Patents

Literature

96results about How to "Expand application channels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

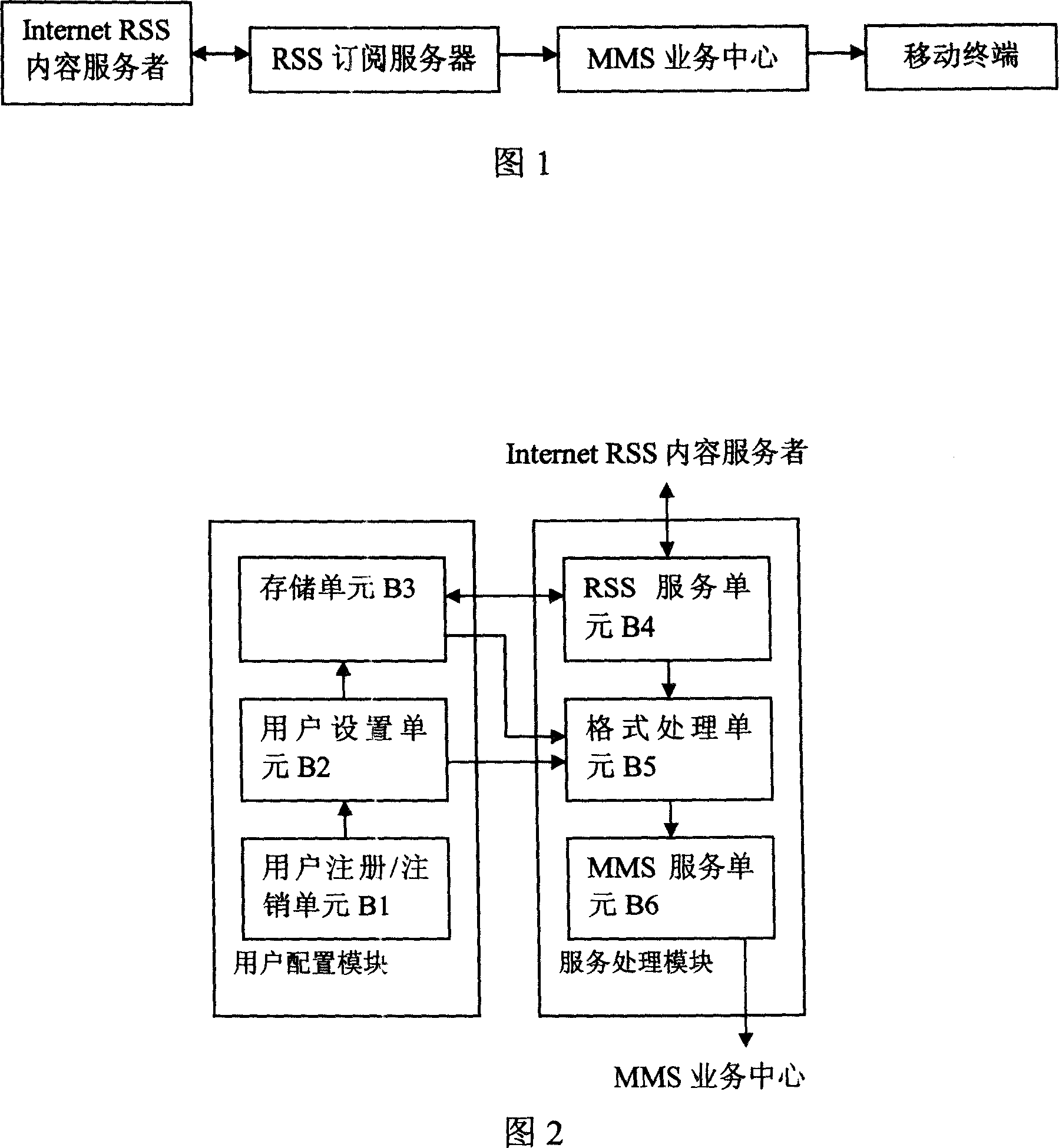

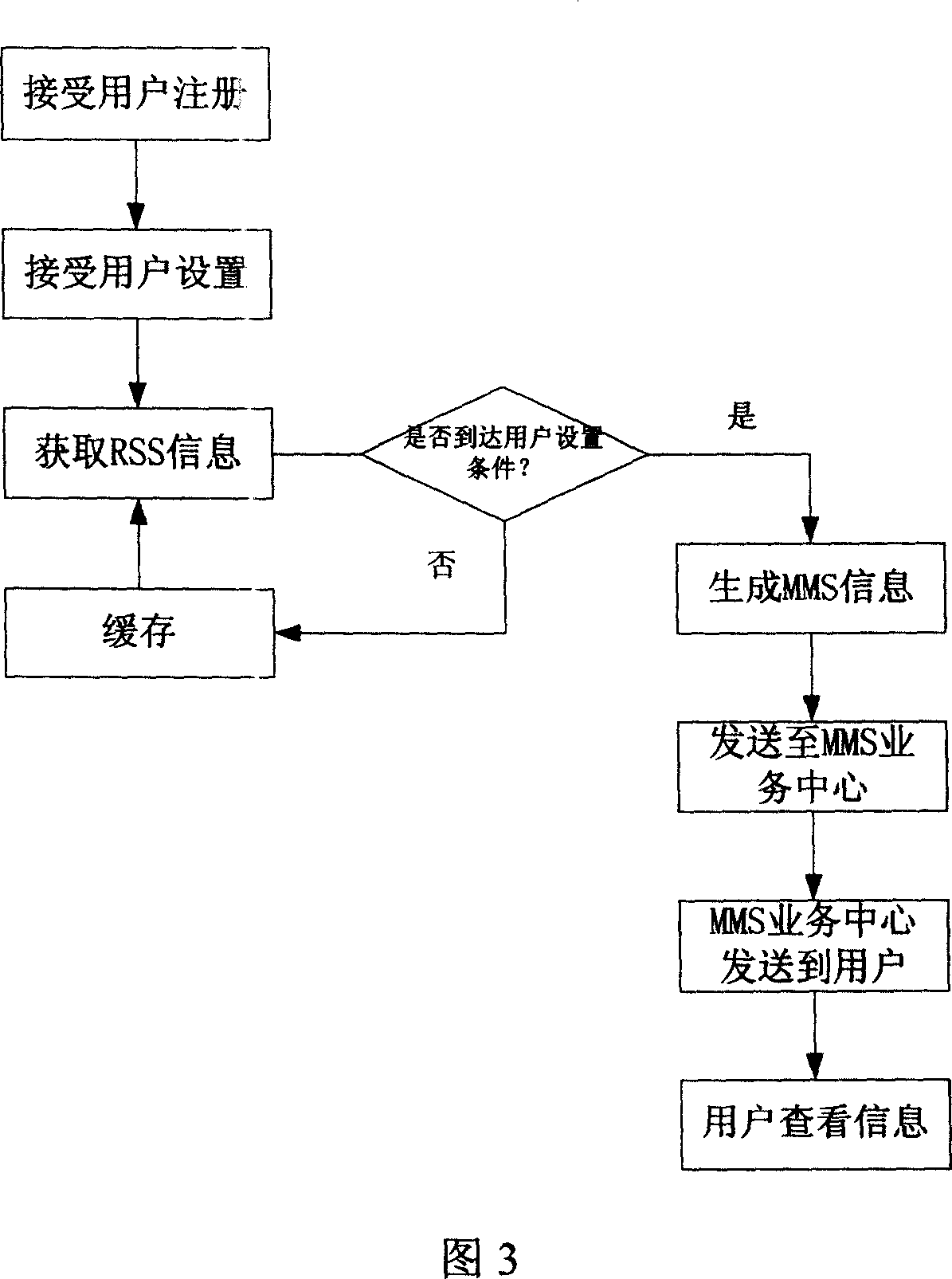

System and method for implementing RSS subscription using multimedia message of mobile terminal

InactiveCN101115225AExpand application channelsSave battery powerRadio/inductive link selection arrangementsMessaging/mailboxes/announcementsInternet networkComputer terminal

The invention discloses a mobile terminal system and method, which uses multimedia messaging to realize RSS subscription so that the users who have opened MMS service can achieve RSS subscription. The invention comprises an MMS service center, a mobile terminal with the capacity of MMS, and an RSS subscription server connected with the MMS service center. The RSS subscription server comprises a user configuration module, by which users can log in, log out and set RSS subscription service, and a service processing module, which acquires RSS contents released by Internet network according to the received configuration information from the user configuration module, and then the content is transformed into MMS format and sent to MMS service center. The method is that when users succeed in logging in by RSS subscription service, the RSS subscription server acquires updated RSS channel information from Internet RSS content providers, organizes and transforms the information into MMS format of the multimedia messaging and sends to corresponding user mobile terminals.

Owner:ZTE CORP

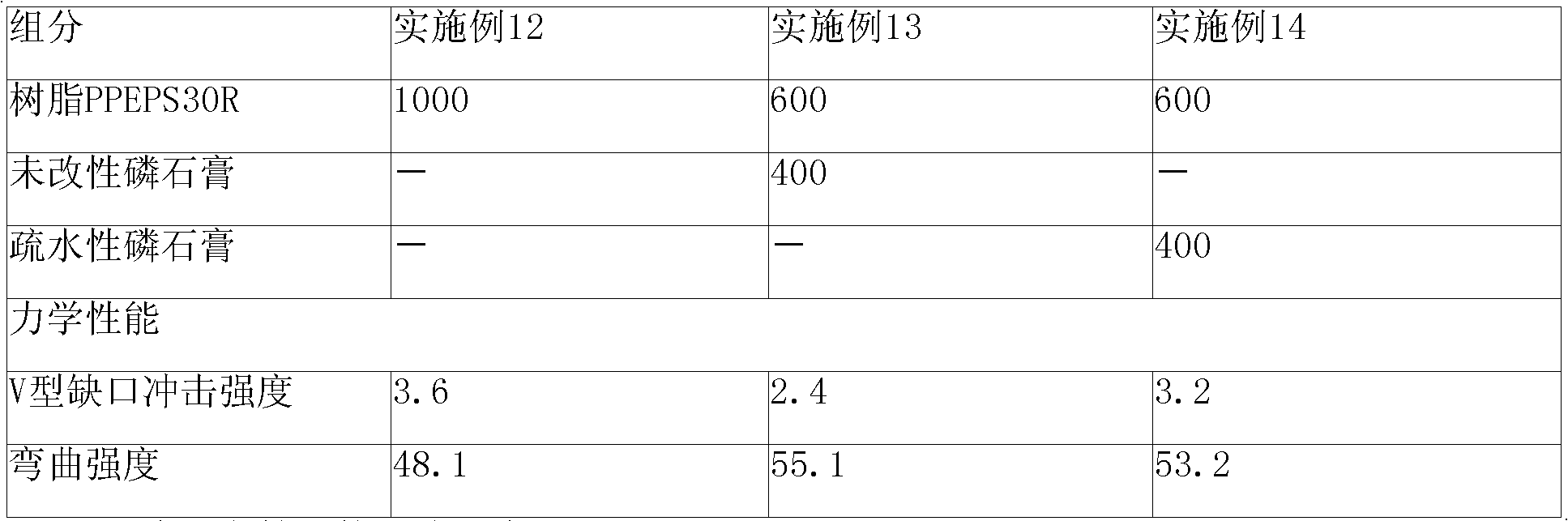

Hydrophobic phosphogypsum, and preparation method and application thereof

The invention discloses hydrophobic phosphogypsum, and a preparation method and application thereof. The hydrophobic phosphogypsum is prepared from phosphogypsum and a hydrophobic modifying agent. The preparation method comprises the following steps of: dissolving the hydrophobic modifying agent into solvent to produce the solution of the hydrophobic modifying agent; adding the phosphogypsum intothe solution; stirring the solution uniformly; reacting under a heating condition; pumping and filtering the solution when the solution is hot; and drying filter residue to obtain the hydrophobic phosphogypsum. The hydrophobic phosphogypsum can be used as inorganic filler applied to polymer. Compared with the prior art, the hydrophobic phosphogypsum has hydrophobic property due to the hydrophobicmodifying agent and is dispersed in the polymer highly and modifies the polymer by serving as the inorganic filler due to the hydrophobic property; the preparation method has the advantages of simpleness, easily-controlled technological parameters, readily available raw materials and low preparation cost; and the application way of the solid waste phosphogypsum is expanded and the modifying cost of the polymer is reduced.

Owner:WENGFU (GRP) CO LTD +2

Preparation method for silk fibroin composite gel

The invention discloses a preparation method for silk fibroin composite gel. The preparation method comprises the following steps: conducting a dissolution treatment on silk fibroin obtained by degumming in a LiBr solution; preparing a regenerated fibroin solution through dialysis; mixing the regenerated fibroin solution with Gamma- polyglutamic acid; finally, preparing the silk fibroin composite gel under the action of a cross linking agent. The preparation method is simple in technology and short in the gelation time; the efficiency is greatly improved; the required amount of the cross linking agent is small; the safety is strong; the prepared silk fibroin composite gel is degradable and has relatively high mechanical property and stronger water absorbability, so that the silk fibroin composite gel is superior to silk fibroin composite gel prepared from other methods. The silk fibroin composite gel can be used for the fields of medicine and health, tissue engineering, environmental protection and the like; the application of the silk fibroin composite gel is broadened and a novel thought and a novel method of preparing high-strength silk fibroin composite gel are provided.

