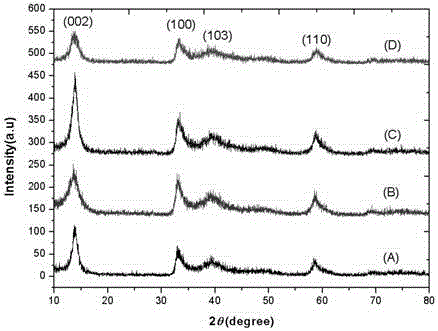

Graphene/molybdenum disulfide composite lubricant and preparation method thereof

A compound lubricant and molybdenum disulfide technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of limited addition amount, high cost of graphene preparation, and general anti-friction effect, so as to reduce the possibility of adhesive wear High performance, guaranteed long-term performance, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of graphene / molybdenum disulfide composite lubricant is prepared by the method comprising the following steps:

[0031] (1) Preparation of graphene oxide solution

[0032] Add the weighed 5g phosphorus flake graphite (Sigma-Aldrich company, the same below) and 3.75g NaNO in a 1L dry beaker 3 (Shanghai Sinopharm Chemical Reagent Co., Ltd., the same below), and stirred vigorously for 10 minutes. Then, 150 mL of 98% concentrated H 2 SO 4 (Shanghai Sinopharm Chemical Reagent Co., Ltd., the same below) was slowly poured into the above-mentioned beaker, and continued to stir for 30 minutes. Slowly add 20gKMnO 4 (Shanghai Sinopharm Chemical Reagent Co., Ltd., the same below), the addition was completed in 30 minutes, and after stirring for 20 hours, the system showed a purple-red color mixed with a small amount of sequins (graphite). After standing for 5 days, add 500mL water and 30mLH 2 o 2 (Shanghai Sinopharm Chemical Reagent Co., Ltd., the same below), and fin...

Embodiment 2

[0039] The preparation method is basically the same as in Example 1, except that the solvent in the step 1) is ethylene glycol (Shanghai Lingfeng Chemical Reagent Co., Ltd., the same below), and the surfactant is polyvinylpyrrolidone (Aladdin's reagent ( Shanghai) Co., Ltd., the same below), promptly obtains graphene / molybdenum disulfide composite lubricant B.

