High-strength tuff-based foamed cement thermal-insulation test block and preparation method thereof

A technology of foamed cement and tuff, which is applied in the manufacture of tools, ceramic products, and other household appliances. It can solve the problems of complex process, high energy consumption, and low compressive strength, and achieve simple preparation and operation, lower thermal conductivity, and The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 The effect of the dosage of sodium hydroxide on the compressive strength and thermal conductivity of the tuff-based foam cement insulation test block ore

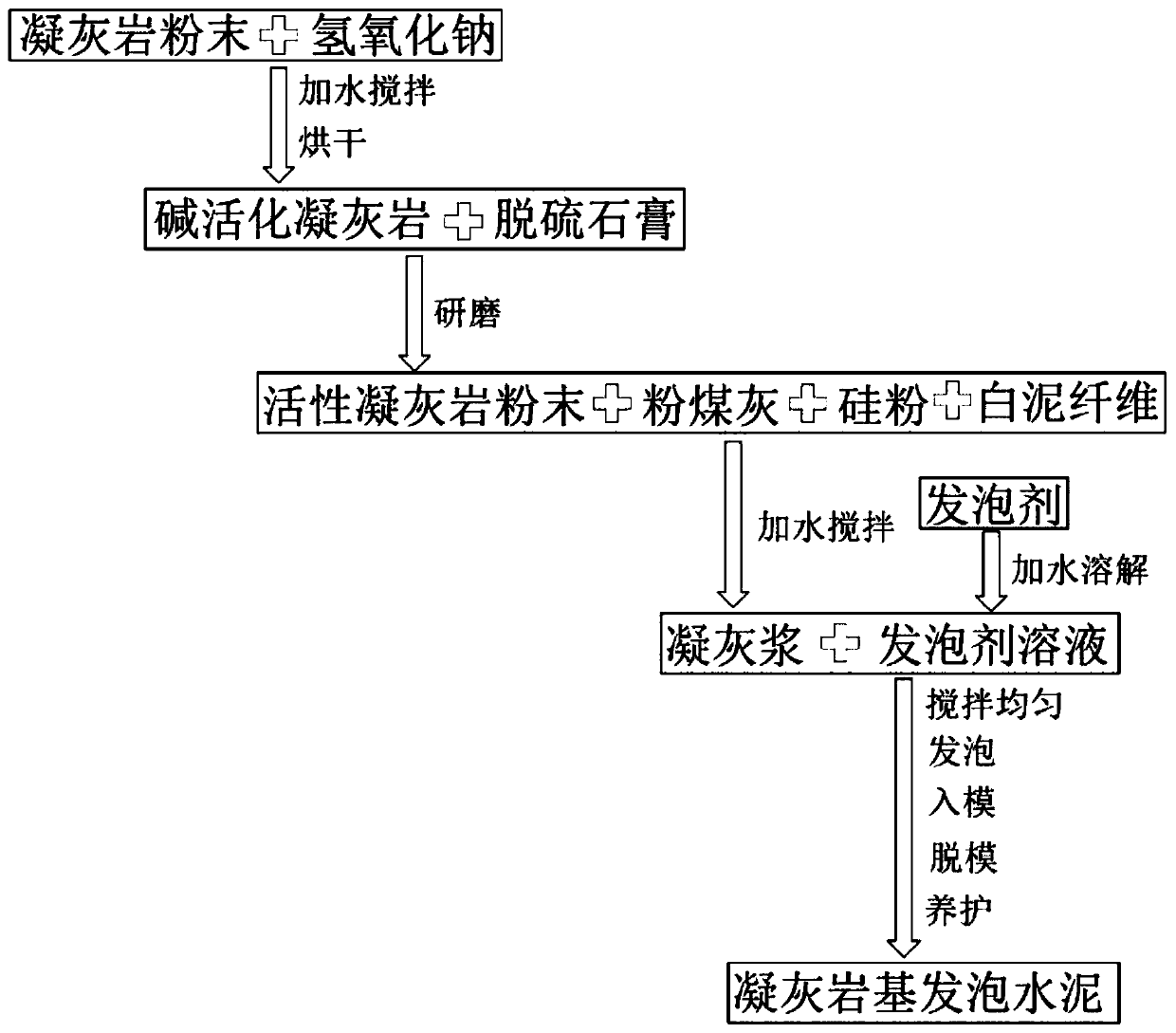

[0030] Preparation of tuff-based foamed cement insulation test block: the high-strength tuff-based foamed cement insulation test block includes 100 parts by weight of tuff powder, 2.0 parts, 2.2 parts, 2.4 parts, 2.5 parts, 5 parts, 7.5 parts, 7.6 parts, 7.8 parts, 8 parts, 2 parts of desulfurized gypsum, 5 parts of fly ash, 5 parts of silica fume, 8 parts of lime mud fiber, and 2 parts of foaming agent. Wherein, the foaming agent is tea saponin foaming agent. The preparation method of the high-strength tuff-based foamed cement insulation test block comprises the following steps: 1) weighing sodium hydroxide and tuff powder, mixing, adding water and stirring to make them fully dissolved, and drying to obtain alkali-activated tuff; 2) weighing alkali Activated tuff and desulfurized gypsum are mixed and full...

