Large structural member sling system and hoisting method

A technology of large-scale components and hoisting methods, applied in the directions of transportation and packaging, load hoisting components, elevators, etc., can solve the problems of difficult leveling of large-scale components and affect the stability of hoisting, so as to improve the stability of hoisting, improve hoisting efficiency, Easy to level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

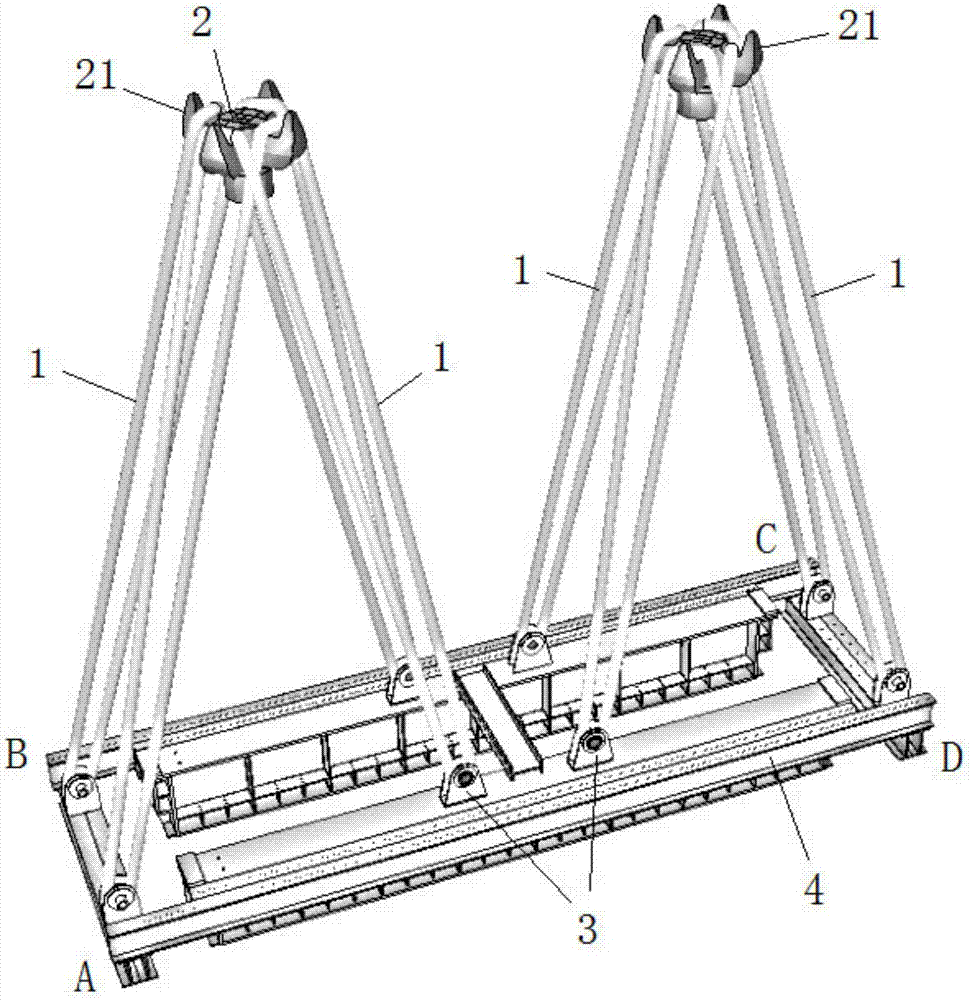

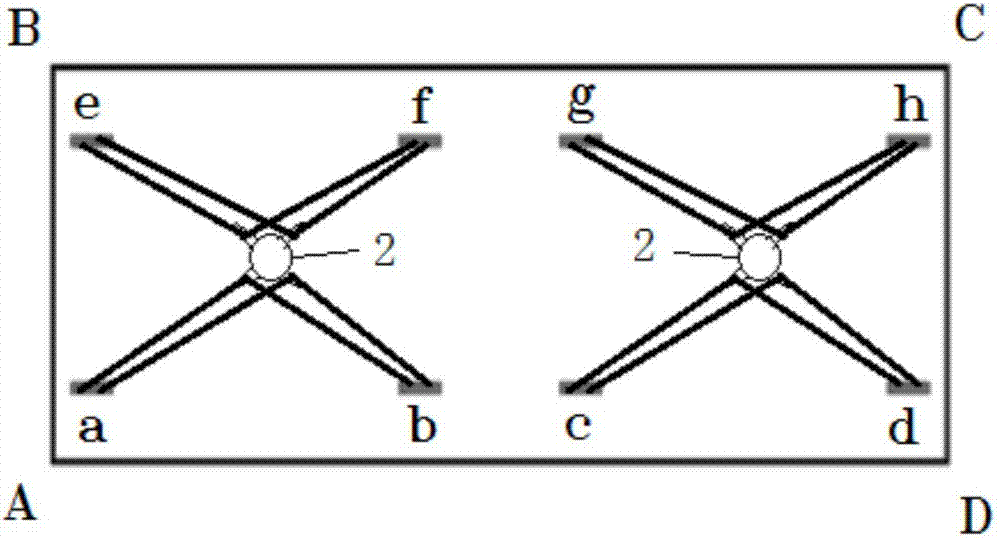

[0057] Such as Figure 1-3 As shown, a large component 4 spreader system includes at least one set of spreader assemblies, wherein each set of spreader assemblies includes:

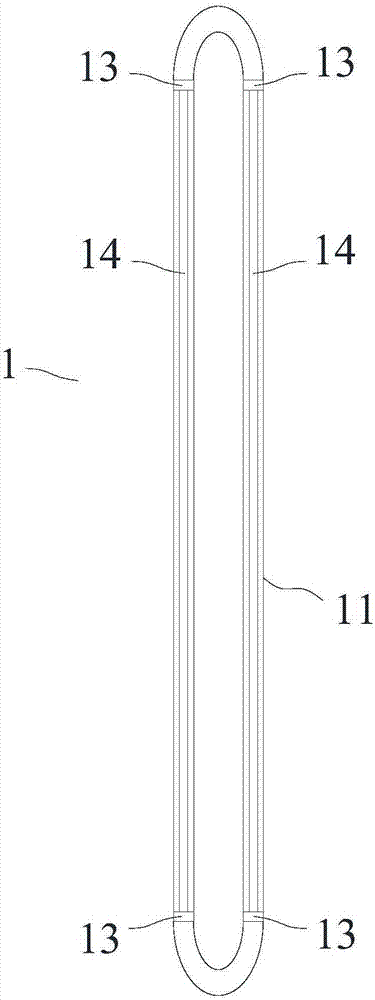

[0058] Two ring-shaped slings 1, each of which includes several sub-cables, and each sub-cable is made of ultra-high molecular weight polyethylene plastic material;

[0059] One hook 2, each hook 2 includes four hooks 21;

[0060] Four lifting lugs 3 are all arranged on the large component 4;

[0061] When hoisting the large component 4, each of the above-mentioned endless slings 1 passes through the two lifting lugs 3 on one side of the large component 4, and the two parts of the sling 1 between the two lifting lugs 3 are hung separately The hanging hook 2 is located on the two hooks 21 on the side corresponding to the two lifting ears 3 .

[0062] The above-mentioned sling 1 adopts several sub-cables, because each sub-cable is made of ultra-high molecular weight polyethylene plastic material (abbrevi...

Embodiment 2

[0072] Such as Figure 1-2 As shown, the present invention also provides a hoisting method of a large component 4 with a spreader system, comprising the following steps:

[0073] Step 1, select the number of spreader components, and select the spreader components suitable for the quantity according to the weight and size of the large component 4;

[0074] Step 2, install the lifting lugs 3, according to the number of selected sling components, set a suitable number of lifting lugs 3 on the large component 4, and all the lifting lugs 3 are installed symmetrically on the large component 4;

[0075] Step 3: Select the hook 2, select the same number of hooks 2 according to the number of selected sling components, and connect the hook 2 to the crane, adjust the position of the hook 2 so that all the hooks 2 are mutually Parallel, located at the same height of the crane; by adjusting the projection position of each hook 2 on the large component 4 to coincide with the center positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com