Polymer concrete composition containing atomized steel slag and method for producing the same

A technology of concrete and composition, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of increased drying shrinkage, deterioration of chemical corrosion resistance, application of atomized steel slag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

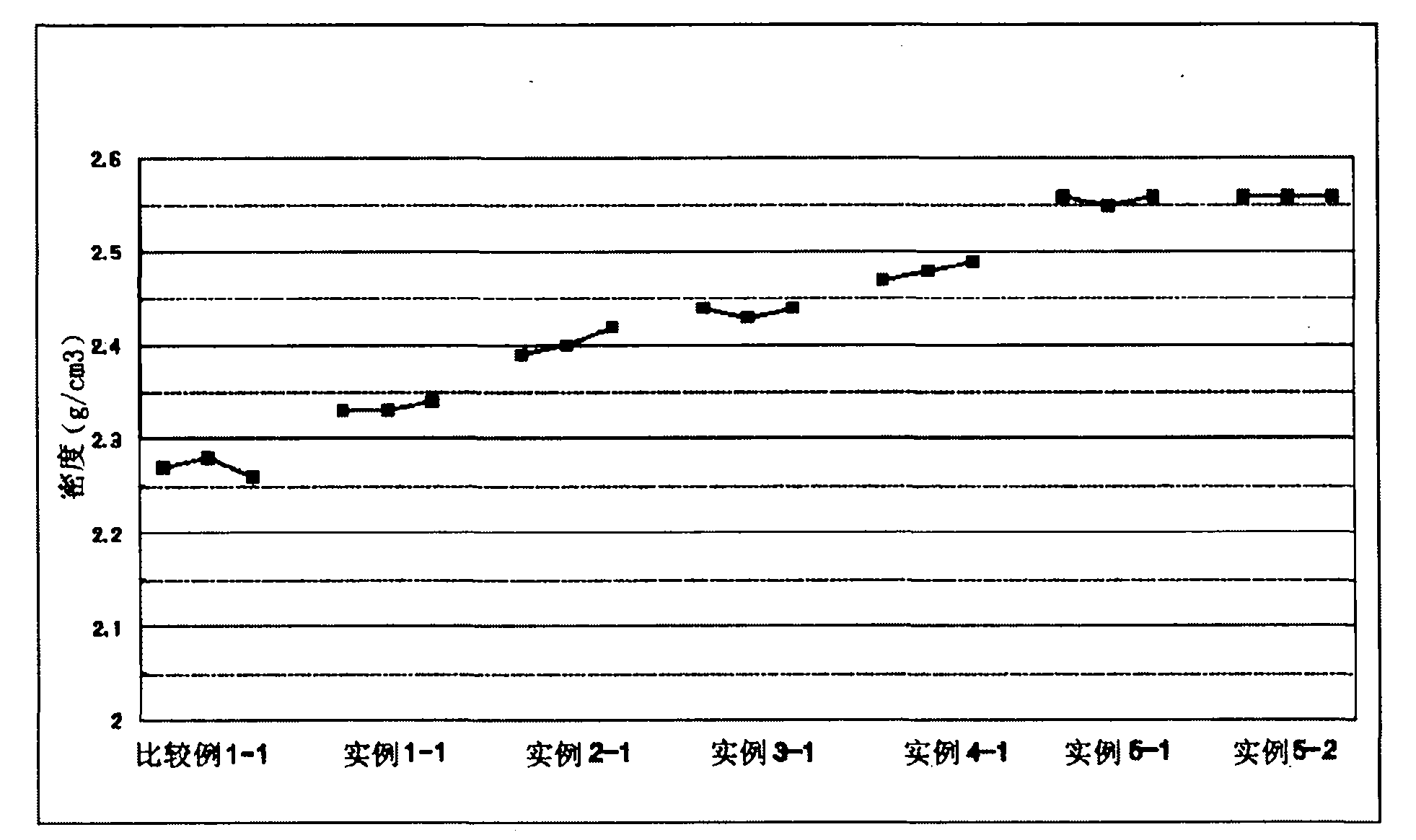

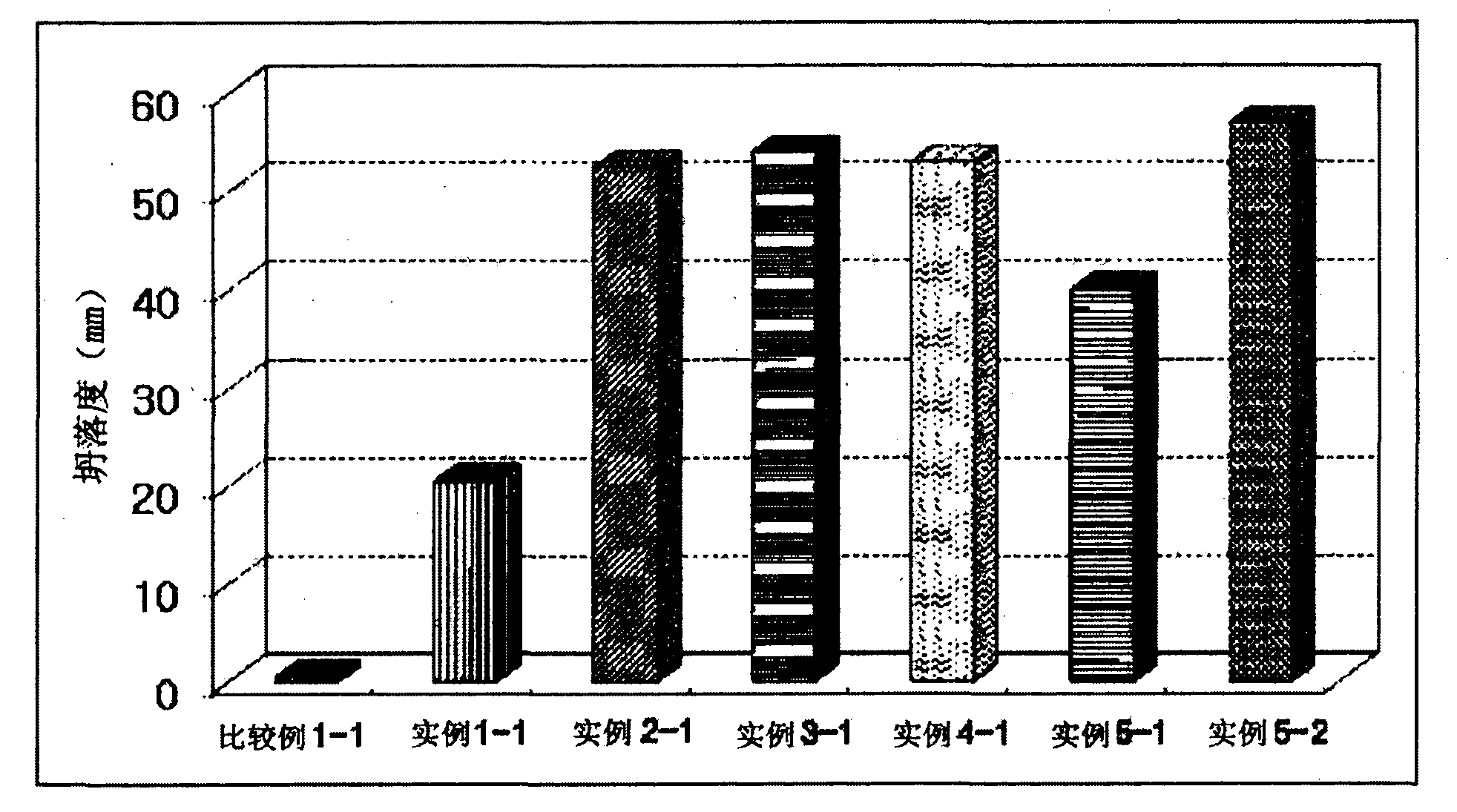

example 1

[0052] The polymer concrete product according to the present invention is manufactured using atomized steel slag as a 25% replacement of conventional fine aggregate while varying the amount of unsaturated polyester resin.

[0053] 1-1: When the amount of polymer resin is 15 vol%

[0054] (a) Using a forced mixer, 12 vol% of unsaturated polyester resin and 3 vol% of polystyrene resin were mixed.

[0055] (b) Using a forced mixer, 16.85vol% ground calcium carbonate, 47vol% coarse aggregate, 15.75vol% fine aggregate and 5.25vol% atomized steel slag were mixed together.

[0056] (c) Mix the polymer resin obtained in step (a) and the powder mixture obtained in step (b) together, after adding 0.15vol% of methyl ethyl ketone peroxide, then use a forced mixer to fully mix, by This produces a polymer concrete composition comprising atomized steel slag.

[0057] (d) The polymer concrete composition thus produced was stirred for 5 minutes, and then loaded into a mold.

[0058] (e) Vib...

example 2

[0069] The polymer concrete product according to the present invention is manufactured using atomized steel slag as a 50% replacement of conventional fine aggregate while varying the amount of unsaturated polyester resin.

[0070] 2-1: When the amount of polymer resin is 15vol%

