Toughened type water-borne epoxy resin and preparation method thereof

A water-based epoxy resin and toughening technology, which is applied in the field of coating materials, can solve the problems of poor heat resistance and impact damage resistance, poor impact resistance and moisture resistance, and high bonding strength of epoxy resin, so as to achieve washing resistance Excellent performance, easy cleaning, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

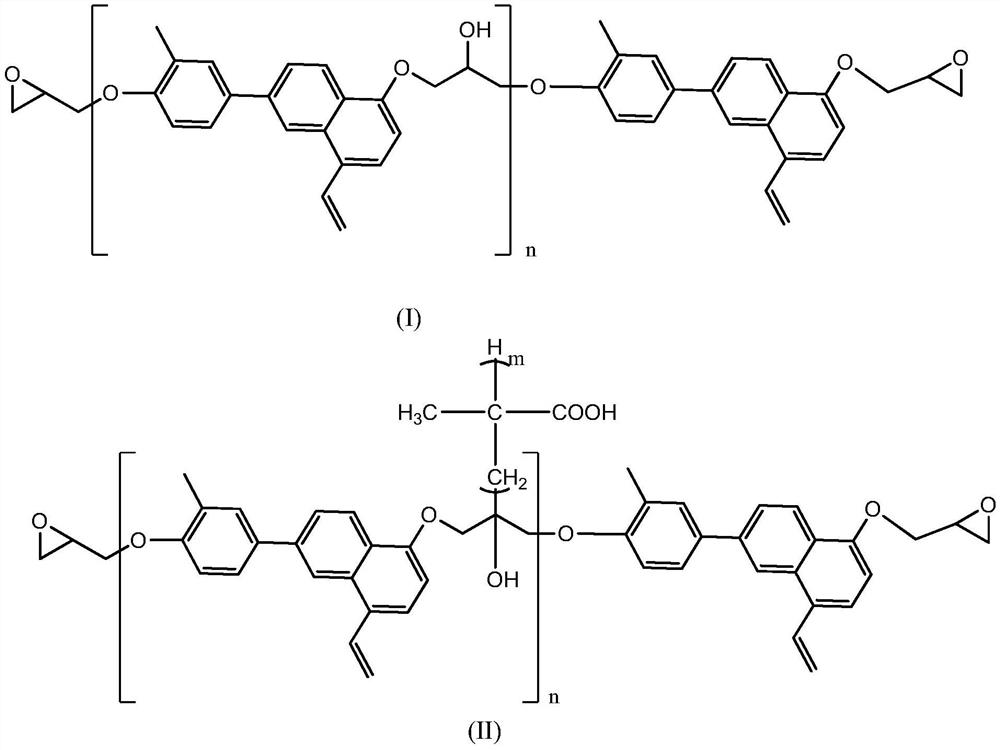

[0026] Dissolve the compound represented by formula III in toluene, add aqueous sodium hydroxide solution, heat while stirring, stir at a constant temperature when the temperature rises to 65°C, and add glycidol dropwise, and the dropwise addition is completed within 2 hours; raise the temperature , kept at 80°C for 1.5h; add distilled water, stir, statically separate and remove the water layer, evaporate the toluene layer to dryness under reduced pressure to obtain the compound shown in formula I; the molar ratio of the compound shown in formula III to glycidyl alcohol is n: (2n+2 to 2n+4); the content of sodium hydroxide in the aqueous sodium hydroxide solution is 0.5n-1.5n moles; the volume ratio of distilled water and toluene is 3:1.

