Large-scale venue assembly type combined prefabricated stand

A prefabricated stand technology, applied in podiums, pipeline layout, etc., can solve the problems of messy pipeline laying, lack of waterproof quality of bleachers, and cumbersome installation of air outlets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

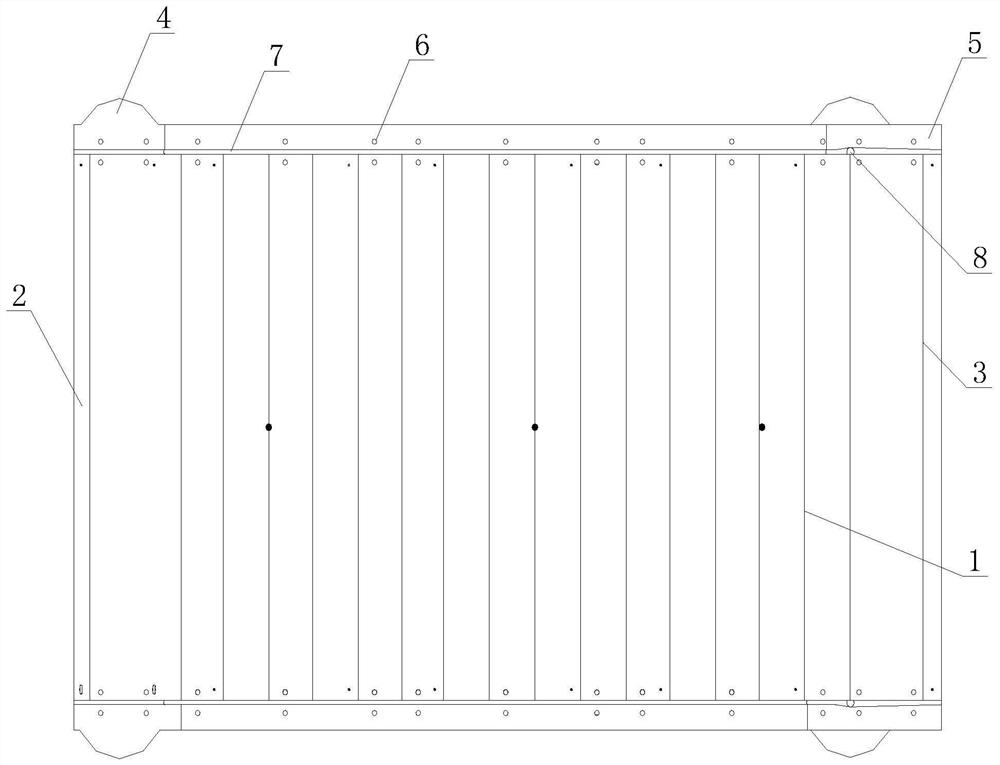

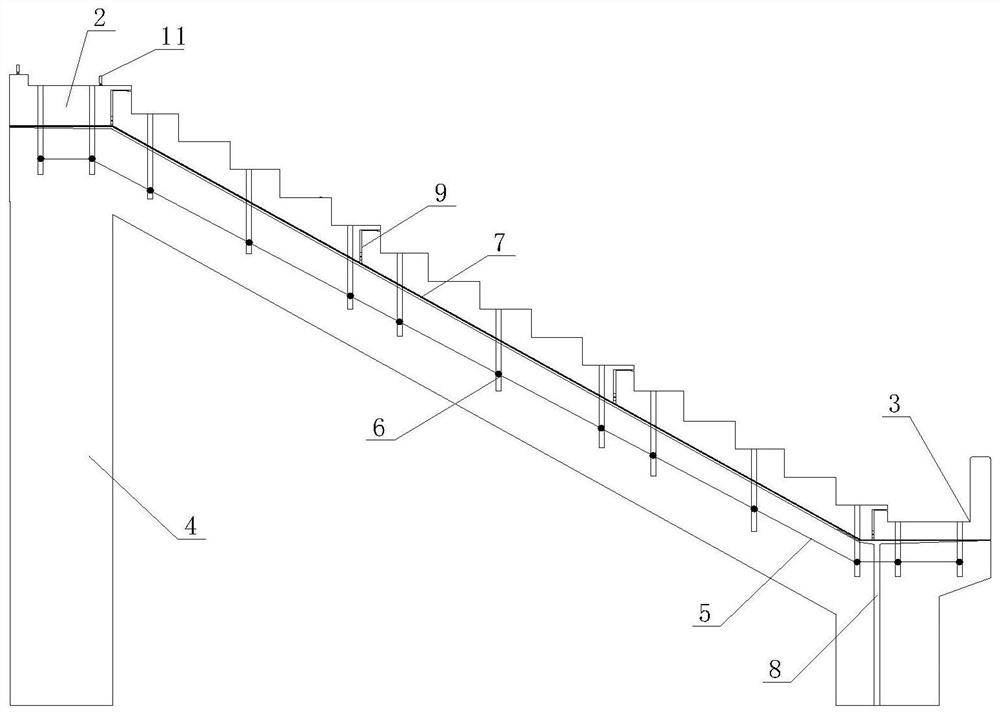

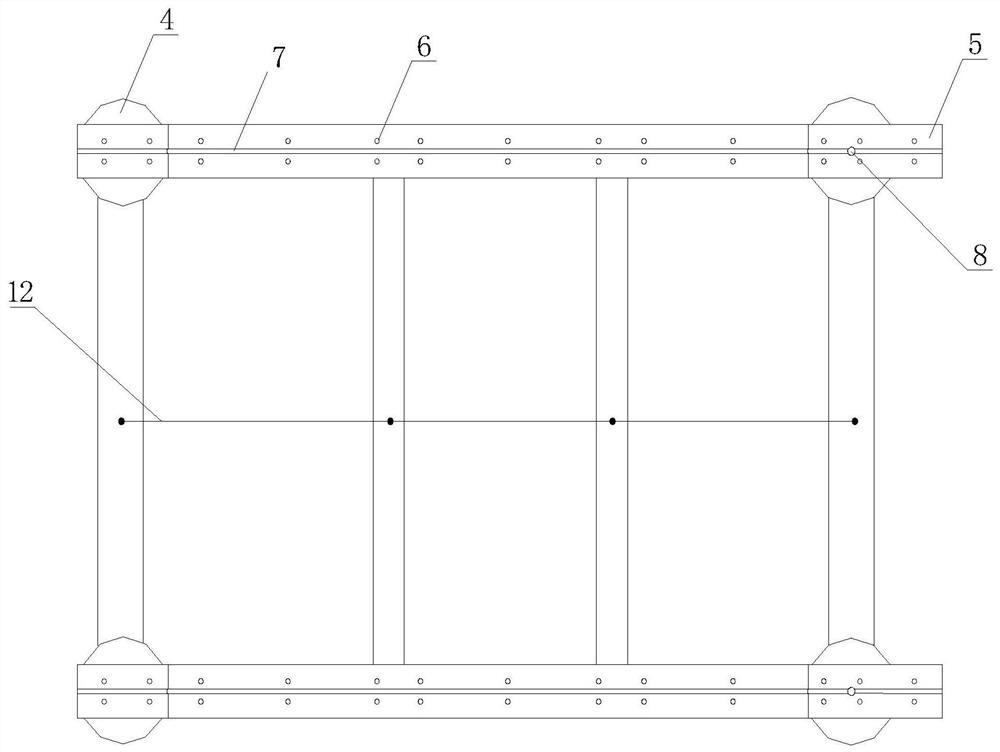

[0031] A prefabricated combined prefabricated stand for large venues, including a prefabricated stand 1, a prefabricated middle aisle platform 2, and a prefabricated platform 3 with a protective wall, and also includes a lower support structure, a prefabricated stand 1, a prefabricated middle aisle platform 2, and a prefabricated platform with a protective wall. Platform 3 is sequentially connected to the lower support structure from top to bottom. The front end of prefabricated stand 1 is spliced with prefabricated middle aisle platform 2, and the rear end of prefabricated stand 1 is spliced with prefabricated platform 3 with parapet. Prefabricated stand 1 has a built-in air supply system 15. The air supply system 15 includes air supply outlets 16 behind the seats, the main interface of the air supply system 17 and the built-in main air supply ring pipe 20. There are multiple air supply outlets 16 at the rear seat, the air supply outlets 16 for the rear seats, the main air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com