Fly ash-based dredger fill solidification reinforcing agent

A technology of dredger fill and reinforcement, which is applied in the field of dredger fill solidification enhancer, which can solve problems such as insufficient bearing capacity of dredger fill foundations, and achieve the effects of alleviating environmental problems, excellent durability, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

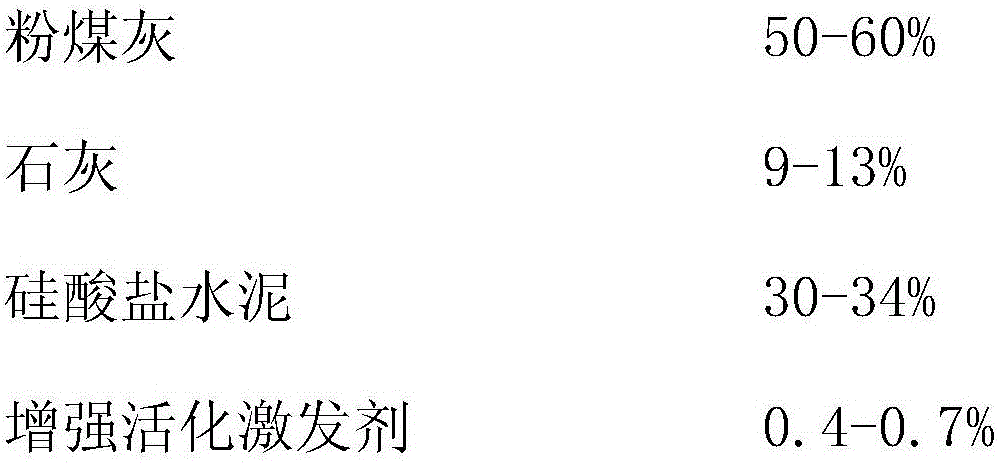

[0018] A dredger fill soil solidification reinforcing agent, which is composed of the following raw materials in mass percentage

[0019] 54% of fly ash, 10.45% of lime, 35% of Portland cement, and 0.55% of enhanced activation activator.

[0020] Wherein: the enhanced activation stimulating agent is composed of 65% of lignin, 12% of natural high molecular polymer, 20% of amide organic matter and 3% of sodium salt. Portland cement is ordinary Portland cement.

[0021] The natural high molecular polymer is cellulose, and the organic amide is N,N-dimethylformamide.

[0022] The powders of the above-mentioned various materials are uniformly mixed in proportion, and the specific surface area of the particle size of the powder is 250-800㎡ / kg. During the storage and transportation of the mixture, strict attention should be paid to moisture-proof measures to prevent rain and water immersion.

Embodiment 2

[0024] A dredger fill soil solidification reinforcing agent, which is composed of the following raw materials in mass percentage

[0025] 55% of fly ash, 10.45% of lime, 34% of Portland cement, and 0.55% of enhanced activation activator.

[0026] Wherein: the enhanced activation stimulating agent is composed of 65% of lignin, 12% of natural high molecular polymer, 20% of amide organic matter and 3% of sodium salt. Portland cement is ordinary Portland cement.

[0027] The natural high molecular polymer is sodium lignosulfonate, and the amide organic matter is benzamide.

[0028] Mix the powders of the above-mentioned various materials uniformly in proportion. During the storage and transportation of the mixture, strict attention should be paid to moisture-proof measures to prevent rain and water immersion.

Embodiment 3

[0030] A dredger fill soil solidification reinforcing agent, which is composed of the following raw materials in mass percentage

[0031] 57% of fly ash, 10.45% of lime, 32% of Portland cement, and 0.55% of enhanced activation activator.

[0032] Wherein: the enhanced activation stimulating agent is composed of 55% of lignin, 12% of sodium lignosulfonate, 30% of acrylamide and 3% of sodium salt. Portland cement is ordinary Portland cement.

[0033] The natural high molecular polymer is sodium lignosulfonate, and the organic amide is acrylamide.

[0034] Mix the powders of the above-mentioned various materials uniformly in proportion. During the storage and transportation of the mixture, strict attention should be paid to moisture-proof measures to prevent rain and water immersion.

[0035] The dredging fill solidifying agent provided by the present invention, its use method is as follows: according to the soil condition of actual engineering situation, on-the-spot dredging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com