Owner:ZHEJIANG UNIV

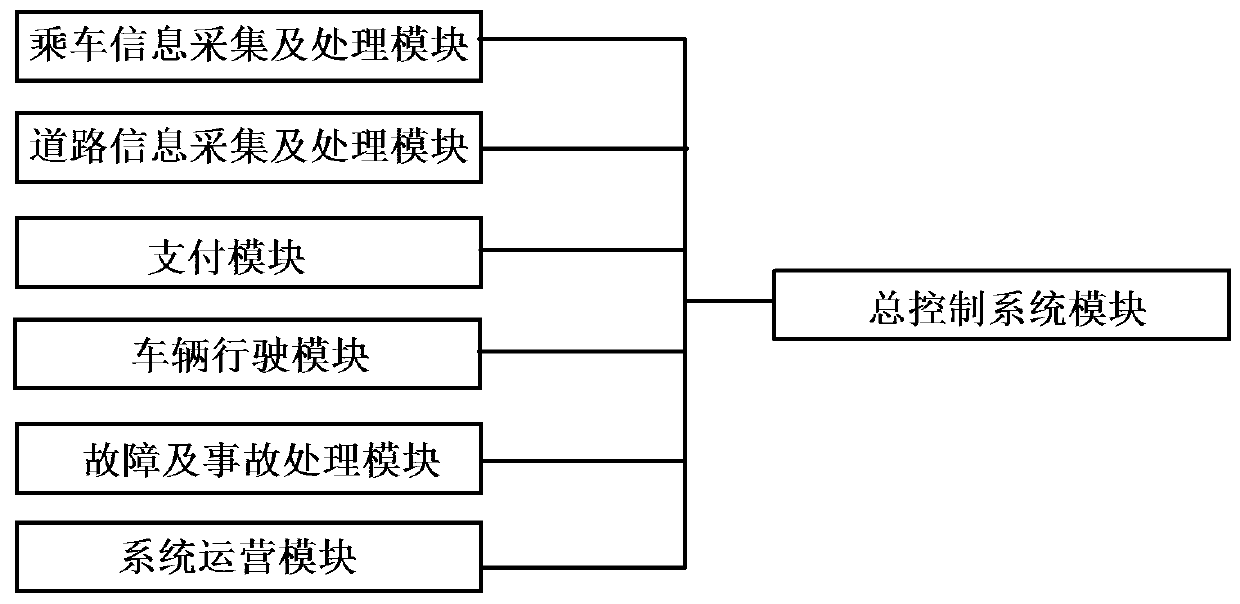

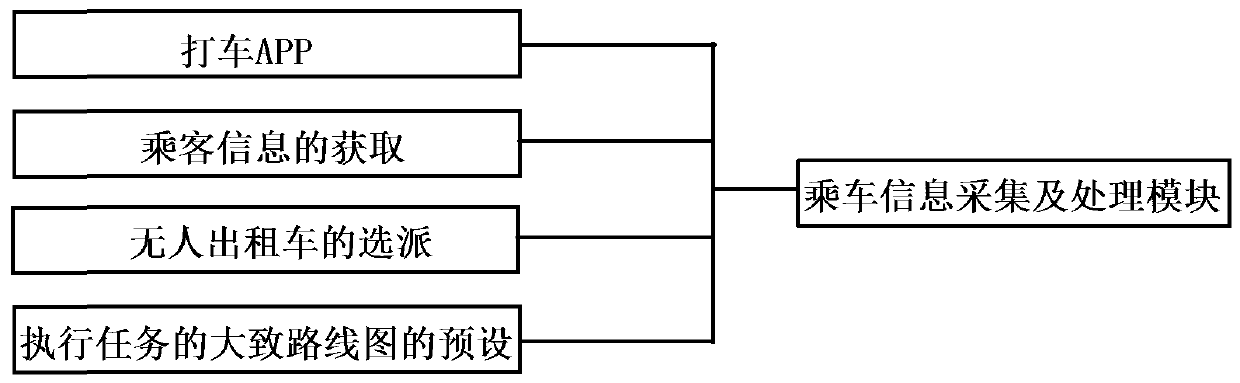

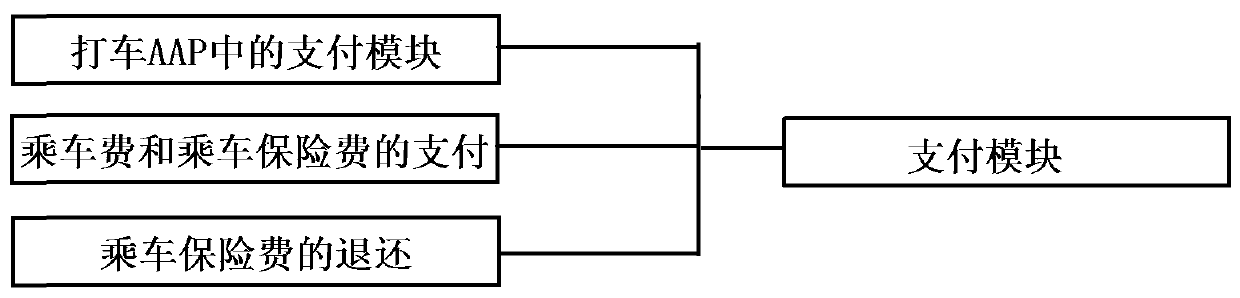

Unmanned taxi system and control method thereof

InactiveCN109559501AConvenient travelEase traffic congestionFinanceDetection of traffic movementTraffic congestionEngineering

The invention belongs to the technology field of an automobile, and particularly relates to an unmanned taxi system and a control method thereof. The system comprises an unmanned taxi, a control system, and unmanned taxi roads. The control system comprises a total vehicle control module and a total control system module. The total control system module comprises a riding information collecting andprocessing module, a road information collecting and processing module, a payment module, a vehicle traveling module, a fault and accident processing module, and a system operation module. The unmanned taxi roads comprise special roads used for the unmanned taxi and ordinary roads used for an ordinary manned vehicle. According to the unmanned taxi system and the control method thereof, a new wayof transportation for people to travel can be provided. The unmanned taxi system has advantages of safety, intelligence, convenience, low fare, and high comfort compared with an existing conventionaltransportation mode. The efficiency for people to travel is improved, which is very convenient for people in cities to travel and is of great significance for alleviating urban traffic congestion.

Owner:浙江智莱科技有限公司

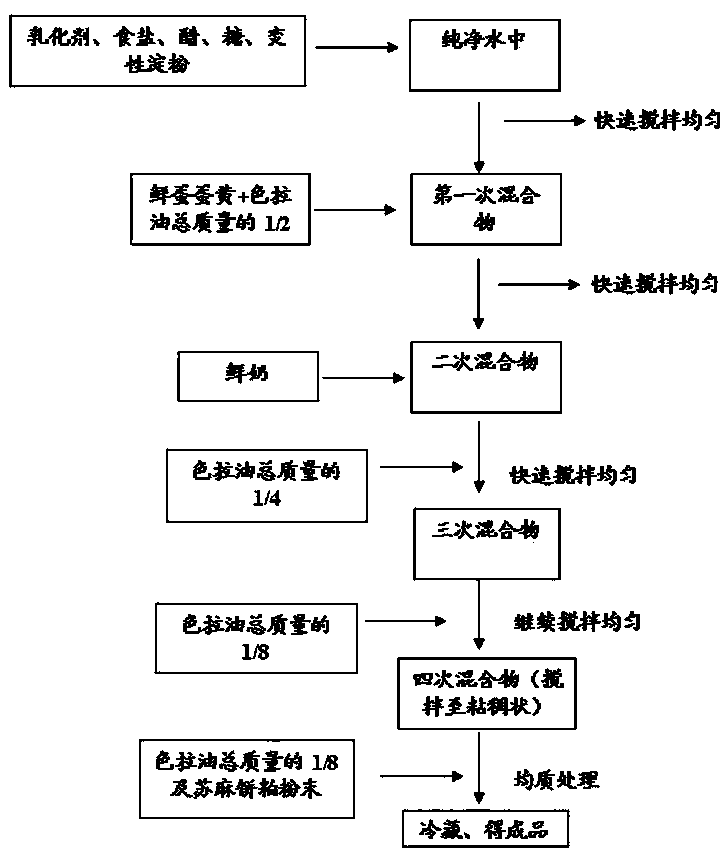

Perilla frutescens salad dressing and preparation method thereof

InactiveCN103478688AExpand application channelsReduce manufacturing costFood preparationFood ingredient as emulsifierNutritive valuesFlavor

The invention aims at disclosing a perilla frutescens salad dressing and a preparation method of the perilla frutescens salad dressing. The perilla frutescens salad dressing with perilla frutescens nutrition and special flavor is prepared mainly by the raw material of dregs obtained after oil expression of perilla frutescens seeds and auxiliary materials such as fresh eggs, fresh milk and salad oil. The perilla frutescens salad dressing product prepared by the method has very high nutritive value; the dregs of the perilla frutescens have a large quantity of protein as well as alpha-linolenic acid and the like, so that the perilla frutescens salad dressing has unique flavor and taste, and can be widely used as table sauce for fruit salad, vegetable salad or pastry. The preparation method is easy to operate, and takes dregs of perilla frutescens oil as the raw material for preparing the salad dressing, thus turning waste into wealth and allowing perilla frutescens to have more applications.

Owner:GUIZHOU UNIV

Method for adsorbing heavy metal ions by corncob cellulose-based hydrogel

ActiveCN107552008AStable structureLarge adsorption capacityOther chemical processesWater contaminantsEthylenediamineMethylene bisacrylamide

The invention discloses a method for adsorbing heavy metal ions by corncob cellulose-based hydrogel. The method comprises the steps of dissolving corncob cellulose at first, adding montmorillonoid toheat and stir to insert the corncob cellulose into montmorillonoid layers, adding tetramethyl ethylenediamine and ammonium persulfate to stir, then adding acrylic acid and N,N'-methylene bisacrylamideand continuing heating and stirring to obtain the hydrogel. The corncob cellulose is pure cellulose which is extracted from corncob by a nitric acid-ethyl alcohol method. By means of optimizing dosage of the montmorillonoid, the N,N'-methylene bisacrylamide and the acrylic acid, the corncob cellulose-based hydrogel which has the optimal structure and adsorption performance is obtained; by means of optimizing different concentrations, pH values and adsorption times of the heavy metal ion solutions, the optimal adsorption condition of the hydrogel disclosed by the invention is determined. The preparation method disclosed by the invention has the advantage of simple technology, and the prepared hydrogel has the advantages of better adsorption performance, better structural stability and goodadsorption effect on heavy metal ions.

