Scale support for cross-fault leveling

A leveling measurement and ruler technology, applied in height/level measurement, measuring device, machine platform/support, etc., can solve problems such as inconvenient movement, and achieve the effects of stable clamping, accurate screw height, and convenient and quick leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

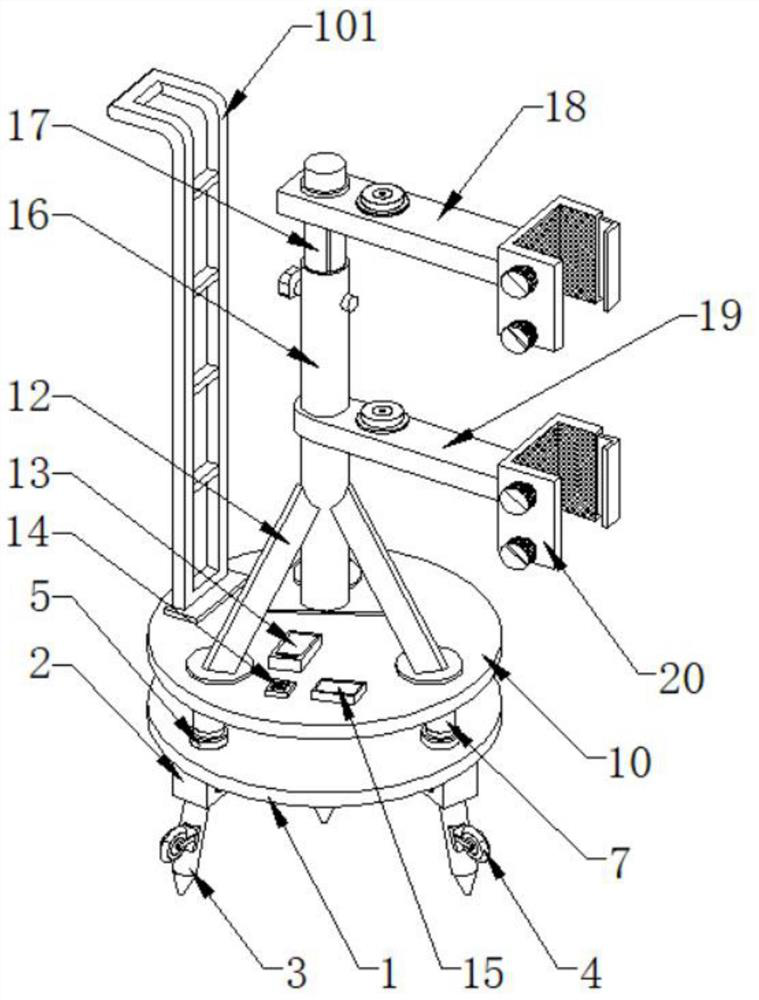

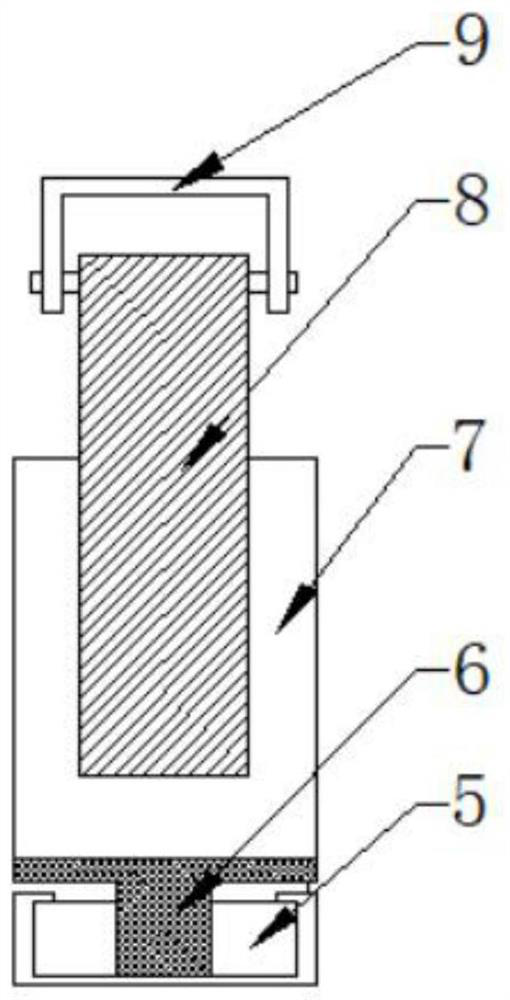

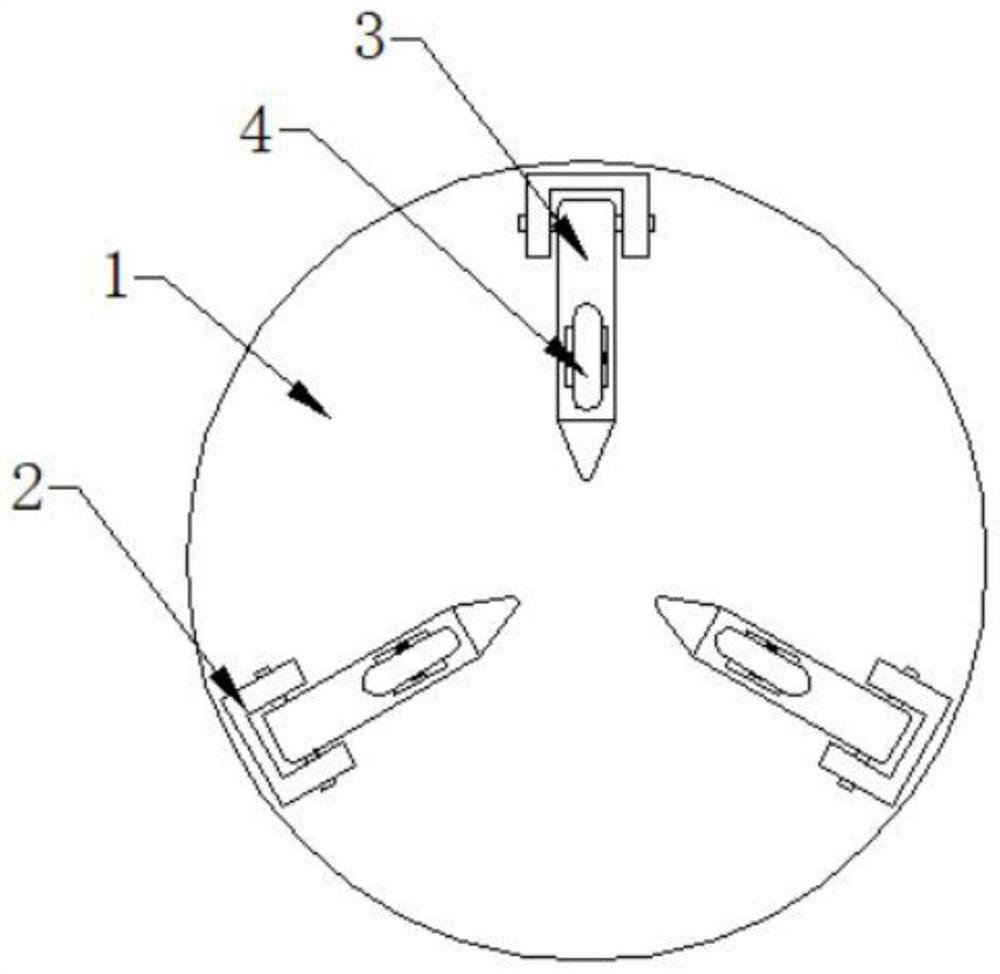

[0022] like Figure 1-5 As shown, the present invention provides a scale support for cross-fault leveling survey, which includes a circular chassis 1, a plurality of supports 2 are installed around the bottom surface of the circular chassis 1, and a support is installed inside the support 2 through a pin shaft. Rod 3, the outer side of pole 3 is equipped with universal wheel 4, the top surface of circular chassis 1 is surrounded by a plurality of bearing sleeves 5, and the inside of bearing sleeve 5 is sleeved with rotating disk 6, the top of rotating disk 6 A sleeve 7 is installed on the surface, and the internal thread of the sleeve 7 is sleeved with a screw rod 8. The top of the screw rod 8 is installed with a connecting leg 9 through a pin shaft, and a top plate 10 is installed on the top surface of the connecting leg 9. An angle sensor 11 is installed at the center of the bottom surface, a tripod 12 is installed on the top surface of the top plate 10, a battery compartmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com