Inorganic fullerene molybdenum disulfide/graphene composite lubricant and preparation method thereof

A fullerene molybdenum disulfide and graphene composite technology, applied in lubricating compositions, petroleum industry, base materials, etc., can solve problems such as differences in structure and preparation method, and achieve extended lubrication effective time, good effect, and preparation method. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

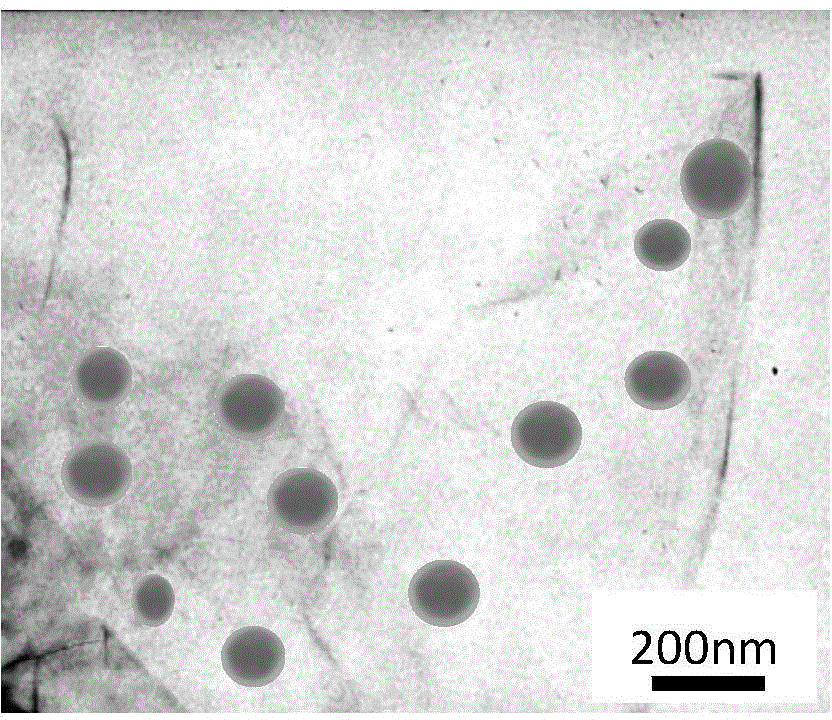

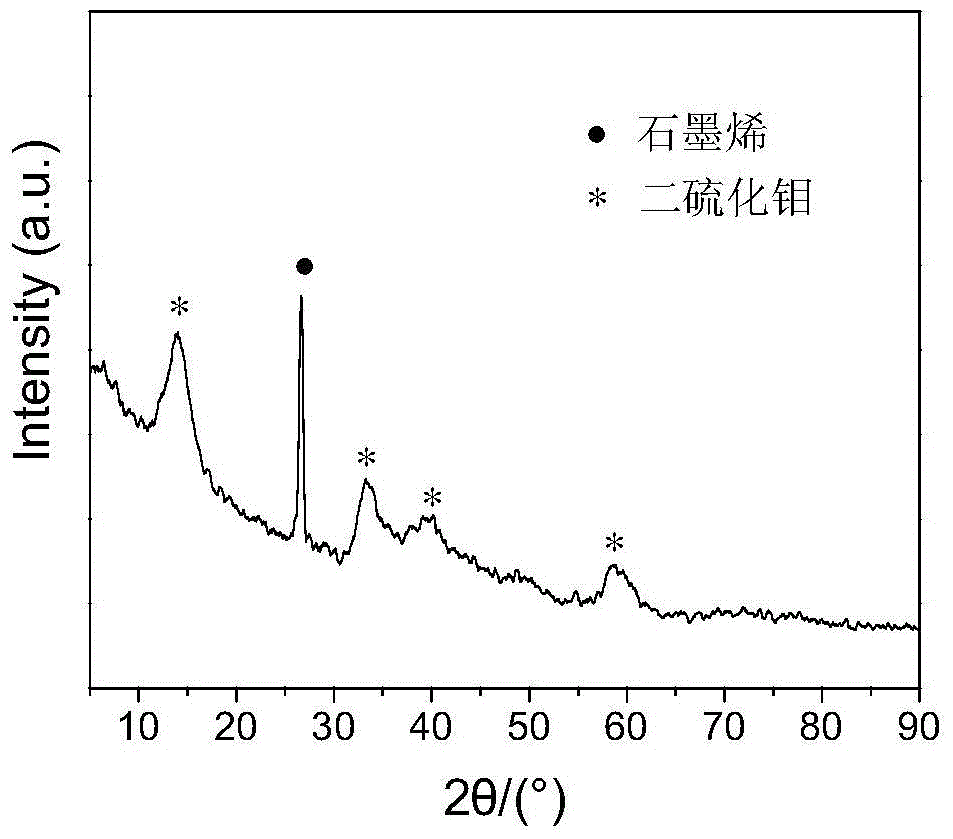

[0025] 1 part of graphene (single-layer graphene accounts for 95%, specific surface area 3800m 2 / g) adding 2000 parts of glycerol-water (mass ratio 1:5) mixed solvent containing 2% tetradecyltrimethylammonium bromide in mass concentration, adjusting system pH=2 with hydrochloric acid, and ultrasonically dispersing for 10 min; In the ice-bath ultrasonic state, add 12 parts of magnesium molybdate, 108 parts of sodium sulfide, and 5 parts of thioacetamide to the solution in sequence, and then move the system to a pressure-resistant reactor. After the system is sealed, replace the upper atmosphere with 0.2 MPa hydrogen gas, control the temperature rise rate of the reactor to 20°C / min, rise to the system temperature of 420°C, keep it warm for 1.2h, cool down, release the pressure, filter the system to obtain a black solid, rinse it with deionized water, and dry it, that is Inorganic fullerene molybdenum disulfide / graphene composite lubricant was obtained.

Embodiment 2