Owner:QILU UNIV OF TECH

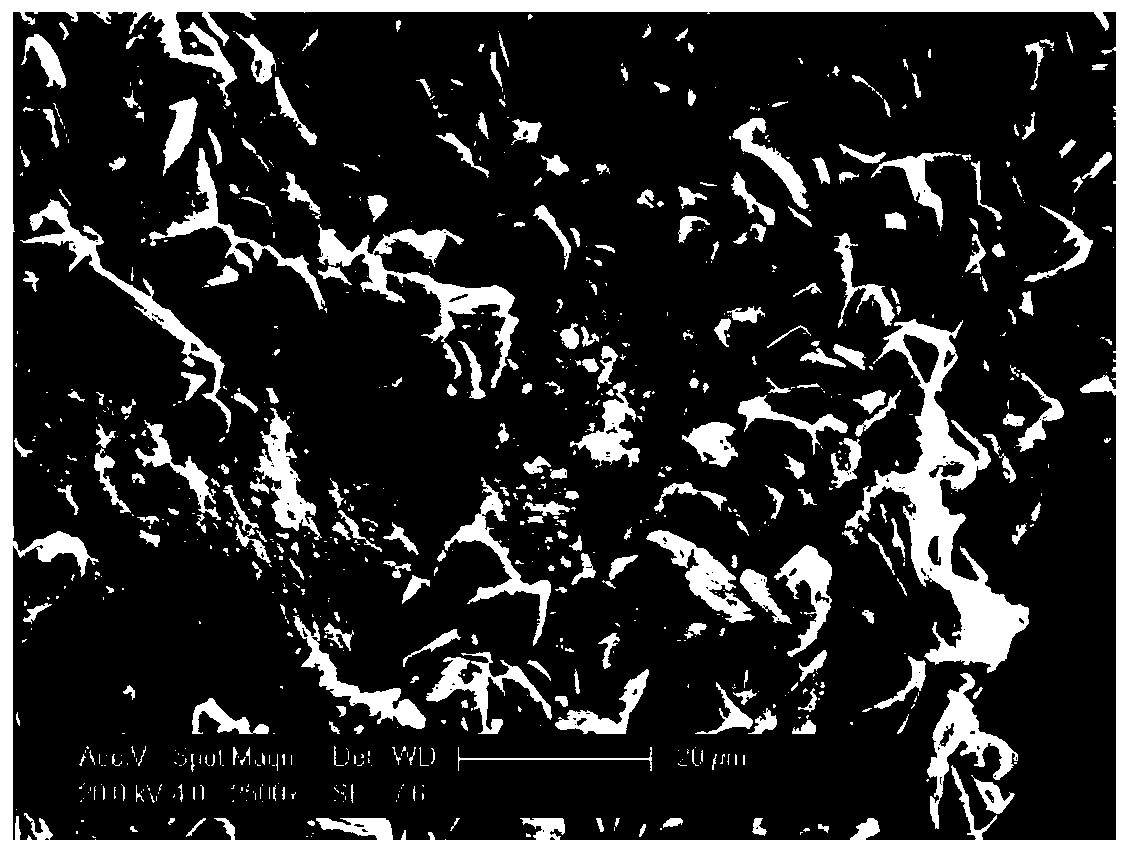

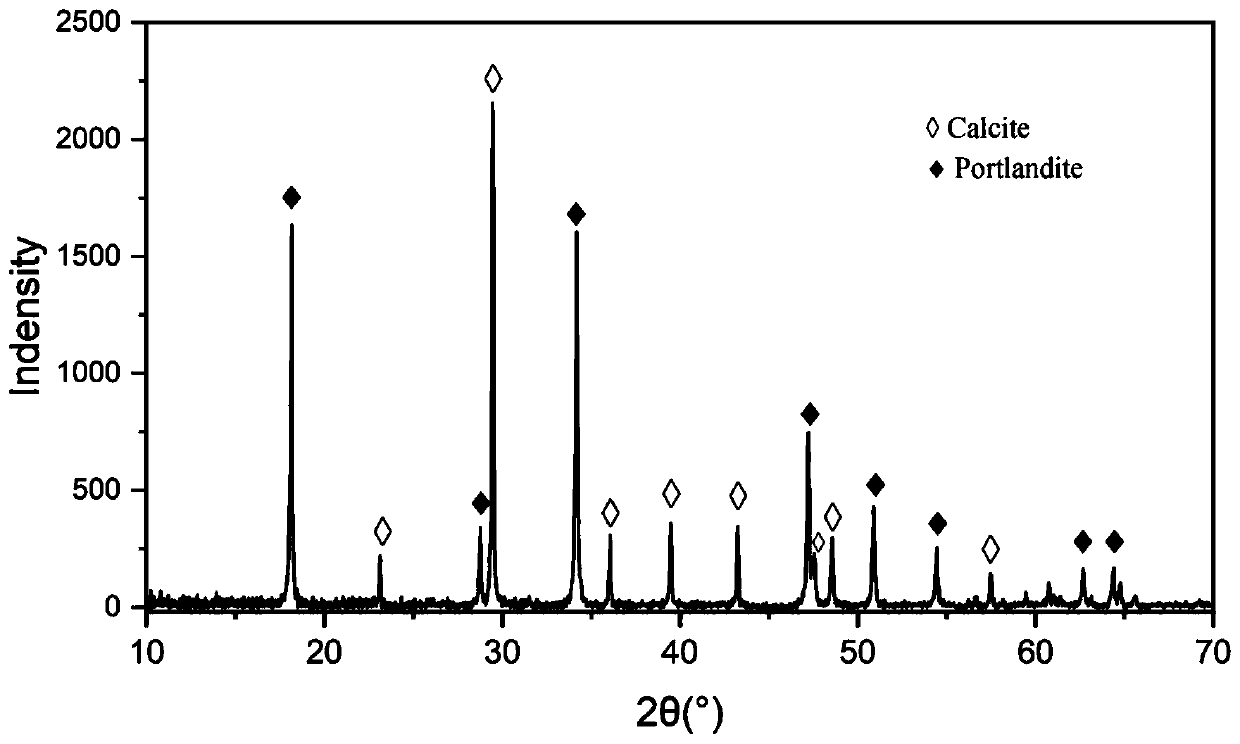

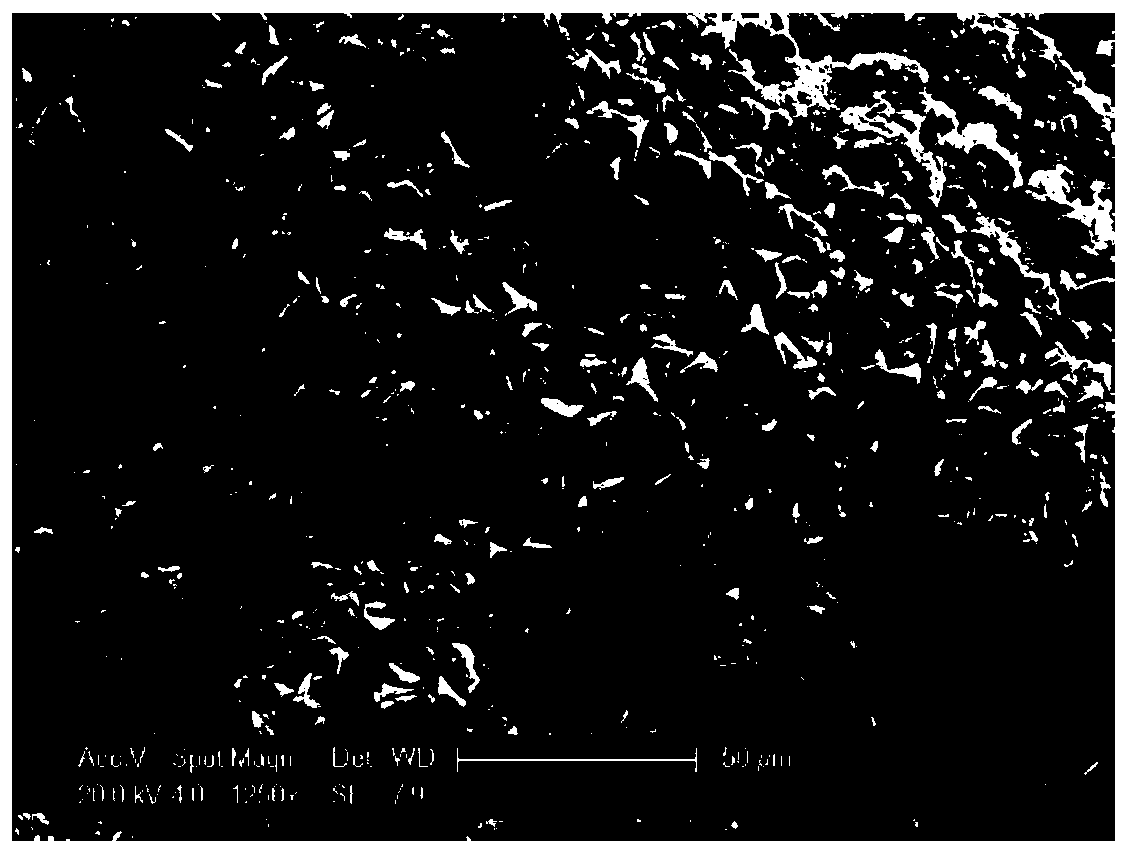

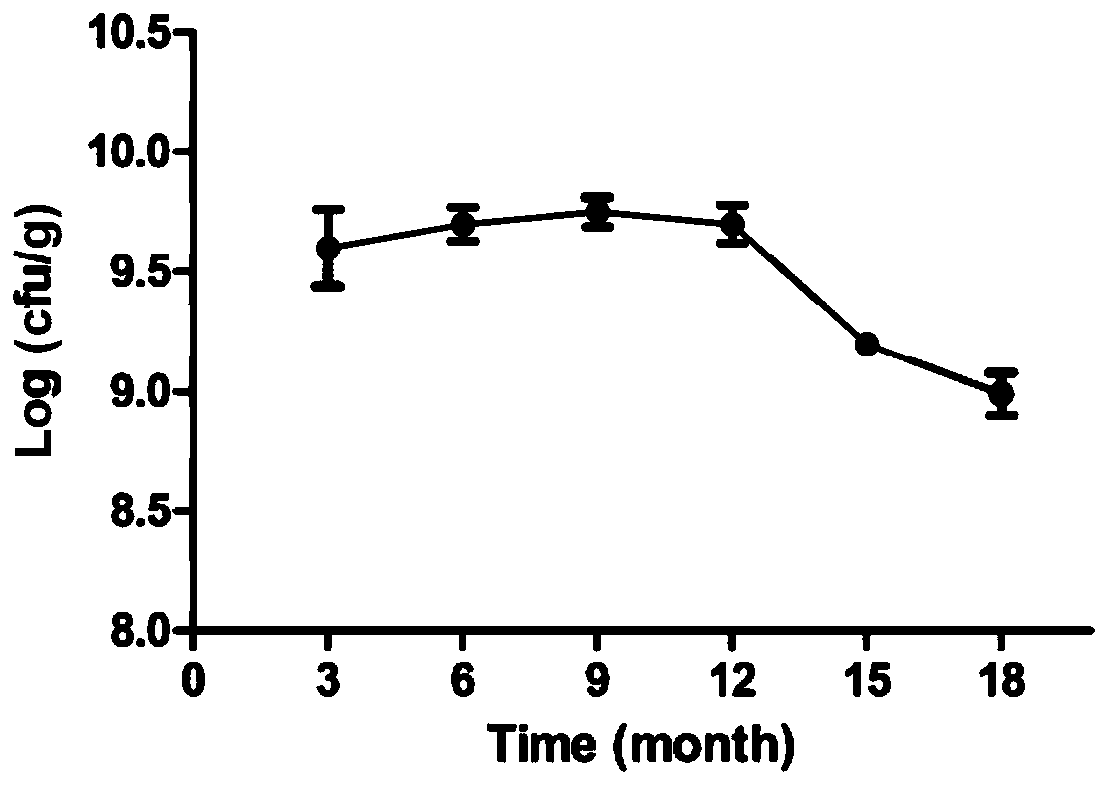

Method for reinforcing recycled aggregates through biological carbonization

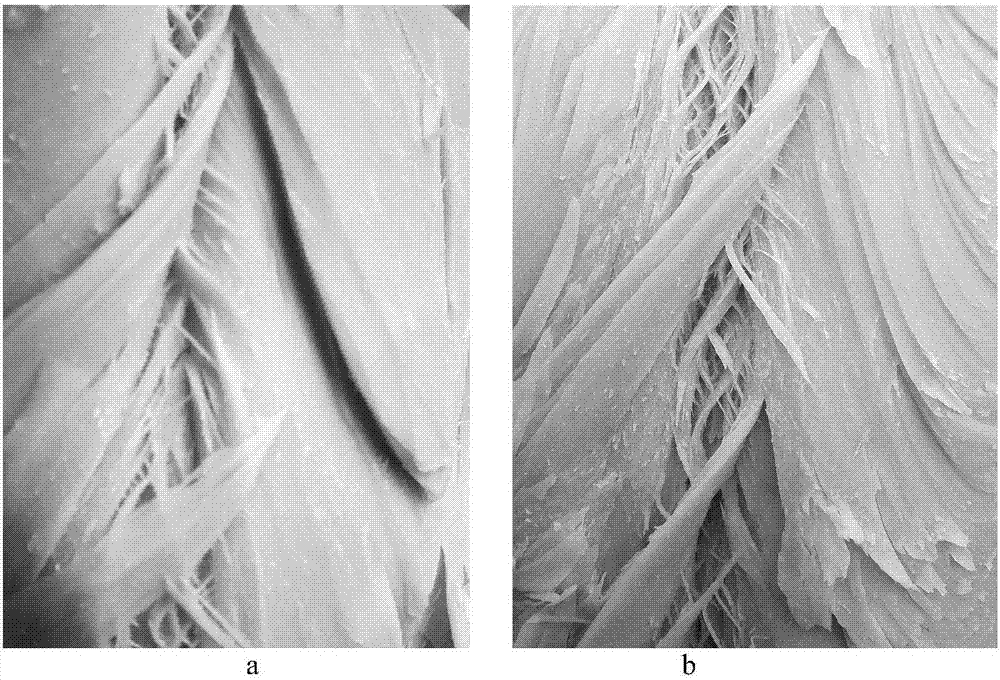

InactiveCN110615628AImprove qualityExpand application channelsSolid waste managementCarbonizationScanning electron microscope

The invention provides a method for strengthening recycled aggregates through biological carbonization. The method comprises: a step of collecting recycled aggregates and preparing a calcium salt solution; a step of obtaining a Bacillus mucilaginosus bacterial solution; a step of carrying out carbonization strengthening treatment, namely a step of spraying the calcium salt solution and the bacillus mucilaginosus bacterial solution to the surface of the recycled aggregates until the surface of the recycled aggregates is wet, repeating the spraying operation every 6 hours, with total 2-5 times of the spraying operation being performed, putting the sprayed recycled aggregates in a closed container or a curing chamber, performing vacuumizing, then feeding carbon dioxide, controlling the pressure to 0.1-0.6 MPa, and keeping the pressure for 2-6 h to obtain biologically-strengthened recycled aggregate particles; a step of testing the water absorption rate of the recycled aggregates, samplingthe aggregate particles, observing a tissue diagram under a scanning electron microscope. According to the method, the recycled aggregates are strengthened through the enzymatic and mineralization effects of microorganisms, the quality of the recycled aggregates is improved, the application way of the recycled aggregates is expanded, aggregate demand tension in engineering construction can be relieved, construction waste resources can be recycled, and efforts are made for solving the problem of 'cities are besieged with construction waste'.

Owner:THE THIRD ENG CO LTD OF CCCC SECOND HIGHWAY ENG BUREAU +1

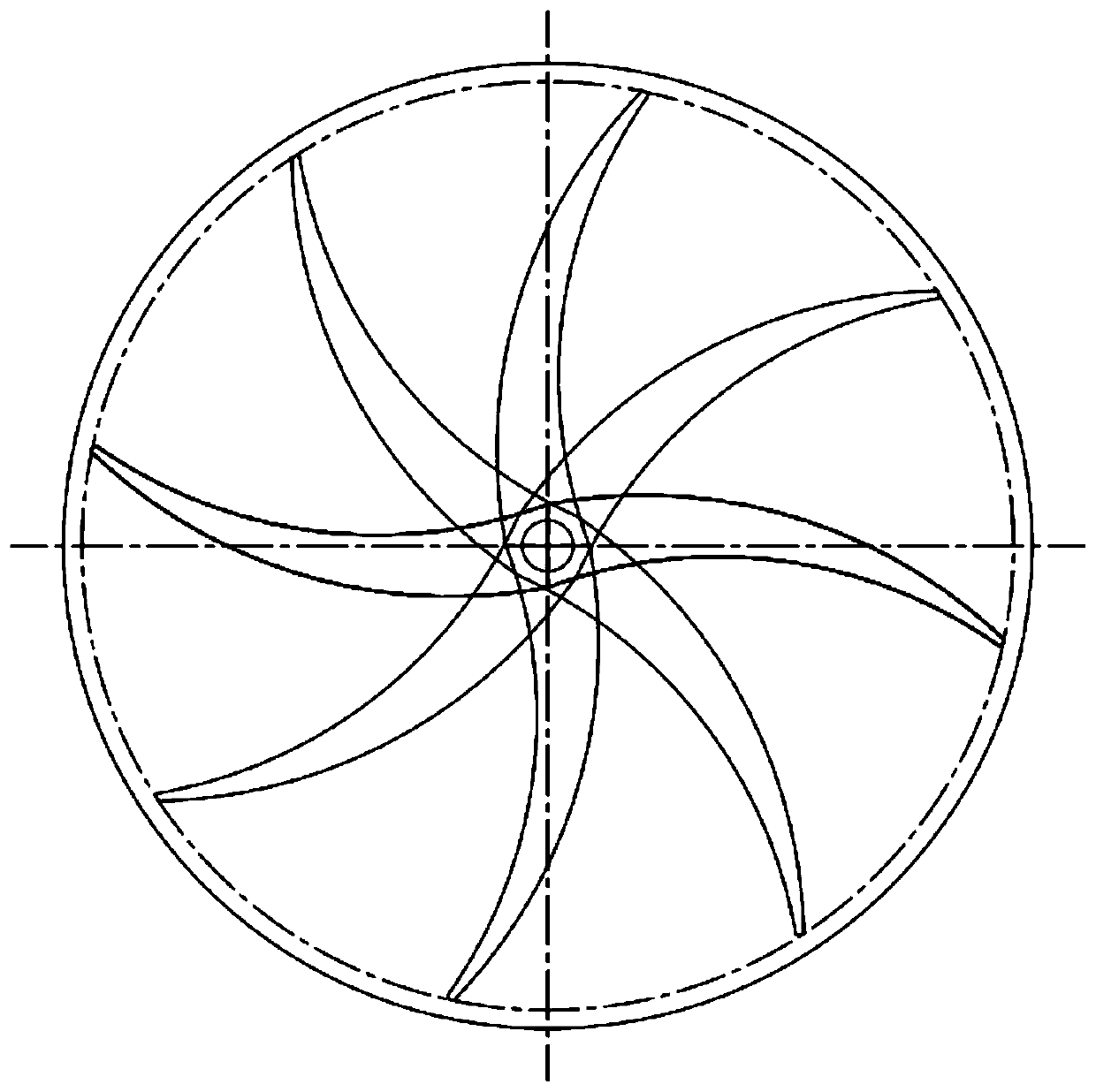

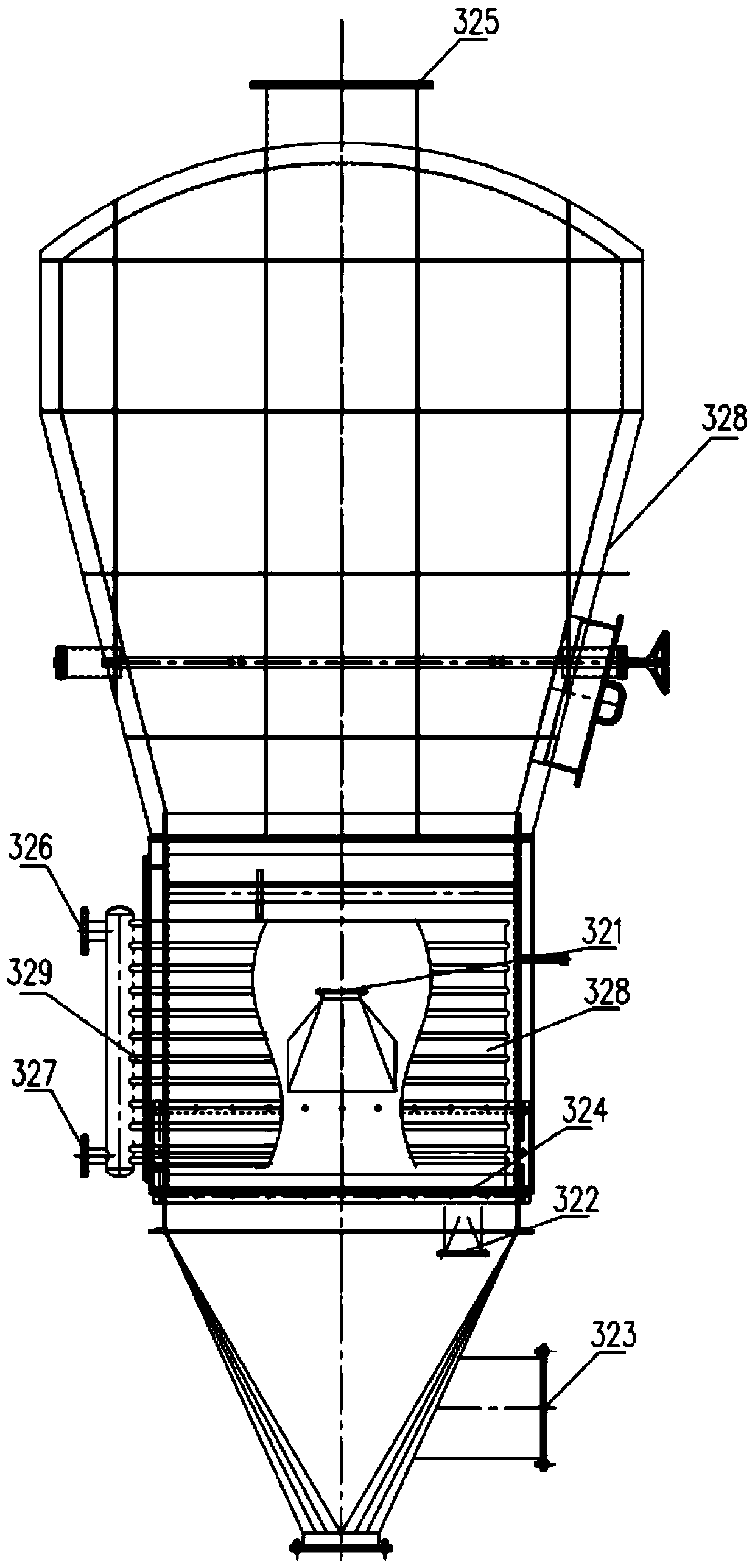

Device and method for producing type II anhydrous gypsum from phosphogypsum

PendingCN110803878AImprove resource utilizationDoes not affect strengthCalcium/strontium/barium sulfatesPhysical chemistryAcid corrosion

The invention provides a device and a method for producing type II anhydrous gypsum from phosphogypsum. The device comprises a pretreatment unit, a drying unit, a calcining unit and a product collecting unit which are sequentially connected, wherein the pretreatment unit comprises a spiral stirring device; the drying unit comprises a scattering device and at least one-stage drying device; the calcining unit comprises a calcining device; and a heat source pipeline is arranged in the calcining device. According to the device disclosed by the invention, the phosphogypsum is accurately converted into the II-type anhydrous gypsum through the combination of pretreatment, drying and calcination processes, soluble phosphorus and fluorine in the phosphogypsum are effectively removed, conversion ofinsoluble phosphorus and decomposition of organic matters are realized, the problem of acid corrosion is solved, and the influence of harmful impurities on gypsum products is reduced; the method improves the comprehensive utilization efficiency of the phosphogypsum, the product is not easy to hydrate, the product can be compounded with super sulfate cement, supersulphated cement or gypsum composite cementing materials, the product has stable performance and high strength, and the application way of the phosphogypsum is expanded.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

Coal gangue-based composite geopolymer grouting filling material and preparation method thereof

InactiveCN111018423AReduce bulk stackingWide variety of sourcesSolid waste managementCement productionSlagGeopolymer

The invention discloses a coal gangue-based composite geopolymer grouting filling material and a preparation method thereof. The preparation method comprises a step of weighing raw materials in partsby mass. According to the method, coal gangue powder and slag powder are used as main raw materials; a KOH solid and a water glass solution form an alkali solution; slag powder with good activation performance and ground coal gangue powder with insufficient activation performance are subjected to alkali-excited activation by adopting an alkali excitation technology, active glass bodies in the slagpowder and active components such as SiO2 and Al2O3 in the coal gangue powder are leached out in a strong alkali environment to form a grouting material with a gelling effect, and compared with a cement material, the grouting material is lower in manufacturing cost and wide in material source; meanwhile, comprehensive and effective utilization of coal gangue is improved, stacking of a large amount of coal gangue is reduced, and good environmental protection and social benefits are achieved. Compared with a cement grouting material, the grouting material prepared by the invention is lower in bleeding rate and higher in stone rate, has a rapid hardening effect, can reduce water damage caused by permeation of water into a roadbed in a non-setting stage of slurry, and effectively reduces airshrinkage and crack extension after slurry hardening.

