Manufacturing method of graphene oxide microstructure cladding filter based on laser reduction

A production method and graphene technology, applied in clad optical fiber, optical waveguide, light guide, light guide, etc., can solve problems such as immature technical means, and achieve the effect of broadening application channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

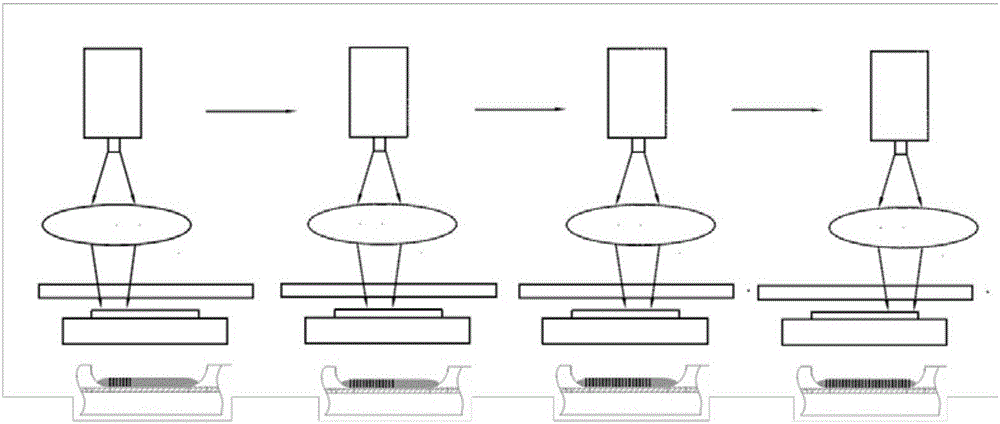

[0033] Such as figure 1 Shown, a kind of cladding filter fabrication method based on laser reduction graphene oxide microstructure comprises the following steps:

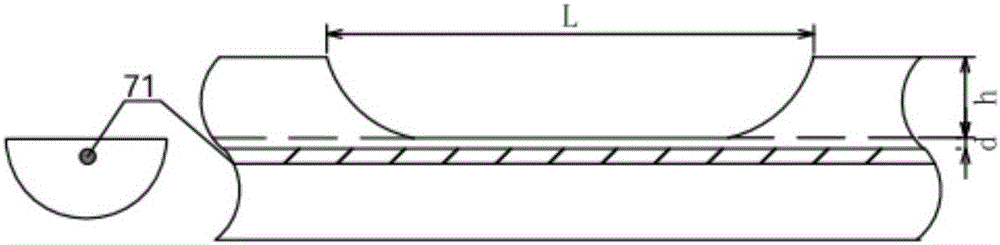

[0034] made as figure 1 Side polished fiber shown;

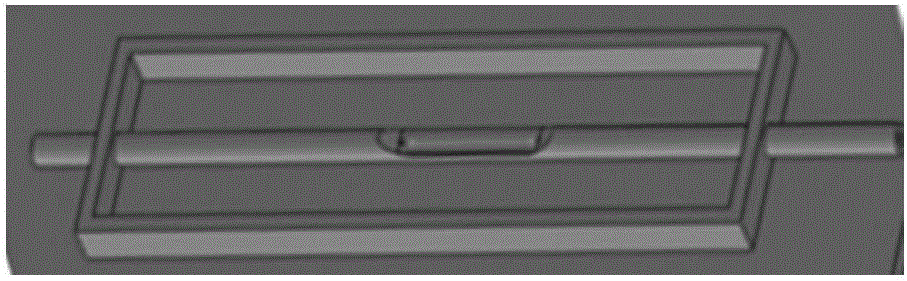

[0035] Such as figure 2 As shown, make a tank-type device for depositing graphene oxide on the side-polished optical fiber, and use this device to package the side-polished optical fiber;

[0036] Depositing graphene oxide on the side-polished optical fiber includes: ultrasonically treating the graphene oxide solution so that the graphene oxide is evenly distributed in the aqueous solution to avoid clustering of graphene oxide; depositing on the side-polished optical fiber Graphene oxide film, that is, take out the graphene oxide solution and drop it into the groove of the sink-type device, and place it for a period of time to allow the water to evaporate, so that the polishing surface of the side-polished optical fiber is completely covered by the graphene ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com