Interior wall water paint and preparation method thereof

A water-based paint and interior wall technology, applied in the field of interior wall decoration coatings, can solve problems such as canceration, nervous system and hematopoietic function hazards, and environmental pollution, and achieve the effects of good water resistance, ultra-low heavy metal element content, and high contrast ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides the preparation method of interior wall paint described in above-mentioned scheme, comprises the following steps:

[0042] Dissolving the cellulose in part of the water, and then performing the first mixing with the water-based dispersant, part of the water-based defoamer, water-based wetting agent, film-forming aid and neutralizing agent to obtain the first mixture;

[0043] The first mixture is mixed with rutile titanium dioxide, mica powder, calcined kaolin, talcum powder, and heavy calcium for a second time to obtain a second mixture;

[0044] The second mixture is mixed with the water-based special emulsion, the remaining water-based defoamer, bactericide and antifreeze to obtain the third mixture;

[0045] The third mixing material, the thickener and the neutralizing agent are mixed for the fourth time, so that the pH value of the mixing material reaches 7.5-9, and then the remaining water is added to obtain the interior wall water p...

Embodiment 1~5

[0051] The trade mark and following of the raw material used in the embodiment:

[0052] Water-based special emulsion (8178 Wanhua Chemical)

[0053] Cellulose (HS30000YP2 Clariant)

[0054] Water-based dispersant (731A Dow)

[0055] Water-based wetting agent (070 Dow)

[0056] Water-based defoamer (A) (KFK Dow)

[0057] Water-based defoamer (B) (6002 Solvay)

[0058] Coalescing agent (DALPAD C Dow)

[0059] Neutralizer (MAP95 Dow)

[0060] Antifreeze (FT-100 Solvay)

[0061] Fungicide (BZ55 Wilbur)

[0062] Thickener (8W Dow)

[0063] Rutile titanium dioxide (996 Sichuan Lomon Group Co., Ltd., particle size 5-20 μm)

[0064] Heavy calcium (20~80μm)

[0065] Calcined kaolin (SX-80A Inner Mongolia Sanxin Kaolin Co., Ltd.)

[0066] Mica powder (1250 mesh)

[0067] Talc powder (1250 mesh)

[0068] deionized water (homemade)

