Automobile leaf spring free quenching technology

A technology of automobile plate and freedom, which is applied in the direction of quenching agent, quenching device, manufacturing tools, etc., can solve the problems of affecting the quality of leaf spring, unscientific coordination of contact cooling speed, hardenability and hardness of leaf spring cannot be consistent, etc. , to achieve efficient production and improve the effect of quenching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

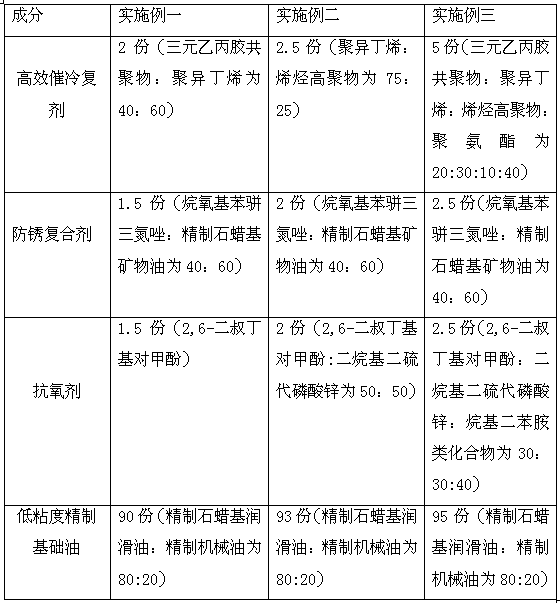

[0031] A kind of automobile leaf spring free quenching process of the present invention comprises the following steps:

[0032] (1) Heat the reed to 860°C to 920°C in a step-by-step quenching furnace, and keep it warm for 20-25min;

[0033] (2) The reeds are sorted out according to the length of ≤700mm, 700-900mm, 900-1300mm, and ≥1300mm;

[0034] (3) After the reed is moved to the forming platform by the robot, it is formed by chain-type pressing;

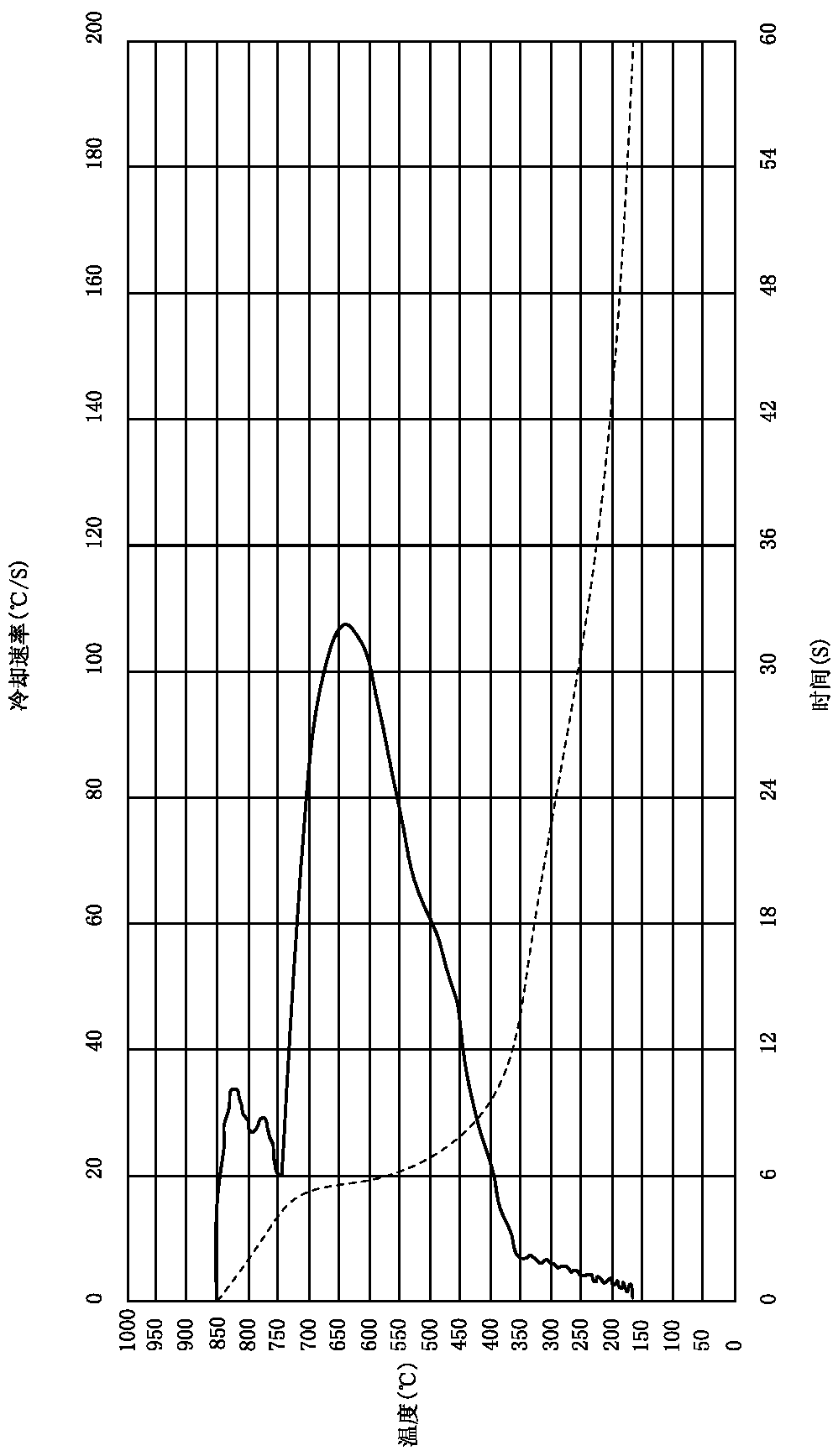

[0035] (4) Set rapid quenching oil in the quenching oil tank, and the reed is directly sent into the quenching oil tank in a free state by the forming platform, and the temperature of the reed when entering the oil tank is 840°C to 860°C. Set circulation device, stirring device and Venturi nozzle in the oil tank, so that the rapid quenching oil can quickly wash the reed at a flow rate of 0.5-0.7m / s, so that the reed can cool the reed to below 400°C within 10 seconds. To achieve the purpose of free quenching.

[0036] Described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com