Process for mounting splicing type low-carbon heat insulating energy-saving plate

An installation process and energy-saving board technology, which is applied in covering/lining, building, building structure, etc., can solve the problems of not being as strong as pre-embedded, waste of skeleton materials, and complicated construction technology, so as to reduce garbage removal and reduce The effect of project cost and perfect visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

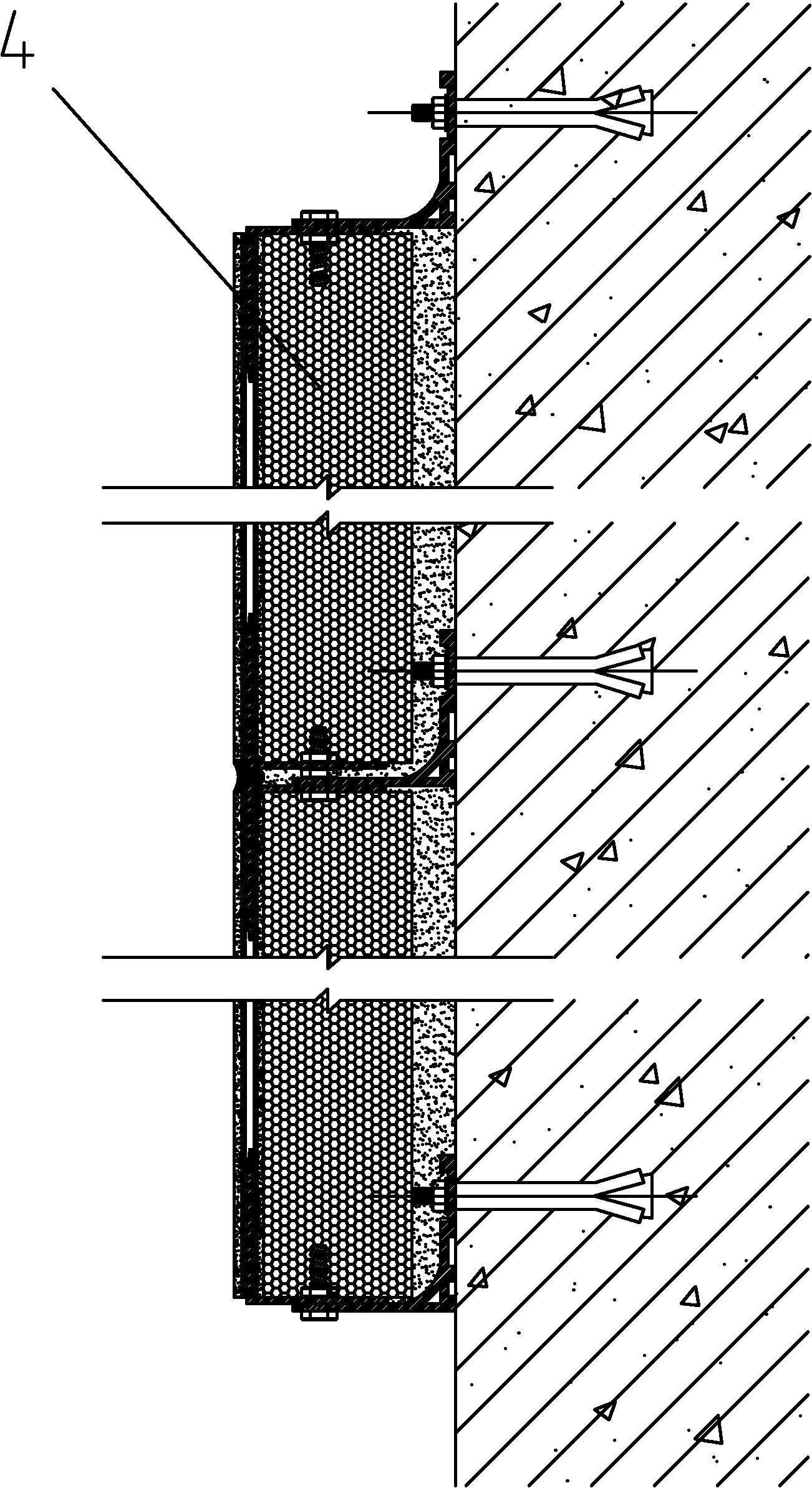

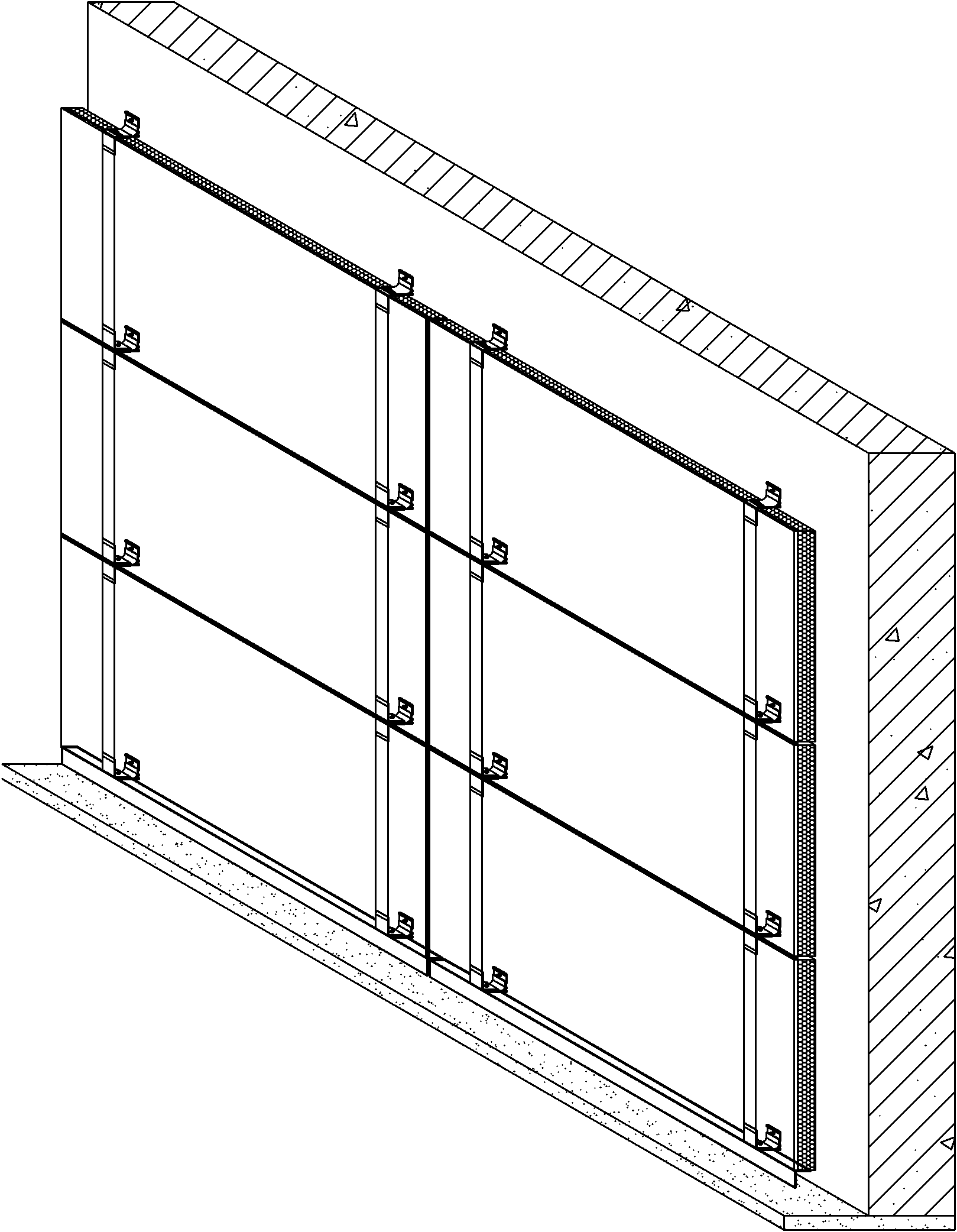

[0039]The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, the plug-in low-carbon thermal insulation energy-saving board 4 is mainly composed of a decorative surface layer, a surface layer, a middle layer of glass fiber mesh, a low-carbon plate, stainless steel mesh, a bottom layer of glass fiber mesh, a solid-resistant adhesive layer 7 and SPS extrusion insulation. The plates are connected in turn to form a whole plate. There are several hollow plug-in tubes in the middle of the low-carbon plate 1 , the insertion pipe radially runs through the middle of the low-carbon plate, and its cross-sectional shape is a rectangular tube shape, made of aluminum alloy, and the outer surface of the insertion pipe is provided with several ribs 2 , can ensure that the plug-in tube is firmly connected with the low-carbon plate. The splice tube and stainle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com