A wear-resistant liner used in grinding operations to produce alumina

A technology for production and wear-resistant linings, applied in the field of wear-resistant linings, can solve problems such as short service life of steel linings, and achieve the effects of prolonging service life, increasing compatibility, and improving fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Further, the preparation method of described composite epoxy resin comprises the following steps:

[0043] 1) Prepare modified nano-silica and modified silica sol respectively for later use;

[0044] The modified nano-silica is obtained by mixing commercially available nano-silica and a surface modifier of 3-5% by weight thereof, and the surface modifier is composed of KH550, ethanol, acetone and barium hydroxide in a weight ratio of 3-4 :80:2-3:1-2 ratio mixed;

[0045] The modified silica sol is obtained by sequentially adding 2-3% silica sol weight silica powder, 1-2% silica sol weight potassium hexatitanate whiskers and 0.8-1% silica sol weight acetic acid to commercially available silica sol. sodium, and then stirred the resulting mixture at 70-80°C for 1-2h;

[0046] 2) Weigh each component according to the stated ratio, then melt the novolac epoxy resin, add the weighed polybutadiene epoxy resin and diisocyanate to it, stir until it is completely melted, and th...

Embodiment 1

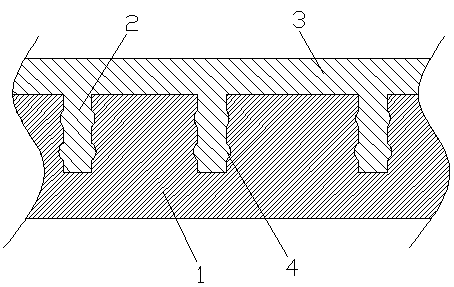

[0055] Such as figure 1 As shown, a wear-resistant liner used in grinding operations to produce alumina includes a steel liner 1 and a wear-resistant rubber liner 3 arranged on its inner wall surface, and the inner wall surface of the steel liner 1 is distributed There are several countersunk holes, so that when the wear-resistant rubber material is pressed on the inner wall surface of the wear-resistant rubber liner 3 to form the wear-resistant rubber liner 3, a part of the wear-resistant rubber material enters into the counterbore to form the connecting bolt 2, realizing the steel lining Plate 1 is connected with the wear-resistant rubber liner 3; according to the weight ratio, the wear-resistant rubber material consists of 180 parts of polyurethane rubber, 120 parts of natural rubber, 60 parts of nitrile rubber, 3 parts of vulcanizing agent, 30 parts additives, 14 parts of composite fiber and 25 parts of wear-resistant admixture, among which the additives are carbon black, ...

Embodiment 2

[0073] Such as figure 1 As shown, a wear-resistant liner used in grinding operations to produce alumina includes a steel liner 1 and a wear-resistant rubber liner 3 arranged on its inner wall surface, and the inner wall surface of the steel liner 1 is distributed There are several countersunk holes, so that when the wear-resistant rubber material is pressed on the inner wall surface of the wear-resistant rubber liner 3 to form the wear-resistant rubber liner 3, a part of the wear-resistant rubber material enters into the counterbore to form the connecting bolt 2, realizing the steel lining Plate 1 is connected with the wear-resistant rubber liner 3; according to the weight ratio, the wear-resistant rubber material consists of 220 parts of polyurethane rubber, 140 parts of natural rubber, 80 parts of nitrile rubber, 5 parts of vulcanizing agent, 40 parts additives, 18 parts of composite fibers and 30 parts of wear-resistant admixtures, among which the additives are carbon black...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com