Cement fiber melamine laminated board and manufacturing method thereof

A technology of cement fiber and melamine, applied in the direction of chemical instruments and methods, layered products of hydraulic substances, layered products, etc., can solve problems affecting the quality of veneers, surface film water separation, and environmental protection failures, etc., to achieve Light weight, long durability, good moisture-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

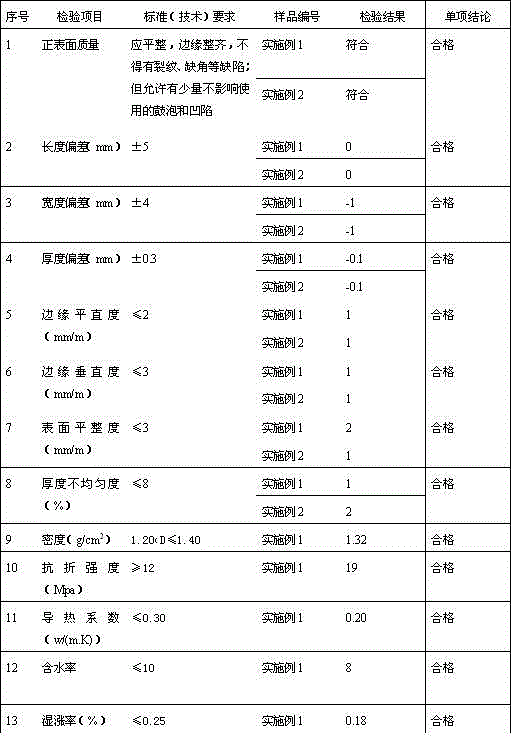

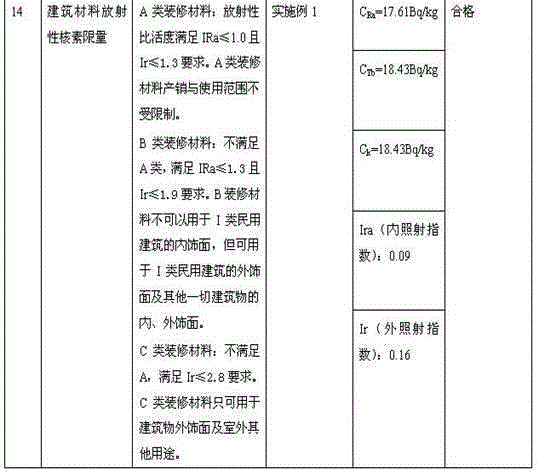

[0022] The preparation process of the cement fiber melamine veneer panel of the present invention is as follows: (1) take the cement fiber substrate, and sand the surface smooth (industry conventional sand light treatment process); (2) process the cement after step (1) surface sand smooth Fiber substrate, the surface is hot-pressed with a layer of melamine-impregnated paper veneer at high temperature; the hot-pressing pressure is 1,200 tons, the hot-pressing time is 50 seconds, and the hot-pressing temperature is 170°C.

Embodiment 2

[0024] The preparation process of the cement fiber melamine laminated panel of the present invention is as follows: (1) take the cement fiber substrate, and sand the surface to make it smooth; One layer of melamine-impregnated paper veneer; hot-pressing pressure of 1,000 tons, hot-pressing time of 50 seconds, and hot-pressing temperature of 175°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com