Embodiment 3

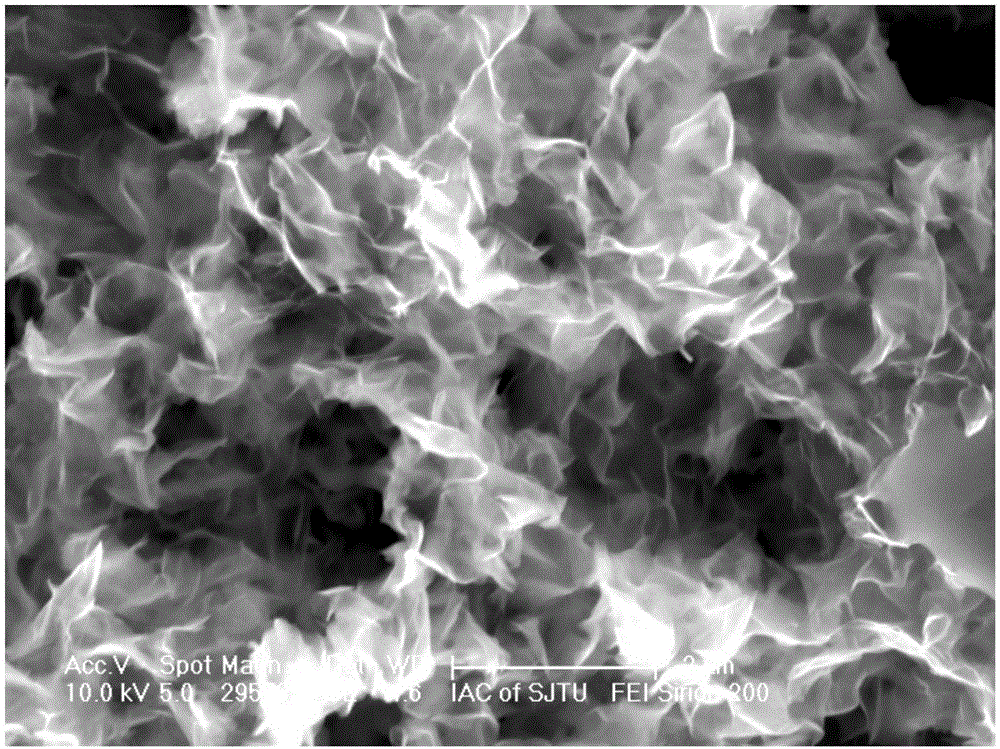

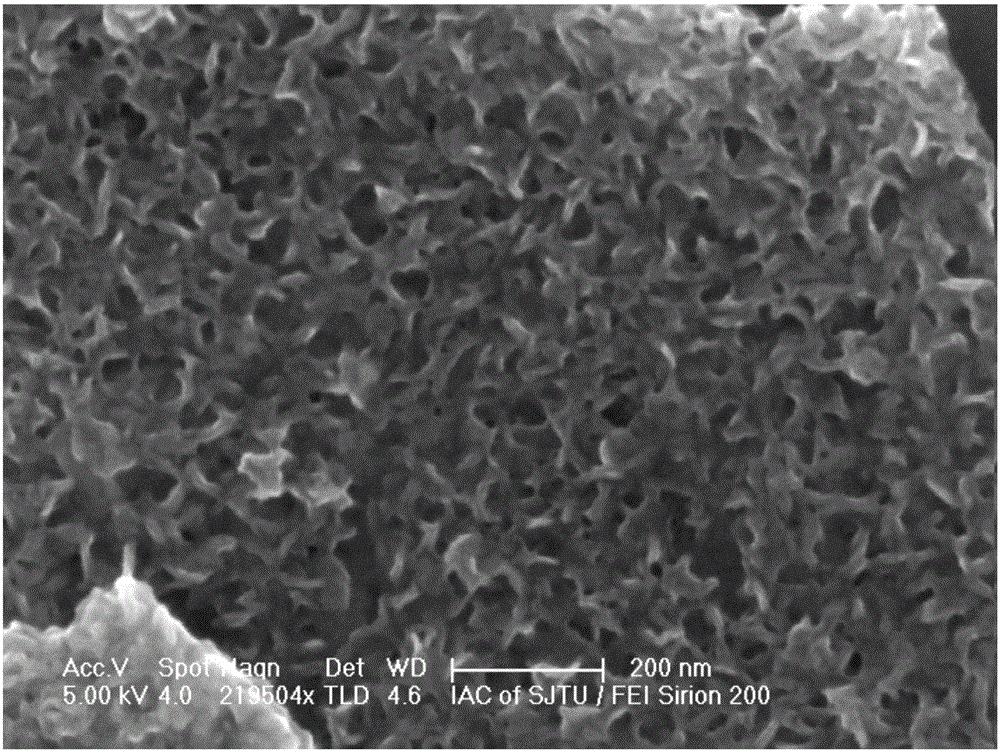

[0041] A kind of graphene / molybdenum disulfide composite lubricant is prepared by the method comprising the following steps:

[0042] (1) the preparation of graphene oxide solution is with embodiment 1;

[0043] (2) Preparation of graphene / molybdenum disulfide composite lubricant

[0044]1) Take 15 mg of the 1 mg / mL graphene oxide solution in the above step (1), and disperse it in 80 mL of deionized water, then add 250 mg of sodium molybdate, 800 mg of thiourea and 450 mg of polyvinylpyrrolidone into it, and stir at room temperature uniform to obtain a precursor solution;

[0045] 2) Put the precursor solution obtained in step 1) into a polytetrafluoroethylene reactor at 240°C for 24 hours;

[0046] 3) Wash the suspension and filtrate obtained in step 2) three times with deionized water and absolute ethanol respectively, and place them in a vacuum oven at 60°C for 12 hours to dry;

[0047] 4) Place the product prepared in step 3) in a quartz boat for heat treatment under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com