Ultra-high-performance concrete-partial profile steel combined beam unit, ultra-high-performance concrete-profile steel combined beam unit and combined beam

An ultra-high-performance, concrete beam technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problem that the durability of bridges cannot meet the design service life, reduce the connection strength of bridge decks at joints, and affect the traffic flow of roads Pedestrian safety and other issues, to achieve the effect of simple structure, firm and reliable connection, and enhanced structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

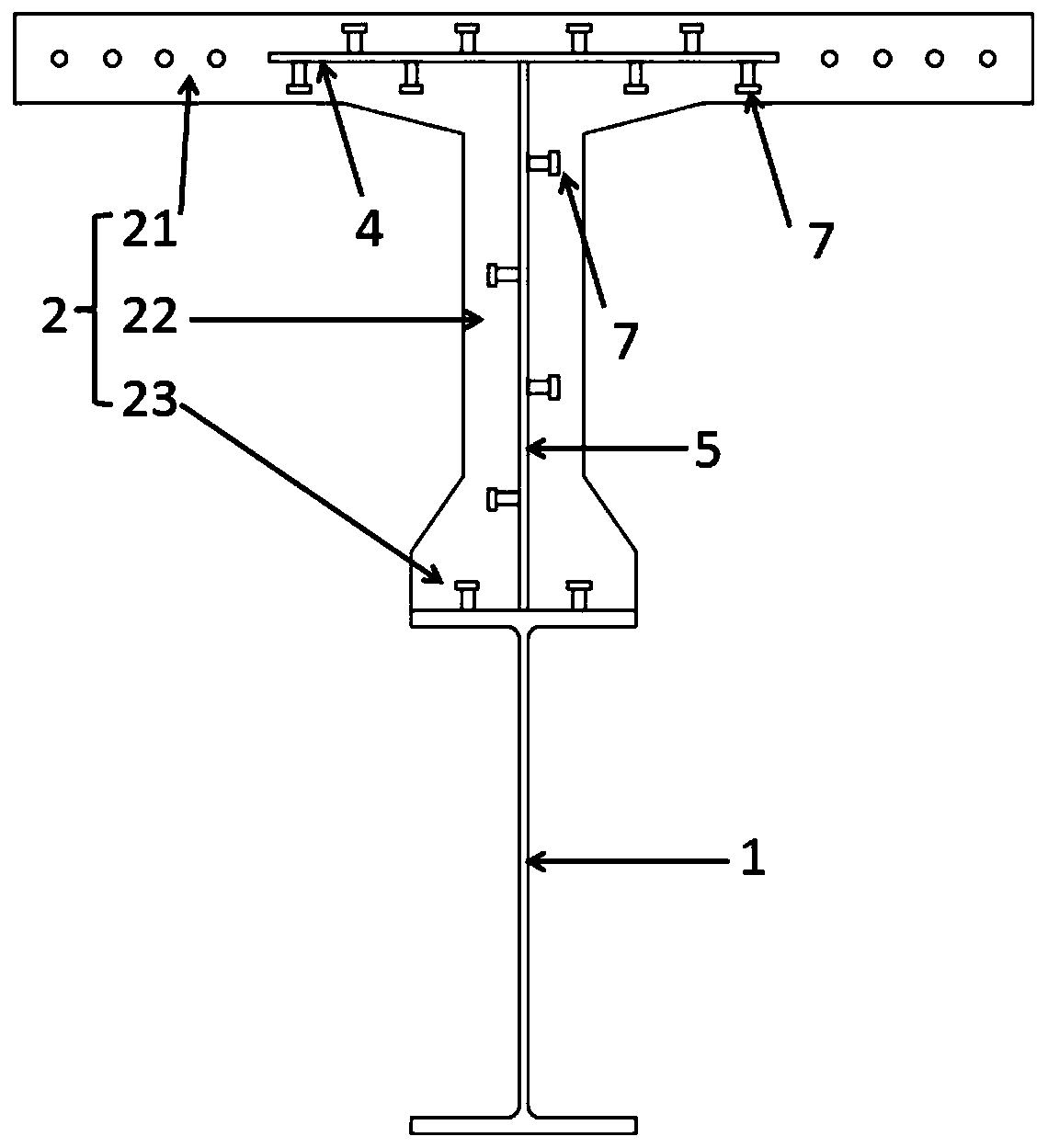

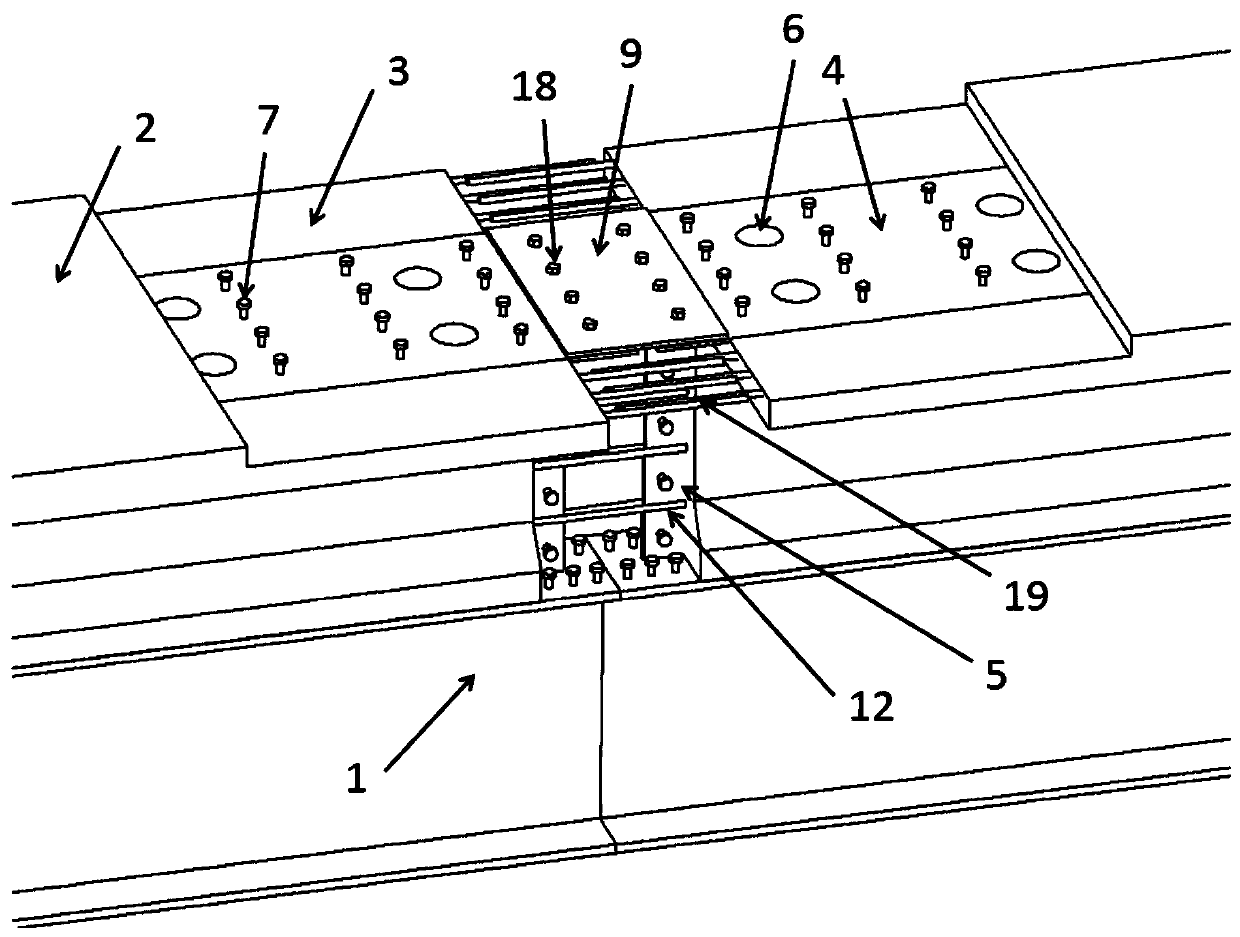

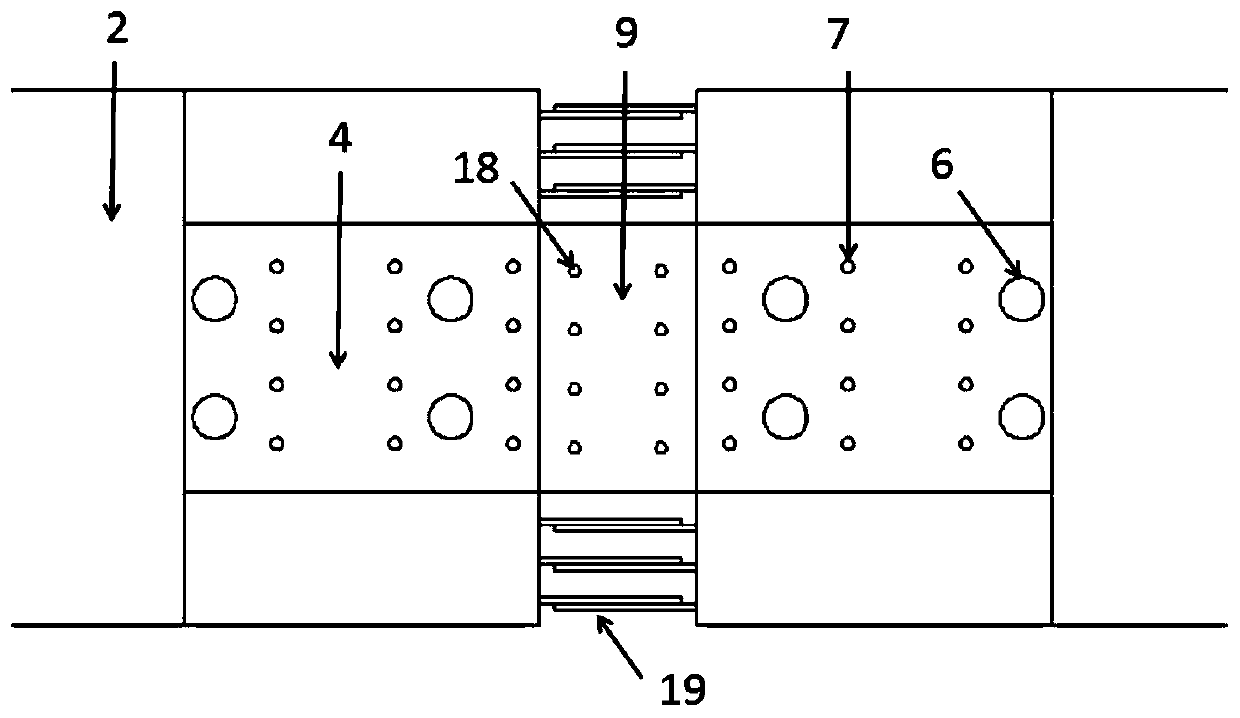

[0061] Such as Figure 1-Figure 5 , Figure 18 As shown, the ultra-high performance concrete-partial steel composite beam unit of this embodiment, the ultra-high performance concrete-partial steel composite beam unit includes a main beam steel 1 and an ultra-high performance concrete beam 2 fixed on the main beam steel 1, The ultra-high-performance concrete beam 2 includes a top plate 21, a web 22 and a bottom plate 23. The end of the top plate 21 is provided with a half-notch 3, and the half-notch 3 is provided with a