 3

[0068] The difference between embodiment 3 and embodiment 1 lies in the content of sizing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com