High-strength concrete plate and preparation method thereof

A high-strength concrete and plate technology, applied in the field of building materials, can solve problems such as plate damage, safety production accidents, and crushing, and achieve the effects of improving concrete strength, reducing cement consumption, and improving compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

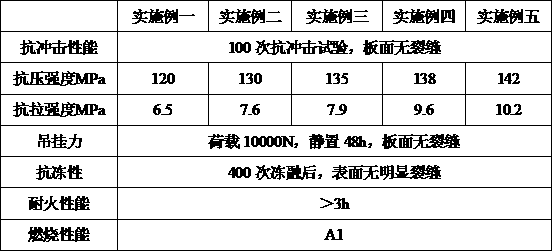

Examples

Embodiment approach 1

[0028] This embodiment provides a high-strength concrete slab, which consists of the following parts by mass: 100 parts of cement, 100 parts of limestone powder, 100 parts of slag powder, 700 parts of high-strength internal curing aggregate with 10% water content and a particle size of less than 1mm, water-reducing 5 parts of agent, 6 parts of starch glue, 18 parts of silica sol, 6 parts of pure acrylic emulsion, 75 parts of water, and 10 parts of PVA fiber.

[0029] The specific preparation steps of the above-mentioned high-strength concrete slab are as follows:

[0030] 1) Stir starch glue, silica sol, pure acrylic emulsion, water reducer and water in proportion;

[0031] 2) Mix cement, limestone powder, slag powder, internal curing aggregate and PVA fiber in proportion, and add the mixed liquid in step 1) into it in the form of spray evenly during the stirring process, and the spray rate is 10 g / s;

[0032] 3) Pour the obtained mixed material into the mold, and use a pre...

Embodiment approach 2

[0035] This embodiment provides a high-strength concrete slab, which consists of the following parts by mass: 150 parts of cement, 300 parts of limestone powder, 50 parts of mineral powder, 1500 parts of high-strength internal curing aggregate with 30% water content, 15 parts of water reducing agent, 10 parts of starch glue, 30 parts of silica sol, 10 parts of pure acrylic emulsion, 30 parts of water, 5 parts of PVA fiber.

[0036] The specific preparation steps of the above-mentioned high-strength concrete slab are as follows:

[0037] 1) Stir starch glue, silica sol, pure acrylic emulsion, water reducer and water in proportion;

[0038] 2) Stir the cement, limestone powder, slag powder, internal curing aggregate and PVA fiber evenly in proportion, and add the mixed liquid in step 1) into it in the form of spray evenly during the stirring process, and the spray rate is 50 g / s;

[0039] 3) Pour the obtained mixed material into the mold, and use a press to vacuum compact the...

Embodiment approach 3

[0043] This embodiment provides a high-strength concrete slab, which consists of the following parts by mass: 100 parts of cement, 250 parts of limestone powder, 150 parts of mineral powder, 900 parts of high-strength internal curing aggregate with 15% water content, 10 parts of water reducing agent, 8 parts of starch glue, 24 parts of silica sol, 8 parts of pure acrylic emulsion, 50 parts of water, 10 parts of PVA fiber.

[0044] The specific preparation steps of the above-mentioned high-strength concrete slab are as follows:

[0045] 1) Stir starch glue, silica sol, pure acrylic emulsion, water reducer and water in proportion;

[0046] 2) Stir the cement, limestone powder, slag powder, internal curing aggregate and PVA fiber in proportion, and add the mixed liquid in step 1) into it in the form of spray evenly during the stirring process, and the spray rate is 30 g / s;

[0047] 3) Pour the obtained mixed material into the mold, and use a press to vacuum compact the above m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com