Vitrified-microbead decorative thermal-insulation board

A technology of vitrified microbeads and expanded vitrified microbeads, which is applied in the field of building boards, can solve the problems of self-heaviness, difficulty in quality assurance, and high construction costs, and achieve high dimensional stability, reduce construction costs, and reduce dust pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

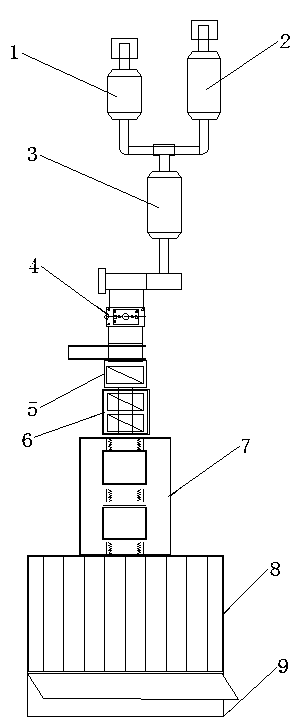

[0032]First, add 1000kg and 20kg foaming agent in the foaming mixing system 1, stir for 6 minutes, and carry out chemical foaming; simultaneously add dry powder in the dry powder mixing system 2, wherein 500kg of expanded vitrified microbeads, 190kg of slaked lime, 100kg of quicklime, Cement 200kg, silica fume 40kg, gypsum 3kg, fiber 3kg, waterproofing agent 1kg, rubber powder 5kg, fly ash 10kg, foaming agent 20kg, and stir for 4 minutes; then unload the foamed and stirred materials to the mixing and stirring In system 3, when unloading, unload the liquid foam material in the foaming mixing system 1 first, and then unload it with the dry powder material in the dry powder mixing system 2 at the same time, and then mix the mixture in the mixing system 3 Stir for 3 minutes for physical and chemical foaming; then unload the mixture into the initial pressure molding system 4, push the mixture into the initial pressure molding system 4 by air pressure for initial molding, and then au...

Embodiment 2

[0035] First, add 1000kg of water and 25kg of foaming agent to the foaming mixing system 1, stir for 6 minutes, and perform chemical foaming; at the same time, add dry powder into the dry powder mixing system 2, including 510kg of expanded vitrified microbeads, 195kg of slaked lime, and 110kg of quicklime , 220kg of cement, 45kg of silica fume, 4kg of gypsum, 4kg of fiber, 2kg of waterproofing agent, 7.5kg of rubber powder, 12.5kg of fly ash, and stir for 4 minutes; then unload the foamed and stirred materials to the mixing system 3 When unloading, unload the liquid foam material in the foaming mixing system 1 first, and then unload it with the dry powder material in the dry powder mixing system 2 at the same time, and then stir the mixture in the mixing system 3 for 3 Minutes, physical and chemical foaming; then unload the mixture into the initial pressure molding system 4, push the mixture into the initial pressure molding system 4 by air pressure for initial molding, and the...

Embodiment 3

[0038] First, add 1000kg of water and 30kg of foaming agent to the foaming mixing system 1, stir for 6 minutes, and perform chemical foaming; at the same time, add dry powder into the dry powder mixing system 2, including 520kg of expanded vitrified microbeads, 200kg of slaked lime, and 120kg of quicklime , 240kg of cement, 50kg of silica fume, 5kg of gypsum, 5kg of fiber, 3kg of waterproofing agent, 10kg of rubber powder, 15kg of fly ash, and stir for 4 minutes; then unload the foamed and stirred materials into the mixing system 3 respectively, When unloading, unload the liquid foam material in the foam mixing system 1 first, and then unload the dry powder material in the dry powder mixing system 2 at the same time after unloading half, and then stir the mixture in the mixing system 3 for 3 minutes, Carry out physical and chemical foaming; then unload the mixture into the initial pressure molding system 4, push the mixture into the initial pressure molding system 4 by air pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com