Owner:CHANGAN UNIV +1

Ceramsite prepared from residues generated in oil containing sludge pyrolysis and preparation method thereof

InactiveCN109851323AExpand application channelsHigh porosityCeramic materials productionCeramicwarePorositySludge

The invention provides a ceramsite prepared from residues generated in oil containing sludge pyrolysis and a preparation method thereof. The ceramsite is prepared from following raw materials in percentage by weight through burning: 45 to 50% of residues generated in oil containing sludge pyrolysis, 35 to 40% of fly ash, and 10 to 20% of waste glass powder. Residues generated in oil containing sludge pyrolysis are taken as the main raw material and is mixed with fly ash and waste glass powder to prepare the ceramsite having the advantages of lightness, high porosity, high cylinder compressivestrength, low bulk density, and low water absorption; the application range of residues generated in oil containing sludge pyrolysis is enlarged; a new approach is provided for converting residual solid phases in oil containing sludge processing into valuable resources; the residue utilization rate can reach 50%; the problem that the residues generated in oil containing sludge pyrolysis cannot beeffectively processed and radically utilized is solved, sustainable development of oil fields is realized, and good social benefits and economic benefits are generated.

Owner:WUHAN UNIV OF TECH

Silicon recovery method

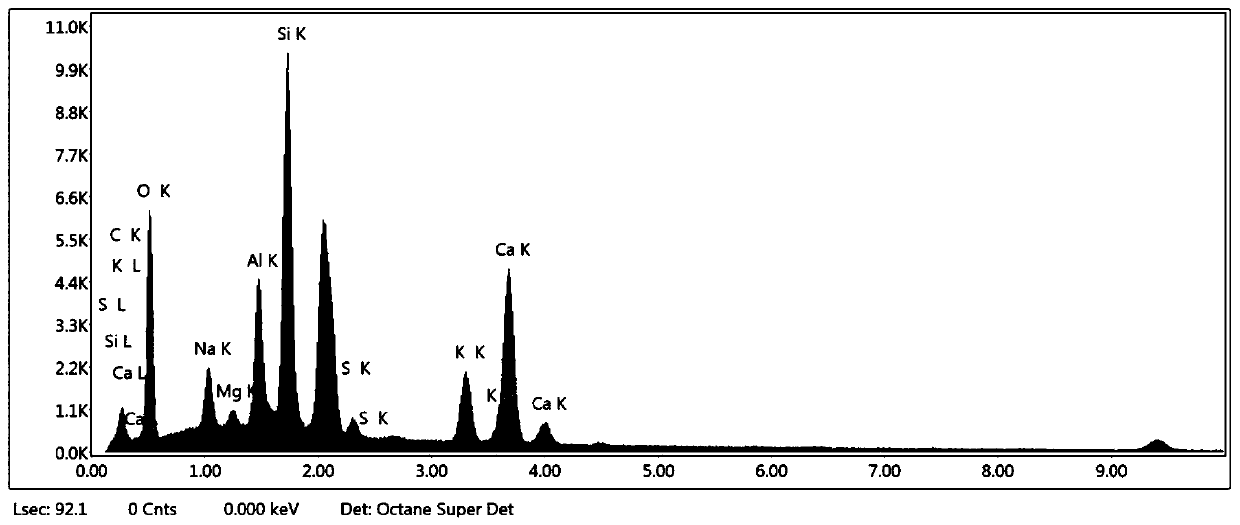

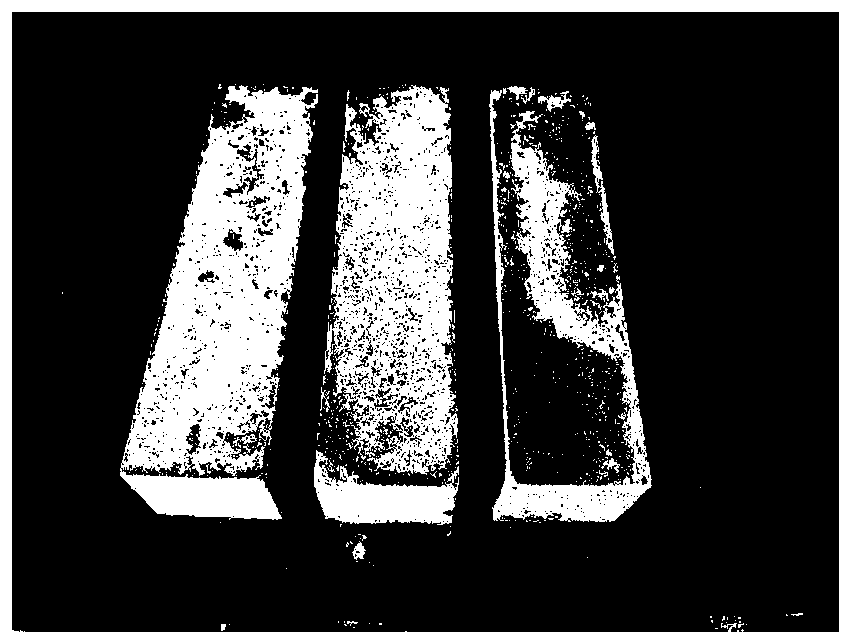

ActiveCN102515186AHigh extraction rateHigh recovery rateAlkali metal silicatesSlagEnvironmental engineering

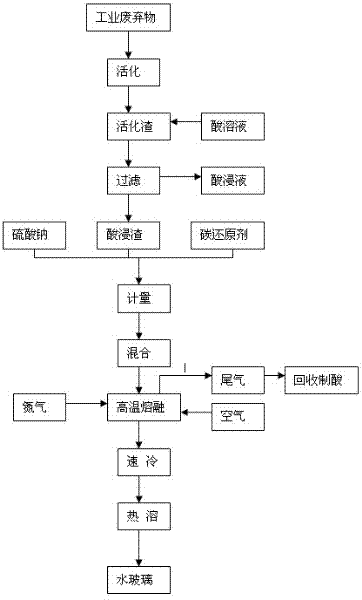

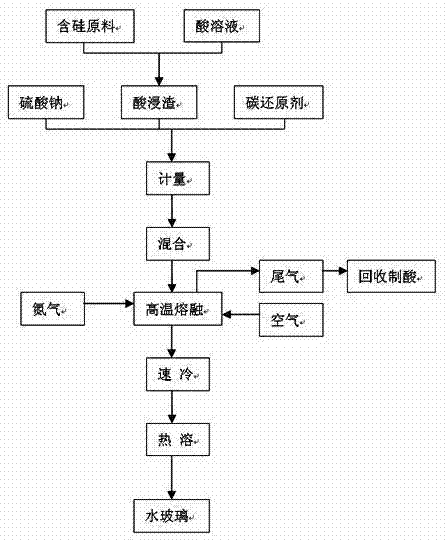

The invention discloses a silicon recovery method, which comprises: taking an industrial waste as a raw material, using an acid solution for acid leaching, filtering, and washing, then adding anhydrous sodium sulfate into an acid leaching residue, employing carbon as a reducing agent, and conducting high temperature fusion reaction so as to obtain sodium silicate, which is then subjected to thermal dissolution or high temperature water dissolution, thus obtaining water glass. The method of the invention has the characteristics of high silicon recovery rate, fewer residue, reasonable resource utilization, and adjustable water glass modulus ranging from 1 to 3.5, provides a new for industrial waste acid leaching slag silicon provides a new technological route for silicon extraction from the acid leaching residue of an industrial waste, and is conducive to resource comprehensive application of industrial wastes.