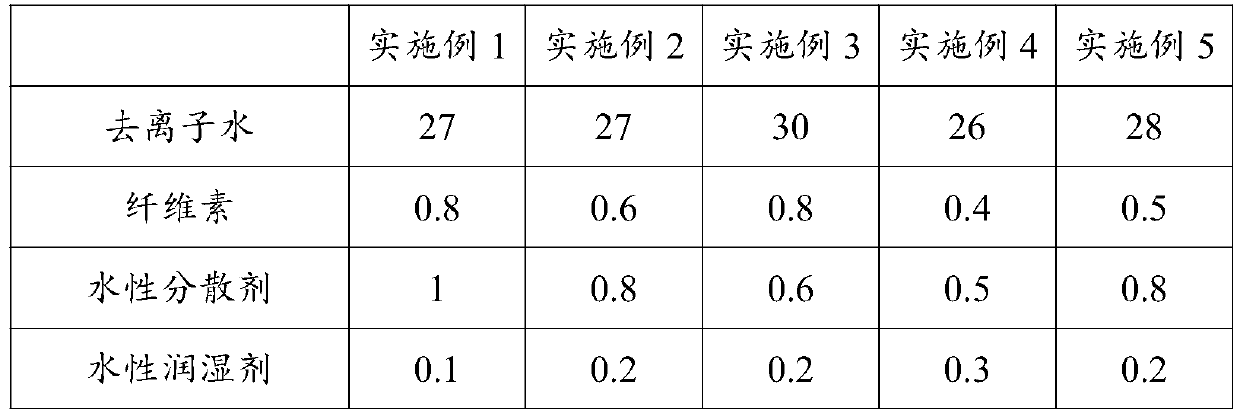

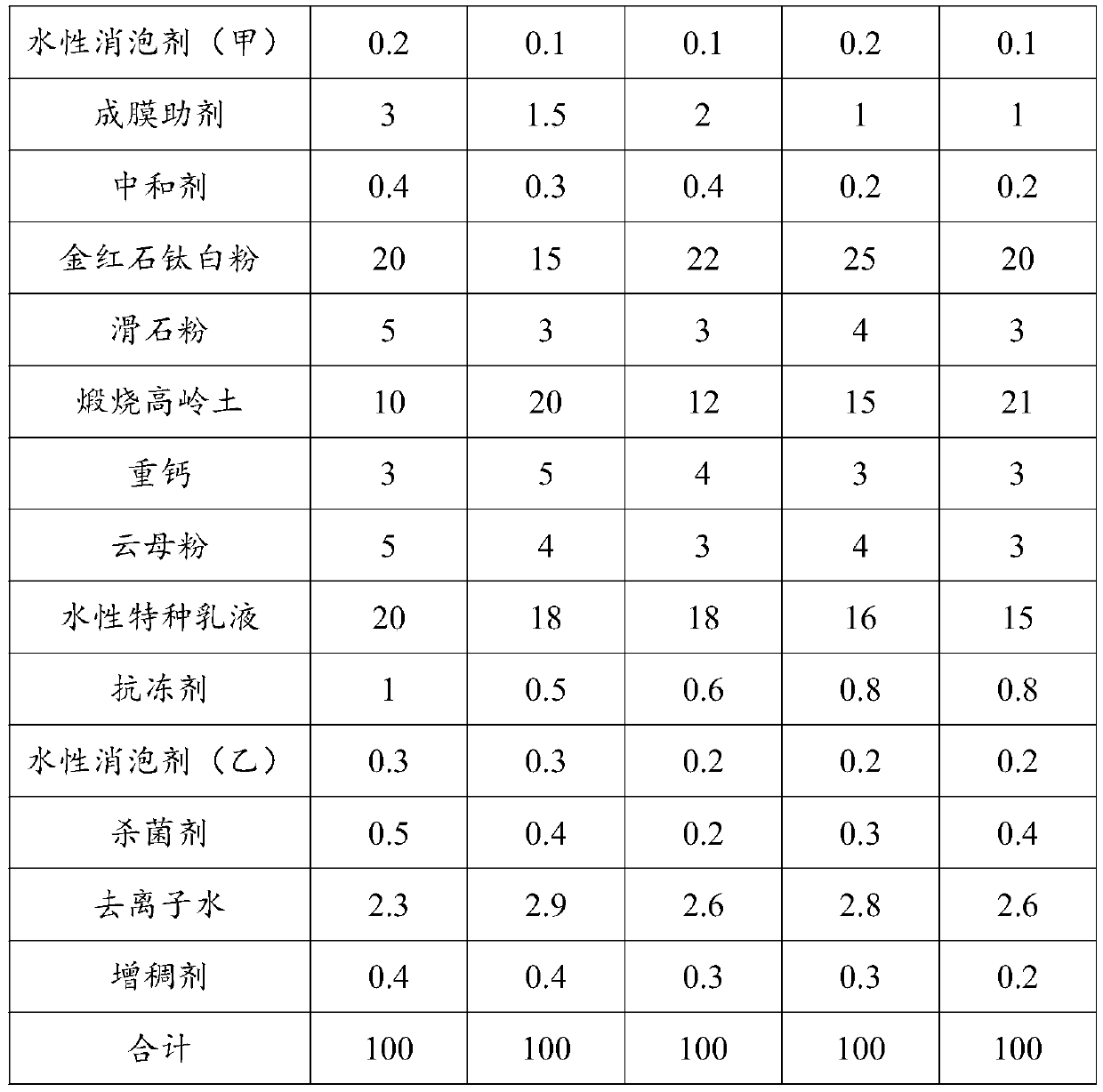

[0069] The component distribution ratio of the zero-VOC interior wall water paint in Examples 1-5 is shown in Table 1:

[0070] Table 1: The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com