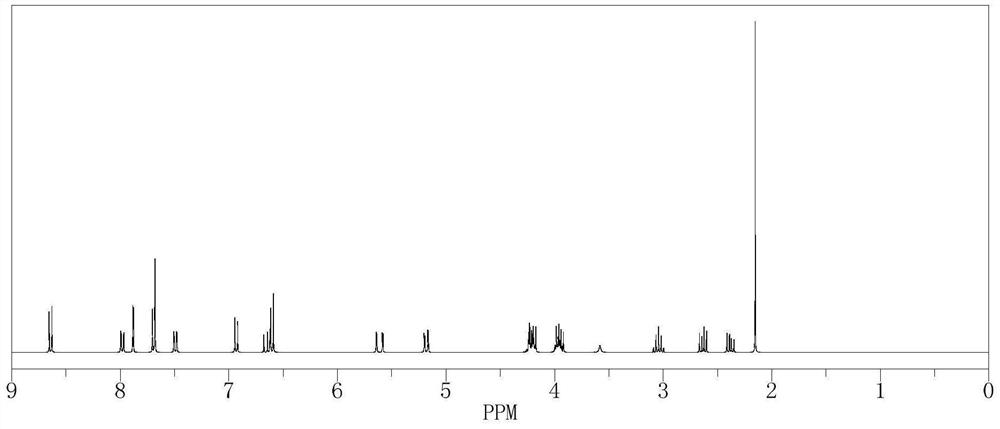

[0027] Obtain reaction product 674.1g, m / z 720.31, hydrogen spectrum see figure 1 .

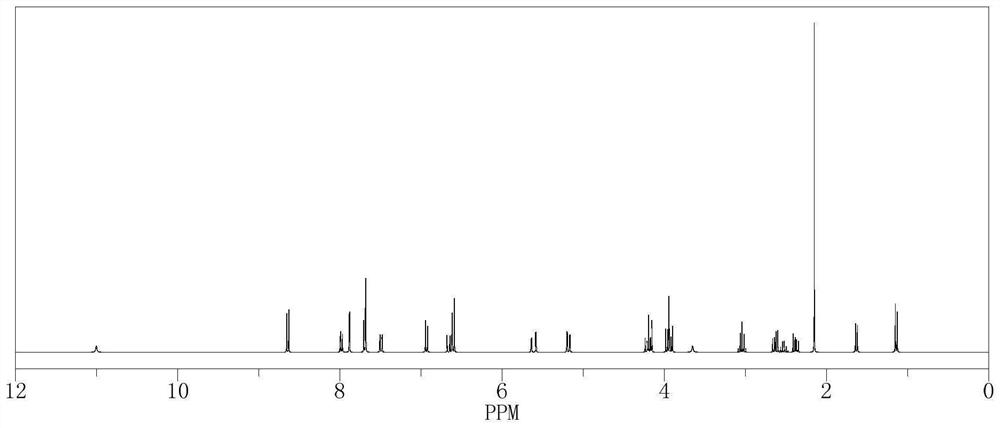

[0028] Dissolve the compound shown in formula I in a mixed solvent, under the protection of nitrogen, slowly add methacrylic acid and styrene dropwise, th...

Embodiment 2

[0031] Dissolve the compound represented by formula III in toluene, add sodium hydroxide aqueous solution, heat while stirring, when the temperature rises to 60°C, stir at a constant temperature and add glycidol dropwise, and the dropwise addition is completed within 2 hours; raise the temperature , kept at 75°C for 2h; add distilled water, stir, statically separate and remove the water layer, evaporate the toluene layer to dryness under reduced pressure to obtain the compound shown in formula I; the molar ratio of the compound shown in formula III to glycidyl alcohol is n:( 2n+2 to 2n+4); the content of sodium hydroxide in the aqueous sodium hydroxide solution is 0.5n-1.5n moles; the volume ratio of distilled water and toluene is 4:1.

[0032] Obtain reaction product 569.1g, m / z 720.31, hydrogen spectrum see figure 1 .

[0033] Dissolve the compound shown in formula I in a mixed solvent, under the protection of nitrogen, slowly add methacrylic acid and styrene dropwise, then...

Embodiment 3

[0036] Dissolve the compound represented by formula III in toluene, add aqueous sodium hydroxide solution, heat while stirring, stir at a constant temperature when the temperature rises to 70°C, and add glycidol dropwise, and the dropwise addition is completed within 2 hours; raise the temperature , kept at 85°C for 1h; add distilled water, stir, statically separate and remove the water layer, evaporate the toluene layer under reduced pressure to obtain the compound shown in formula I; the molar ratio of the compound shown in formula III to glycidyl alcohol is n:( 2n+2 to 2n+4); the content of sodium hydroxide in the aqueous sodium hydroxide solution is 0.5n-1.5n moles; the volume ratio of distilled water and toluene is 2:1.

[0037] Obtain reaction product 497.3g, m / z 720.31, hydrogen spectrum sees figure 1 .

[0038] Dissolve the compound shown in formula I in a mixed solvent, under the protection of nitrogen, slowly add methacrylic acid and styrene dropwise, then add the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com