Making method of light-fermentation mashed fruit and vegetable meat pie

A light fermentation and production method technology, applied in baking, baked goods with modified ingredients, baked goods, etc., can solve the problems of restricting the consumption and promotion of fruit and vegetable products, high drying costs, and high prices, etc. Commercial utilization channels, rich flavor layers, and the effect of reducing sugar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

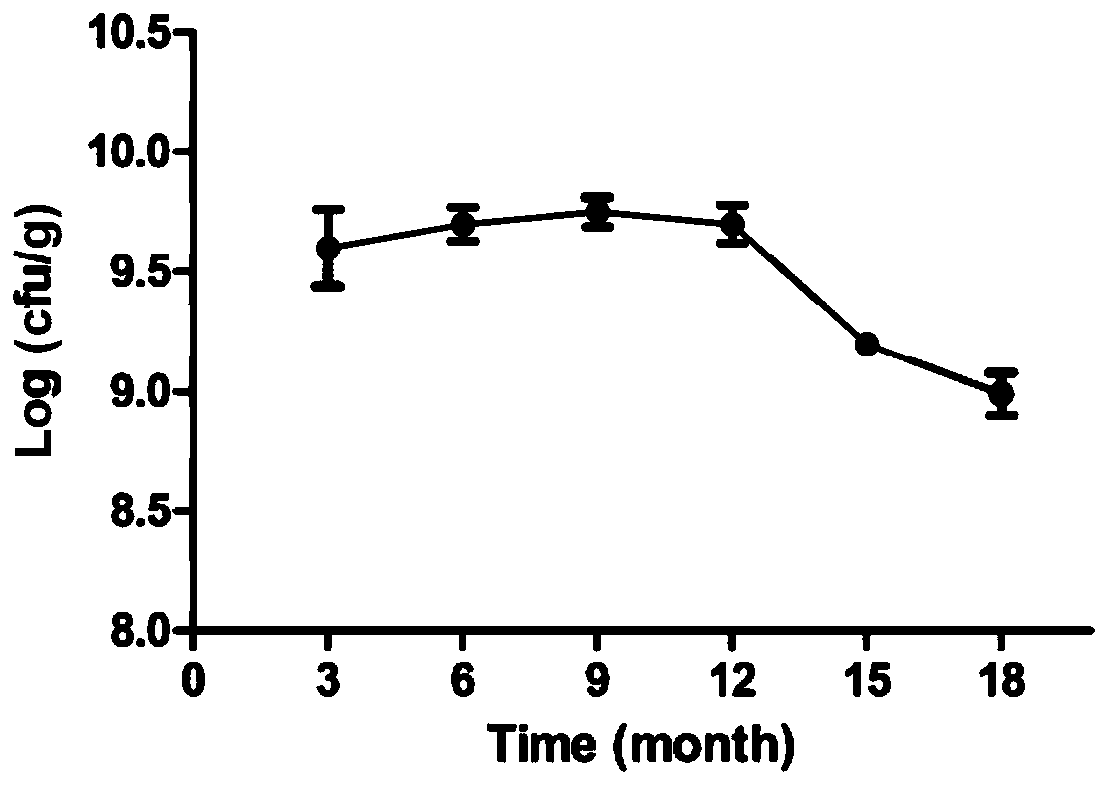

Image

Examples

Embodiment 1

[0032] A production method of lightly fermented carrot puree pie is prepared according to the following steps:

[0033] 1) Raw material processing

[0034] Wash the carrots, peel them, cut them into pieces, put them into a blender and crush them into a puree.

[0035] 2) Syrup making

[0036] Take 50 grams of maltose, 25 grams of sucrose, 25 grams of rock sugar, and 5 grams of water, and mix them evenly to make a syrup.

[0037] 3) Filling preparation

[0038] Add the syrup to 300 grams of carrot puree and stir evenly, heat at 121°C for 30s to sterilize, cool to 37°C, press 10 in a sterile environment 6 The inoculum of Lactobacillus plantarum was inoculated with the inoculation amount of CFU / g stuffing, and fermented at 37°C for 36 hours.

[0039] 4) Leather production

[0040] The leather is made of the following raw materials: 80 grams of low-gluten flour, 20 grams of water, 70 grams of butter, 15 grams of powdered sugar, 1 gram of salt, 35 grams of whole milk powder, a...

Embodiment 2

[0047] A production method of lightly fermented apple puree pie is prepared according to the following steps:

[0048] 1) Raw material processing

[0049] Wash the apples, peel them, cut them into pieces, and leave the apple puree after the juicer is squeezed.

[0050] 2) Syrup making

[0051] Take 30 grams of maltose, 30 grams of sucrose, 20 grams of rock sugar, and 5 grams of water, and mix them evenly to make a syrup.

[0052] 3) Filling preparation

[0053] Add the syrup to 350 grams of apple puree and stir evenly, heat at 121°C for 15s to sterilize, cool to 37°C, press 10 in a sterile environment 7 The inoculation amount of CFU / g stuffing is inoculated with the mixed bacterial agent of Lactobacillus plantarum and Bifidobacterium, and fermented at 37°C for 5 hours.

[0054] 4) Leather production

[0055] The leather is made of the following raw materials: 120 grams of low-gluten flour, 50 grams of water, 80 grams of butter, 25 grams of powdered sugar, 2 grams of salt,...

Embodiment 3

[0062] A production method of lightly fermented pumpkin puree pie is prepared according to the following steps:

[0063] 1) Raw material processing

[0064] Wash the pumpkin, peel it, cut it into pieces, put it into a blender, crush it and stir it into a puree.

[0065] 2) Syrup making

[0066] Take 40 grams of maltose, 10 grams of sucrose, 30 grams of rock sugar, and 5 grams of water, and mix them evenly to make a syrup.

[0067] 3) Filling preparation

[0068] Add the syrup to 320 grams of pumpkin puree and stir evenly, heat at 121°C for 25s to sterilize, cool to 35°C, press 10 in a sterile environment 7 The inoculum amount of CFU / g stuffing is inoculated with the mixed bacterial agent of Lactobacillus plantarum, Lactobacillus delbrueckii and Lactobacillus reuteri, and fermented at 35°C for 6h.

[0069] 4) Leather production

[0070] The leather is made of the following raw materials: 100 grams of low-gluten flour, 40 grams of water, 75 grams of butter, 20 grams of powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com