Plug-in type low-carbon heat preservation energy-saving board

An energy-saving board, plug-in technology, used in covering/lining, architecture, building structure, etc., can solve problems such as anti-aging and glue opening, achieve good processability, pure and diverse colors, and reduce engineering costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

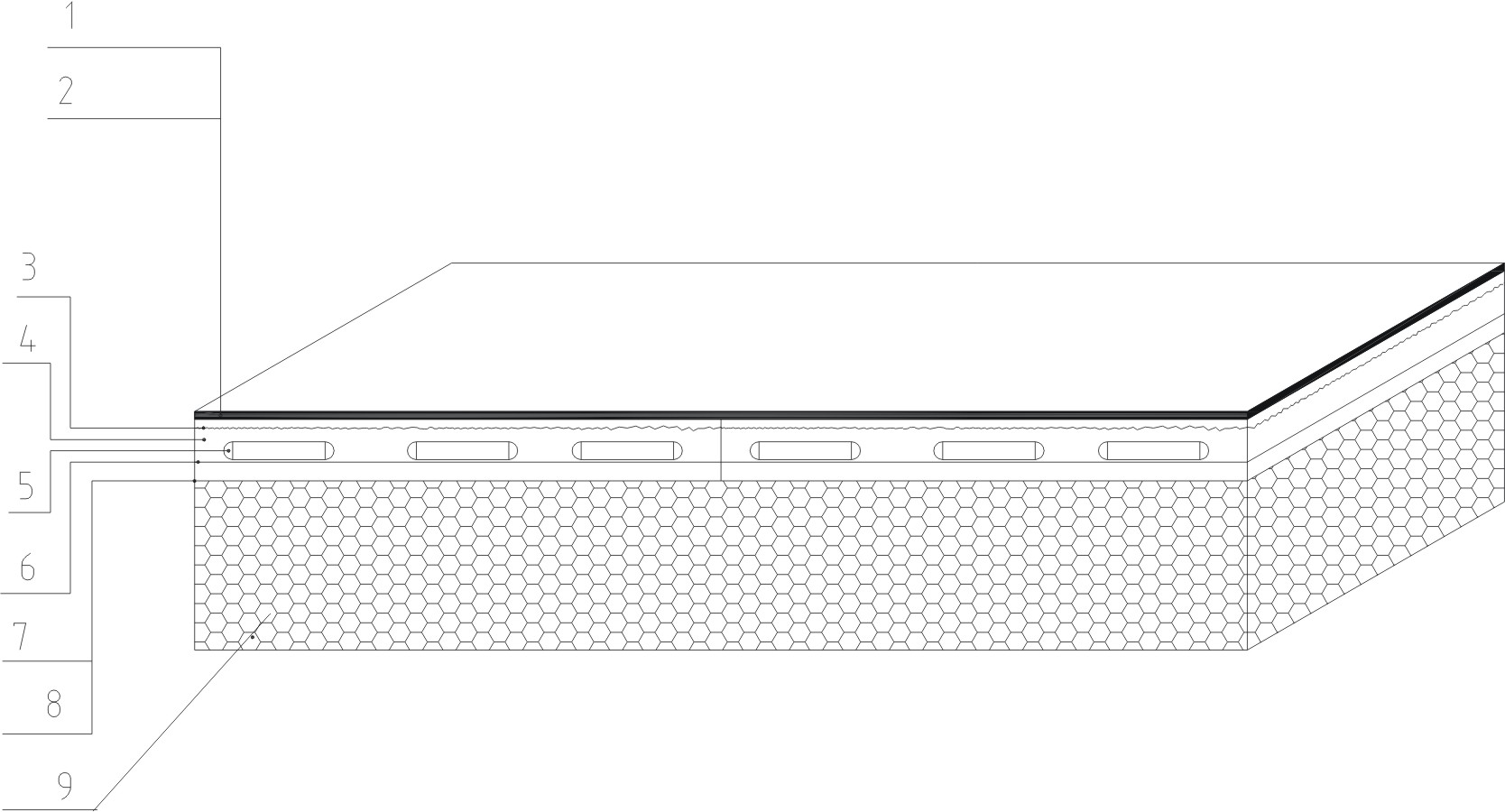

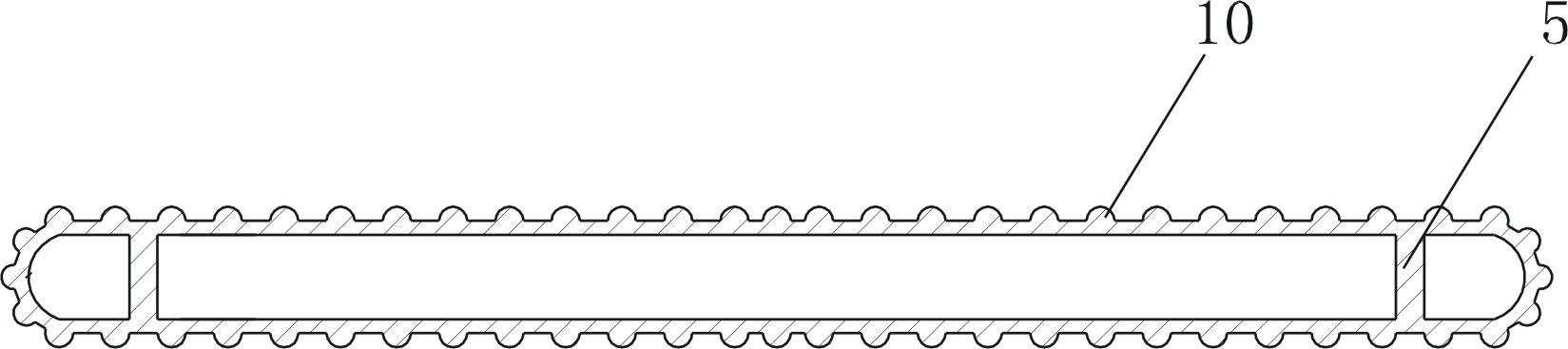

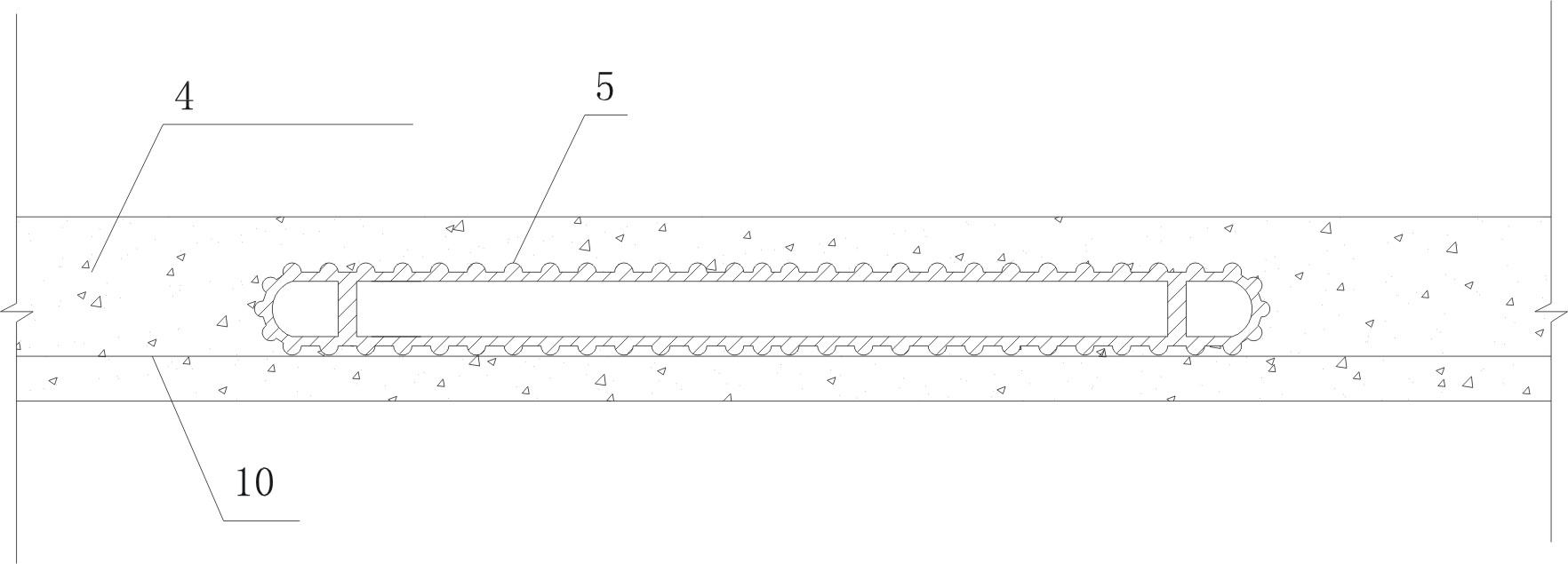

[0012] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, a plug-in low-carbon heat preservation and energy-saving board is mainly composed of decorative surface layer 1, surface layer 2, middle layer glass fiber mesh 3, low carbon plate 4, stainless steel mesh 5, bottom layer glass fiber mesh 6, solid The adhesive layer 7 and the SPS extruded plastic insulation board 8 are sequentially connected to form an integral board. The middle of the low-carbon plate is provided with a number of hollow plug-in tubes 9, which run radially through the middle of the low-carbon plate, and its cross-sectional shape is a rectangular tube made of aluminum alloy. The surface is provided with several corrugations 10, which can ensure the firm connection between the plug-in pipe and the low-carbon board. The insertion pipe is bound and fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com