top-plate reinforcing steel plate 4 arranged in the longitudinal bridge direction. The top-plate reinforcing steel plate 4 One end is fixed in the top plate 21, and the other end extends out of the end of the top plate 21. The web 22 is provided with a web strengthening steel plate 5 arranged in the longitudinal bridge direction, and one end of the web strengthening steel plate 5 is fixed in the web 22. , and the other end extends from the end of the web 22 . ...

Embodiment 2

[0073] Such as Figure 6-8 , Figure 18 As shown, the ultra-high performance concrete-partial steel composite beam unit of this embodiment, the ultra-high performance concrete-partial steel composite beam unit includes a main beam steel 1 and an ultra-high performance concrete beam 2 fixed on the main beam steel 1, The ultra-high-performance concrete beam 2 includes a top plate 21, a web 22 and a bottom plate 23. The end of the top plate 21 is provided with a half-notch 3, and the half-notch 3 is provided with a top-plate reinforcing steel plate 4 arranged in the longitudinal bridge direction. The top-plate reinforcing steel plate 4 One end is fixed in the top plate 21, and the other end extends out of the end of the top plate 21. The web 22 is provided with a web strengthening steel plate 5 arranged in the longitudinal bridge direction, and one end of the web strengthening steel plate 5 is fixed in the web 22. , and the other end extends from the end of the web 22 . The lon...

Embodiment 3

[0086] Such as Figure 9-11 , Figure 18 As shown, the ultra-high performance concrete-partial steel composite beam unit of this embodiment, the ultra-high performance concrete-partial steel composite beam unit includes a main beam steel 1 and an ultra-high performance concrete beam 2 fixed on the main beam steel 1, The ultra-high-performance concrete beam 2 includes a top plate 21, a web 22 and a bottom plate 23. The end of the top plate 21 is provided with a half-notch 3, and the half-notch 3 is provided with a top-plate reinforcing steel plate 4 arranged in the longitudinal bridge direction. The top-plate reinforcing steel plate 4 One end is fixed in the top plate 21, and the other end extends out of the end of the top plate 21. The web 22 is provided with a web strengthening steel plate 5 arranged in the longitudinal bridge direction, and one end of the web strengthening steel plate 5 is fixed in the web 22. , and the other end extends from the end of the web 22 . The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com