Embodiment 2

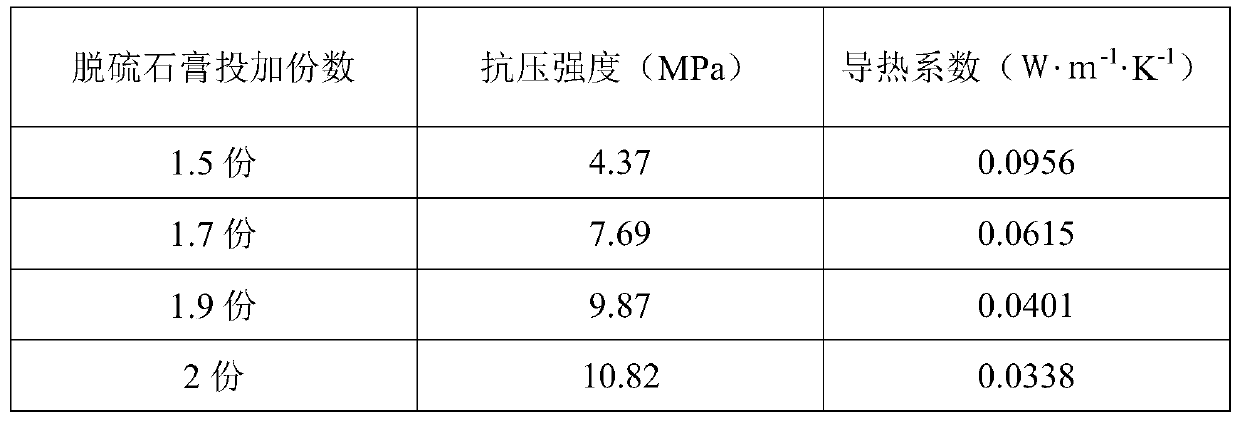

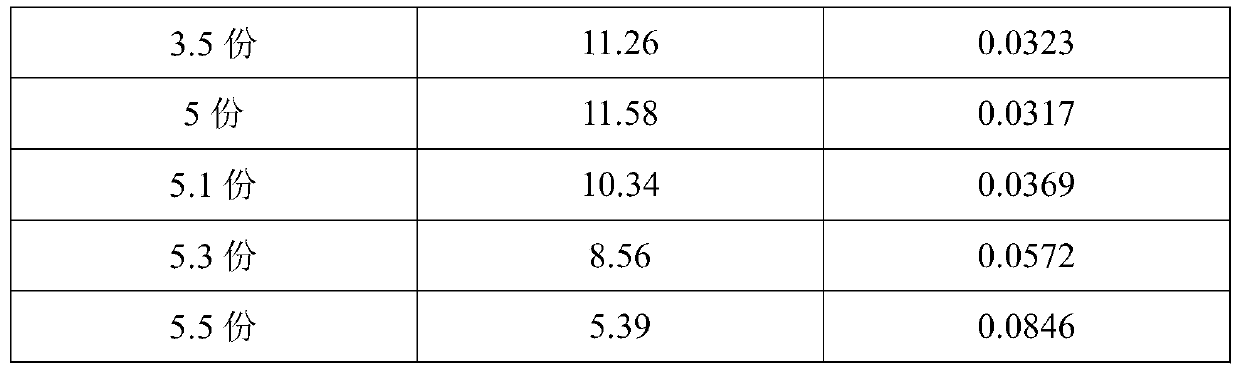

[0036] Example 2 Influence of the dosage of desulfurized gypsum on the compressive strength and thermal conductivity of the tuff-based foam cement insulation test block ore

[0037] Preparation of tuff-based foamed cement insulation test block: The high-strength tuff-based foamed cement insulation test block includes 100 parts by weight of tuff powder, 7.5 parts of sodium hydroxide, 1.5 parts, 1.7 parts, 1.9 parts, and 2 parts of desulfurized gypsum. Parts, 3.5 parts, 5 parts, 5.1 parts, 5.3 parts, 5.5 parts, 7.5 parts of fly ash, 7.5 parts of silica fume, 9 parts of white mud fiber, and 3.5 parts of foaming agent. Wherein, the foaming agent is tea saponin foaming agent. The preparation method of the high-strength tuff-based foamed cement insulation test block comprises the following steps: 1) weighing sodium hydroxide and tuff powder, mixing, adding water and stirring to make them fully dissolved, and drying to obtain alkali-activated tuff; 2) weighing alkali Activated tuff ...

Embodiment 3

[0044] Influence of the dosage of fly ash, silica fume and lime mud fiber on the compressive strength and thermal conductivity of tuff-based foam cement insulation test block

[0045] Preparation of tuff-based foamed cement insulation test block: the high-strength tuff-based foamed cement insulation test block includes 100 parts by weight of tuff powder, 7.5 parts of sodium hydroxide, 5 parts of desulfurized gypsum, 4.6 parts of fly ash, 4.8 parts of parts, 5 parts, 7.5 parts, 10 parts, 10.2 parts, 10.4 parts, silica fume 4.6 parts, 4.8 parts, 5 parts, 7.5 parts, 10 parts, 10.2 parts, 10.4 parts, white clay fiber 7.6 parts, 7.8 parts, 8 parts Parts, 9 parts, 10 parts, 10.2 parts, 10.4 parts, and 5 parts of foaming agent. Wherein, the foaming agent is tea saponin foaming agent. The preparation method of the high-strength tuff-based foamed cement insulation test block comprises the following steps: 1) weighing sodium hydroxide and tuff powder, mixing, adding water and stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com