sPS (syndiotactic polystyrene) film for FPC (Flexible Printed Circuit) industry and preparation method thereof

A technology of adhesive film and viscose resin, which is applied in the direction of adhesives, film/sheet adhesives, polyether adhesives, etc., can solve the problems of high brittleness and limit the application field of sPS, and achieve strong polarity and good Abrasion resistance, enhanced overall performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

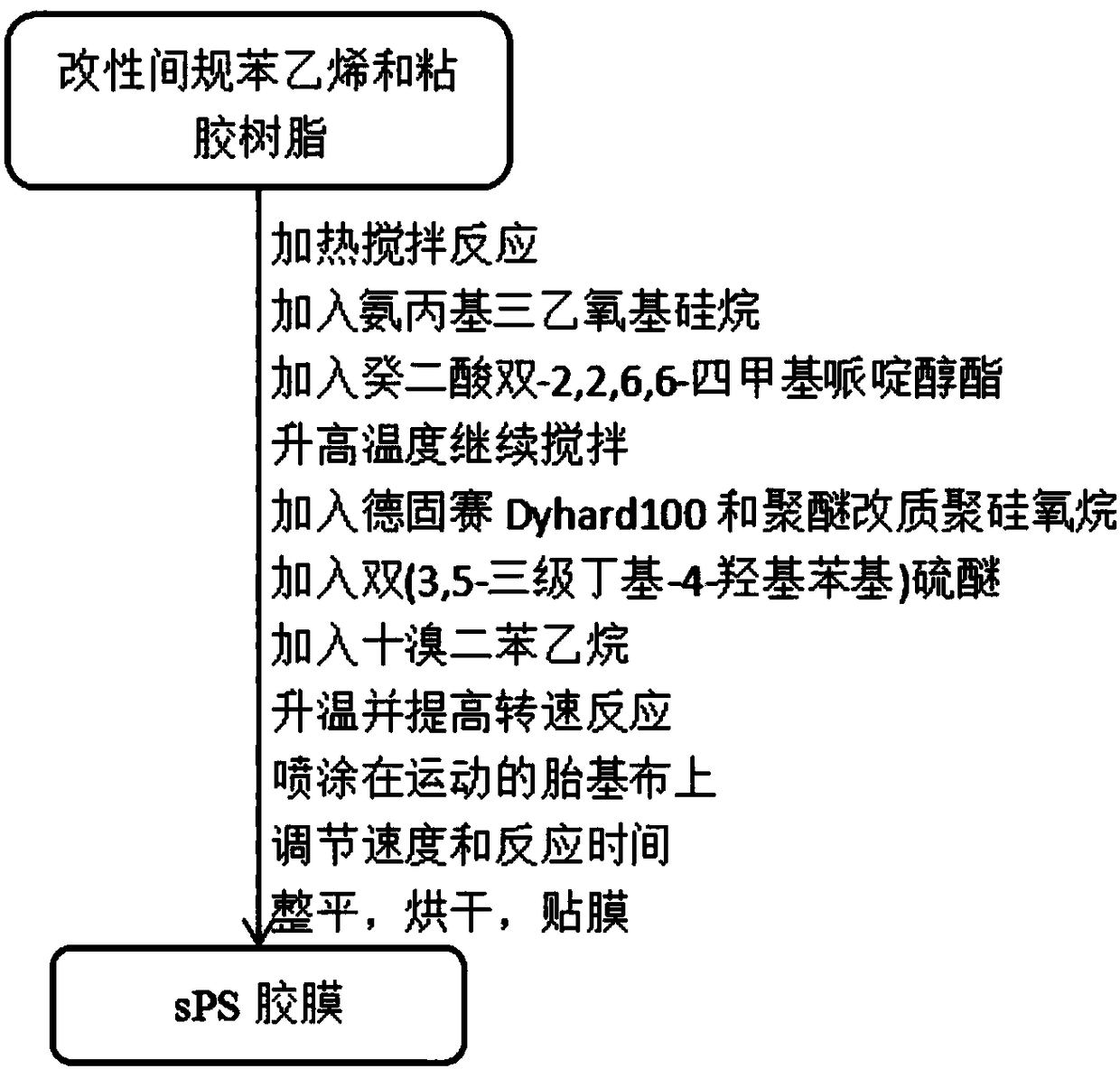

Method used

Image

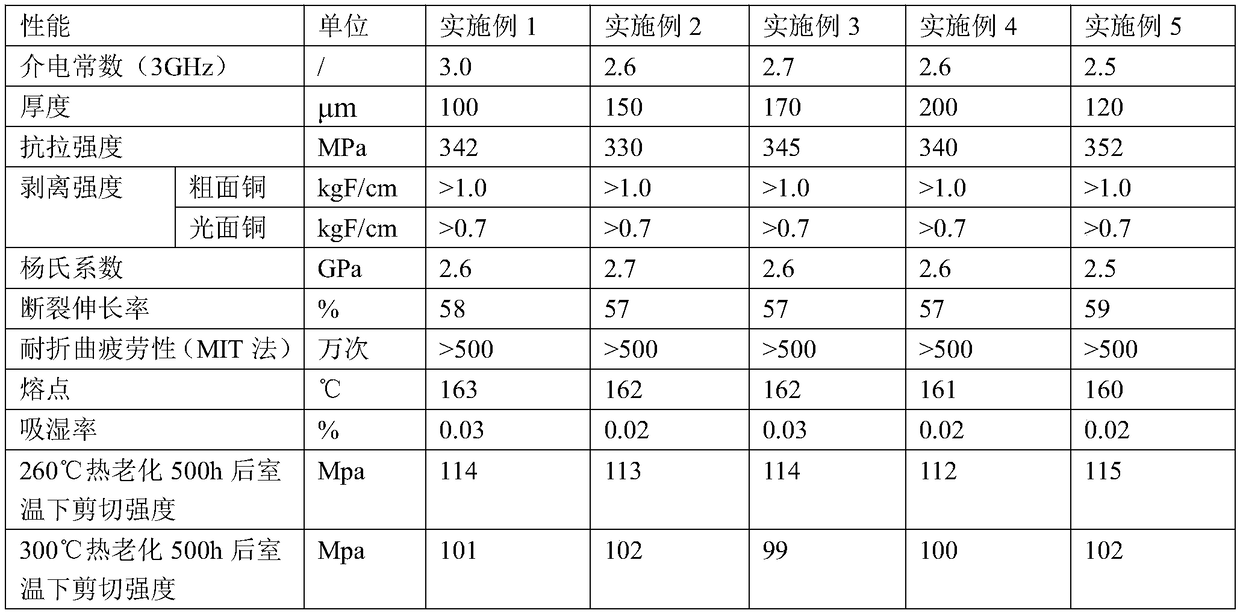

Examples

Embodiment 1

[0025] The preparation of embodiment 1 sPS film

[0026] Composition of raw materials (parts by weight): 100 parts of modified syndiotactic styrene, 60 parts of phenoxy resin, 10010 parts of Degussa Dyhard, 5 parts of polyether modified polysiloxane, bis(3,5-tertiary butyl -4-hydroxyphenyl)sulfide 5 parts, decabromodiphenylethane 1-4 parts, bis-2,2,6,6-tetramethylpiperidinol sebacate 1 part and aminopropyl tris 1 part of ethoxysilane;

[0027] The preparation method of modified syndiotactic styrene is as follows:

[0028] (1) Adopt improved Hummers method to prepare graphene oxide:

[0029] Step 1. Weigh 10g of natural graphite powder, 4g of potassium persulfate, and 10g of phosphorus pentoxide, and add them into a three-necked flask filled with 24mL of sulfuric acid while stirring, and react in a constant temperature water bath at 60°C for 3h, and then Move the three-necked flask into a constant temperature water bath at 25°C to react for 5 hours, filter it with suction, w...

Embodiment 2

[0034] The preparation of embodiment 2 sPS film

