Seaweed biomass plate, its processing method and special mold

A processing method and biomass technology, applied in the direction of fiberboard, textiles, papermaking, papermaking, etc., can solve the problems of complex production process of biomass boards, decreased degradability of boards, hazards to human health, etc., to achieve compact structure and reduce deformation , the effect of increasing the load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

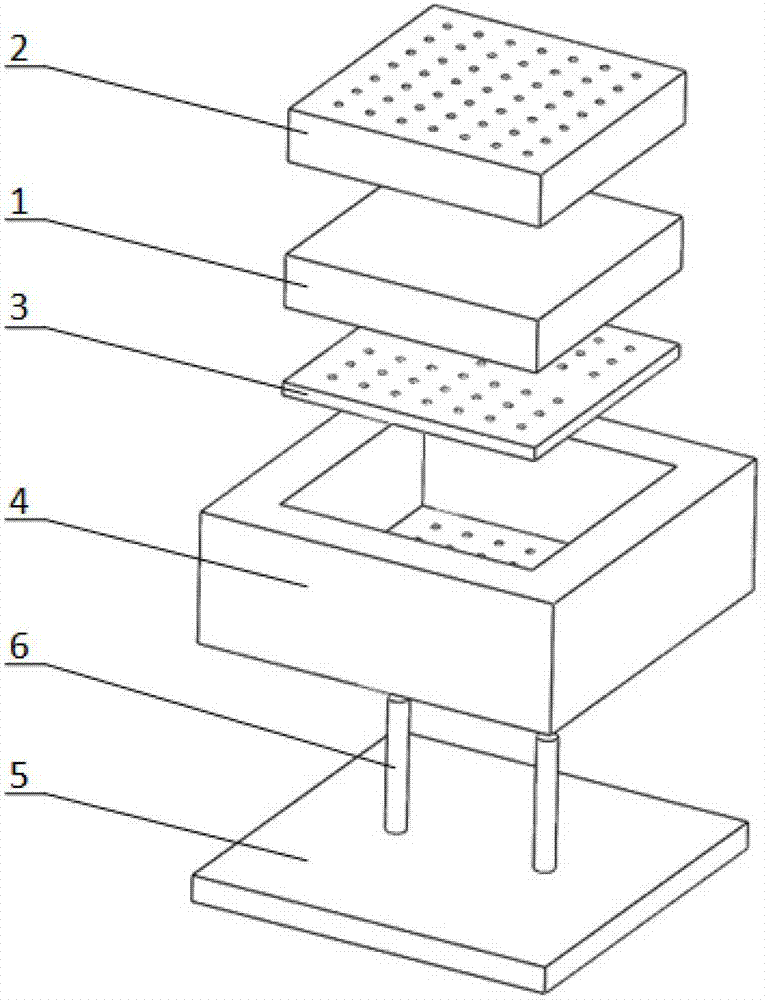

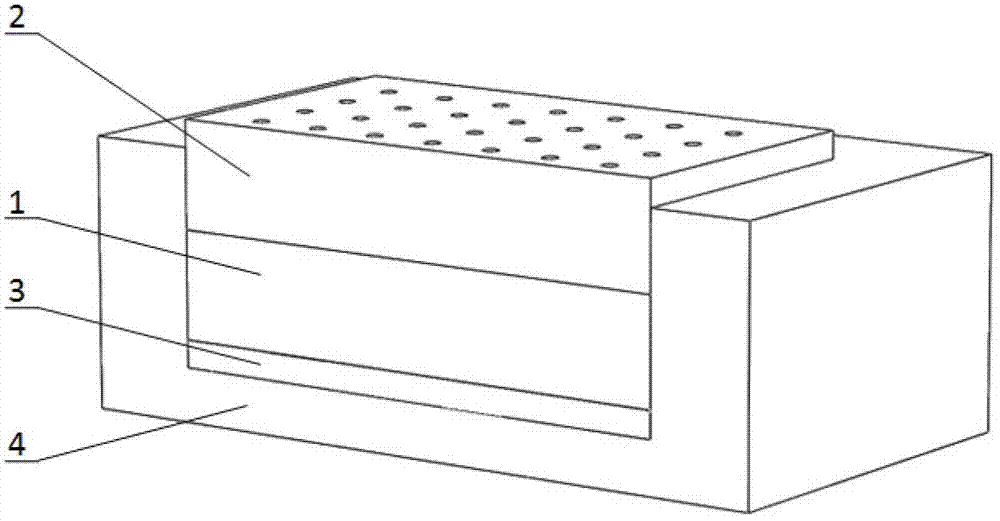

[0031] Special molds are required to make seaweed biomass panels. The special mold is made of aluminum alloy, the structure is as follows figure 2 As shown, it includes a pressing plate 2, a groove body 4 and a demoulding device. The demoulding device consists of a base 5, two push rods 6 vertically fixed on the base 5 and a movable plate 3, wherein the pressing plate 2, the movable plate 3 and the concave The bottom of the tank body 4 is provided with some seepage holes 8 ( Figure 5 shown), in order to cooperate with the demoulding device, the groove body 4 is provided with through holes 7 corresponding to the positions of the two push rods 6 .

[0032] The method of using this special mold to make Ulva pore biomass plates is as follows:

[0033] (1) Raw material pretreatment: salvage Ulva ulva from ashore, wash it with tap water, and rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fracture strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com