Owner:KUNMING UNIV OF SCI & TECH +1

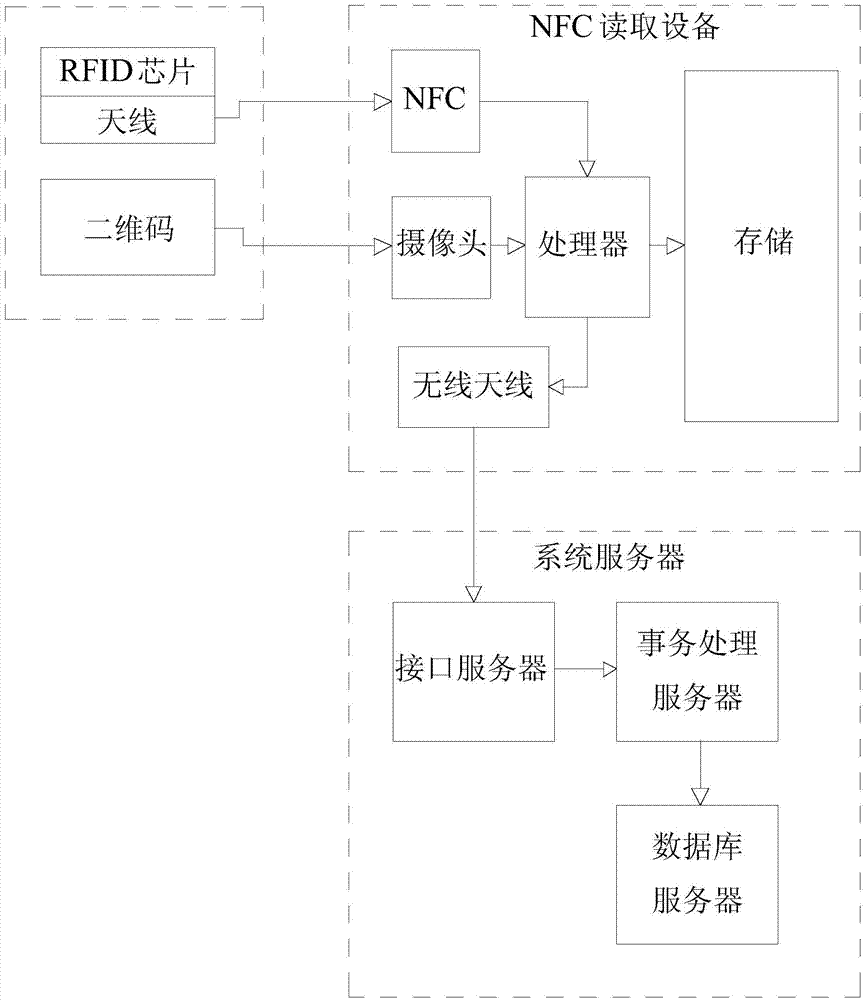

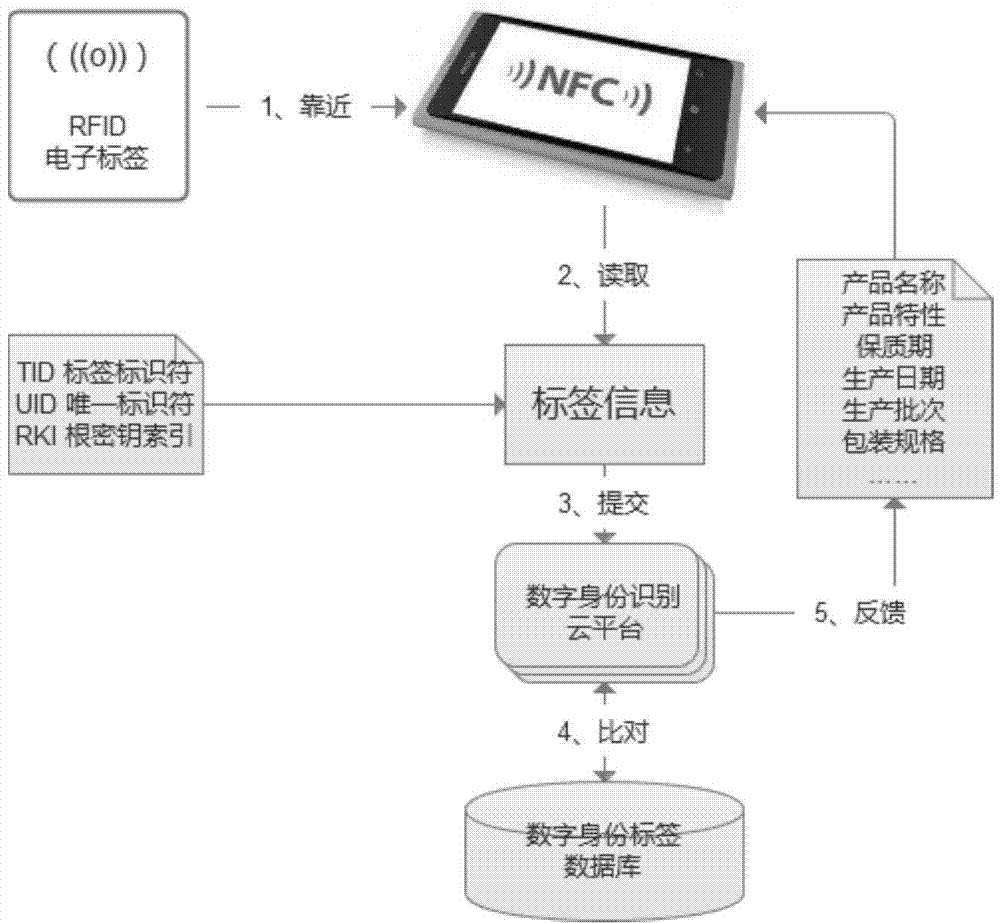

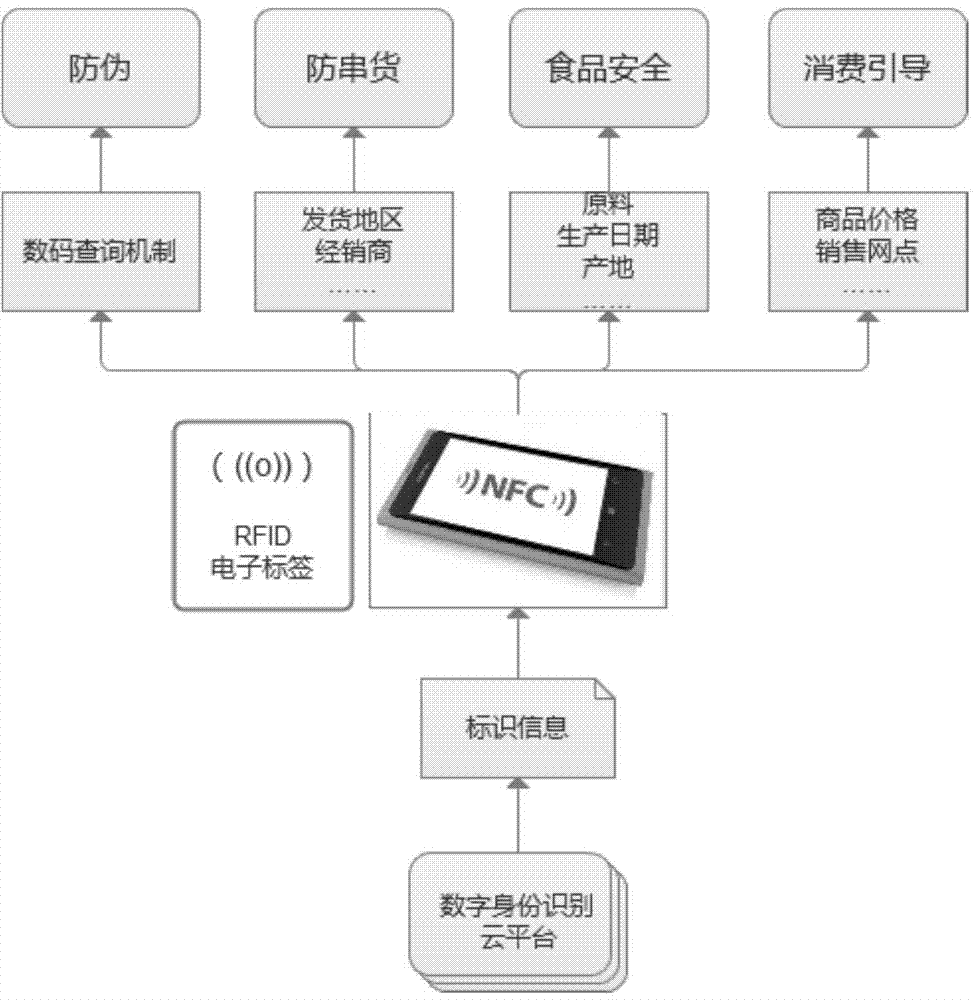

Mobile network digital identity recognition system utilizing NFC (near field communication) technology

InactiveCN103593631ASave money on purchasesImprove convenienceSensing record carriersTransmissionDigital identityRadio frequency signal

The invention provides a mobile network digital identity recognition system utilizing an NFC (near field communication) technology. A software part comprises a digital identity recognition system, digital identity tags, a commodity information database and a security recognition mechanism module. A hardware part comprises an RFID (radio frequency identification) chip, an NFC reading device and a system server, wherein the RFID chip is used for recording a digital identity marker of a certain product, an identity code is stored in an encrypted storage mode of a symmetrical algorithm, a user defined encrypted area is provided, radio frequency signals are transmitted to a front-end NFC device through a built-in antenna so as to realize identity marker verification. According to the invention, the digital identity recognition system applied to intelligent mobile phones is expanded, designed and developed on the basis of a digital identity recognition cloud platform through combining the NFC and RFID technologies. The system provided by the invention is improved and upgraded to a large extent in reading mode, recognition mechanism and standby recognition mechanism, thereby being capable of effectively improving the safety and the information comprehensiveness of RFID recognition.

Owner:北京兆信信息技术股份有限公司

Method for treating pulping black liquor through alkali cooking method taking gramineous plants as materials

InactiveCN104153232AReduce carbon dioxide emissionsPrevent warming from the greenhouse effectRegeneration of alkali lyeAdhesiveBlack liquor

The invention discloses a method for treating pulping black liquor through an alkali cooking method taking gramineous plants as materials. The black liquor discharged in the pulping process through the alkali cooking method taking the gramineous plants as the materials is turned into a useful lignin product. The treating process mainly comprises the steps as follows: recovering easily deposited macromolecular lignin as a high-purity lignin product by adding an acid into the black liquor, and recovering low-molecular-weight lignin not easily deposited under the acidizing condition, like a monomer or a biopolymer, as well as other components as a low-molecular-weight lignin product. The invention adopts the low-cost high-efficiency treatment method to treat the pulping black liquor, meanwhile, the obtained high-purity lignin product and the lignin product are respectively applied to synthetic resins and adhesives, the waste resources are fully utilized, the environment is protected, and the social and economic benefits are increased.

Owner:广西星岛科技发展有限公司

Device and method for producing type II anhydrous gypsum from desulfurized gypsum

PendingCN110803877AImprove resource utilizationReduce water consumptionCalcium/strontium/barium sulfatesSulfatePhysical chemistry

The invention provides a device and a method for producing type II anhydrous gypsum from desulfurized gypsum. The device comprises a drying unit, a calcining unit and a product collecting unit which are sequentially connected, wherein the drying unit comprises a crushing device and at least one-stage drying device, and the calcining unit comprises a fluidized calcining device. According to the device disclosed by the invention, the desulfurized gypsum is accurately converted into the II-type anhydrous gypsum through the combination of drying and calcining processes, oxidation of calcium sulfite and decomposition of organic matters in the desulfurized gypsum can be realized, the impurity removal rate reaches more than 99%, and the influence of harmful impurities on gypsum products is greatly reduced; according to the method, when super sulfate cement is taken as a target product, the lowest limit value of chloride ions in desulfurized gypsum raw materials is increased, and the pretreated water consumption and secondary water pollution are indirectly reduced; according to the invention, the comprehensive utilization efficiency of the desulfurized gypsum is improved, the super sulfatecement is further compounded, the product has stable performance and high strength, and the application way of the desulfurized gypsum is expanded.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

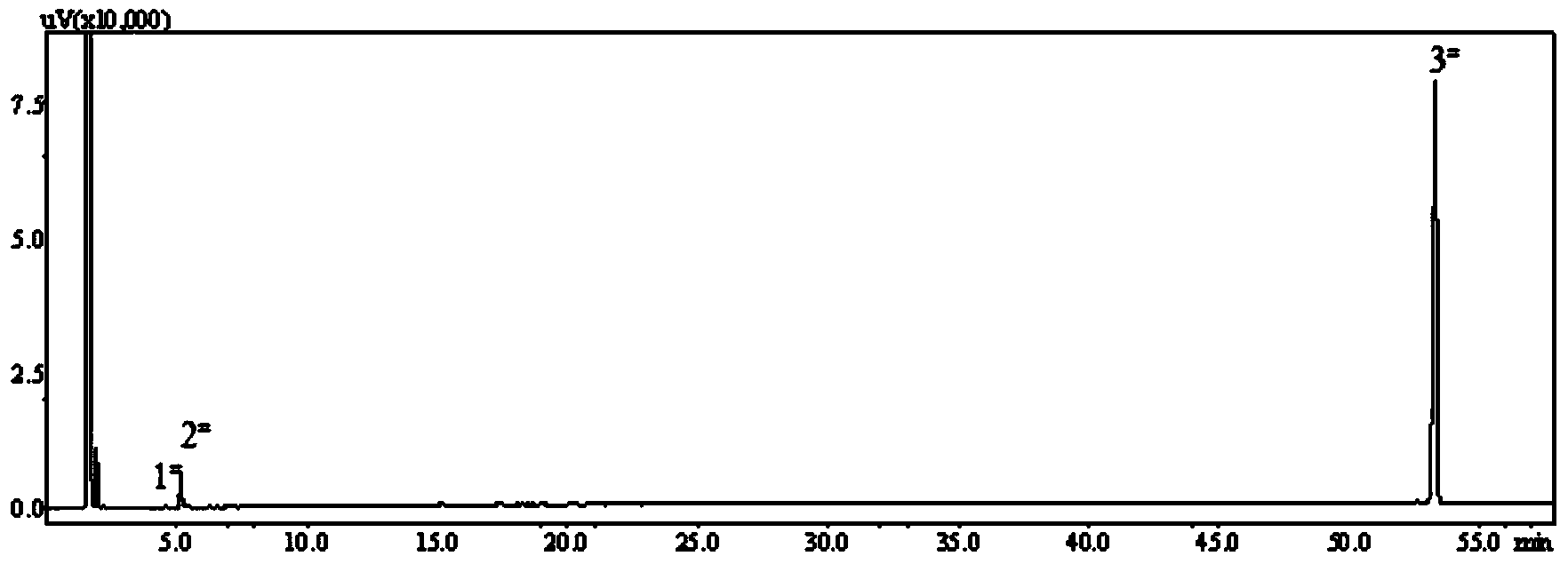

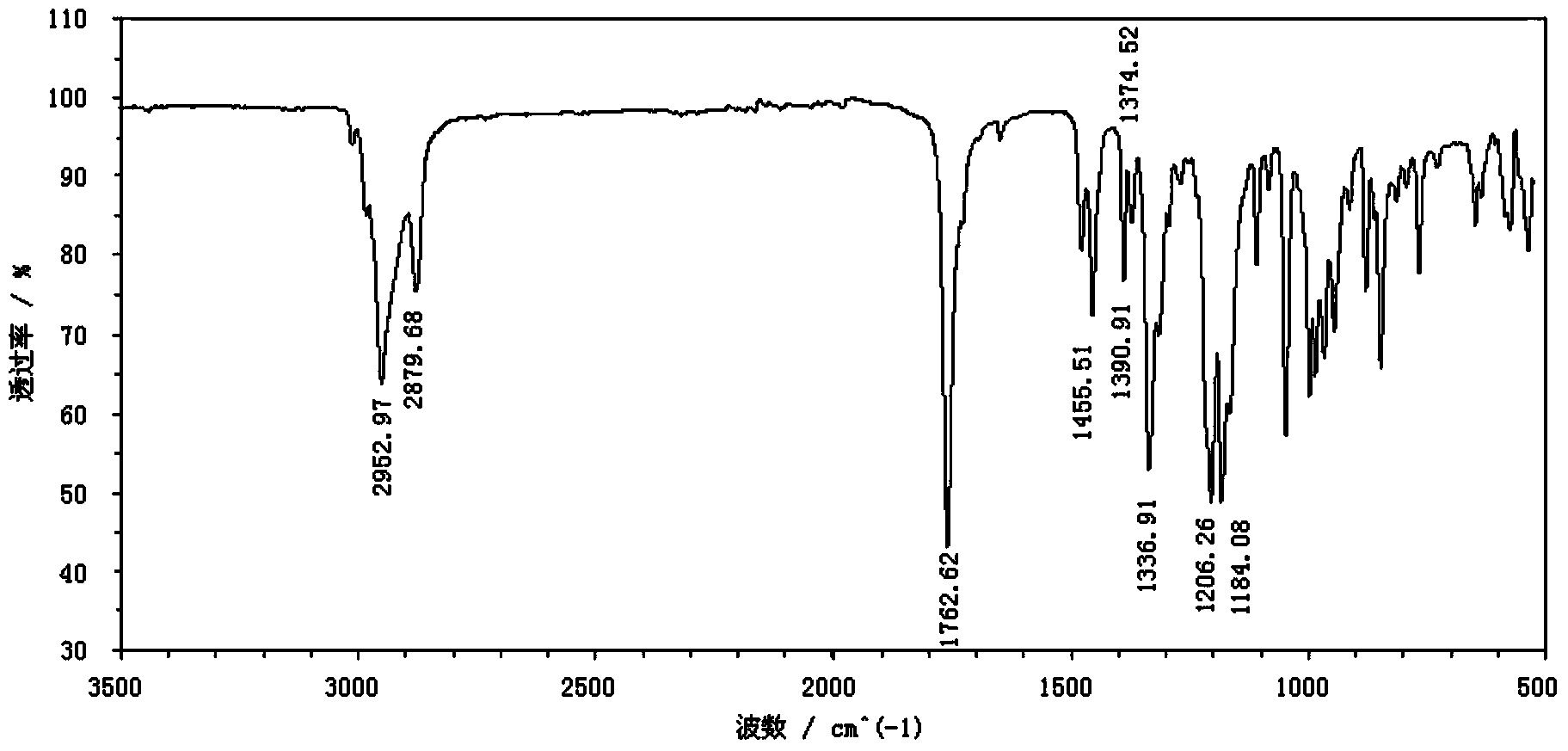

Method for synthesizing diisoborneol oxalate

ActiveCN103980117AMild reaction conditionsEasy to getOrganic compound preparationCarboxylic acid esters preparationWater vaporSolvent

The invention discloses a method for synthesizing diisoborneol oxalate. The diisoborneol oxalate is prepared from such raw materials as industrial camphene, camphene, tricyclene and isoborneol. The method comprises the following steps: dissolving raw materials in a certain amount of an organic solvent, reacting with anhydrous oxalic acid at certain temperature for a certain duration in the presence of such catalysts as boron anhydrous, pyroboric acid or metaboric acid or titanium sulfate, or metatitanic acid, filtering and removing the catalysts and unreacted anhydrous oxalic acid, washing for several times, rotatably evaporating upper liquid to remove most solvents, removing camphene and tricyclene as raw materials which are not reacted completely as well as a few of isoborneol as a byproduct to obtain a crude product, and recrystallizing to obtain diisoborneol oxalate. The method disclosed by the invention can adopt such organic solvents as aromatic hydrocarbon and branched paraffin as reaction mediums in reaction. The method, which adopts conventional heating, is moderate in conditions, simple and convenient to operate, low in side reaction and high in product yield, and raw materials are easily separated from products.

Owner:株洲松本药业有限公司

Manufacturing method of straw granular feed using biological and puffing technique, its equipment and product

InactiveCN1409983AIncrease nutritionImprove palatabilityAnimal feeding stuffWorking-up animal fodderIt equipmentTrace element

A process for preparing granular feed from straw and stalk by the biological puffing technology includes such steps as treating the powdered straw and stalk with urea, pretreating with polyenzyme, biological fermenting, proportional mixing it with energy component, additive and trace elements, puffing, granulating, drying and cooling. Its apparatus and product are also disclosed.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Fibroin/carboxymethyl chitosan composite gel and preparation method thereof

The invention discloses fibroin / carboxymethyl chitosan composite gel and a preparation method of the composite gel. The composite gel mainly comprises fibroin and carboxymethyl chitosan at a mass ratio of (0.05-2):1. The method comprises the steps of performing silk layer treatment to obtain a fibroin fiber, preparing a fibroin solution, preparing a carboxymethyl chitosan solution, uniformly mixing the fibroin solution and the carboxymethyl chitosan solution to obtain a mixed solution, adding a certain amount of cross-linking agent, stirring the solution for a short time on a magnetic stirrer, immediately pouring the solution into a die for standing, and then immersing the solution into an alcohol aqueous solution to finally obtain the fibroin / carboxymethyl chitosan composite gel. According to the method, the gel with higher mechanical property and higher stability is prepared by a simpler technology and a shorter time; a novel clue is provided for improving a preparation method of fibroin composite gel; an application approach of the fibroin is further expanded.

