Construction technology for morbidezza soft rock finished product sticker for outer walls

A technology of construction technology and stone products, which is applied in the direction of building components, climate change adaptation, heat preservation, etc., can solve the problems of long construction period, affecting project quality, cumbersome construction procedures, etc., and achieve stable product quality, simple process, and crack resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

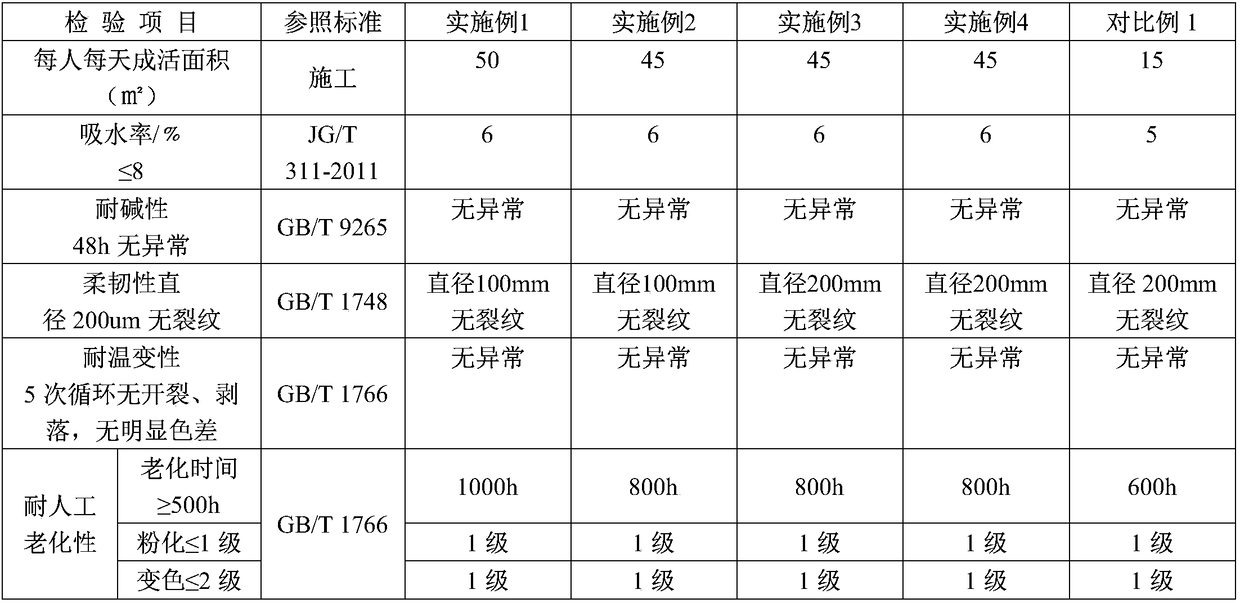

Examples

Embodiment 1

[0046] The construction technology of soft and beautiful soft stone finished paste for exterior wall described in this embodiment comprises the following process steps:

[0047] Step a. Base-level pretreatment: Clean the dust and dirt on the base surface of the outer wall, and use leveling putty to repair the holes, cracks and sanding parts to ensure the smoothness of the construction wall surface; use a 2m ruler to check the smoothness of the wall surface Degree and verticality, the maximum deviation shall not be greater than 5mm;

[0048] Step b. Before pasting the polystyrene board: measure and set out the external wall according to the design requirements; pop up the horizontal control line on the wall, hang the vertical reference steel line on the external corner of the building external wall; hang a horizontal line at an appropriate position on each floor to control Verticality and flatness of polystyrene board;

[0049] Adhere the polystyrene board to the exterior wall...

Embodiment 2

[0060] The construction technology of soft and beautiful soft stone finished paste for exterior wall described in this embodiment comprises the following process steps:

[0061] Step a. Base-level pretreatment: Clean the dust and dirt on the base surface of the outer wall, and use leveling putty to repair the holes, cracks and sanding parts to ensure the smoothness of the construction wall surface; use a 2m ruler to check the smoothness of the wall surface Degree and verticality, the maximum deviation shall not be greater than 5mm;

[0062] Step b. Before pasting the polystyrene board: measure and set out the external wall according to the design requirements; pop up the horizontal control line on the wall, hang the vertical reference steel line on the external corner of the building external wall; hang a horizontal line at an appropriate position on each floor to control Verticality and flatness of polystyrene board;

[0063] Adhere the polystyrene board to the exterior wall...

Embodiment 3

[0074] The construction technology of soft and beautiful soft stone finished paste for exterior wall described in this embodiment comprises the following process steps:

[0075] Step a. Base-level pretreatment: Clean the dust and dirt on the base surface of the outer wall, and use leveling putty to repair the holes, cracks and sanding parts to ensure the smoothness of the construction wall surface; use a 2m ruler to check the smoothness of the wall surface Degree and verticality, the maximum deviation shall not be greater than 5mm.

[0076] Step b. Before pasting the polystyrene board: measure and set out the external wall according to the design requirements; pop up the horizontal control line on the wall, hang the vertical reference steel line on the external corner of the building external wall; hang a horizontal line at an appropriate position on each floor to control Verticality and flatness of polystyrene board;

[0077] Adhere the polystyrene board to the exterior wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com