High-fluidity ultrahigh-strength cement-based grouting material and preparation method thereof

An ultra-high-strength, high-fluidity technology, applied in the field of building materials, can solve problems such as failure to meet environmental protection requirements, large environmental pollution, and single performance, and achieve the effects of reliable quality, long service life, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

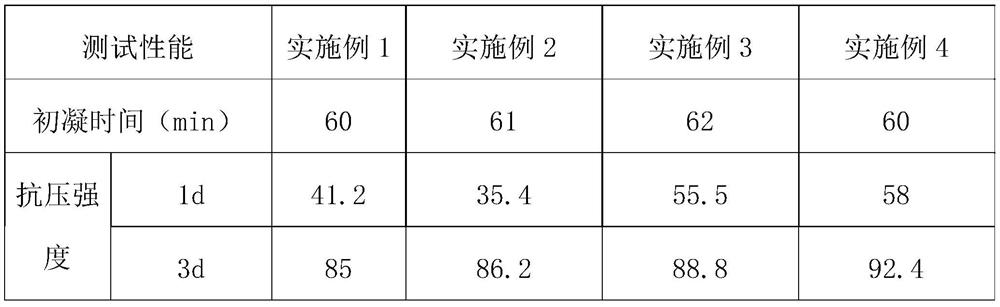

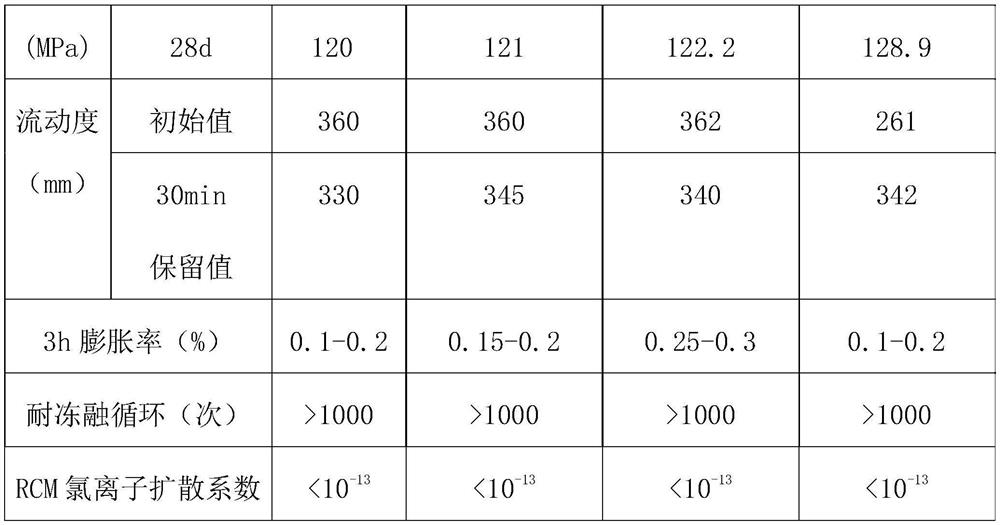

Examples

preparation example Construction

[0043] The preparation method of the above-mentioned high-fluidity ultra-high-strength cement-based grouting material comprises the following steps:

[0044] Mixing steps: Wet the barrel of the mixer, then add the formula amount of cement, quartz sand, coagulant and expansion agent, and stir for 2-3 minutes to obtain the mixture;

[0045] Steps for preparing the finished product: Add the formulated amount of water reducer and water into the mixture, and continue to stir for 2-3 minutes to obtain a highly fluid, ultra-high-strength cement-based grouting material.

Embodiment 1

[0047] A high-fluidity, ultra-high-strength cement-based grouting material, comprising the following components in parts by weight:

[0048] 10 parts of water, 50 parts of cementitious material, 60 parts of quartz sand, 5 parts of water reducer, 3 parts of coagulant and 0.1 part of expansion agent.

[0049] Among them, the cement includes the following components: P·I52.5 ordinary Portland cement, sulphoaluminate cement, silica fume, fine mineral powder, superfine fly ash, gypsum and quartz powder. The apparent density of quartz sand is 2500kg / m 3 , The particle size of quartz sand is 70 mesh. The water reducer is a polycarboxylate water reducer.

[0050] The expansion agent is plastic expansion agent, calcium sulfoaluminate expansion agent and calcium oxide expansion agent, and the 3h limit expansion rate of the expansion agent is 0.1%.

[0051] The preparation method of the above-mentioned high-fluidity ultra-high-strength cement-based grouting material comprises the foll...

Embodiment 2

[0055] A high-fluidity, ultra-high-strength cement-based grouting material, comprising the following components in parts by weight:

[0056] 30 parts of water, 150 parts of cementitious material, 100 parts of quartz sand, 1 part of water reducer, 0.1 part of coagulant and 0.01 part of expansion agent.

[0057] Among them, the cementitious material components are P·I 52.5 ordinary Portland cement, sulphoaluminate cement, silica fume, ultrafine mineral powder, ultrafine fly ash, gypsum and quartz powder, and the percentage examples are: P· I 52.5 Ordinary Portland cement: Sulphoaluminate cement: Silica fume: Ultrafine mineral powder: Ultrafine fly ash: Gypsum: Quartz powder = 50~55:5:10~15:10~12:5:10 :5.

[0058] As a further embodiment, the apparent density of quartz sand is 2500kg / m 3 -2700kg / m 3 , the particle size of the quartz sand is 20-100 mesh. The particle size distribution is: 20-40 mesh: 40-70 mesh: 70-110 mesh = 2:5:3.

[0059] The expansion agent is a plastic e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com