Stone powder waste material regeneration easy plaster and preparation method thereof

A technology for benefiting cement and waste, which is applied in the field of stone powder waste recycling and beneficial cement and its preparation, can solve the problems of waste pollution, mountain damage, environmental pollution, etc., and achieves high bonding strength, strong impermeability, and good water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of stone powder waste regenerated beneficial clay comprises the following steps:

[0020] A. Separately crush waste stone powder and undried sea sand through a pulverizer;

[0021] B, drying the pulverized powder in step A through a gas dryer;

[0022] C. The powder dried in step B is separated by mesh size through a vibrating sieve, and the sieved powder is lifted to the raw material warehouse for storage by the hoist, and the unsifted powder is sent back to the pulverizer to continue pulverization;

[0023] D. Put the raw materials in the raw material warehouse into the mixer according to a certain proportion, and add a certain amount of redispersible latex powder, hydroxypropyl methylcellulose and hydrophobic agent. ;

[0024] E. Stir the mixture in step D evenly for a certain period of time, and finally put it into the finished product leveling bin, and pack it through a valve port packaging machine to obtain the regenerated benefit cement f...

Embodiment 1

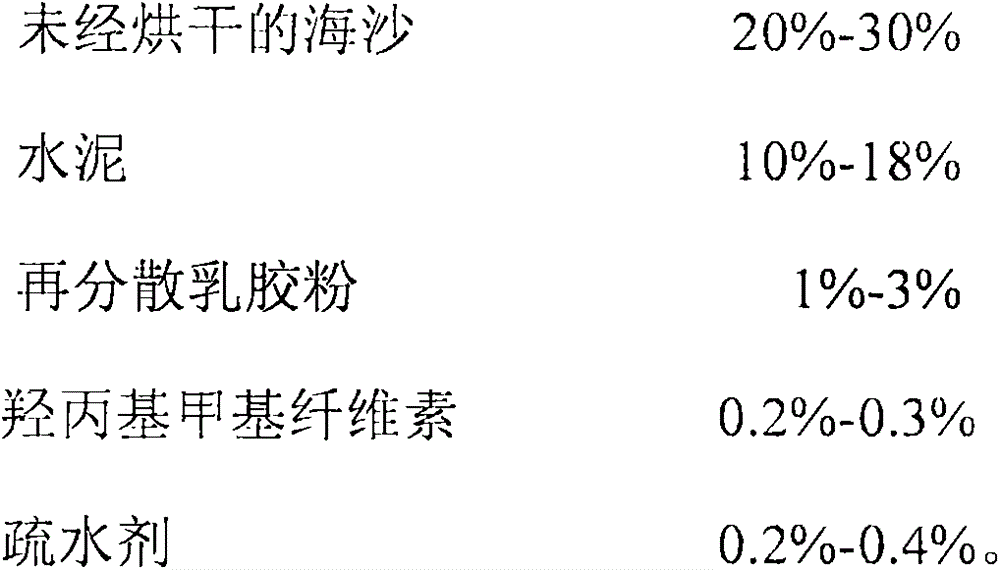

[0027] The contents of the waste stone powder, undried sea sand and cement are respectively as follows:

[0028]

[0029] The stirring time of the mixture in the step E is 3 min; the mesh size of the vibrating sieve is 30 mesh; the stirring speed of the mixer is 80 rpm.

Embodiment 2

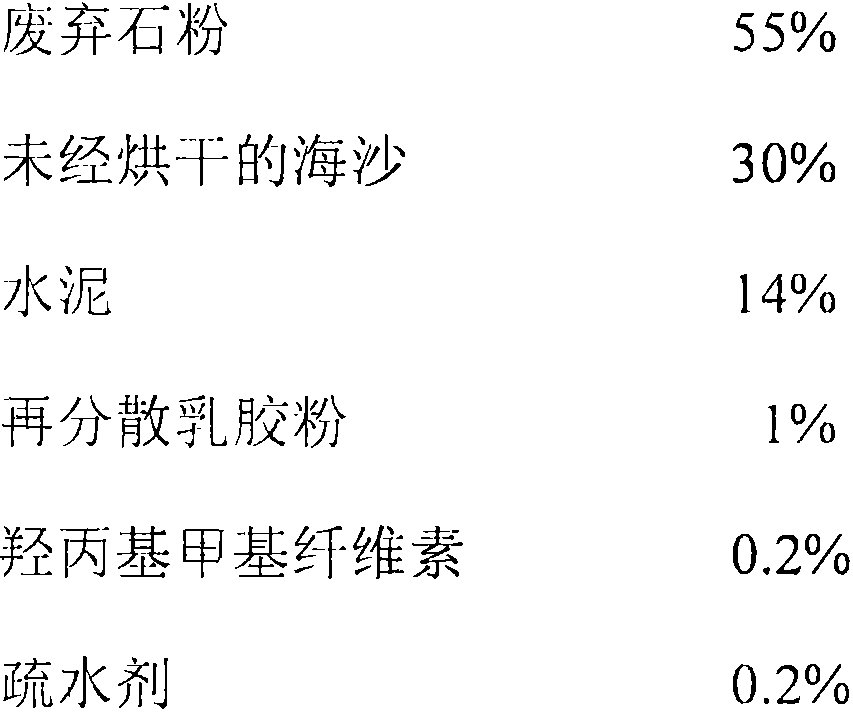

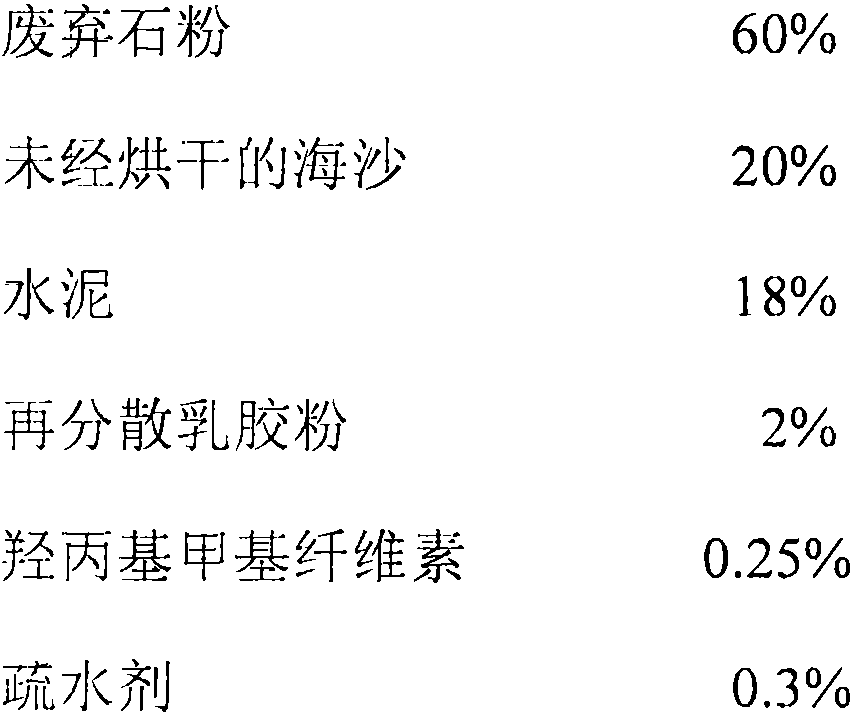

[0031] The contents of the waste stone powder, undried sea sand and cement are respectively as follows:

[0032]

[0033] The stirring time of the mixture in the step E is 4 min; the mesh size of the vibrating sieve is 45 mesh; the stirring speed of the mixer is 100 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com