Base latex coating for interior wall and preparation method for base latex coating

A basic paint, latex technology, applied in latex paint, polyester paint, coating and other directions, can solve the problem of rapid share growth, achieve the effect of good performance and positive environmental protection significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

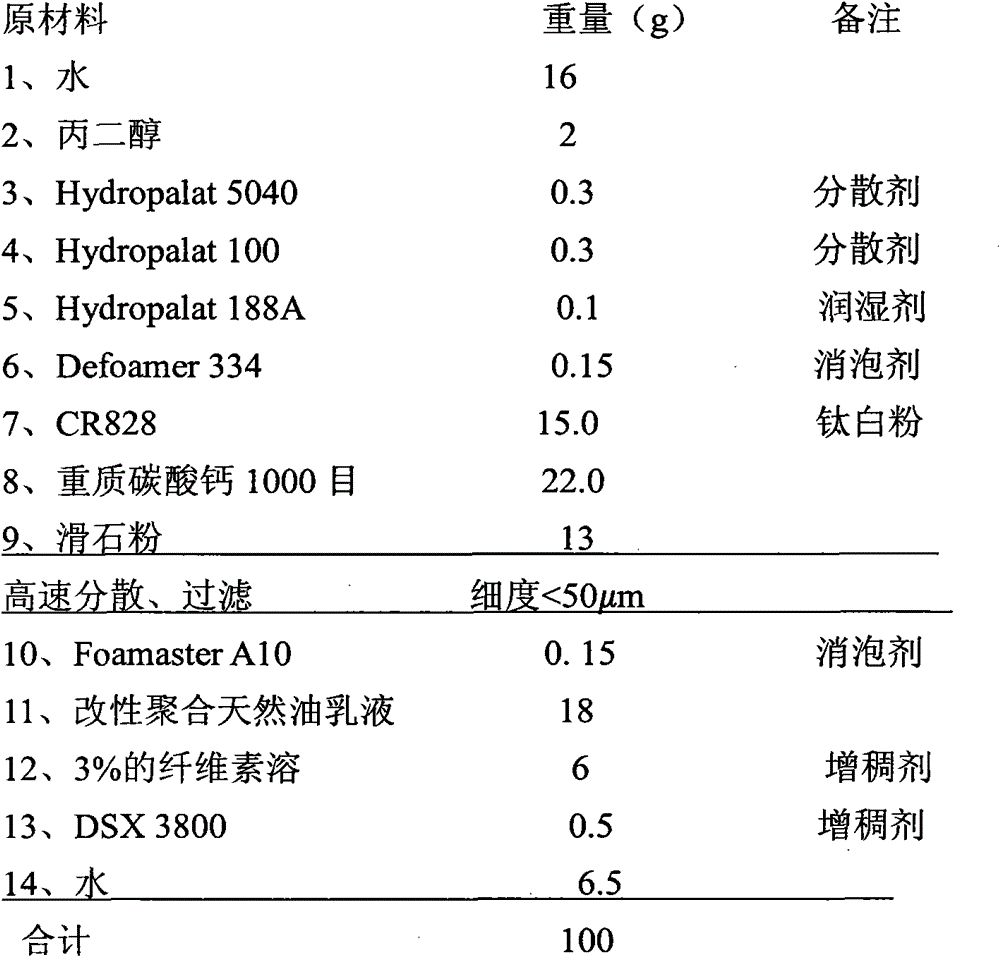

Embodiment 1

[0026]

[0027] After adding 1 to 9 components in sequence with low-speed stirring, disperse at high speed until the fineness is less than 50μm, then, under low-speed stirring, add the remaining components and adjust to 100g with water to complete the preparation of latex base paint.

[0028] Coating properties are as follows:

[0029]

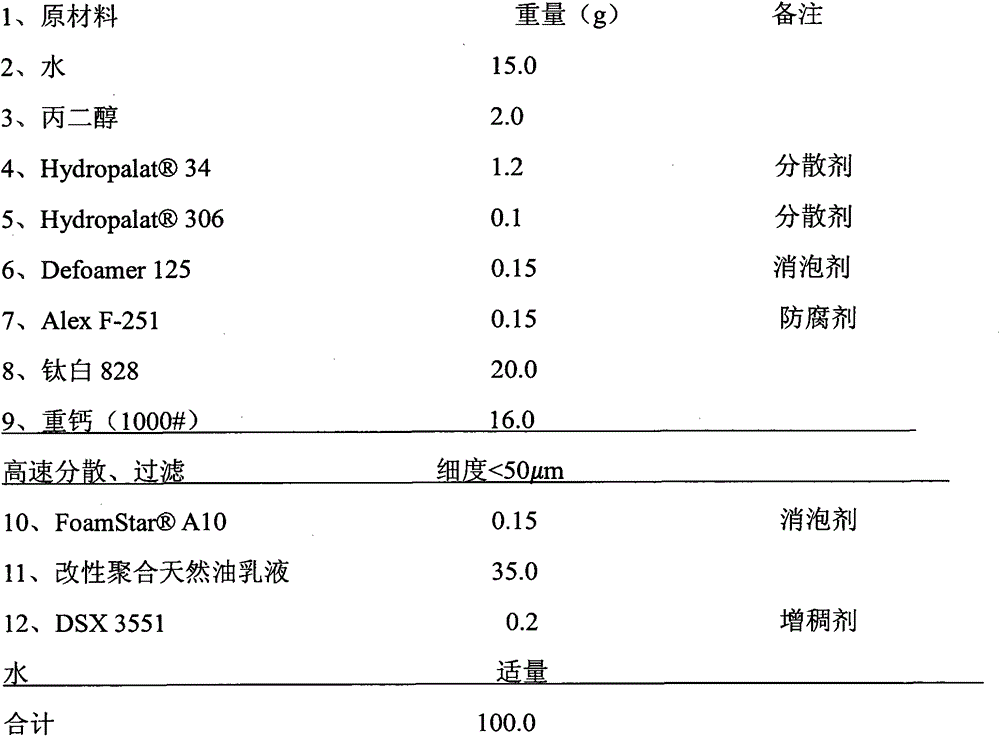

Embodiment 2

[0031]

[0032] After adding 1 to 9 components in sequence with low-speed stirring, disperse at high speed until the fineness is less than 50 μm, then, under low-speed stirring, add the remaining components and adjust to 100 with water to complete the preparation of latex base paint.

[0033] Coating properties are as follows:

[0034] 1

Embodiment 3

[0036]

[0037] After adding 1 to 11 components in sequence with low-speed stirring, disperse at high speed until the fineness is less than 30 μm, then, under low-speed stirring, add the remaining components and adjust to 100 with water to complete the preparation of latex base paint.

[0038] Coating properties are as follows:

[0039] 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com