Owner:ZHEJIANG UNIV

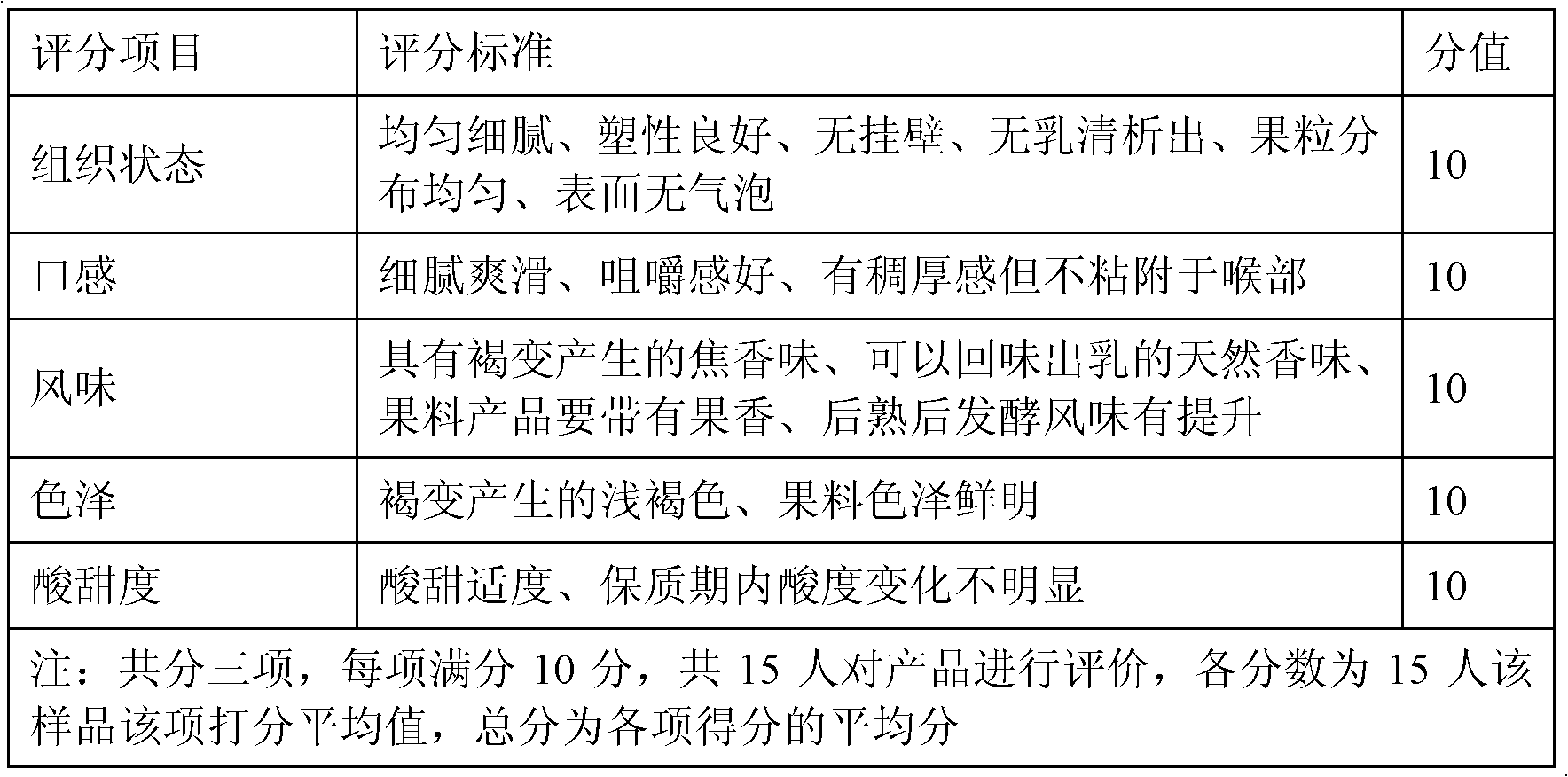

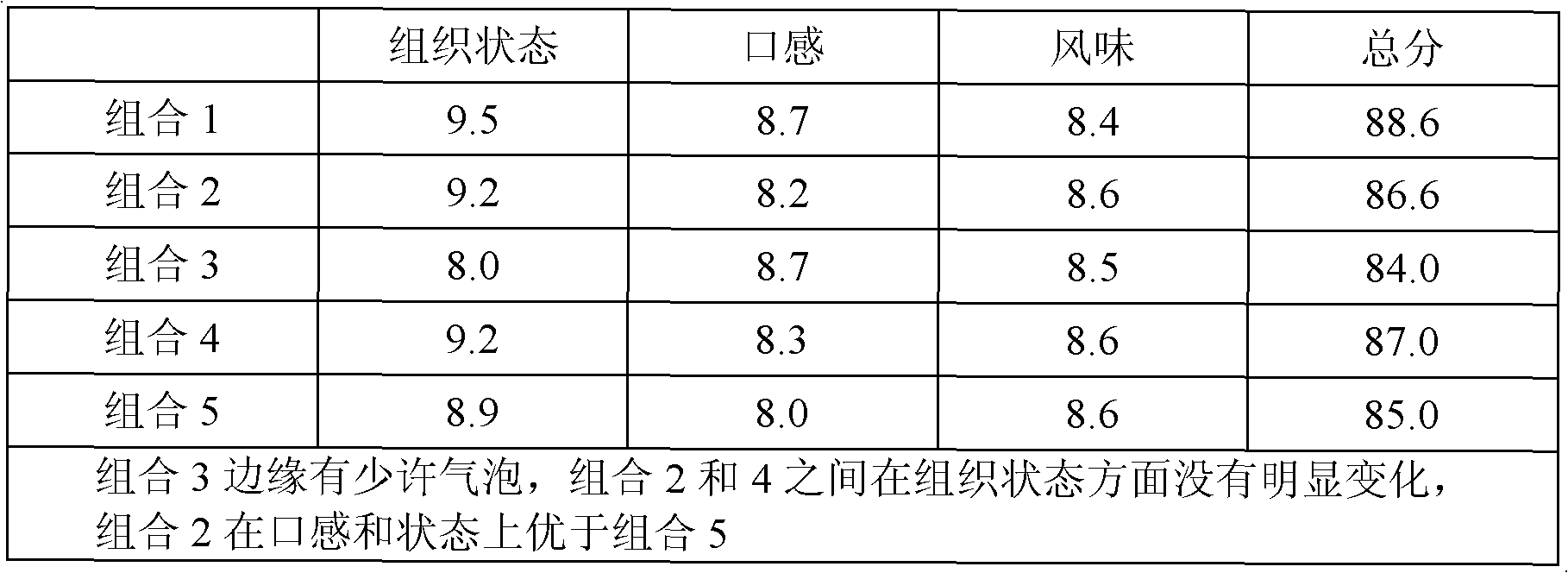

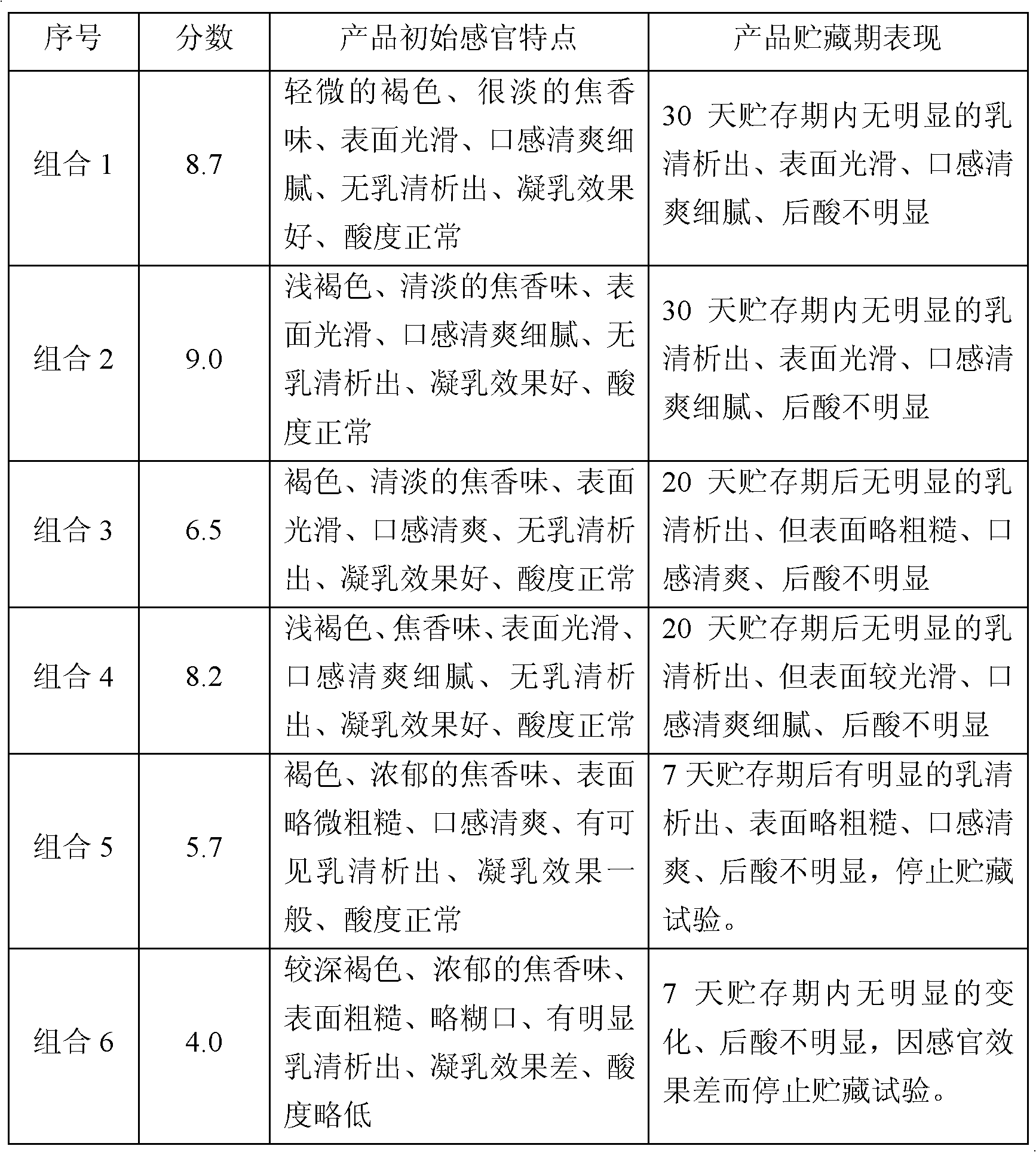

Partly skimmed cheese and preparation method thereof

The invention relates to partly skimmed cheese and a preparation method thereof. Each 100 parts of the partly skimmed cheese consists of the following raw materials by weight: 10 to 90 parts of whole milk powder, 750 to 860 parts of fresh milk, 20 to 50 parts of milk protein powder, 10 to 80 parts of inulin, 30 to 90 parts of sweetener, 5 to 15 parts of stabilizer and 10 to 15 parts of mixed lactobacillus starter. The invention also provides a preparation method of the partly skimmed cheese. The partly skimmed cheese is prepared by scientifically and effectively combining fresh cheese, nonenzymatic browning and the inulin, has the characteristics of soft and unique flavor, smooth mouthfeel, simple and elegant color, low cost and the like, and also has good nutritional and healthy functions and high market value.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

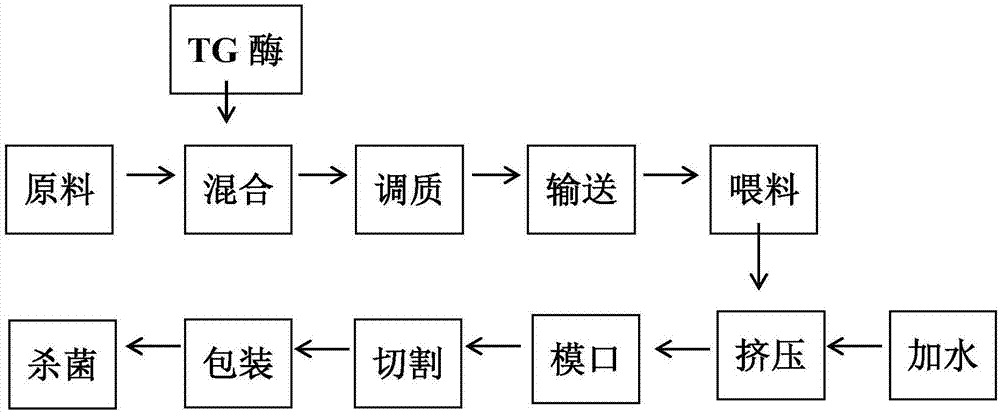

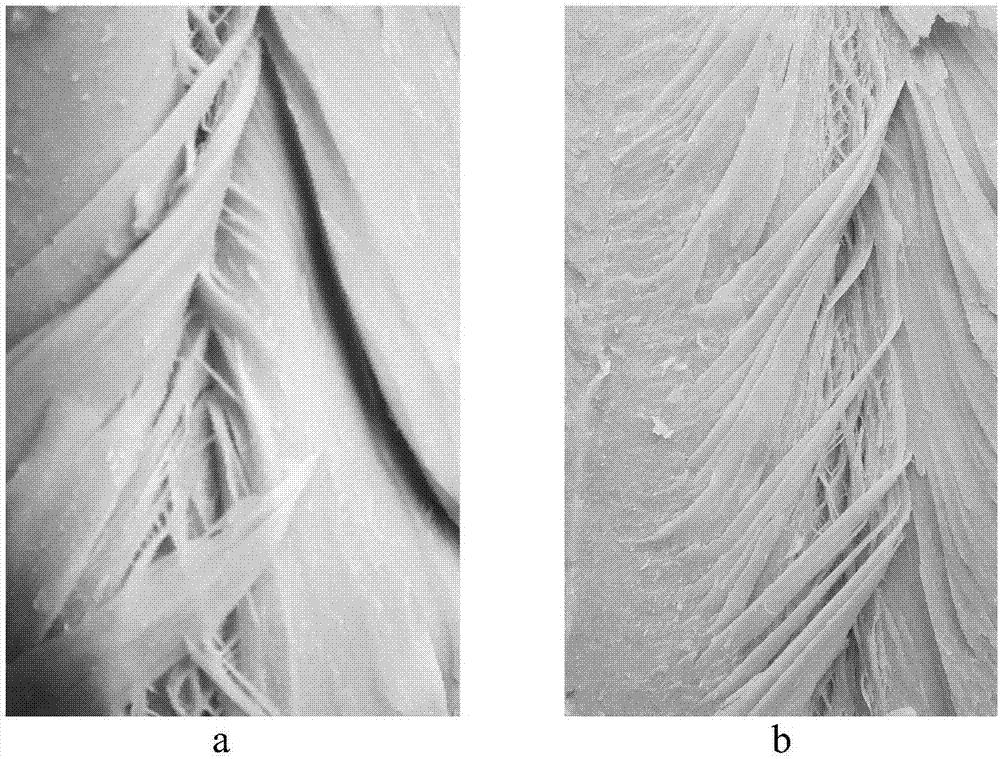

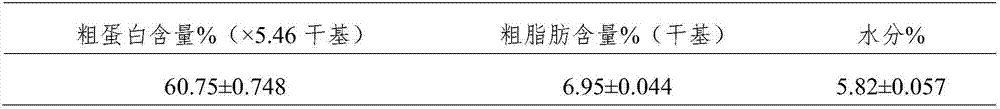

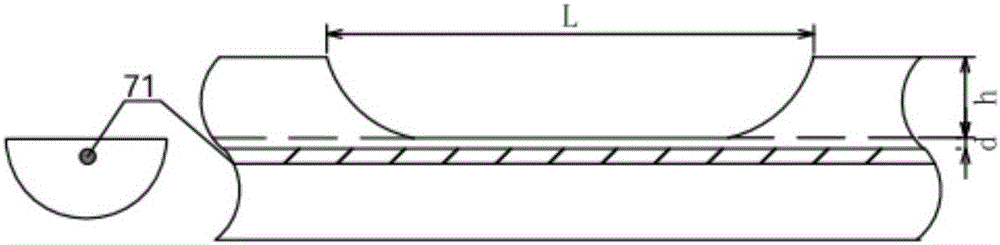

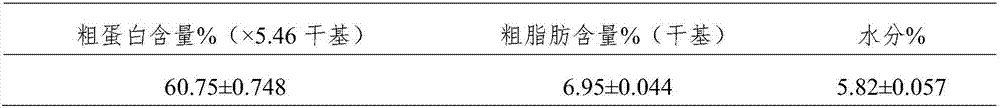

Method for improving quality of high-moisture peanut drawing protein by TG enzyme

ActiveCN107259066AEfficientReduce dosageProtein composition from vegetable seedsProteins working-up by texturisingFiberBright-white

The invention relates to a method for improving the quality of high-moisture peanut drawing protein by TG enzyme. The method comprises the following steps: pulverizing low-temperature defatted peanut protein powder, and uniformly mixing the peanut protein powder with a right amount of TG enzyme; conducting extruding and texturizing treatment, wherein the extrusion temperatures are sequentially as follows: a feed zone is 60-80 DEG C, a mixing zone is 80-100 DEG C, a cooking zone is 130-160 DEG C, a cooling zone is 90-130 DEG C, and a molding zone is 50-90 DEG C; adding water on line in the extrusion process, and regulating the moisture of the material to be 45%-65%; and cooling after extrusion molding for preparing the high-moisture peanut drawing protein. The high-moisture peanut drawing protein produced by the method provided by the invention is bright white in color, subtly fragrant in taste, smooth in surface, rich in fiber silk-like structures, rich in fiber-like structures and high in the intensity of fiber silks, and can be used as a substitute for high-grade meat for processing vegetarian beef. The method increases the fibration degree of the high-moisture peanut drawing protein, enhances the intensity of the fiber silks and extends the application range of the high-moisture peanut drawing protein.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Manufacturing method of graphene oxide microstructure cladding filter based on laser reduction

InactiveCN106019468AExpand application channelsBreak through limitationsCladded optical fibreOptical waveguide light guideFiber Bragg gratingGraphene

The invention discloses a cladding filter based on laser-reduced graphene oxide microstructure and its manufacturing method, which uses purple light irradiation to reduce graphene oxide, and deposits the processed graphene oxide on the packaged side-polished optical fiber Afterwards, the polished surface can be observed through an optical microscope and a scanning electron microscope to verify that graphene oxide has covered the polished surface. Finally, use an amplitude mask to write on the graphene oxide on the polished surface The grating structure forms a cladding refractive index modulated optical fiber grating, thereby preparing a cladding refractive index modulated optical fiber grating of graphene oxide-graphene periodic structure.