[0071] A polymer concrete product was produced in the same manner as in Example 1-1. In addition to use: 12vol% unsaturated polyester resin, 3vol% polystyrene resin, 47vol% coarse aggregate, 10.05vol% fine aggregate, 10.05vol% atomized steel slag, 16.85vol % of ground calcium carbonate and 0.15 vol% of methyl ethyl ketone peroxide.

[0072] 2-2: When the amount of polymer resin is 17vol%

[0073] A polymer concrete product was produced in the same manner as in Example 1-1. In addition to use: 13.6vol% unsaturated polyester resin, 3.4vol% polystyrene resin, 46vol% coarse aggregate, 10.25vol% fine aggregate, 10.25vol% atomized steel slag, 16.33 vol% ground calcium carbonate and 0.17 vol% methyl ethy...

example 3

[0081] The polymer concrete product according to the present invention is manufactured using atomized steel slag as a 75% replacement of conventional fine aggregate while varying the amount of unsaturated polyester resin.

[0082] 3-1: When the amount of polymer resin is 15vol%

[0083] A polymer concrete product was produced in the same manner as in Example 1-1. In addition to use: 12vol% unsaturated polyester resin, 3vol% polystyrene resin, 47vol% coarse aggregate, 5.25vol% fine aggregate, 15.75vol% atomized steel slag, 16.85vol % of ground calcium carbonate and 0.15 vol% of methyl ethyl ketone peroxide.

[0084] 3-2: When the amount of polymer resin is 17vol%

[0085] A polymer concrete product was produced in the same manner as in Example 1-1. In addition to use: 13.6vol% unsaturated polyester resin, 3.4vol% polystyrene resin, 46vol% coarse aggregate, 5.13vol% fine aggregate, 15.37vol% atomized steel slag, 16.33 vol% ground calcium carbonate and 0.17 vol% methyl ethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com