[0027] 1 part of graphene (single-layer graphene accounts for 96%, specific surface area 3910m 2 / g) adding 3000 parts of glycerin-water (mass ratio 1:10) mixed solvent containing 5% tetradecyltrimethylammonium bromide in mass concentration, adjusting system pH=2.5 with hydrochloric acid, and ultrasonically dispersing for 15 minutes; In the ice-bath ultrasonic state, add 20 parts of sodium molybdate, 280 parts of sodium sulfide, and 15 parts of thioacetamide to the solution in sequence, and then move the system to a pressure-resistant reactor. After the system is sealed, replace the upper atmosphere with 1MPa Hydrogen, control the heating rate of the reactor to 25°C / min, raise the temperature of the system to 300°C, keep it warm for 1.5h, cool down, release the pressure, filter the system to obtain a black solid, rinse it with deionized water, and dry it to obtain Inorganic fullerene molybdenum disulfide / graphene composite lubricant.

Embodiment 3

[0029] 1 part of graphene (single-layer graphene accounts for 95%, specific surface area 3800m 2 / g) adding 4000 parts of glycerol-water (mass ratio 1:15) mixed solvent containing 5% tetradecyltrimethylammonium bromide in mass concentration, adjusting system pH=3 with hydrochloric acid, and ultrasonically dispersing for 10 min; In the ice-bath ultrasonic state, add 40 parts of ammonium molybdate, 360 parts of ammonium sulfide, and 40 parts of thioacetamide to the solution in sequence, and then move the system to a pressure-resistant reactor. After the system is sealed, replace the upper atmosphere with 2MPa Hydrogen, control the heating rate of the reactor to 30°C / min, rise to the system temperature of 200°C, keep warm for 2 hours, cool, release the pressure, filter the system to obtain a black solid, rinse it with deionized water, and dry it to obtain the inorganic Fullerene-like molybdenum disulfide / graphene composite lubricant.

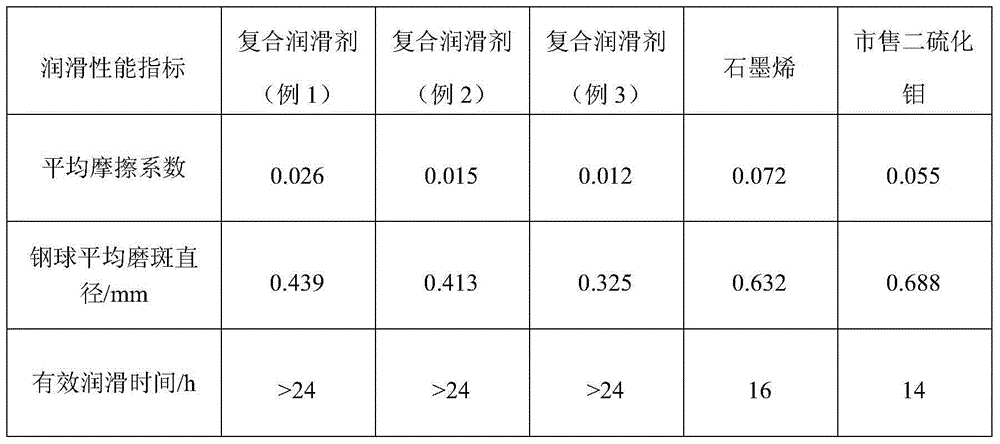

[0030] In the embodiment, the friction and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com