[0035] Composition of raw materials (parts by weight): 120 parts of modified syndiotactic styrene, 80 parts of bisphenol epoxy resin, 10015 parts of Degussa Dyhard, 10 parts of polyether modified polysiloxane, bis(3,5-tertiary 10 parts of butyl-4-hydroxyphenyl) sulfide, 4 parts of decabromodiphenylethane, 3 parts of bis-2,2,6,6-tetramethylpiperidinol sebacate and aminopropyl tris 3 parts of ethoxysilane;

[0036] The preparation method of modified syndiotactic styrene is as follows:

[0037] (1) Graphene oxide was prepared by the improved Hummers method; 1 g of graphene oxide was dissolved in 100 mL of deionized water, 2 mL of concentrated sulfuric acid was added, and an excess of 2 mol / L aqueous solution of twelve amino acids was added dropwise under vigorous stirring at 80 ° C. After adding, keep the temperature for 3 hours, filter with suction, wash with water until neutral, and dry in vacuum at 70C to constant weight to o...

Embodiment 3

[0040] The preparation of embodiment 3 sPS film

[0041] Composition of raw materials (parts by weight): 105 parts of modified syndiotactic styrene, 65 parts of acrylate resin, 10012 parts of Degussa Dyhard, 6 parts of polyether modified polysiloxane, bis(3,5-tertiary butyl- 7 parts of 4-hydroxyphenyl)sulfide, 2 parts of decabromodiphenylethane, 2 parts of bis-2,2,6,6-tetramethylpiperidinol sebacate and aminopropyltriethoxy 1 part of silane;

[0042] The preparation method of modified syndiotactic styrene is as follows:

[0043] (1) Graphene oxide was prepared by the improved Hummers method; 1 g of graphene oxide was dissolved in 100 mL of deionized water, 2 mL of concentrated sulfuric acid was added, and an excess of 2 mol / L aqueous solution of twelve amino acids was added dropwise under vigorous stirring at 80 ° C. After adding, keep the temperature for 3 hours, filter with suction, wash with water until neutral, and dry in vacuum at 70C to constant weight to obtain sulfon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com