A self-cleaning organic-inorganic hybrid composite coating and its preparation method and application

A hybrid composite, self-cleaning technology, applied in the field of building interior and exterior wall coatings, can solve the problems of easy cracking, expensive fluorine-containing monomers, dirty coatings, etc., to prevent cracking, excellent self-cleaning and antifouling performance, The effect of preventing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

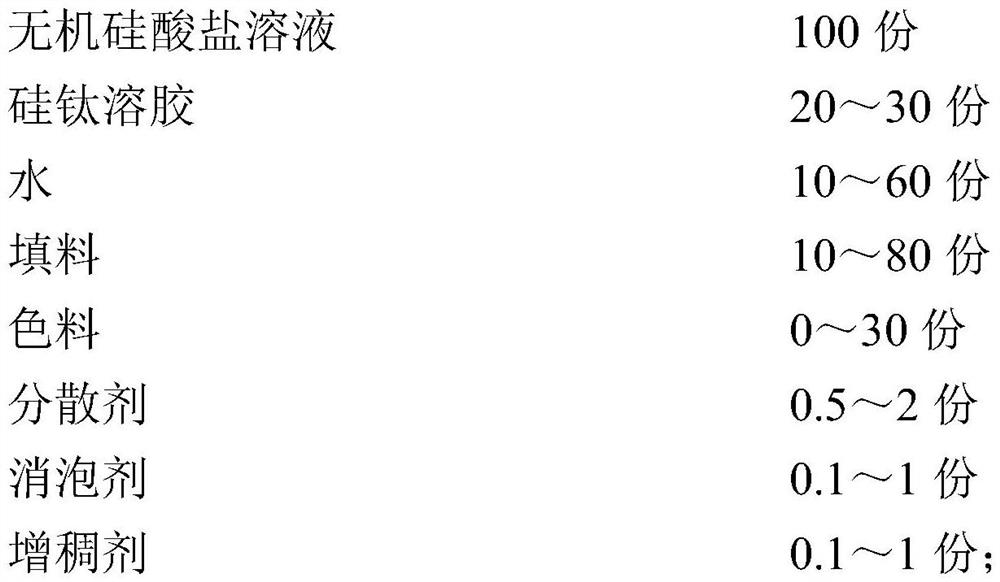

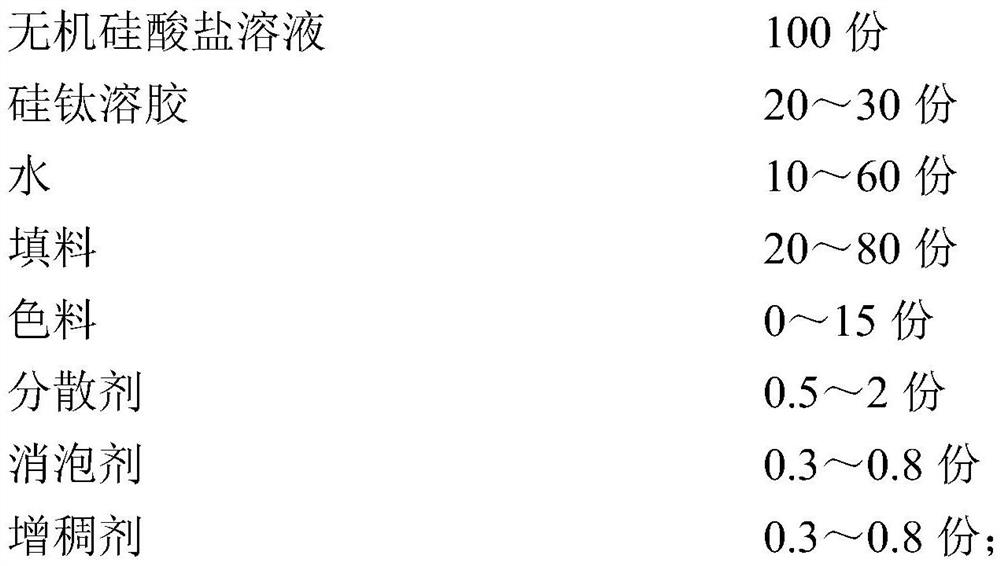

Method used

Image

Examples

preparation example Construction

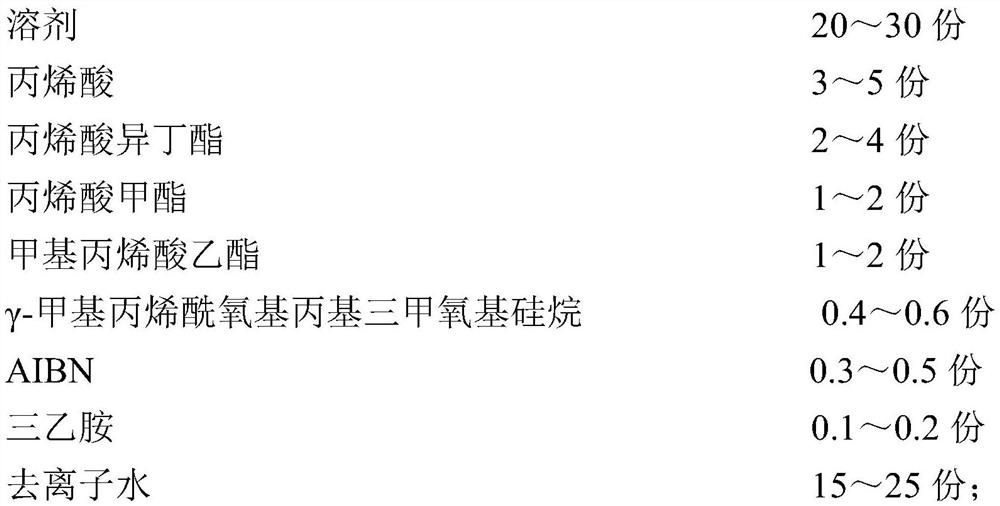

[0067] The preparation steps of the high-silicon-content silicone-acrylic emulsion grafted with silicone are as follows:

[0068] a. Preparation of acrylate emulsion: After adding 20g butanone solvent into the reaction flask, add 4g acrylic acid, 3g isobutyl acrylate, 1.5g methyl acrylate, 1.5g ethyl methacrylate at 80°C for 3.5h at reflux, Then add 0.5 g of γ-methacryloxypropyl trimethoxysilane, 0.4 g of AIBN (dissolved in 5 g of butanone), and carry out a second reflux reaction at 80 ° C for 1 h; finally, after cooling to room temperature, 0.15 g of triethylamine was added dropwise for partial hydrolysis, 20 g of deionized water was added, and finally the solvent butanone was removed by rotary evaporation to obtain an acrylate emulsion.

[0069] b. Preparation of siloxane anionic emulsion: add 10g octamethylcyclotetrasiloxane (D4) and 1g dodecylbenzenesulfonic acid (DBSA) in the reaction flask, finally add 20g deionized water, and heat up to 75 °C, reflux and stir for 1.75h...

Embodiment A

[0073] In a beaker, add 50 parts by weight of the silicone-grafted high-silicon-content silicon-acrylic emulsion prepared in Example I, add 50 parts by weight of silica sol and 10 parts by weight of titanium sol, stir at room temperature, and the ternary system is mixed. After reaction for 3 h, a stable silica-titanium sol was obtained.

Embodiment B

[0075] In a beaker, add 50 parts by weight of the silicone-grafted high-silicon-content silicon-acrylic emulsion prepared in Example I, add 50 parts by weight of silica sol and 15 parts by weight of titanium sol, stir at room temperature, and the ternary system is mixed. After reaction for 3 h, a stable silica-titanium sol was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com