Inorganic active thermal-insulation mortar

A thermal insulation mortar and inorganic technology, applied in the field of building materials, can solve the problems of loss of thermal insulation effect and poor fire resistance, and achieve the effects of superior waterproof and crack resistance, good thermal insulation performance, and enhanced impermeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

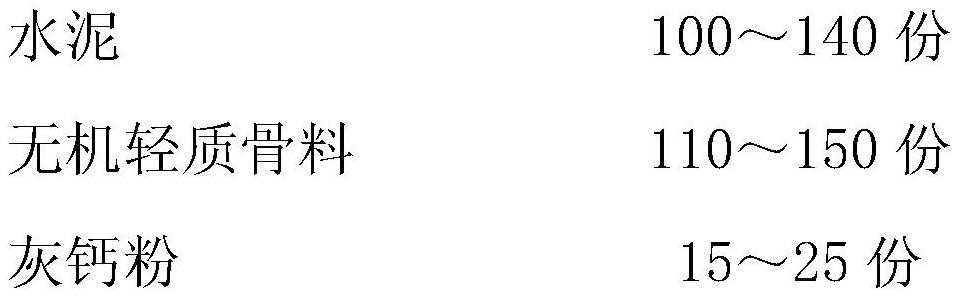

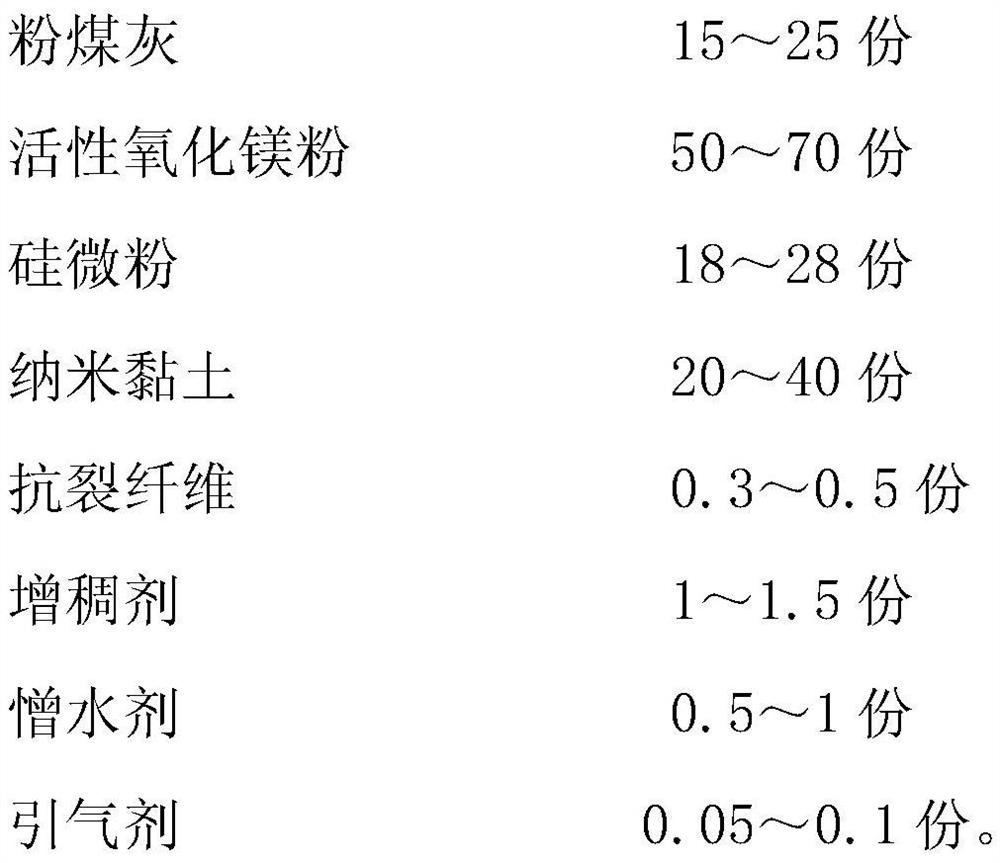

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides an inorganic active thermal insulation mortar, including 100g of cement, 110g of vitrified microspheres, 15g of ash calcium powder, 15g of fly ash, 50g of active magnesium oxide powder, 18g of silicon micropowder, 20g of nanoclay, and 0.3g of anti-crack fiber , cellulose ether 1g, water-repellent agent 0.5g, air-entraining agent 0.05g.

[0023] This embodiment also provides a preparation method of inorganic active thermal insulation mortar, said method comprising the following steps:

[0024] Step S1, weighing raw materials according to proportional weight: 100g of cement, 110g of vitrified microspheres, 15g of lime calcium powder, 15g of fly ash, 50g of activated magnesium oxide powder, 18g of silicon micropowder, 20g of nanoclay, and 0.3 g, cellulose ether 1g, water-repellent agent 0.5g, air-entraining agent 0.05g;

[0025] Step S2, put the above-mentioned weighed raw materials into a stirring container, stir and mix well to obtain an inorgan...

Embodiment 2

[0032] This embodiment provides an inorganic active thermal insulation mortar, including 120g of cement, 130g of vitrified microspheres, 18g of ash calcium powder, 18g of fly ash, 58g of active magnesium oxide powder, 22g of silicon micropowder, 28g of nanoclay, and 0.4g of crack-resistant fiber , cellulose ether 1.1g, water-repellent agent 0.6g, air-entraining agent 0.07g.

[0033] This embodiment also provides a preparation method of inorganic active thermal insulation mortar, said method comprising the following steps:

[0034] Step S1, weighing raw materials according to proportional weight: 120g of cement, 130g of vitrified microspheres, 18g of lime calcium powder, 18g of fly ash, 58g of activated magnesium oxide powder, 22g of silicon micropowder, 28g of nanoclay, 0.4g of anti-crack fiber g, cellulose ether 1.1g, water-repellent agent 0.6g, air-entraining agent 0.07g;

[0035] Step S2, put the above-mentioned weighed raw materials into a stirring container, stir and mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com