Owner:JINAN UNIVERSITY

Preparation method for nigrum fruit products

ActiveCN106509579AIncrease contentExpand application channelsNatural extract food ingredientsFood dryingFruit juiceFunctional food

The invention discloses a preparation method for nigrum fruit products. The preparation method comprises the steps that immature nigrum fruit in June, or July or August is used as a raw material, washed, squeezed or boiled, then squeezed or dewatered, squeezed and filtered, secondary filter residues and filter liquid are obtained; the secondary filter residues are added with 60-85% ethanol to be extracted for 2-3 times, and extracting solution combining, concentration, pH adjusting, water adding, filtering and drying are conducted, and a nigrum fruit extract is obtained; the filter liquid is concentrated and dried, and nigrum fruit juice powder is obtained; and the nigrum fruit extract and the nigrum fruit juice powder are evenly mixed to be powdery or granular, and the nigrum fruit products are obtained. The preparation method is reasonable in design and simple and convenient to operate, and the content of effective components in the nigrum fruit products is increased; the products obtained through the preparation method are portable, easy to store, can be directly brewed by adding water to serve as a nigrum fruit beverage to be drunk, and can also be reprocessed to be applied to the fields of functional food and health food, and the application ways of nigrum fruit food is broadened.

Owner:张锦超 +1

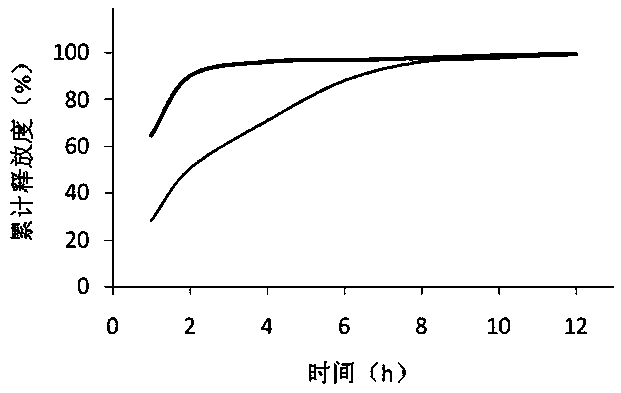

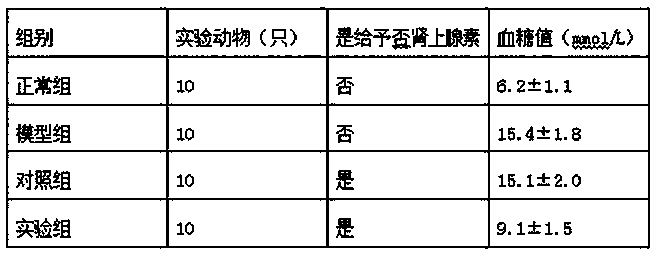

Malus toringoides leaf extract tablet and preparation method thereof

ActiveCN107714794AExpand application channelsControllableMetabolism disorderPharmaceutical non-active ingredientsDrug release rateAdhesive

The invention discloses a malus toringoides leaf extract tablet and a preparation method thereof, and relates to the field of pharmaceutical preparations. According to the present invention, the malustoringoides leaf extract tablet is prepared by using a malus toringoides leaf extract, a slow release agent, a filler and an adhesive as raw materials, wherein the malus toringoides leaf extract is prepared through microbial fermentation; the malus toringoides leaf extract has slow release property and blood glucose lowering effect; after the malus toringoides leaf extract is prepared into the molded tablet, the application range of the malus toringoides leaf is expanded, and the quality of the malus toringoides leaf can be controlled so as to improve the application safety; the slow releaseagent contains the corrosive and hydrophilic gelling slow-release framework materials, such that the suitable drug release rate can be achieved through the combination of the two materials; and the malus toringoides leaf extract tablet preparation method has advantages of reasonable process, simpleness and easy performing.

Owner:炉霍雪域俄色有限责任公司

Modified slag powder and preparation method thereof

ActiveCN104761160AExpand application channelsImprove performance indicatorsSolid waste managementCement productionHot blastGypsum

The invention relates to a modified slag powder and a preparation method thereof. The preparation method comprises the following steps: performing heat treatment on the silico-calcium slag to obtain the heat-treated silico-calcium slag; mixing the heat-treated silico-calcium slag with coal ash, slag, gypsum, a cement grinding aid and an additive and grinding to obtain the modified slag powder. According to the preparation method, the silico-calcium slag powder is prepared by use of the silico-calcium slag by-product of producing alumina from the coal ash, and therefore, the application ways of the silico-calcium slag are expanded and the performance indices such as the strength of the concrete can be improved; on the other hand, the modified slag powder prepared by use of the method is superior to common blast furnace slag powder in both early strength and long-term strength, and the various indices at least conform to the standards of the national S95 grade slag powder, and therefore, the modified slag powder can be used as a cement or concrete admixture; the production operation process of the modified slag powder is simple and convenient and the problems of consumption and high value utilization of the silico-calcium slag can be effectively solved; in short, the modified slag powder has great popularization and application value.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Healthy nutritional lucid ganoderma noodles and processing method thereof

ActiveCN104256360AImprove the degree of deep processingTake advantage ofFood ingredient functionsFood preparationHigh pressureFood flavor

The invention relates to healthy nutritional lucid ganoderma noodles and a processing method thereof, and belongs to food processing methods. The processing method comprises the following steps: removing the inedible parts of the roots of lucid ganoderma, hammering and crushing at high pressure, finely grinding, softening at high temperature under high pressure, blending, and performing curing forming in one step. The processed noodles have the thick flavor and nutritional health effects of the lucid ganoderma, are suitable for various consumer groups, and also can be used as a nourishing food for tumor patients after radiotherapy and chemotherapy; the noodle processing process is free of pollution and harmful substances; any chemical and artificially synthesized additive is not used, so that the noodles are safe to eat.

Owner:JILIN AGRICULTURAL UNIV

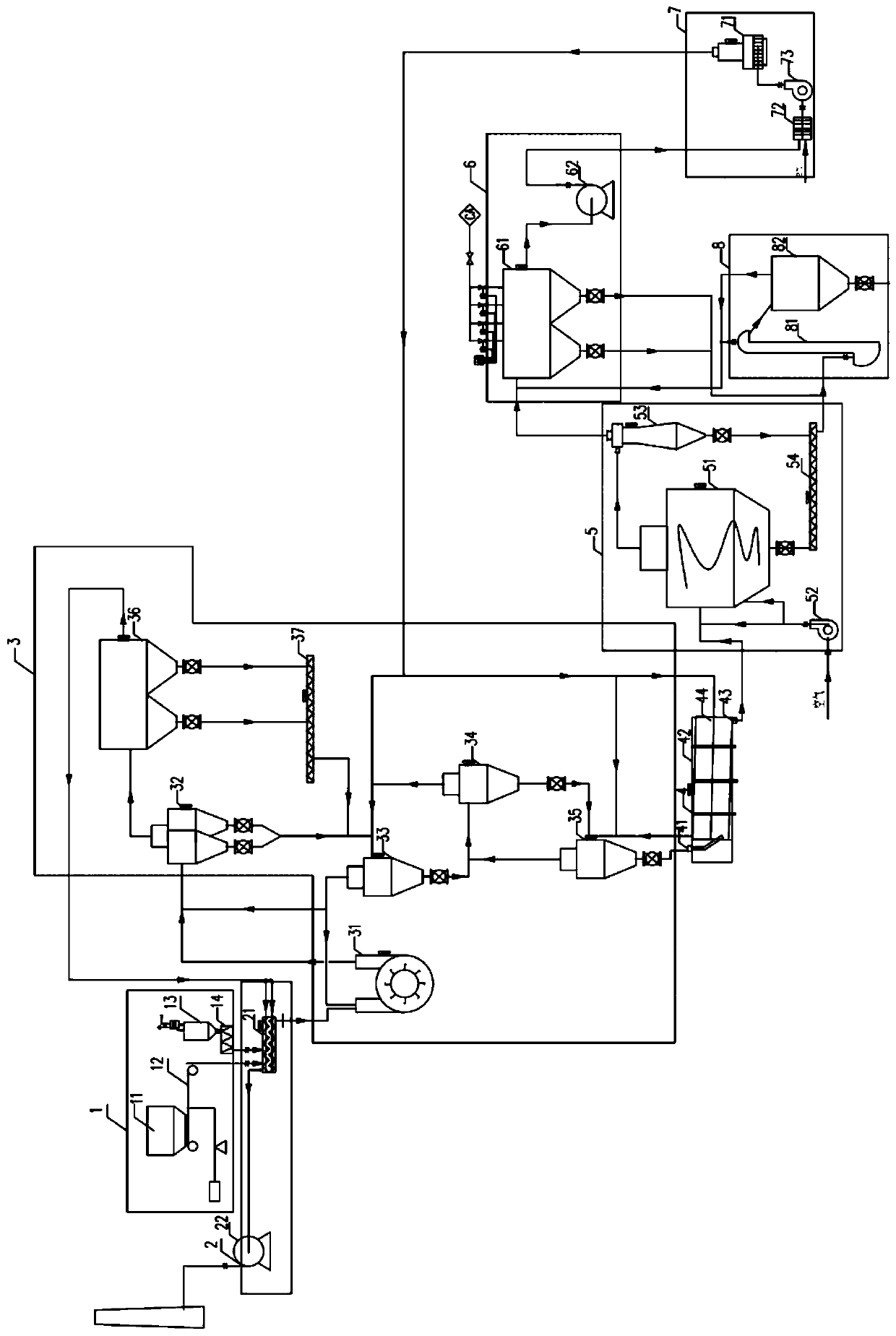

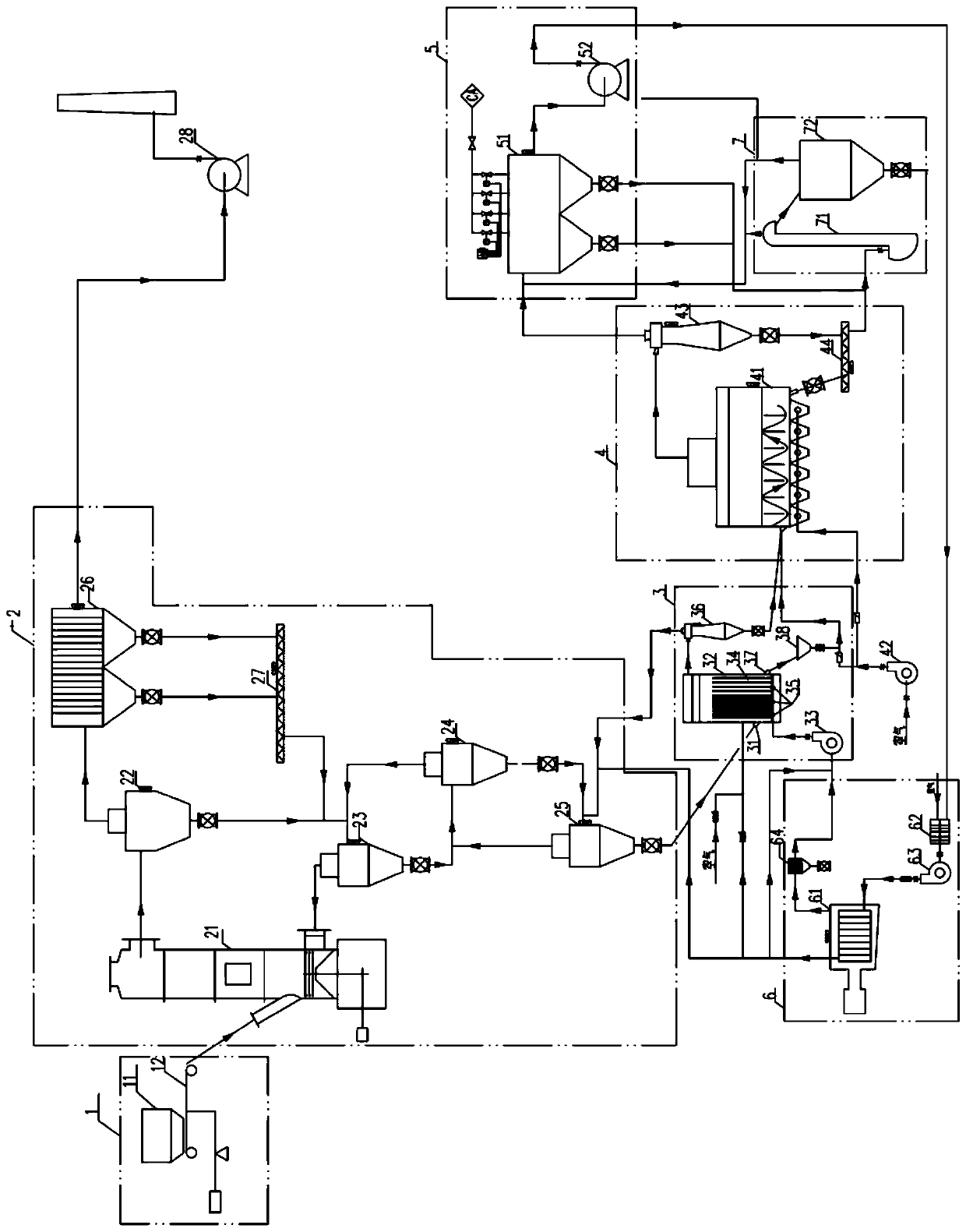

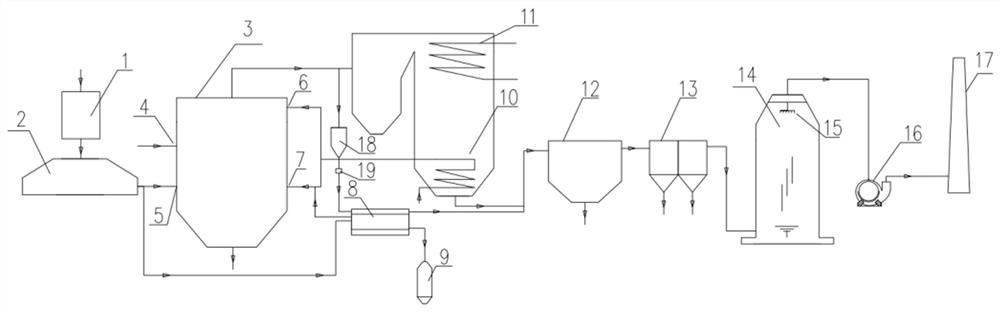

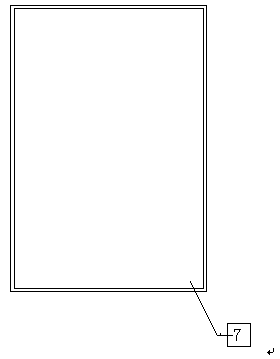

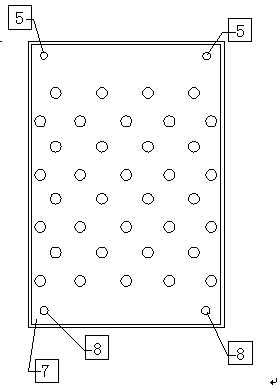

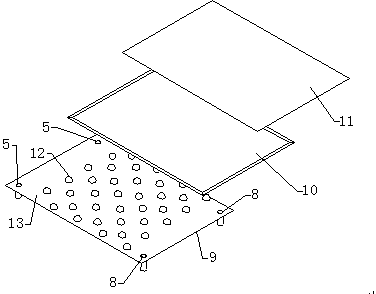

Sludge incineration and carbonization cooperative treatment system

PendingCN111807671AExpand application channelsEasy to handleCombination devicesSludge treatment by de-watering/drying/thickeningFlue gasCarbonization

