Post-grouting floor tile paving construction method

A construction method and a technology of laying floor tiles, which are applied in the field of architectural decoration and decoration, can solve the problems of affecting the service life of tiles, high labor intensity, time-consuming and laborious, etc., and achieve the effects of reducing labor intensity, enhancing housing experience, and unifying tile tiling methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] See attached picture.

[0021] A post-grouting floor tile construction method is characterized in that: the floor tiles are laid first, and then the cement mortar is grouted. The specific method is as follows:

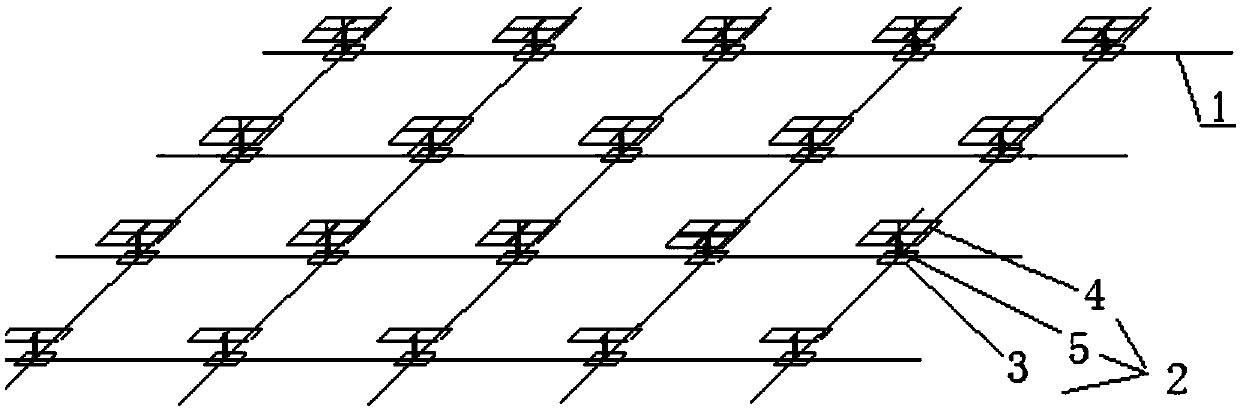

[0022] (1), first determine the size of the floor tiles, determine the installation location according to the size, arrange the floor tiles of the decorated house on the drawing, and place the positioning line 1 in the decorated house according to the arranged floor tiles;

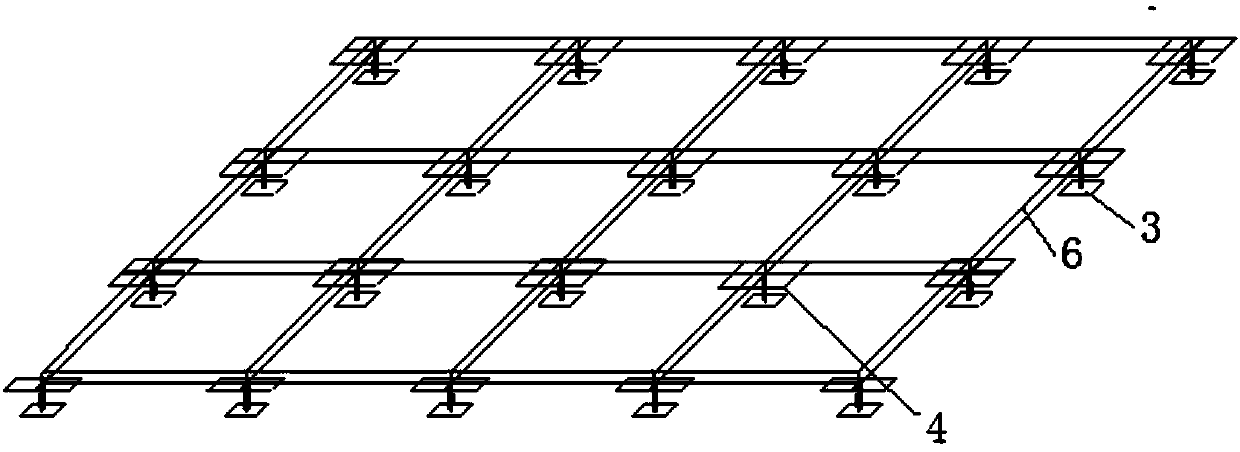

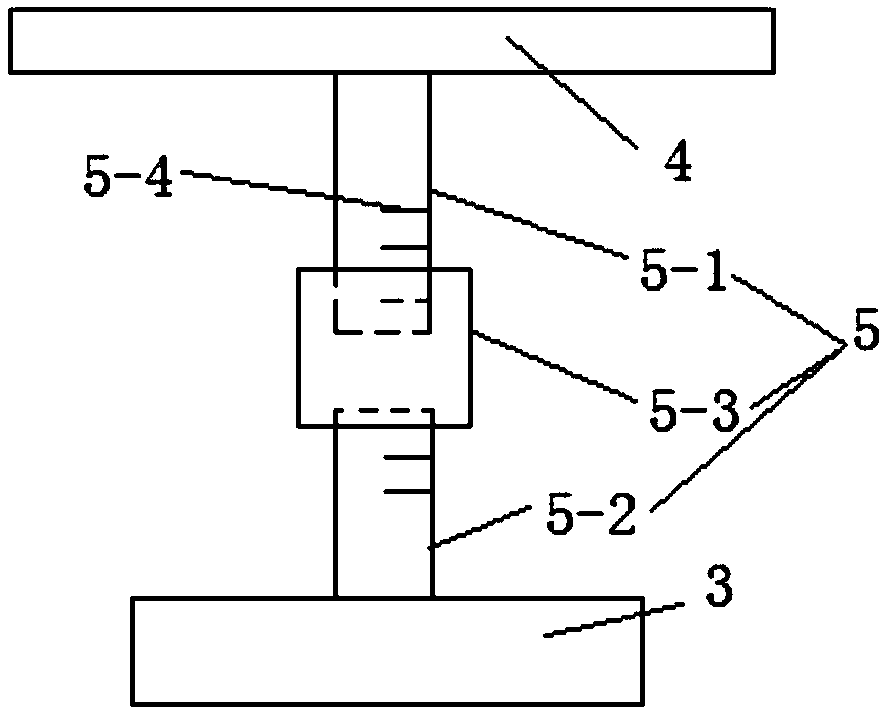

[0023] (2) Determine the position of the floor tile regulator 2, adjust the height of the floor tile regulator 2 respectively, place the floor tile regulator 2 at the corresponding position, and place a floor tile regulator 2 for every four floor tiles in the middle area, and the floor tile adjustment The device 2 includes a base 3, and a liftable support plate 4 is erected above the base 3, and the base 3 and the support plate 4 are connected and supported by a height-adjustable positioning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com