Fly ash coated sludge ceramsite and preparation method therefor

A technology for sludge ceramsite and fly ash, which is applied to ceramic products, clay products, other household appliances, etc., to achieve the effect of inhibiting escape and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

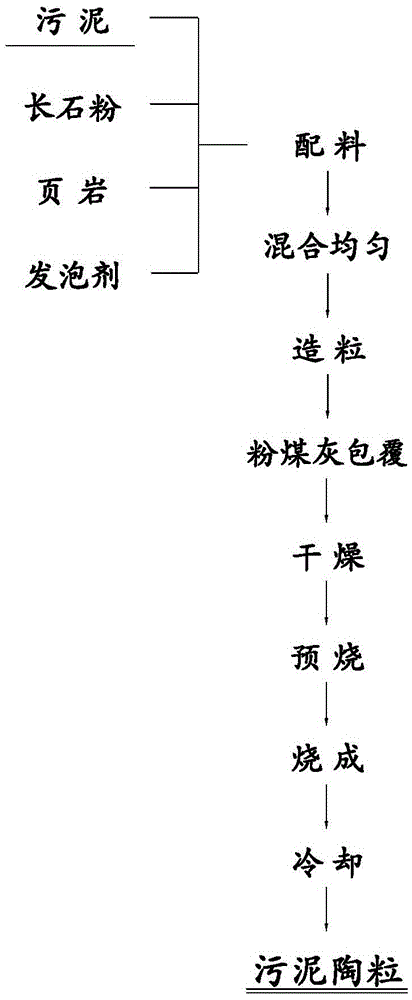

[0032] A fly ash-coated sludge ceramsite and a preparation method thereof, comprising the following steps:

[0033] (1) The sludge was dried and pulverized in a drying oven at 110°C, and 45.0g of dewatered sludge, 30.8g of shale, 22.0g of feldspar powder, and 2.2g of silicon carbide were accurately weighed according to the composition ratio. Put the accurately weighed dewatered sludge, shale, feldspar powder and silicon carbide into the mixer and mix evenly to obtain the sludge ceramsite basic mixture;

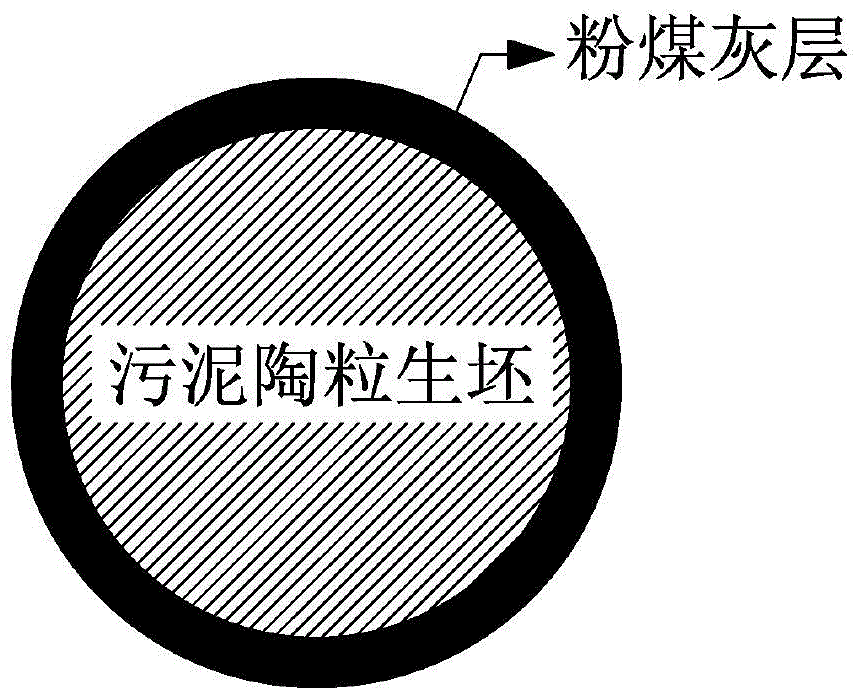

[0034] (2) Granulate the sludge ceramsite base mixture to make spherical particles with a diameter of 5-20 mm, and then coat a layer of fly ash layer on the surface of the spherical particles to obtain fly ash-coated sludge Ceramsite green body;

[0035] (3) The obtained fly ash-coated sludge ceramsite green body is placed in an oven at 110° C. for drying;

[0036] (4) Sintering the fly ash-coated sludge ceramsite green body in the step (3), the firing system is: heating up ...

Embodiment 2

[0039] A fly ash-coated sludge ceramsite and a preparation method thereof, comprising the following steps:

[0040] (1) The sludge was dried and pulverized in a drying oven at 110°C, and 46.0g of dewatered sludge, 32.8g of shale, 18.7g of feldspar powder, and 2.5g of silicon carbide were accurately weighed according to the composition ratio. Put the accurately weighed dewatered sludge, shale, feldspar powder and silicon carbide into the mixer and mix evenly to obtain the sludge ceramsite basic mixture;

[0041] (2) Granulate the sludge ceramsite base mixture to make spherical particles with a diameter of 5-20 mm, and then coat a layer of fly ash layer on the surface of the spherical particles to obtain fly ash-coated sludge Ceramsite green body;

[0042] (3) The obtained fly ash-coated sludge ceramsite green body is placed in an oven at 120° C. for drying;

[0043] (4) Sintering the fly ash-coated sludge ceramsite green body in the step (3), the firing system is: heating up ...

Embodiment 3

[0046] A fly ash-coated sludge ceramsite and a preparation method thereof, comprising the following steps:

[0047] (1) The sludge was dried and pulverized in a drying oven at 110°C, and 50.0g of dewatered sludge, 31.2g of shale, 16.1g of feldspar powder, and 2.7g of silicon carbide were accurately weighed according to the composition ratio. Put the accurately weighed dewatered sludge, shale, feldspar powder and silicon carbide into the mixer and mix evenly to obtain the sludge ceramsite basic mixture;

[0048] (2) Granulate the sludge ceramsite base mixture to make spherical particles with a diameter of 5-20 mm, and then coat a layer of fly ash layer on the surface of the spherical particles to obtain fly ash-coated sludge Ceramsite green body;

[0049] (3) The obtained fly ash-coated sludge ceramsite green body is placed in an oven at 130° C. for drying;

[0050] (4) Burning the fly ash-coated sludge ceramsite green body in the step (3), the firing system is: heating up to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com