Composite steel roller

A composite steel and roll body technology, applied in the field of composite steel rolls, can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

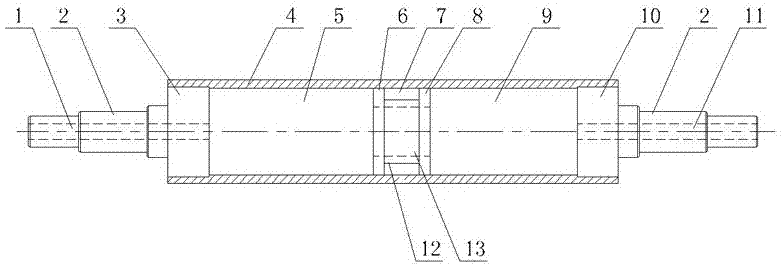

[0010] As shown in the figure, the composite steel roll of the present invention includes a roll body 4, the roll body 4 is a hollow tube, the two ends of the roll body 4 are fixedly provided with a left end cover 3 and a right end cover 10, and the outer end faces of the left and right end covers are fixedly connected to the left and right sides. The roller shaft 2, the inner hole of the roller body 4 is provided with a left partition 6 and a right partition 8 in the middle position, and a middle closed cavity 7 is formed between the left and right partitions, and the left partition 6 and the left end cover 3 The left closed cavity 5 is surrounded, and the right closed cavity 9 is surrounded between the right partition 8 and the right end cover 10. The left and right closed cavities communicate through the tube hole 13, and the tube sleeve 12 with the tube hole 13 is closed from the middle. The middle of the body 7 runs through and its two ends are respectively fixed on the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com