Environment-friendly external wall thermal-insulation putty and preparation method thereof

An external wall insulation and environmental protection technology, applied in the field of building materials, can solve the problems of high construction cost, shedding, hollowing and other problems of plastering materials, and achieve the effect of high strength, light weight and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

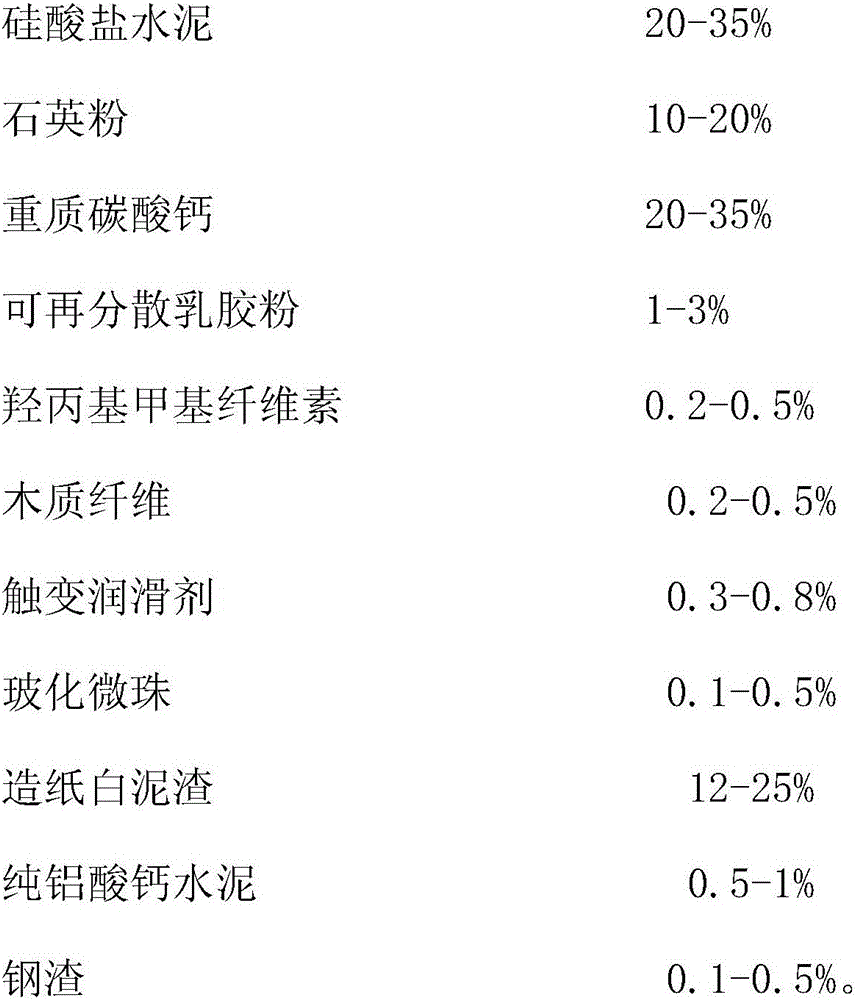

[0028] An environment-friendly external wall thermal insulation putty is composed of the following components by weight percentage:

[0029]

[0030] The particle size of the quartz powder is 120 mesh.

[0031] The particle size of the heavy calcium carbonate and papermaking lime mud is 325 mesh.

[0032] The particle size of the steel slag is 200 mesh.

[0033] The bulk density of the vitrified microbeads is 80-120kg / m 3 .

[0034] A preparation method of environment-friendly external wall thermal insulation putty, comprising the following steps:

[0035] Step 1: After turning on the mixer, follow the order of heavy calcium carbonate-hydroxypropyl methylcellulose-redispersible latex powder-steel slag-wood fiber-pure calcium aluminate cement-thixotropic lubricant-vitrified beads Add to the blender and mix well;

[0036] Step 2: Continue to add Portland cement, quartz powder and papermaking white mud slag, and stir evenly.

[0037] When the environment-friendly exterio...

