Assembled-type well lane construction method

A construction method and prefabricated technology, which is applied in the direction of sinking, shaft lining, shaft equipment, etc., can solve the problems of long shaft and roadway construction procedures, weak initial strength of concrete, and poor safety, so as to simplify the on-site construction process and reduce operations Time, the effect of increasing the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

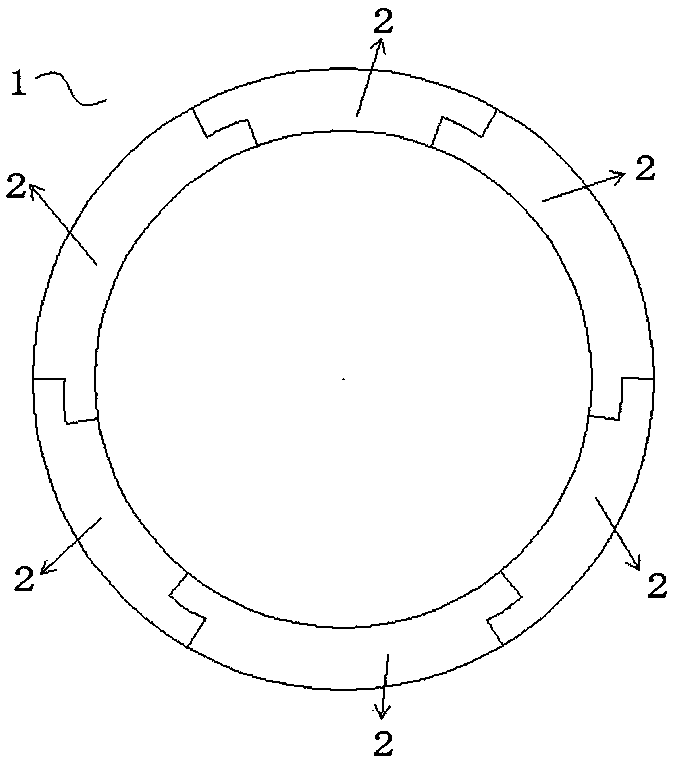

[0082] Such as figure 2 As shown, the adjacent well wall monomers 2 in this embodiment are overlapped with each other by annular steel belts 3 to form the whole well wall 1, or the part of one end of the well wall monomer 2 is processed to have a boss form, which can be used The boss is plugged and connected to the shaft wall as a whole 1 .

Embodiment 2

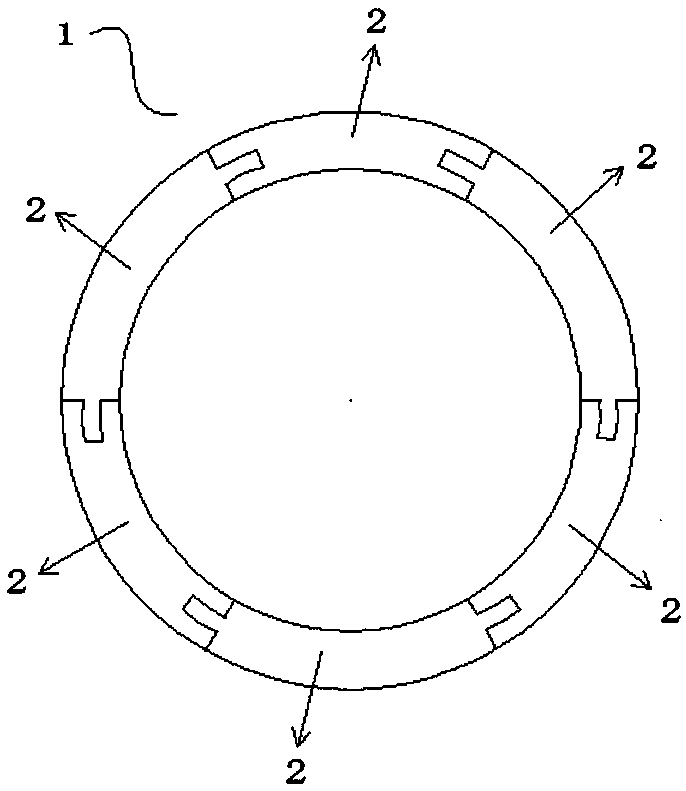

[0084] Such as image 3 As shown, in this embodiment, the adjacent well wall monomers 2 are overlapped by the annular steel belt 3 and the groove to form the whole well wall 1, or the well wall monomer 2 is processed into a second monomer with grooves and the first unit with the protruding part, the first unit and the second unit are plugged and connected. Specifically, the grooves and protrusions in this embodiment are both rectangular.

Embodiment 3

[0086] Such as Figure 4 As shown, in this embodiment, the adjacent well wall monomers 2 do not use overlapping joints, nor do they use plug-in connections, but only use connecting pieces to connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com