Adhesive high-surface-tension glass-fiber-reinforced PA6/ABS (polyamide 6/acrylonitrile-butadiene-styrene) composite material and preparation method thereof

A composite material and surface tension technology, applied in the field of glass fiber reinforced PA6/ABS composite material and its preparation, can be viscose high surface tension glass fiber reinforced PA6/ABS composite material and its preparation field, which can solve the problem of inappropriate glass fiber reinforcement PA6/ABS composite materials and other problems, to achieve the effect of improving processing rheology, easy control of process parameters, and strong viscose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

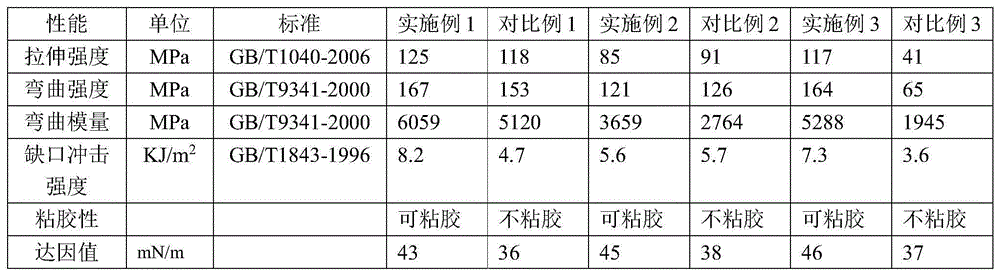

Embodiment 1

[0033]In the present embodiment, PA6 is that intrinsic viscosity is 2.4, and the PA6 resin that terminal amino content is 55Meq / Kg, and glass fiber is alkali-free glass fiber, and ABS is the butadiene content 16%, and melt index is the ABS resin of 12g / 10min, The PA6 / ABS alloy grafted compatibilizer is acrylonitrile-butadiene-styrene copolymer grafted maleic anhydride (ABS-MAH), the surface tension modifier is hydroxyl-terminated nitrile rubber, and the lubricant is silicone , the antioxidant is N,N-bis[β(3,5-di-tert-butyl-4-hydroxyphenyl) propionyl]-1,6-hexanediamine and tris(2,4-di-tert-butyl Phenol) phosphite is mixed at a mass ratio of 1:1.

[0034] In this implementation, the preparation method of adhesive high surface tension glass fiber reinforced PA6 / ABS composite material is as follows:

[0035] Weigh each component according to the following parts by weight: 10 parts of PA6 resin, 30 parts of glass fiber, 46 parts of ABS, 3 parts of grafted compatibilizer, 10 parts ...

Embodiment 2

[0038] In the present embodiment, PA6 is that intrinsic viscosity is 3.0, and the PA6 resin that terminal amino content is 38Meq / Kg, and glass fiber is alkali-free glass fiber, and ABS is the butadiene content 52%, and the ABS resin that melting index is 2.6g / 10min , PA6 / ABS alloy grafted compatibilizer is styrene-acrylonitrile copolymer grafted maleic anhydride (SMA-800), surface tension modifier is N, N-dihydroxyethyl long-chain fatty acid amide, lubricating The agent is silicone, and the antioxidant is N,N-bis[β(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]-1,6-hexanediamine and tris(2,4- Di-tert-butylphenol) phosphite is mixed at a mass ratio of 1:1.

[0039] In this implementation, the preparation method of adhesive high surface tension glass fiber reinforced PA6 / ABS composite material is as follows:

[0040] Weigh each component according to the following parts by weight: 45 parts of PA6 resin, 5 parts of glass fiber, 36 parts of ABS, 8 parts of grafted compatibilizer, 5...

Embodiment 3

[0043] In the present embodiment, PA6 is the PA6 resin that intrinsic viscosity is 2.8, and the terminal amino content is 45Meq / Kg, and glass fiber is alkali-free glass fiber, and ABS is butadiene content 24%, and melting index is the methyl alcohol of 4.5g / 10min. Methyl acrylate-butadiene-styrene terpolymer, PA6 / ABS alloy grafted compatibilizer is acrylonitrile-styrene-glycidyl methacrylate copolymer, surface tension modifier is hydroxybutyronitrile The compound of rubber and polyacrylonitrile with a mass ratio of 1:1, the lubricant is modified ethylene bis fatty acid amide, and the antioxidant is N,N-bis[β(3,5-di-tert-butyl-4 -Hydroxyphenyl)propionyl]-1,6-hexanediamine mixed with tris(2,4-di-tert-butylphenol)phosphite at a mass ratio of 1:1.

[0044] In this implementation, the preparation method of adhesive high surface tension glass fiber reinforced PA6 / ABS composite material is as follows:

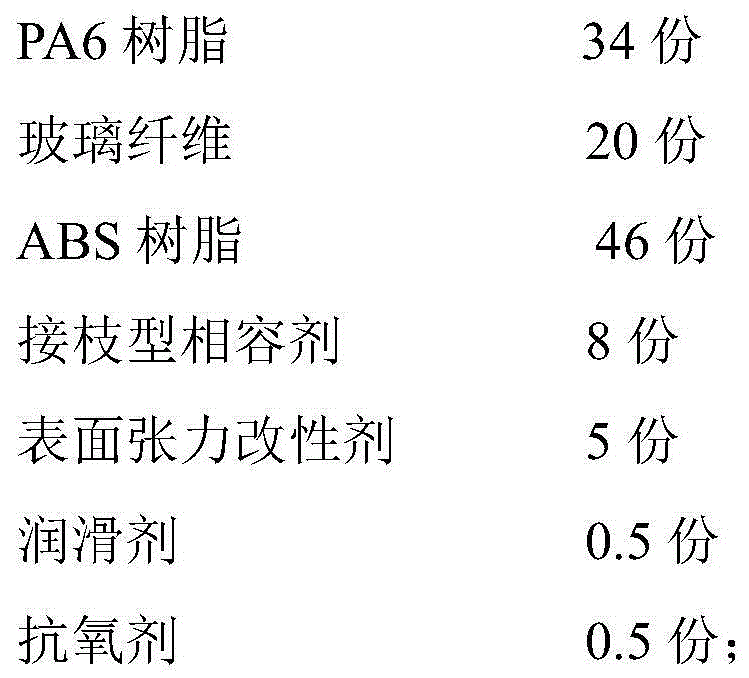

[0045] Weigh each component according to the following parts by weight: 34 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com