The invention discloses a sludge incineration and carbonization cooperative treatment system. According to the sludge incineration and carbonization cooperative treatment system, a sludge drying device is used for drying sludge; sludge dried by the sludge drying device is introduced into an incinerator through a sludge inlet through a sludge conveying and feeding device, an auxiliary fuel inlet isused for adding an auxiliary fuel, air is introduced into the incinerator through an air inlet to be incinerated with the sludge, and smoke generated by incineration is exhausted from an air outlet.The sludge dried by the sludge drying device is introduced into a carbonization furnace to be carbonized, high-temperature flue gas is introduced into a jacket of the carbonization furnace to heat thecarbonization furnace, and high-temperature combustible gas and combustible liquid generated by pyrolysis of the carbonization furnace are recycled back into the incinerator through the air inlet tobe incinerated; an air outlet of a waste heat boiler and a flue gas outlet of a sludge carbonization furnace jacket are connected with a flue gas treatment device, after treatment in the flue gas treatment device, a product is guided into a chimney by an induced draft fan to be discharged. Through sludge incineration and carbonization cooperative treatment, the application way of a sludge heat treatment product can be expanded, and the carbonization hot flue gas treatment link is simplified.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Manufacturing method using biological puffing technology to prepare pellet feed from straws

InactiveCN105211613AIncrease nutritionImprove palatabilityFeeding-stuffAnimal feeding stuffTrace elementPre treatment

The invention discloses a manufacturing method using a biological puffing technology to prepare a pellet feed from straws, equipment, and product. The manufacturing method is characterized in that straw powder, which has been processed by urea, is subjected to multi-enzyme pretreatment and biological fermentation, then the processed straw powder is evenly mixed with energy components, additives, and trace elements according to a specific ratio, and finally the mixture is granulated, dried and cooled to produce the puffed pellet feed for sheep and cows in a puffing machine and drying-cooling machine. The dry and yellow straws, which cannot be processed by common technology and have a low feeding value, are adopted to replace the grains, and the application range of agricultural straws is enlarged.

Owner:都江堰惠农生物技术有限责任公司

Superthin superconducting-type heat absorbing plate core and flat-plate solar collector

InactiveCN103759432AImprove pressure bearing capacityReduce dosageSolar heating energyHeat transfer optimizationHeat transfer efficiencyThin sheet

The invention discloses a novel superthin superconducting-type heat absorbing plate core and a flat-plate solar collector. The flat-plate solar collector is creatively characterized by comprising the heat absorbing plate core based on a corrugated metal thin plate structure, a superconducting mixed heat-transfer working medium, a transparent cover plate, a heat-insulating material layer and a frame. The flat-plate solar collector has the advantages of being compact in structure, high in heat-transfer efficiency, small in pressure loss, light in weight, flexible to mount, high in pressure-bearing capacity, antifreezing, resistant to scaling, corrosion-resistant, long in service life, low in cost and the like, and is quite suitable for being combined with a building. A mixed superconducting heating medium is adopted as a heat-transfer working condition, so that the flat-plate solar collector still can normally run at low temperature, heat utilization efficiency of the flat-plate solar collector is greatly improved, using range of the flat-plate solar collector are greatly expanded, application path of the flat-plate solar collector is widened, and the flat-plate solar collector is widely suitable for solar collection places like civil buildings and industrial workshops.

Owner:SHANGHAI LVJIAN ENERGY TECH

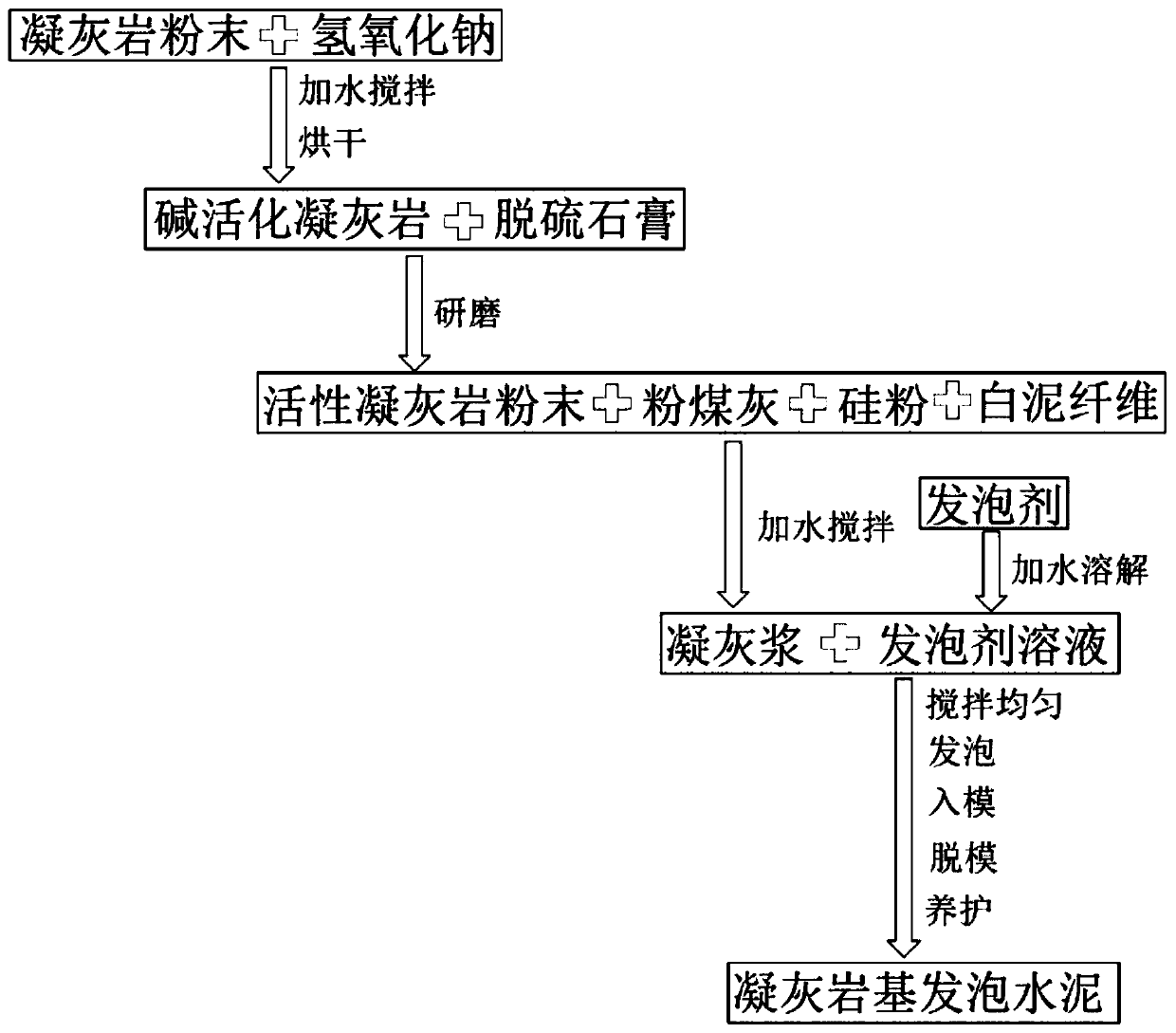

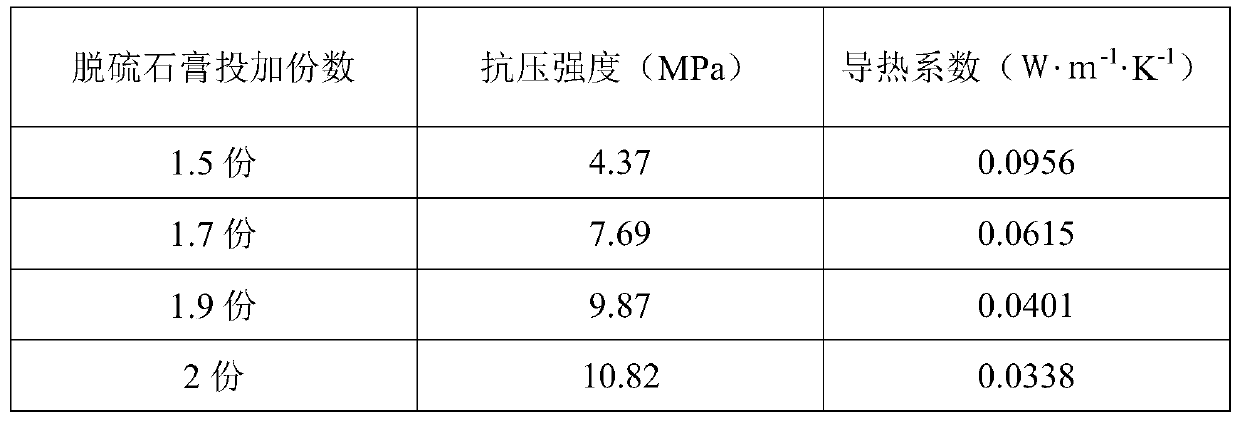

High-strength tuff-based foamed cement thermal-insulation test block and preparation method thereof

ActiveCN110054467AImprove solubilityPromote along the extensionCeramic shaping apparatusCeramicwareFiberThermal insulation

The invention discloses tuff slurry and a preparation method thereof. The tuff slurry comprises tuff powder, sodium hydroxide, fly ash, silica fume and white mud fibers. The invention also discloses ahigh-strength tuff-based foamed cement thermal-insulation test block and a preparation method thereof. The high-strength tuff-based foamed cement thermal-insulation test block has simple preparationoperation process and low equipment requirement, and can be directly commercialized and popularized. The application way of the tuff is expanded, the strength of the prepared tuff-based foamed cementthermal-insulation material can reach 13.49 MPa in 28 days, and the thermal conductivity coefficient is 0.0245 W / (m-K). The invention provides a new idea for preparing the high-strength tuff-based foamed cement thermal-insulation test block from tuff.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

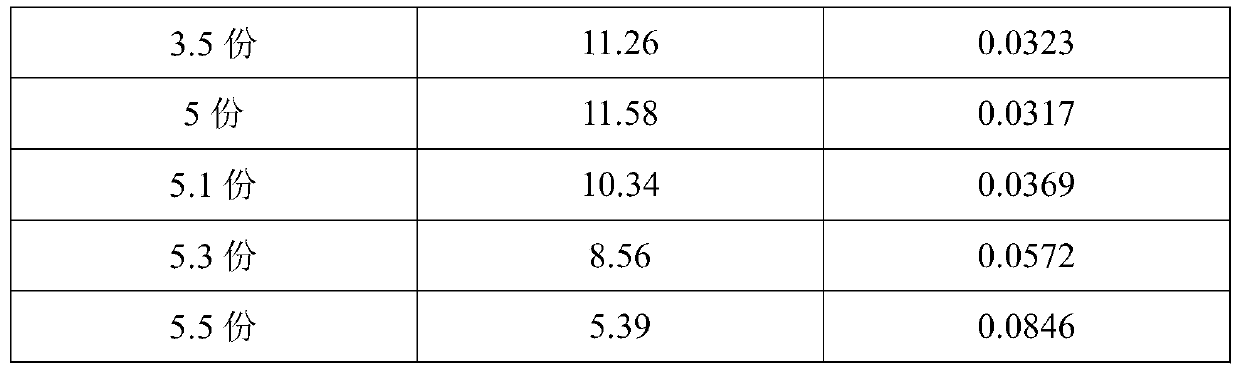

Method of modifying quality of high water content peanut textured proteins by polysaccharides

The present invention relates to a method of modifying quality of high water content peanut textured proteins by polysaccharides. The method comprises the following steps: low-temperature defatted peanut protein powder is crushed and the crushed powder is mixed evenly with an appropriate amount of the polysaccharides; the mixture is subjected to a texturized treatment by an extrusion and extrusion temperatures are successively as follows: a material feeding zone at 60 DEG C-80 DEG C, a mixing zone at 80 DEGC-100 DEGC, a cooking zone at 130 DEG C-160 DEG C, a cooling zone at 90 DEG C-130 DEG C, and a shaping zone at 50 DEG C-90 DEG C; in the extrusion process, water is added online, a water content of the materials is adjusted to be 45%-65%; and after the extrusion and shaping, the materials are cooled to prepare the high water content peanut textured proteins. The produced high water content peanut textured proteins by using the method are bright and white in color and luster, delicate in flavor, rich in fibrous structures and relatively high in fiber strength, can be used as a substitute for high-grade meat, and can be used for processing of shredded meat, vegetarian pork, etc. The method increases fiberization degrees of the high water content peanut textured proteins, enhances the strength of the fiber and broadens application channels.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Making method of light-fermentation mashed fruit and vegetable meat pie

InactiveCN110140739AExpand application channelsIncrease added valueModified nutritive productsHorticultureVegetable pie

The invention discloses a making method of a light-fermentation mashed fruit and vegetable meat pie, and belongs to the field of food processing. The sift pie comprises a wrapper and a filler. The making method comprises the following technology steps of (1) preparing the raw materials; (2) making filler fermentation mashed fruits and vegetables; (3) making the wrapper; (4) making the meat pie; and (5) packing products. The remaining mashed fruits and vegetables after preparing juice through squeezing are used as the raw materials, light fermentation is performed on the remaining mashed fruitsand vegetables with probiotics, the fermented remaining mashed fruits and vegetables are used as a biscuit filler, and the meat pie is made. The unpleasant flavor existing in the mashed fruits and vegetables is improved, new flavor is given to the mashed fruits and vegetables, the nutrient absorption of the mashed fruits and vegetables is promoted, the mashed fruits and vegetables in the modern field of processing of fruit and vegetable juice are sufficiently used, the deep processing potential of the fruits and vegetables is deeply excavated, waste of the fruits and vegetables in the processing course can be avoided, and the added value of the processing of the fruits and vegetables is increased.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com