Embodiment 2

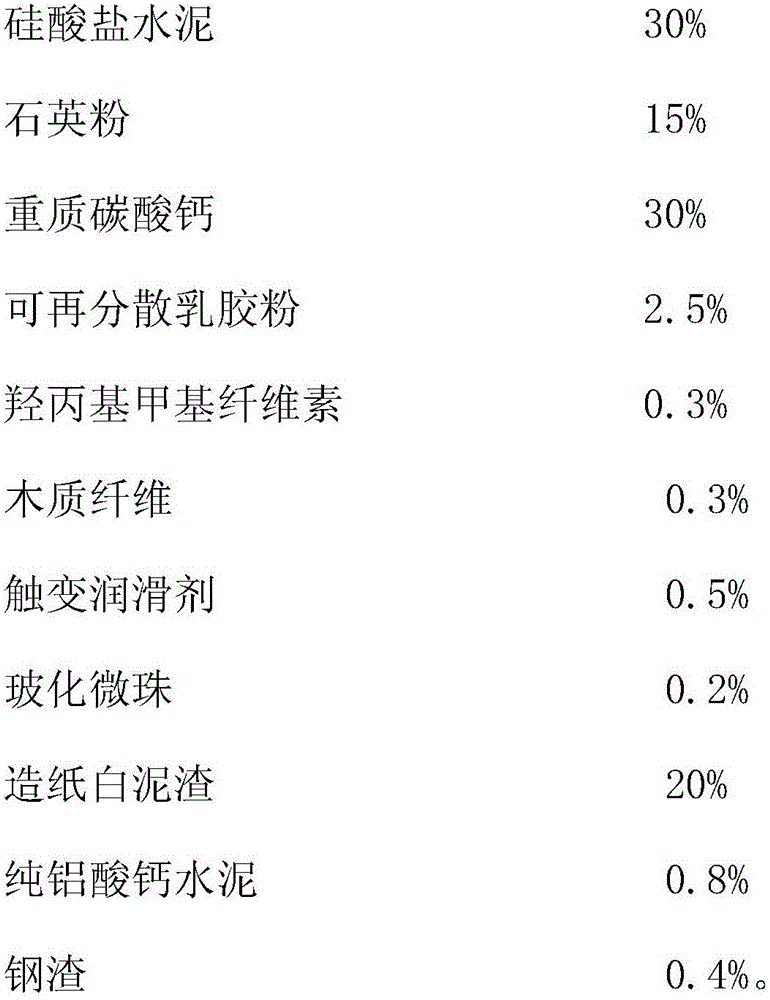

[0039] An environment-friendly external wall thermal insulation putty is composed of the following components by weight percentage:

[0040]

[0041] The particle size of the quartz powder is 120 mesh.

[0042] The particle size of the heavy calcium carbonate and papermaking lime mud is 325 mesh.

[0043] The particle size of the steel slag is 200 mesh.

[0044] The bulk density of the vitrified microbeads is 80-120kg / m 3 .

[0045] A preparation method of environment-friendly external wall thermal insulation putty, comprising the following steps:

[0046] Step 1: After turning on the mixer, follow the order of heavy calcium carbonate-hydroxypropyl methylcellulose-redispersible latex powder-steel slag-wood fiber-pure calcium aluminate cement-thixotropic lubricant-vitrified beads Add to the blender and mix well;

[0047] Step 2: Continue to add Portland cement, quartz powder and papermaking white mud slag, and stir evenly.

[0048] When the environment-friendly exterio...

Embodiment 3

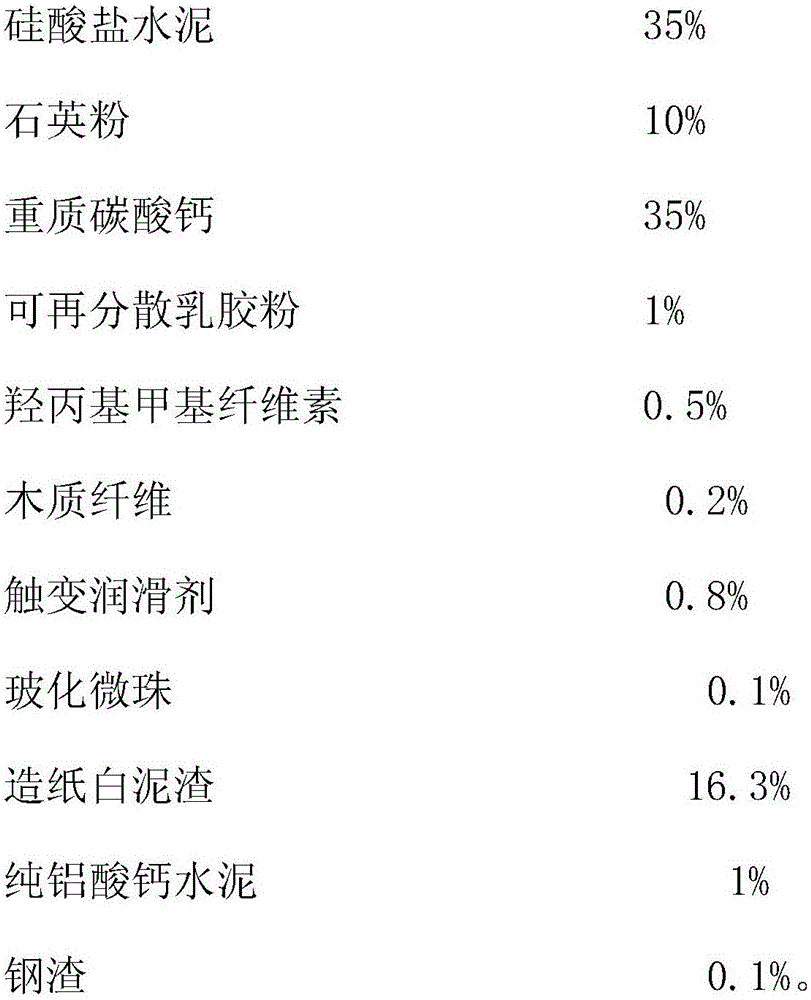

[0050] An environment-friendly external wall thermal insulation putty is composed of the following components by weight percentage:

[0051]

[0052] The particle size of the quartz powder is 120 mesh.

[0053] The particle size of the heavy calcium carbonate and papermaking lime mud is 325 mesh.

[0054] The particle size of the steel slag is 200 mesh.

[0055] The bulk density of the vitrified microbeads is 80-120kg / m 3 .

[0056] A preparation method of environment-friendly external wall thermal insulation putty, comprising the following steps:

[0057] Step 1: After turning on the mixer, follow the order of heavy calcium carbonate-hydroxypropyl methylcellulose-redispersible latex powder-steel slag-wood fiber-pure calcium aluminate cement-thixotropic lubricant-vitrified beads Add to the blender and mix well;

[0058] Step 2: Continue to add Portland cement, quartz powder and papermaking white mud slag, and stir evenly.

[0059] When the environment-friendly exterio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com